Pineapple Racing Solid One-piece Dowel Pins

#1

Original Gangster/Rotary!

Thread Starter

iTrader: (213)

Evening boys,

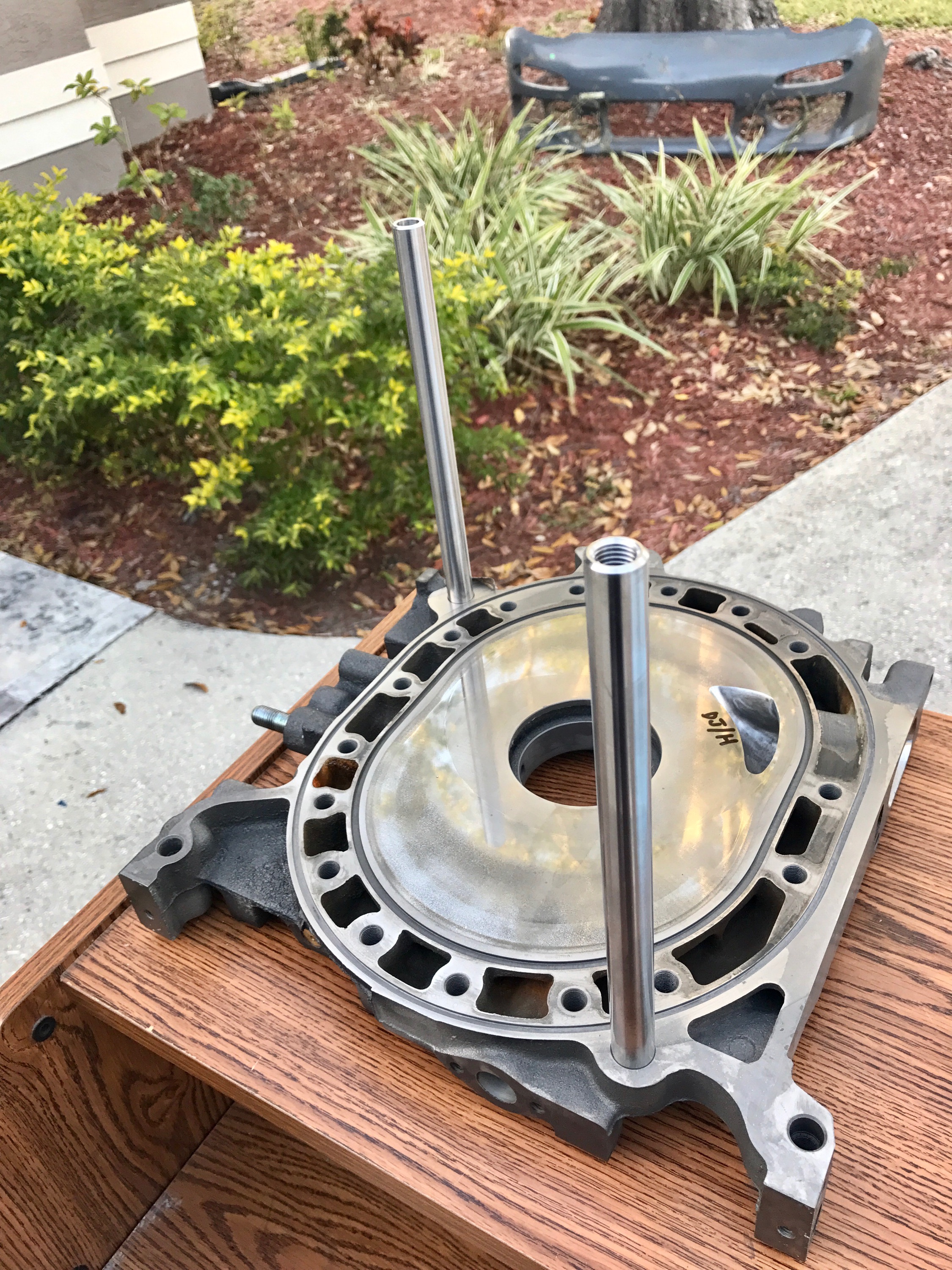

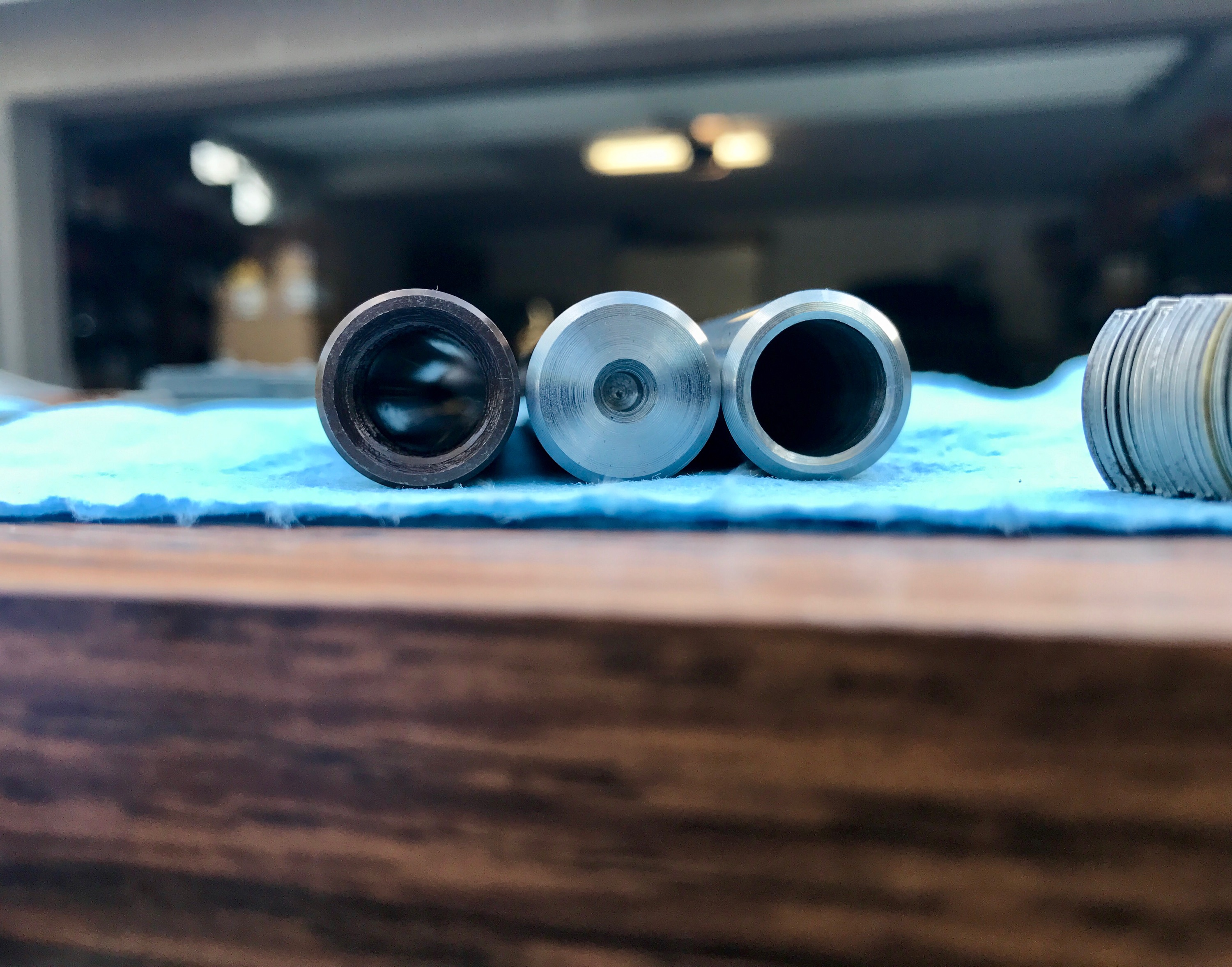

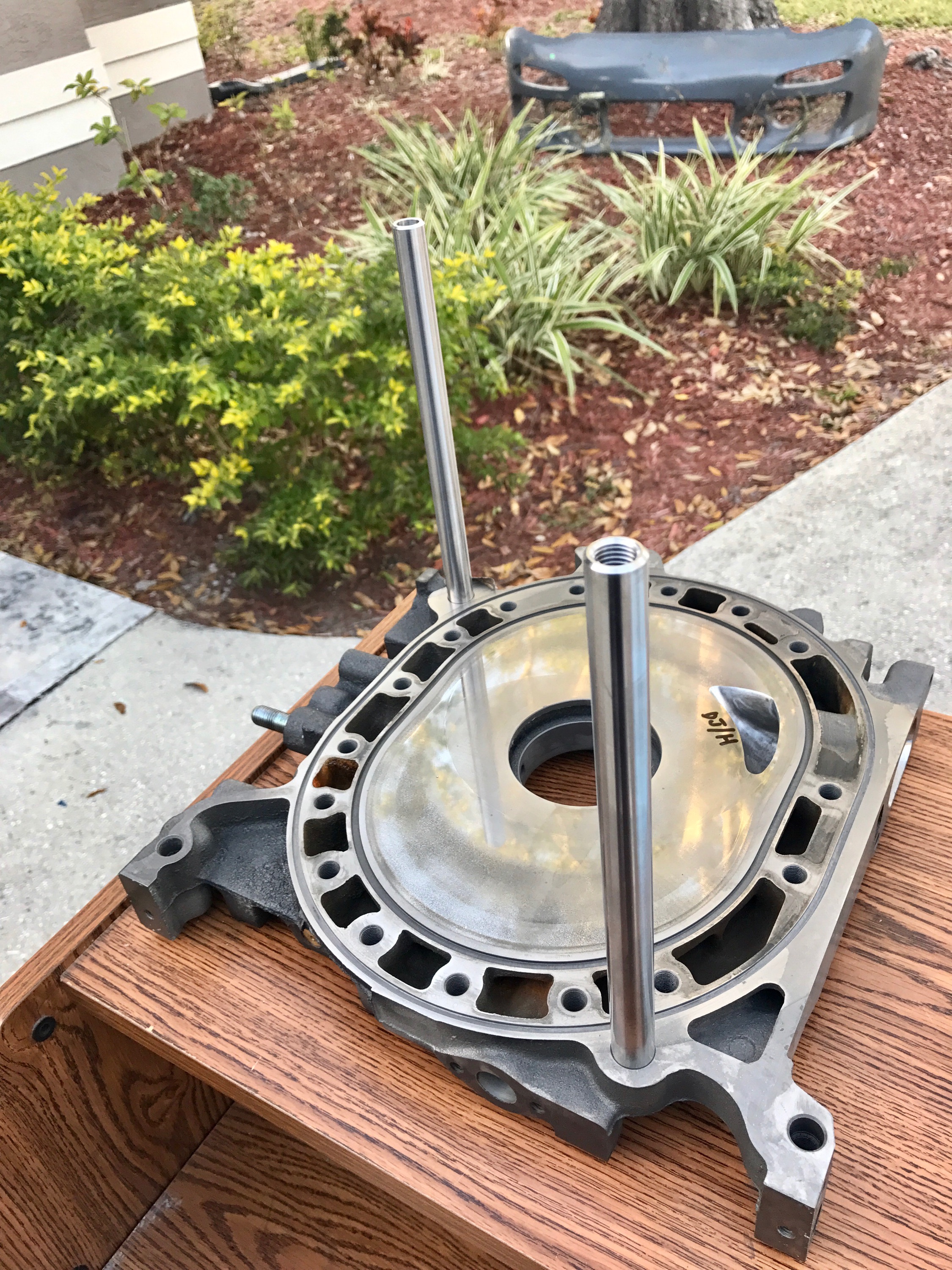

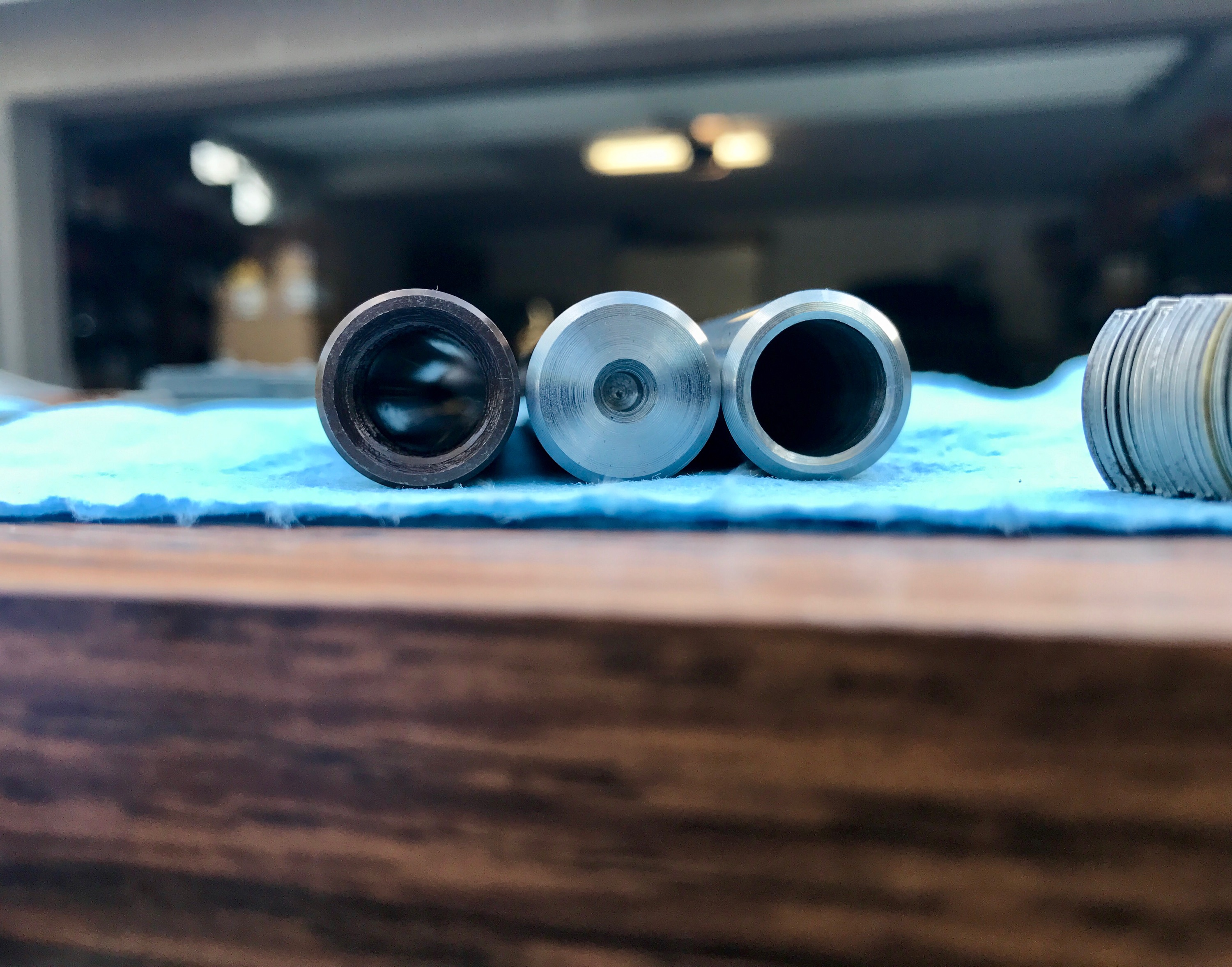

I'm pretty excited about this new product....... a true improvement to an OEM design, reasonably priced, and (as per Rob Golden) tested and proven in 13B engines making up to 700 rwhp. Anyone can run the solid dowel in the lower position with zero changes, the factory upper dowels have an oil galley running between the oil filter pedestal area on the rear iron and the turbo oil feed on the front iron which necessitates an external oil line.

