Making The Case For The <Rotary> Powered FD: The Fix

#1

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

“going to the dark side… pursuing other options…“ we see it every day on the Board and we all know it is code for going piston.

The trend is understandable given the amount of blown rotary motors.

Plan A, remaining unmodded, becomes more unrealistic as our 13+ year FDs age and the ravages of cumulative thermal meltdown work on the fragile turbo control system and motor.

Plan B, modding for either longevity or more power often misses the mark for lack of a crucial subsystem.

Before we get into the substance of this post let me say, clearly, that if you want to switch your rotary out for an alternative power plant I have zero problem with that. Permit me to state the obvious: it is your car, do what you want with it. Some of my best friends own transplants. i currently have my nephew’s GTO powered FD in my garage. It drives well. Most transplants are born out of frustration with continued FD rotary engine problems.

I wish to make the case for retaining the rotary. This is not to be confused with a diatribe against transplants. Further, it would be great if the thread continues this direction.

How'd all the rotary reliability issues come to pass and are they really fixable?

Back in 83-89 when i was racing rotaries versus factory backed piston engines in SCCA GT3 class one of the most significant aspects of the rotary was that it was bullet proof. The $20,000 four valve Toyota engines that were the primary competition were running cams that were so radical they had about 4 thou piston to valve clearance so as to make enough hp to run w the rotary. Over-rev 500 rpm on a shift and you had a bushel basket of shrapnel for your $20,000.

My Roger Mandeville or Daryl Drummond motors ran from 7000 minimum to 10,000 max for the entire 35 minute race. i remember at the 83 Runoffs at Road Atlanta asking Roger after qualifying if he thought we should throw in a fresh motor. The motor in the car had run 12 National races, plus two days of practice and two days of Runoffs qualifying... Roger asked if the motor hot started O K and i answered in the affirmative. He laughed and said that if we liked working we could change it but it wouldn't add another hp.

Try that w a piston engine.... the valve stems would be loosey goosey leaking oil into the combustion chamber, the valve springs would be shot, the rod bolts would be stretching etc etc.

I ran 72 National races, 5 Road Atlanta Runoffs and had one blown motor.

The circumstance of my one misfortune was after the first day of qualifying at the Runoffs I was fourth. I asked Daryl if we might put one more tooth (Speedway Eng quick change rear end) in the overall gear ratio for Q2. We were pulling 10,000 at the bottom of the hill after the long back straight… the change would add an additional 400 rpm in 5th. Daryl said it would be 50/50 the motor would live as it had been pulling hard from the keyhole. I gave it a shot and the motor lost a seal at 10,400. Unlike a piston motor, most of it was salvageable.

Even when wounded, racing rotaries just keep on humming. i remember seeing Chris Dembs at the (approx) 82 Runoffs pouring oil down his Weber carb to get his rotary started and he blew off a very strong field...

Perhaps the most demonstrative example of rotary reliability was in the 24 Hours of Daytona. During the 80s Mazda racked up a huge number of wins in GTU and GTO over Porsche.

At the end of the 24 hours all the Mazda racers would make a point of bringing their cars into the pits and letting the engines idle while they leisurely extricated themselves. The engines (huge bridgeports or peripherals) would just brap brap away like they had been on a cruise.

Bullet Proof.

The piston engine cars still running after 24 hours would idle at about 5000 rpm. They were total junk. I use the J word literally. After a 24 hour race most piston engines are torn down and almost all moving parts are discarded or sold for pennies down the food chain.

Rotaries ruled the 24 Hours in the 80s. All from a shortblock that is approx 13 inches by 13 inches by 13 inches... w no rods to bend, no valves to crunch, no cams to screw with no windage problems in the crankcase....

So what happened to the FD rotary?

Turbos happened.

A turbo is exactly what the rotary needs to take advantage of the motor’s immense breathing ability. While the rotary doesn’t make as much hp as a piston engine per given unit of airflow it can flow much more air and that’s where the turbo enters the picture.

Mazda threw some air at the FD with a couple of turbos.

More air, more power more heat... and here is where our journey will take two roads...

The OEM FD turbo system being Road One and the aftermarket single setup being Road Two.

The OEM Mazda turbo system is a thermal disaster. In an effort to build early spool/torque Mazda created a manifold system that bolts 22 pounds of cast iron, one of the most heat retentive materials, to the aluminum rotor housings. Aluminum is one of the most heat receptive materials.

The rotary runs around 200-400 degrees F more EGT than a piston engine. This heat is channeled into a huge hunk of cast iron that is highly restrictive (the two turbines flow exhaust directly at each other?) and the whole deal ends up as a very effective heat retention device bolted to the side of the motor.

Then there’s the turbo control system… 72 rubber hoses in an oven. Tick, tick, tick.

I can just see the design engineer feeling all warm and fuzzy looking at the Centrino-like web of hoses on his CAD machine. Maybe he wouldn’t have felt so satisfied had he considered that instead of copper conductors the control paths on his diagram would be composed of rubber hoses that would need to function and maintain integrity in oven-like conditions.

There's other aspects such as the fact that the turbo compressors cavitate above a wimpy 14 psi superheating the charge air . Raise the boost from that point and you get more pressure and less oxygen into the motor. Lose- lose.

But hey, Penske won the 71 Trans-Am in a Javelin… you can make anything work if you throw enough at it. So we do silicone hoses, pre-cat elimination, the down pipe and settle for modest hp increases and cross our fingers. All due to the turbo system.

Road One is whistling past the graveyard.

It doesn't have to be that way.

Turbocharging and melting your rotary do not go necessarily hand in hand.

Road Two

A properly fixtured and tuned single turbo system can make lots more power with LESS ENGINE STRESS.

I designed my own single turbo system. Actually, it features a single (TO4) turbo for each rotor. Two rotors, two turbos, two three inch downpipes. One of my design objectives was to increase the heat removal from the engine by decreasing exhaust back pressure.

My twins run stage 5 turbine wheels that are 10.816 square inches in area versus the largest T4 Q wheel at 6.646 square inches. How does it work?

I log/monitor (EBP) exhaust back pressure. At 20 psi boost my EBP is 21 PSI! That's very close to F1 turbo standards. I have run my twins for 5 years.