He currently offers them only as solid, but I convinced Rob to modify a few of the upper dowels so that they're hollow (but still one piece) and external oiling mods aren't required. Not as effective as a pair of true solid bad boys, but the engine I'm currently working on won't clear 600, let alone 700

Note that on those high hp cars they were all using the GZ/Excessive/Pineapple Oil Pan which also aids in block rigidity. The Baconator Pan is also a great option for this, I have a Limited Edition 'Lenny Signed' Gold piece on my '95 car . Also note that it does alter the engine building process a bit--very minor but worth mentioning.

. Also note that it does alter the engine building process a bit--very minor but worth mentioning.

Here's the link from the PR site with more info and a better explanation:

Solid, One Piece Dowel Pin(s)

Onwards to the Eye Candy

I'm pretty excited about this new product....... a true improvement to an OEM design, reasonably priced, and (as per Rob Golden) tested and proven in 13B engines making up to 700 rwhp. Anyone can run the solid dowel in the lower position with zero changes, the factory upper dowels have an oil galley running between the oil filter pedestal area on the rear iron and the turbo oil feed on the front iron which necessitates an external oil line.

He currently offers them only as solid, but I convinced Rob to modify a few of the upper dowels so that they're hollow (but still one piece) and external oiling mods aren't required. Not as effective as a pair of true solid bad boys, but the engine I'm currently working on won't clear 600, let alone 700

Note that on those high hp cars they were all using the GZ/Excessive/Pineapple Oil Pan which also aids in block rigidity. The Baconator Pan is also a great option for this, I have a Limited Edition 'Lenny Signed' Gold piece on my '95 car

. Also note that it does alter the engine building process a bit--very minor but worth mentioning.