The engine has been in my car for four years, 14,000 miles, has logged over 100 2000-8000 4th gear dyno pulls and still shows 17 inches of vacuum at idle. On my Sep 28 dyno run we raised the boost to 20 psi and made 498 rwhp. All with a very conservative tune. I expect to make 630 at 27 psi.

Most of what i have can be obtained w any well designed single turbo system.

For instance, and this is not inconsequential, a single setup replaces the 22 pounds of heat soaking cast iron with 5 pounds of heat rejecting stainless steel flanges. a huge thermal help for your motor.

In addition to greatly reducing the heat soaking mass consider the flow enhancement. We all have seen pictures of the major cracks in the OEM manifold. These cracks are caused by poor flow which creates EBP and heat build up. Cast iron never cracks when it is able to efficiently pass heat.

The poor flow of the OEM manifold is especially important as the rotary needs exhaust flow much more than the piston engine.

The typical single manifold efficiently transfers exhaust energy to the turbine wheel and directly out the exhaust. Less EBP, less heat retained in the engine. Win win. An aftermarket single turbo system, Plan B, needs to be on your shopping list.

Of course a single turbosystem, in itself does not solve the turbo’d rotary’s reliability issues. Many of the transplanted FDs were built after the owner had gone the Plan B route.

Here’s where my story gets really interesting…

A Two-Fer.

Howsabout we solve the reliability problem and deliver racegas horsepower 24-7.

A month or so ago I received a PM and a comment within remained with me…. “Tuned for 500 rwhp but driving around with 300 and something. Racegas on the dyno, but 93 pump on the street. Typical rotary.”

If you stroll thru our board’s archives you will find an almost unending amount of threads where XXX made 500+ RWHP on the dyno. If you read the details you will find the “R” word. Racegas.

Racegas means you really are driving a major discount-to dyno hp FD on the street. “But look at my dyno sheet!”

It doesn’t have to be that way. You can have all the hp you made on the dyno all the time! And you can have enhanced reliability to the point you don’t have to be looking at alternative engine projects.

500+ rwhp on 91-93 octane. All the time with greatly improved reliability.

After 4 years of nothing but happy thrashing my curiosity finally won out so a week ago I yanked my perfectly running motor to see what was going on inside.

It looked and spec’d pretty much as it had when I built it four years ago. Zero carbon near any of the seal grooves. Side seal clearance, an under-appreciated but very important engine metric, had increased but one thousandth!

I was talking to my go-to guy about my motor and just for fun asked him to guess my side seal clearance. He knew my motor was in great shape and guessed 5 thousandths. My side seals were a tight 3 thousandths! This guess comes from someone who for the last 3 years has made within a rounding error of 1000 rwhp with his methanol two rotor that he builds and races!

My engine will receive new springs for the apex, side and oil control rings, new oil ring O rings and new coolant seals and go back together.

How in a world of carbon’d up rotaries does my motor look like it has barely been around the block?

While the engine has been properly supported with many of the correct systems of which you are familiar there is one system that you probably don’t run and it is the key:

Auxiliary Injection.

It really is all about heat with the rotary.

A piston engine performs best at approx 1320 F pre-turbo EGT while the rotary is happiest at 1600. When you combine the latent rotary heat with a poorly designed (OEM) manifold you get eventual Armageddon.

Additionally, when you combine a rich AFR in a losing effort to cool the beast with the factory external oil pump that sprays crankcase oil on the apex seals you are generating carbon deposits that eventually fill the gaps that allow apex and side seal movement, (half of the motors I disassemble failed due to the effects of over carbonization.)

Auxiliary Injection (AI) can deliver solutions to 3 FD rotary problems two of which are fatal:

Failure due to heat/knock.

Failure due to over carbonization

Top tick dyno HP on PumpGas 24-7

Here’s what’s going on within your turbo’d rotary…

A turbo vastly increases the motor’s ability to make power by doubling, or more, the amount of airflow. When combined with a commensurate amount of fuel up goes the torque and hp, and (CCP) Combustion Chamber Pressure. It isn’t far off the mark to equate CCP with the mechanical compression ratio. So as you up airflow/boost you are upping the compression ratio. Alot.

More air, more HP, more CCP, more heat. Even if your AFR is perfect, your timing is perfect as torque increases so does CCP.

More CCP equals more heat.

Gasoline auto-ignites at 495 degrees F, all gasoline, that includes race gas. Auto-ignites means ignites by itself, without the aid of a spark. If the fuel in the motor ignites at the wrong time bad things happen. Generally it is the the apex seals as they are more fragile than anything in a piston engine.

If you combine the higher rotary heat with the more fragile character the of the apex seals you have a bad situation… all because we are creating more CCP/heat with the turbo.

Fix the heat, you fix the problem.

AI FIXES THE HEAT.

AI can be water or alcohol or both. Each injectant has it’s own characteristics but both work. I run alcohol. There are three subsets of alcohol: Ethanol, Methanol and Isopropyl. I run methanol.

Alcohol auto ignites at 867 F so it adds 350 degrees of knock protection versus gasoline. Alcohol “flashes” (atomizes) almost instantaneously providing huge cooling to the charge air. Alcohol is a fuel of course and specs out around 110 octane. Being that it is a fuel and I run 1400 CC/Min along with the usual 850/1600 injectors (4900 CC/Min) for my pump gas the addition of methanol has dropped my duty cycle from a close to static near 90% on-time to just under a happy 70%.

Water of course doesn’t burn so it can’t pre-ignite. Water contains significantly more cooling than alcohol but takes alot longer to atomize so much of it‘s cooling takes place in the combustion process. Since water is not a fuel there is a limit to how much you can stuff in the combustion chamber. Water also require more ignition firepower. Most board members have used water as a cooling aid and have not attempted to “tune up” with it. Tuning up would be turning up the boost using the cooling to make the motor happy. Water is of course more easily handled than alcohol and generally is allowed my many sanctioning bodies where alcohol may or may not be.

Water may be the sleeper with a lot of potential. Rice Racing in Australia has developed a water system that injects water so that it is greatly atomized by the turbo compressor. Rice is after reliability and hp with his system. A client recently made 600 rwhp on water and pump gas.

Both water and alcohol remove prodigious amounts of carbon from your motor. Think steam cleaning.

The function of all AI injectants is to remove heat from the CCP. Remove the heat and you can turn up the boost or just drive around at normal boost with your motor benefiting from coolness.

If you are somewhat familiar with AI you know it is generally set to initiate under boost and that you can set a “ramp’ as to delivery generally based on the amount of boost. A major problem with this type of system is that if you make target boost at 4500 RPM and hold it to redline the injectant delivered will not vary as the boost isn’t varying.

We all know that your base fuel map does grow towards peak torque and tapers off after that with the decreasing volumetric efficiency and time per compression event. The system only tracks boost so it is not capable of making adjustments independent of boost. It is RPM Dumb.

The determinant as to how much injectant is delivered is the speed of the pump which is governed by your settings. The injectant enters the motor through a nozzle.

That’s where I started two years ago. After thorough research I bought/installed the Alkycontrol system. I ran it for all of 07 including 3 lengthy dyno sessions. It never failed, it was absolutely constant as to both delivery and timing. The motor loved the alcohol. No knock nowhere on pump and 1200 CC/Min of methanol..

The (old school) nozzle-pump system works great on a dyno and for drag racing.

It is not so great for road racing or aggressive street where you are constantly modulating your throttle. The pump hasn’t a prayer of keeping up. Think autocross in a Hummer.

Consider if you were to power your car with this system running the fuel delivery! Compare the typical computer driven fuel injected OEM system with tuning in milliseconds of injector on-time being able to deliver exactly what you command to a pump speed nozzle (garden hose) system.

Elegant, precise versus stone age.

I bring good news… 21st century AI is now available.

I call it High Definition AI…. HD-AI.

And the best part?

It is invisible.

During my last dyno session (Sep 08) we checked injectant rail pressure initially and never thought about the system again. 23 2000-8000+ 4th gear runs and the only thing I did was to check my methanol level. We just tuned until we ran out of wastegate capability at 20 psi.

Invisible, but not to the motor.

Power FC knock numbers under 9 on pump gas at 20 psi and 498 rwhp.

Preturbo EGTs right on target at 1600.

Featuring an upper intake manifold that was so cold after the 10th 4th gear 2000-8300 run you really wouldn’t want to touch it.

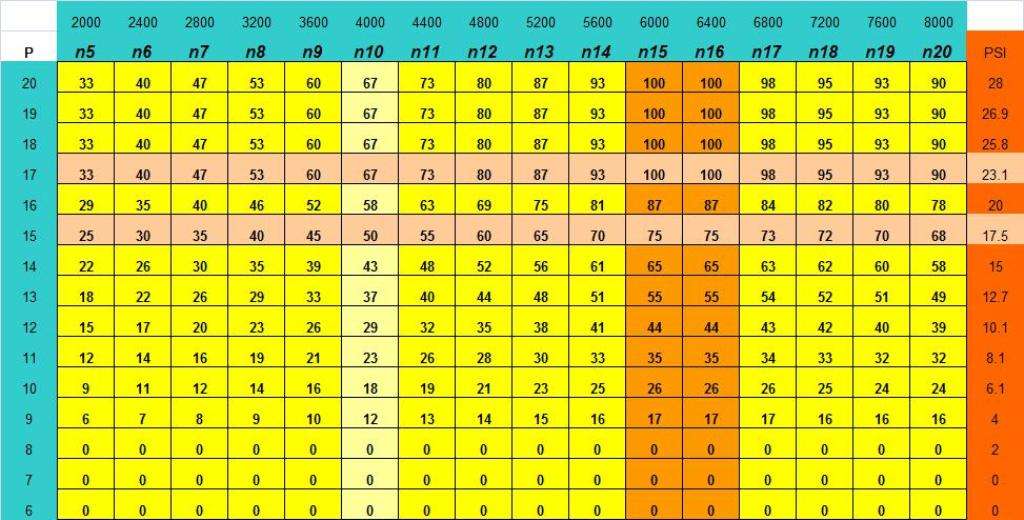

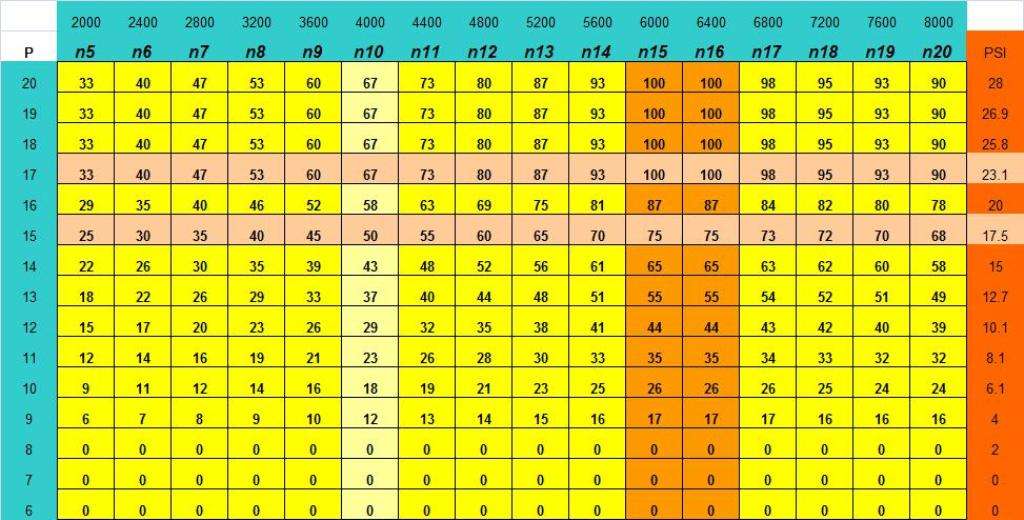

Here’s the knock chart. 93 octane pump, 498 rwhp. a happy motor..

And here is the “money” chart featuring 156 discrete cells for you to tune. Unlike the old school AI notice you can call for any amount of delivery at any cell on the chart. You can of course change the X numbers and Y numbers to whatever you wish. This is pure magic and the answer to the turbo rotaries heat problems.

the module on the left makes it all happen. the module on the right is the FJO wideband. they interface so if there is a problem with AI delivery and the motor goes lean the units cut boost or spark etc.