. Also note that it does alter the engine building process a bit--very minor but worth mentioning.Here's the link from the PR site with more info and a better explanation:

Solid, One Piece Dowel Pin(s)

Onwards to the Eye Candy

The following users liked this post:

ruddyrid (01-19-18)

#2

I ran these in my EFR 9174 build pushing 30psi. I was really happy with the fit and finish on them especially for the price. My only issue occurred during the rebuild (I had warped an apex seal). I'm not sure if heat cycles had caused them to expand or what, but I could not get them to come off and the dowels were amazingly stuck. I ended up having to create a gap between the front iron and rotor housing and cut the solid dowels then use a punch and 3 lbs to hammer them out of the housing. Like I said I'm not blaming the product or rob or anyone, just my personal experience.

#3

RX-7 Bad Ass

iTrader: (55)

Nice! Is there a certain point where one should look at these? In other words would it be good for "standard" builds or are they really only necessary when chasing big numbers?

I imagine the advantage here is more rigidity in the stack.

Dale

I imagine the advantage here is more rigidity in the stack.

Dale

#4

Despite my issues that I had, I would recommend these to anyone that's going single or BNR style setup. Really to anyone that is willing to do the external oil loop line mods for the front iron. They really seemed to lock my motor in place. They are VERY precisely milled, (almost too close maybe).

#6

Despite my issues that I had, I would recommend these to anyone that's going single or BNR style setup. Really to anyone that is willing to do the external oil loop line mods for the front iron. They really seemed to lock my motor in place. They are VERY precisely milled, (almost too close maybe).

-Dan

Trending Topics

#8

Originally Posted by kenpo1441

How hard is it to run that oil line?

with most newer style oil pedestal (PR,SBG,FFE,etc) they included an extra port so a loop line can be added the front iron.

But it's not mandatory now that this product was created .

In the past people it was the only way to re-route the oil from the pedestal to the front bearing because the passage was blocked by a aftermarket solid dowel unless a stock dowel pin was use.

#9

Hard, front iron's tapped oil passage need to be re-opened.

with most newer style oil pedestal (PR,SBG,FFE,etc) they included an extra port so a loop line can be added the front iron.

But it's not mandatory now that this product was created .

In the past people it was the only way to re-route the oil from the pedestal to the front bearing because the passage was blocked by a aftermarket solid dowel unless a stock dowel pin was use.

with most newer style oil pedestal (PR,SBG,FFE,etc) they included an extra port so a loop line can be added the front iron.

But it's not mandatory now that this product was created .

In the past people it was the only way to re-route the oil from the pedestal to the front bearing because the passage was blocked by a aftermarket solid dowel unless a stock dowel pin was use.

#12

RX-7 Bad Ass

iTrader: (55)

So to bring this back up, saw this video on Youtube last night -

They make some really good points on dowels and engine studs. Basically, the best way to truly strengthen the stack is to enlarge all the tension bolt holes through the stack to put slip-fit studs in. The video shows them doing the CNC work and installing the studs, it's REALLY impressive.

Dale

They make some really good points on dowels and engine studs. Basically, the best way to truly strengthen the stack is to enlarge all the tension bolt holes through the stack to put slip-fit studs in. The video shows them doing the CNC work and installing the studs, it's REALLY impressive.

Dale

#13

The video goes over the pro's and con's in a slanted manner if you ask me. Upgrading to drop in studs that are not precision fit is still a good upgrade in that you can torque the hardware to higher levels.

They said that you can easily just do so with the OEM tension bolts, which is true but the problem with that is the OEM bolts are NOT designed to be torqued to to higher specs. This greatly fatigues the bolts and will cause them to stretch and lose the consistent clamping force they would otherwise provide. I realized this after having assembled a S4 13BT making 400whp, in which we used OEM FD bolts and torqued to 36-37lb/ft if memory serves.

When I went to reassemble the engine (after one of the rotors seized it's side seals from heat-soak/expansion), the bolts didn't seem worthy enough to reuse and when torquing them down they felt a bit off. Basically, if you use OEM bolts and over-torque them then you may as well throw them away.

The other issue I see is that you might not want to use precision fit studs if you haven't clearanced the face of the rotor as well. From long heat cycles, you are going to get expansion in the metal and if the rotor housings are essentially fixed now that they have 16 dowels there will likely be problems there.