Looking forward if you fry your rotary it is your fault because with HD-AI it doesn’t have to happen.

Currently 3 companies, to my knowledge offer HD AI:

Aquamist

Coolinmist

FJO

I run the FJO system. I did have to add a methanol pressure regulator and a return line to the system to get it to work properly with 100% methanol. Details available in the Auxiliary Injection section in my thread: “Forging fearlessly ahead with FJO.”

FJO believes this may not be necessary should you be using water as injectant.

Here’s a how I fixtured my two 700 CC/Min FJO injectors. If you run power steering the lower injector won’t fit so I suggest you run one 1200. Actually i suggest you ditch the power steering... manual since 99.

Rather than get too much into the nuts and bolts in this post I suggest you visit the Auxiliary Injection section. While it may not be a high traffic section it has been around for a few years and you will find lots of info amongst the archives and stickies.

Combine HD AI with the proper support systems and a well built motor and your will be close to untouchable.

Support systems that I find valuable:

Dual oil coolers. (see my thread “dual oil coolers cheap”)

Aluminum radiator

Efficient intercooler

Instrumentation:

If it isn’t loggable & digital it doesn’t count.

Pre turbo EGTs-- see my thread “Dual Digital EGTS”

Fuel pressure

AFRs

Oil temperature- loggable not needed. here's how i did it.

Oil pressure- digital, but loggable not needed

All the readouts from the Power FC/Datalogit

Ignition amp and big coils on the lead plugs, required with “tuned up” water

NGK 6725 10.5 plugs in the lead

High quality sparkplug wires

3 inch minimum straight thru exhaust

Battery relocated to rear pass side compartment

Remove/disable exterior oil pump

Premix 2 cycle oil for less carbonization

Mobil One 5-30

Comp Cams ZDDP anti wear w each oil change

Greddy elbow

Relocate air temp sensor to just after IC

Remove double throttle

GT35R or better

Bite the bullet and buy an Exedy twin cerametallic clutch (you’ll need it)

Ditto the 4 wheel RacingBrake package

All this adds up to lots of $s.

Many of us have already spent most of the money to get (almost) there. Many have completed a 90 yard drive, are on the 5 yard line. At this point no points have been scored. AI-HD is the 5 yards and payoff. Do it.

The rotary is a truly awesome beast. As of December 08 it is a beast in a thermal cage. HD-AI unlocks the door to the cage. Do HD-AI right and leave all the turbo’d rotary reliability issues in your rear view mirror along with any car you meet on the street or track.

i am there.

howard coleman

The trend is understandable given the amount of blown rotary motors.

Plan A, remaining unmodded, becomes more unrealistic as our 13+ year FDs age and the ravages of cumulative thermal meltdown work on the fragile turbo control system and motor.

Plan B, modding for either longevity or more power often misses the mark for lack of a crucial subsystem.

Before we get into the substance of this post let me say, clearly, that if you want to switch your rotary out for an alternative power plant I have zero problem with that. Permit me to state the obvious: it is your car, do what you want with it. Some of my best friends own transplants. i currently have my nephew’s GTO powered FD in my garage. It drives well. Most transplants are born out of frustration with continued FD rotary engine problems.

I wish to make the case for retaining the rotary. This is not to be confused with a diatribe against transplants. Further, it would be great if the thread continues this direction.

How'd all the rotary reliability issues come to pass and are they really fixable?

Back in 83-89 when i was racing rotaries versus factory backed piston engines in SCCA GT3 class one of the most significant aspects of the rotary was that it was bullet proof. The $20,000 four valve Toyota engines that were the primary competition were running cams that were so radical they had about 4 thou piston to valve clearance so as to make enough hp to run w the rotary. Over-rev 500 rpm on a shift and you had a bushel basket of shrapnel for your $20,000.

My Roger Mandeville or Daryl Drummond motors ran from 7000 minimum to 10,000 max for the entire 35 minute race. i remember at the 83 Runoffs at Road Atlanta asking Roger after qualifying if he thought we should throw in a fresh motor. The motor in the car had run 12 National races, plus two days of practice and two days of Runoffs qualifying... Roger asked if the motor hot started O K and i answered in the affirmative. He laughed and said that if we liked working we could change it but it wouldn't add another hp.

Try that w a piston engine.... the valve stems would be loosey goosey leaking oil into the combustion chamber, the valve springs would be shot, the rod bolts would be stretching etc etc.

I ran 72 National races, 5 Road Atlanta Runoffs and had one blown motor.

The circumstance of my one misfortune was after the first day of qualifying at the Runoffs I was fourth. I asked Daryl if we might put one more tooth (Speedway Eng quick change rear end) in the overall gear ratio for Q2. We were pulling 10,000 at the bottom of the hill after the long back straight… the change would add an additional 400 rpm in 5th. Daryl said it would be 50/50 the motor would live as it had been pulling hard from the keyhole. I gave it a shot and the motor lost a seal at 10,400. Unlike a piston motor, most of it was salvageable.

Even when wounded, racing rotaries just keep on humming. i remember seeing Chris Dembs at the (approx) 82 Runoffs pouring oil down his Weber carb to get his rotary started and he blew off a very strong field...

Perhaps the most demonstrative example of rotary reliability was in the 24 Hours of Daytona. During the 80s Mazda racked up a huge number of wins in GTU and GTO over Porsche.

At the end of the 24 hours all the Mazda racers would make a point of bringing their cars into the pits and letting the engines idle while they leisurely extricated themselves. The engines (huge bridgeports or peripherals) would just brap brap away like they had been on a cruise.

Bullet Proof.

The piston engine cars still running after 24 hours would idle at about 5000 rpm. They were total junk. I use the J word literally. After a 24 hour race most piston engines are torn down and almost all moving parts are discarded or sold for pennies down the food chain.

Rotaries ruled the 24 Hours in the 80s. All from a shortblock that is approx 13 inches by 13 inches by 13 inches... w no rods to bend, no valves to crunch, no cams to screw with no windage problems in the crankcase....

So what happened to the FD rotary?

Turbos happened.

A turbo is exactly what the rotary needs to take advantage of the motor’s immense breathing ability. While the rotary doesn’t make as much hp as a piston engine per given unit of airflow it can flow much more air and that’s where the turbo enters the picture.

Mazda threw some air at the FD with a couple of turbos.

More air, more power more heat... and here is where our journey will take two roads...

The OEM FD turbo system being Road One and the aftermarket single setup being Road Two.

The OEM Mazda turbo system is a thermal disaster. In an effort to build early spool/torque Mazda created a manifold system that bolts 22 pounds of cast iron, one of the most heat retentive materials, to the aluminum rotor housings. Aluminum is one of the most heat receptive materials.

The rotary runs around 200-400 degrees F more EGT than a piston engine. This heat is channeled into a huge hunk of cast iron that is highly restrictive (the two turbines flow exhaust directly at each other?) and the whole deal ends up as a very effective heat retention device bolted to the side of the motor.

Then there’s the turbo control system… 72 rubber hoses in an oven. Tick, tick, tick.

I can just see the design engineer feeling all warm and fuzzy looking at the Centrino-like web of hoses on his CAD machine. Maybe he wouldn’t have felt so satisfied had he considered that instead of copper conductors the control paths on his diagram would be composed of rubber hoses that would need to function and maintain integrity in oven-like conditions.

There's other aspects such as the fact that the turbo compressors cavitate above a wimpy 14 psi superheating the charge air . Raise the boost from that point and you get more pressure and less oxygen into the motor. Lose- lose.

But hey, Penske won the 71 Trans-Am in a Javelin… you can make anything work if you throw enough at it. So we do silicone hoses, pre-cat elimination, the down pipe and settle for modest hp increases and cross our fingers. All due to the turbo system.

Road One is whistling past the graveyard.

It doesn't have to be that way.

Turbocharging and melting your rotary do not go necessarily hand in hand.

Road Two

A properly fixtured and tuned single turbo system can make lots more power with LESS ENGINE STRESS.

I designed my own single turbo system. Actually, it features a single (TO4) turbo for each rotor. Two rotors, two turbos, two three inch downpipes. One of my design objectives was to increase the heat removal from the engine by decreasing exhaust back pressure.

My twins run stage 5 turbine wheels that are 10.816 square inches in area versus the largest T4 Q wheel at 6.646 square inches. How does it work?

I log/monitor (EBP) exhaust back pressure. At 20 psi boost my EBP is 21 PSI! That's very close to F1 turbo standards. I have run my twins for 5 years.

The engine has been in my car for four years, 14,000 miles, has logged over 100 2000-8000 4th gear dyno pulls and still shows 17 inches of vacuum at idle. On my Sep 28 dyno run we raised the boost to 20 psi and made 498 rwhp. All with a very conservative tune. I expect to make 630 at 27 psi.

Most of what i have can be obtained w any well designed single turbo system.

For instance, and this is not inconsequential, a single setup replaces the 22 pounds of heat soaking cast iron with 5 pounds of heat rejecting stainless steel flanges. a huge thermal help for your motor.

In addition to greatly reducing the heat soaking mass consider the flow enhancement. We all have seen pictures of the major cracks in the OEM manifold. These cracks are caused by poor flow which creates EBP and heat build up. Cast iron never cracks when it is able to efficiently pass heat.

The poor flow of the OEM manifold is especially important as the rotary needs exhaust flow much more than the piston engine.

The typical single manifold efficiently transfers exhaust energy to the turbine wheel and directly out the exhaust. Less EBP, less heat retained in the engine. Win win. An aftermarket single turbo system, Plan B, needs to be on your shopping list.

Of course a single turbosystem, in itself does not solve the turbo’d rotary’s reliability issues. Many of the transplanted FDs were built after the owner had gone the Plan B route.

Here’s where my story gets really interesting…

A Two-Fer.

Howsabout we solve the reliability problem and deliver racegas horsepower 24-7.

A month or so ago I received a PM and a comment within remained with me…. “Tuned for 500 rwhp but driving around with 300 and something. Racegas on the dyno, but 93 pump on the street. Typical rotary.”

If you stroll thru our board’s archives you will find an almost unending amount of threads where XXX made 500+ RWHP on the dyno. If you read the details you will find the “R” word. Racegas.

Racegas means you really are driving a major discount-to dyno hp FD on the street. “But look at my dyno sheet!”

It doesn’t have to be that way. You can have all the hp you made on the dyno all the time! And you can have enhanced reliability to the point you don’t have to be looking at alternative engine projects.

500+ rwhp on 91-93 octane. All the time with greatly improved reliability.

After 4 years of nothing but happy thrashing my curiosity finally won out so a week ago I yanked my perfectly running motor to see what was going on inside.

It looked and spec’d pretty much as it had when I built it four years ago. Zero carbon near any of the seal grooves. Side seal clearance, an under-appreciated but very important engine metric, had increased but one thousandth!

I was talking to my go-to guy about my motor and just for fun asked him to guess my side seal clearance. He knew my motor was in great shape and guessed 5 thousandths. My side seals were a tight 3 thousandths! This guess comes from someone who for the last 3 years has made within a rounding error of 1000 rwhp with his methanol two rotor that he builds and races!

My engine will receive new springs for the apex, side and oil control rings, new oil ring O rings and new coolant seals and go back together.

How in a world of carbon’d up rotaries does my motor look like it has barely been around the block?

While the engine has been properly supported with many of the correct systems of which you are familiar there is one system that you probably don’t run and it is the key:

Auxiliary Injection.

It really is all about heat with the rotary.

A piston engine performs best at approx 1320 F pre-turbo EGT while the rotary is happiest at 1600. When you combine the latent rotary heat with a poorly designed (OEM) manifold you get eventual Armageddon.

Additionally, when you combine a rich AFR in a losing effort to cool the beast with the factory external oil pump that sprays crankcase oil on the apex seals you are generating carbon deposits that eventually fill the gaps that allow apex and side seal movement, (half of the motors I disassemble failed due to the effects of over carbonization.)