One thing I can agree on is that the dowels, whether factory or aftermarket, do not engage the irons a significant amount. The bigger problem though is that both OEM and aftermaket dowels do not make full use of the hole they are designed to sit in. There is some meat left on the table, for lack of a better term, and the dowels could be some 7mm longer to fully engage the mounting holes.

I am in no way an expert but I am always eager to learn more about these engines and maximize their potential, and I figured I would give my 2¢

They said that you can easily just do so with the OEM tension bolts, which is true but the problem with that is the OEM bolts are NOT designed to be torqued to to higher specs. This greatly fatigues the bolts and will cause them to stretch and lose the consistent clamping force they would otherwise provide. I realized this after having assembled a S4 13BT making 400whp, in which we used OEM FD bolts and torqued to 36-37lb/ft if memory serves.

When I went to reassemble the engine (after one of the rotors seized it's side seals from heat-soak/expansion), the bolts didn't seem worthy enough to reuse and when torquing them down they felt a bit off. Basically, if you use OEM bolts and over-torque them then you may as well throw them away.

The other issue I see is that you might not want to use precision fit studs if you haven't clearanced the face of the rotor as well. From long heat cycles, you are going to get expansion in the metal and if the rotor housings are essentially fixed now that they have 16 dowels there will likely be problems there.

One thing I can agree on is that the dowels, whether factory or aftermarket, do not engage the irons a significant amount. The bigger problem though is that both OEM and aftermaket dowels do not make full use of the hole they are designed to sit in. There is some meat left on the table, for lack of a better term, and the dowels could be some 7mm longer to fully engage the mounting holes.

I am in no way an expert but I am always eager to learn more about these engines and maximize their potential, and I figured I would give my 2¢

#15

Sponsor

iTrader: (41)

The video goes over the pro's and con's in a slanted manner if you ask me. Upgrading to drop in studs that are not precision fit is still a good upgrade in that you can torque the hardware to higher levels.

They said that you can easily just do so with the OEM tension bolts, which is true but the problem with that is the OEM bolts are NOT designed to be torqued to to higher specs. This greatly fatigues the bolts and will cause them to stretch and lose the consistent clamping force they would otherwise provide. I realized this after having assembled a S4 13BT making 400whp, in which we used OEM FD bolts and torqued to 36-37lb/ft if memory serves.

When I went to reassemble the engine (after one of the rotors seized it's side seals from heat-soak/expansion), the bolts didn't seem worthy enough to reuse and when torquing them down they felt a bit off. Basically, if you use OEM bolts and over-torque them then you may as well throw them away.

The other issue I see is that you might not want to use precision fit studs if you haven't clearanced the face of the rotor as well. From long heat cycles, you are going to get expansion in the metal and if the rotor housings are essentially fixed now that they have 16 dowels there will likely be problems there.

One thing I can agree on is that the dowels, whether factory or aftermarket, do not engage the irons a significant amount. The bigger problem though is that both OEM and aftermaket dowels do not make full use of the hole they are designed to sit in. There is some meat left on the table, for lack of a better term, and the dowels could be some 7mm longer to fully engage the mounting holes.

I am in no way an expert but I am always eager to learn more about these engines and maximize their potential, and I figured I would give my 2¢

They said that you can easily just do so with the OEM tension bolts, which is true but the problem with that is the OEM bolts are NOT designed to be torqued to to higher specs. This greatly fatigues the bolts and will cause them to stretch and lose the consistent clamping force they would otherwise provide. I realized this after having assembled a S4 13BT making 400whp, in which we used OEM FD bolts and torqued to 36-37lb/ft if memory serves.

When I went to reassemble the engine (after one of the rotors seized it's side seals from heat-soak/expansion), the bolts didn't seem worthy enough to reuse and when torquing them down they felt a bit off. Basically, if you use OEM bolts and over-torque them then you may as well throw them away.

The other issue I see is that you might not want to use precision fit studs if you haven't clearanced the face of the rotor as well. From long heat cycles, you are going to get expansion in the metal and if the rotor housings are essentially fixed now that they have 16 dowels there will likely be problems there.

One thing I can agree on is that the dowels, whether factory or aftermarket, do not engage the irons a significant amount. The bigger problem though is that both OEM and aftermaket dowels do not make full use of the hole they are designed to sit in. There is some meat left on the table, for lack of a better term, and the dowels could be some 7mm longer to fully engage the mounting holes.

I am in no way an expert but I am always eager to learn more about these engines and maximize their potential, and I figured I would give my 2¢

Thread

Thread Starter

Forum

Replies

Last Post