Auxiliary Injection (AI) can deliver solutions to 3 FD rotary problems two of which are fatal:

Failure due to heat/knock.

Failure due to over carbonization

Top tick dyno HP on PumpGas 24-7

Here’s what’s going on within your turbo’d rotary…

A turbo vastly increases the motor’s ability to make power by doubling, or more, the amount of airflow. When combined with a commensurate amount of fuel up goes the torque and hp, and (CCP) Combustion Chamber Pressure. It isn’t far off the mark to equate CCP with the mechanical compression ratio. So as you up airflow/boost you are upping the compression ratio. Alot.

More air, more HP, more CCP, more heat. Even if your AFR is perfect, your timing is perfect as torque increases so does CCP.

More CCP equals more heat.

Gasoline auto-ignites at 495 degrees F, all gasoline, that includes race gas. Auto-ignites means ignites by itself, without the aid of a spark. If the fuel in the motor ignites at the wrong time bad things happen. Generally it is the the apex seals as they are more fragile than anything in a piston engine.

If you combine the higher rotary heat with the more fragile character the of the apex seals you have a bad situation… all because we are creating more CCP/heat with the turbo.

Fix the heat, you fix the problem.

AI FIXES THE HEAT.

AI can be water or alcohol or both. Each injectant has it’s own characteristics but both work. I run alcohol. There are three subsets of alcohol: Ethanol, Methanol and Isopropyl. I run methanol.

Alcohol auto ignites at 867 F so it adds 350 degrees of knock protection versus gasoline. Alcohol “flashes” (atomizes) almost instantaneously providing huge cooling to the charge air. Alcohol is a fuel of course and specs out around 110 octane. Being that it is a fuel and I run 1400 CC/Min along with the usual 850/1600 injectors (4900 CC/Min) for my pump gas the addition of methanol has dropped my duty cycle from a close to static near 90% on-time to just under a happy 70%.

Water of course doesn’t burn so it can’t pre-ignite. Water contains significantly more cooling than alcohol but takes alot longer to atomize so much of it‘s cooling takes place in the combustion process. Since water is not a fuel there is a limit to how much you can stuff in the combustion chamber. Water also require more ignition firepower. Most board members have used water as a cooling aid and have not attempted to “tune up” with it. Tuning up would be turning up the boost using the cooling to make the motor happy. Water is of course more easily handled than alcohol and generally is allowed my many sanctioning bodies where alcohol may or may not be.

Water may be the sleeper with a lot of potential. Rice Racing in Australia has developed a water system that injects water so that it is greatly atomized by the turbo compressor. Rice is after reliability and hp with his system. A client recently made 600 rwhp on water and pump gas.

Both water and alcohol remove prodigious amounts of carbon from your motor. Think steam cleaning.

The function of all AI injectants is to remove heat from the CCP. Remove the heat and you can turn up the boost or just drive around at normal boost with your motor benefiting from coolness.

If you are somewhat familiar with AI you know it is generally set to initiate under boost and that you can set a “ramp’ as to delivery generally based on the amount of boost. A major problem with this type of system is that if you make target boost at 4500 RPM and hold it to redline the injectant delivered will not vary as the boost isn’t varying.

We all know that your base fuel map does grow towards peak torque and tapers off after that with the decreasing volumetric efficiency and time per compression event. The system only tracks boost so it is not capable of making adjustments independent of boost. It is RPM Dumb.

The determinant as to how much injectant is delivered is the speed of the pump which is governed by your settings. The injectant enters the motor through a nozzle.

That’s where I started two years ago. After thorough research I bought/installed the Alkycontrol system. I ran it for all of 07 including 3 lengthy dyno sessions. It never failed, it was absolutely constant as to both delivery and timing. The motor loved the alcohol. No knock nowhere on pump and 1200 CC/Min of methanol..

The (old school) nozzle-pump system works great on a dyno and for drag racing.

It is not so great for road racing or aggressive street where you are constantly modulating your throttle. The pump hasn’t a prayer of keeping up. Think autocross in a Hummer.

Consider if you were to power your car with this system running the fuel delivery! Compare the typical computer driven fuel injected OEM system with tuning in milliseconds of injector on-time being able to deliver exactly what you command to a pump speed nozzle (garden hose) system.

Elegant, precise versus stone age.

I bring good news… 21st century AI is now available.

I call it High Definition AI…. HD-AI.

And the best part?

It is invisible.

During my last dyno session (Sep 08) we checked injectant rail pressure initially and never thought about the system again. 23 2000-8000+ 4th gear runs and the only thing I did was to check my methanol level. We just tuned until we ran out of wastegate capability at 20 psi.

Invisible, but not to the motor.

Power FC knock numbers under 9 on pump gas at 20 psi and 498 rwhp.

Preturbo EGTs right on target at 1600.

Featuring an upper intake manifold that was so cold after the 10th 4th gear 2000-8300 run you really wouldn’t want to touch it.

Here’s the knock chart. 93 octane pump, 498 rwhp. a happy motor..

And here is the “money” chart featuring 156 discrete cells for you to tune. Unlike the old school AI notice you can call for any amount of delivery at any cell on the chart. You can of course change the X numbers and Y numbers to whatever you wish. This is pure magic and the answer to the turbo rotaries heat problems.

the module on the left makes it all happen. the module on the right is the FJO wideband. they interface so if there is a problem with AI delivery and the motor goes lean the units cut boost or spark etc.

Looking forward if you fry your rotary it is your fault because with HD-AI it doesn’t have to happen.

Currently 3 companies, to my knowledge offer HD AI:

Aquamist

Coolinmist

FJO

I run the FJO system. I did have to add a methanol pressure regulator and a return line to the system to get it to work properly with 100% methanol. Details available in the Auxiliary Injection section in my thread: “Forging fearlessly ahead with FJO.”

FJO believes this may not be necessary should you be using water as injectant.

Here’s a how I fixtured my two 700 CC/Min FJO injectors. If you run power steering the lower injector won’t fit so I suggest you run one 1200. Actually i suggest you ditch the power steering... manual since 99.

Rather than get too much into the nuts and bolts in this post I suggest you visit the Auxiliary Injection section. While it may not be a high traffic section it has been around for a few years and you will find lots of info amongst the archives and stickies.

Combine HD AI with the proper support systems and a well built motor and your will be close to untouchable.

Support systems that I find valuable:

Dual oil coolers. (see my thread “dual oil coolers cheap”)

Aluminum radiator

Efficient intercooler

Instrumentation:

If it isn’t loggable & digital it doesn’t count.

Pre turbo EGTs-- see my thread “Dual Digital EGTS”

Fuel pressure

AFRs

Oil temperature- loggable not needed. here's how i did it.

Oil pressure- digital, but loggable not needed

All the readouts from the Power FC/Datalogit

Ignition amp and big coils on the lead plugs, required with “tuned up” water

NGK 6725 10.5 plugs in the lead

High quality sparkplug wires

3 inch minimum straight thru exhaust

Battery relocated to rear pass side compartment

Remove/disable exterior oil pump

Premix 2 cycle oil for less carbonization

Mobil One 5-30

Comp Cams ZDDP anti wear w each oil change

Greddy elbow

Relocate air temp sensor to just after IC

Remove double throttle

GT35R or better

Bite the bullet and buy an Exedy twin cerametallic clutch (you’ll need it)

Ditto the 4 wheel RacingBrake package

All this adds up to lots of $s.

Many of us have already spent most of the money to get (almost) there. Many have completed a 90 yard drive, are on the 5 yard line. At this point no points have been scored. AI-HD is the 5 yards and payoff. Do it.

The rotary is a truly awesome beast. As of December 08 it is a beast in a thermal cage. HD-AI unlocks the door to the cage. Do HD-AI right and leave all the turbo’d rotary reliability issues in your rear view mirror along with any car you meet on the street or track.

i am there.

howard coleman

Last edited by Howard Coleman; 08-18-09 at 06:18 AM.

#2

Original Gangster/Rotary!

iTrader: (213)

Probably the thread of the year, thank you Howard

I've been running a very simple Aquamist 1s water injection system for years now......sprays windshield wiper fluid from my wiper tank into my greddy elbow.

93 octane, 17 psi, 450ish rwhp. And it's reliable---I beat the hell out of the car every chance I get

(Pics on page 2)

https://www.rx7club.com/showthread.p...=aquamist+pics

I may take the next step as Howard details above, but for now I'm pretty happy with my setup

I've been running a very simple Aquamist 1s water injection system for years now......sprays windshield wiper fluid from my wiper tank into my greddy elbow.

93 octane, 17 psi, 450ish rwhp. And it's reliable---I beat the hell out of the car every chance I get

(Pics on page 2)

https://www.rx7club.com/showthread.p...=aquamist+pics

I may take the next step as Howard details above, but for now I'm pretty happy with my setup

#3

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

Would u consider a well ducted Greddy SMIC to be an efficient intercooler for a 35R or similar sized turbo?

a "yes" to you on the IC. as i mentioned, after a number of dyno runs my UIM has frost on it

would a well maintained stock watercooling system, Minus the A/C condensor be adequate cooling or do you still recommend an Aluminum one?

while i run the typical aluminum aftermarket radiator IF your OEM rad is in excellent condition it will work fine. never put anything but distilled water and antifreeze in your cooling system.

oil coolers however do need to be maxed out. i run two mazda coolers.

whats your thoughts on a reverse vented hood? is it true they end up being more for down force then they are for cooling? (minus the obvious staionary heat soak)

don't know. i do run a vented hood and it takes alot of heat out of the eng compartment after shutdown.

for those of us not looking for Huge power numbers (350-400whp) and still on stock ports..

Do we still need a Dual turbo individual runner Setup? or is a larger T4 divided turbine good enough?

the various iterations of the GT35 are great for the rotary especially with alot of hotside.

a "yes" to you on the IC. as i mentioned, after a number of dyno runs my UIM has frost on it

would a well maintained stock watercooling system, Minus the A/C condensor be adequate cooling or do you still recommend an Aluminum one?

while i run the typical aluminum aftermarket radiator IF your OEM rad is in excellent condition it will work fine. never put anything but distilled water and antifreeze in your cooling system.

oil coolers however do need to be maxed out. i run two mazda coolers.

whats your thoughts on a reverse vented hood? is it true they end up being more for down force then they are for cooling? (minus the obvious staionary heat soak)

don't know. i do run a vented hood and it takes alot of heat out of the eng compartment after shutdown.

for those of us not looking for Huge power numbers (350-400whp) and still on stock ports..

Do we still need a Dual turbo individual runner Setup? or is a larger T4 divided turbine good enough?

the various iterations of the GT35 are great for the rotary especially with alot of hotside.

#4

2/4 wheel cornering fiend

Thank you for properly stating what is an amazingly common myth among many, including many with AI. The vast majority of water injected into the intake system does not magically vaporize and "cool" the intake charge. That atomization and cooling takes place during the actual combustion process.

Last edited by Howard Coleman; 12-19-08 at 08:57 AM.

#6

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

Charlie,

i love my fuel system which i have run for 6 years. i run the usual Cosmo/Denso pump which is an inexpensive drop in. by itself it wouldn't run my injectors (850/1600) to 90% duty cycle.

the slick trick is my Kenne Bell Boost A Pump. the system can boost volts to the fuel pump anywhere from zero to 50%. it works only in boost having a diaphragm in the engine compartment tee'd into the manifold that senses boost and sends an electrical go signal back to the electronic module located in my pass side compartment near my battery... and nearish the fuel pump. i have the adjustment dial mounted in the compartment where i can easily reach the dial from the driver's seat... although i find running it at plus 20% works great.

here's a picture with the plastic removed:

since part of my fuel is methanol my pump gas system doesn't have to work as hard to the tune of 20 duty cycle points.

i will comment on the question re HD-AI and moderate hp setups friday.

howard

i love my fuel system which i have run for 6 years. i run the usual Cosmo/Denso pump which is an inexpensive drop in. by itself it wouldn't run my injectors (850/1600) to 90% duty cycle.

the slick trick is my Kenne Bell Boost A Pump. the system can boost volts to the fuel pump anywhere from zero to 50%. it works only in boost having a diaphragm in the engine compartment tee'd into the manifold that senses boost and sends an electrical go signal back to the electronic module located in my pass side compartment near my battery... and nearish the fuel pump. i have the adjustment dial mounted in the compartment where i can easily reach the dial from the driver's seat... although i find running it at plus 20% works great.

here's a picture with the plastic removed:

since part of my fuel is methanol my pump gas system doesn't have to work as hard to the tune of 20 duty cycle points.

i will comment on the question re HD-AI and moderate hp setups friday.

howard

Last edited by Howard Coleman; 12-17-08 at 08:03 AM.

#7

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

and in the other bin i have some real firepower. two Jacobs F3000 amps. each amp runs one leading plug.

then there's the coils MSD 8253. each runs one plug:

the amps are really neat. when you run alot of elec punch it quickly fries the poor old spark plug. the Jacobs amp runs at varying output levels and goes to full output only upon sensing acceleration. when i first started tuning with alcohol the motor went way rich, actually a 9.1 AFR and the ignition fired the mix without a stutter.

BTW, this is overkill on the ignition even for running water as injectant.

i like overkill.

then there's the coils MSD 8253. each runs one plug:

the amps are really neat. when you run alot of elec punch it quickly fries the poor old spark plug. the Jacobs amp runs at varying output levels and goes to full output only upon sensing acceleration. when i first started tuning with alcohol the motor went way rich, actually a 9.1 AFR and the ignition fired the mix without a stutter.

BTW, this is overkill on the ignition even for running water as injectant.

i like overkill.

Trending Topics

#8

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

FDracer makes many good points. as previously stated, i have no problem w transplanted FDs and to some transplants offer a rational solution to obtaining what they want out of the FD.

i would prefer this thread focus on fixing the FD rotary powerplant rather than become a debate re rotaries and piston FDs.

for most FD rotaries, the addition of a HD-AI system running 300-500 CC/Min of water would solve the cooling/carbon problems. you don't need to go out and buy 2 amps etc.

further, as long as you are using water you could do fairly well using the pump/nozzle AI system.

the HD-AI system requires a computer to initially input the settings but other than that is simple to run and actually not particularly expensive, and of course it is greatly advanced versus the old school setup.

my design objective has been to build a reliable 500 rwhp dual purpose FD that gets 21+ mpg and is capable of beating 95% of the cars on a roadcourse. i also want to do 200 mph at the Texas Standing Mile and run the Silver State Classic. that's why my car is built as it is.

hc

i would prefer this thread focus on fixing the FD rotary powerplant rather than become a debate re rotaries and piston FDs.

for most FD rotaries, the addition of a HD-AI system running 300-500 CC/Min of water would solve the cooling/carbon problems. you don't need to go out and buy 2 amps etc.

further, as long as you are using water you could do fairly well using the pump/nozzle AI system.

the HD-AI system requires a computer to initially input the settings but other than that is simple to run and actually not particularly expensive, and of course it is greatly advanced versus the old school setup.

my design objective has been to build a reliable 500 rwhp dual purpose FD that gets 21+ mpg and is capable of beating 95% of the cars on a roadcourse. i also want to do 200 mph at the Texas Standing Mile and run the Silver State Classic. that's why my car is built as it is.

hc

Last edited by Howard Coleman; 12-19-08 at 09:14 AM.

#9

All out Track Freak!

iTrader: (263)

Join Date: Jul 2001

Location: Charlottesville VA 22901

Posts: 10,672

Received 416 Likes

on

252 Posts

Awesome info but forget about writing a book, open up your own rotary shop, become famous and let someone write a book about you.

For those who appreciate the FD for what it is I'd suggest going the old school route

1) PFS or similar IC intake setup

2) 3 inch exhaust but leave the 2.5 inch midcat for inspection, noise and fume reduction

3) Aluminum rad w/ shark tooth mod and ducting

4) PFC tuned well running 10psi with on the simplified seq setup and use Damians boost control ideas. 1200cc secondaries and supra tt fuel pump. Always mix in 4oz of synthetic premix per tank.

5) you could always spray in something to keep the charge temps down and engine clean but honestly w/ a good tune at this power you don't need it.

You'll have a really fun car making 275 plus rwhp that will compete w/ most any stock production car and do it reliably for years if all your supporting parts are in good shape.

Howard when you open the shop up I'll volunteer to be your 1st customer

For those who appreciate the FD for what it is I'd suggest going the old school route

1) PFS or similar IC intake setup

2) 3 inch exhaust but leave the 2.5 inch midcat for inspection, noise and fume reduction

3) Aluminum rad w/ shark tooth mod and ducting

4) PFC tuned well running 10psi with on the simplified seq setup and use Damians boost control ideas. 1200cc secondaries and supra tt fuel pump. Always mix in 4oz of synthetic premix per tank.

5) you could always spray in something to keep the charge temps down and engine clean but honestly w/ a good tune at this power you don't need it.

You'll have a really fun car making 275 plus rwhp that will compete w/ most any stock production car and do it reliably for years if all your supporting parts are in good shape.

Howard when you open the shop up I'll volunteer to be your 1st customer

#13

Howard,

When you talk about knock numbers on the PFC. What exactly do those numbers mean? Such as, a knock reading of 9, whats a 9 vs 80? Is a 9 perfect? bad? good?

The reason why I'm asking is I've had 3 FD's with a power FC in them(four fd's total). They all had different knock numbers for each car. Each one of them were different, but not consistent knock numbers. My last one I just recently sold would knock to 134 while backing out of the garage. Nothing wrong with that car, just basic mods dyno'd at 321rwhp and i drove it for years! Where one before it with a 1/2 bridge port and playing with higher rev's wouldn't even get past a reading 45.

I take knock readings with a grain of salt, it doesn't seem like a very accurate measurement. I'm very interested on you input on this.

When you talk about knock numbers on the PFC. What exactly do those numbers mean? Such as, a knock reading of 9, whats a 9 vs 80? Is a 9 perfect? bad? good?

The reason why I'm asking is I've had 3 FD's with a power FC in them(four fd's total). They all had different knock numbers for each car. Each one of them were different, but not consistent knock numbers. My last one I just recently sold would knock to 134 while backing out of the garage. Nothing wrong with that car, just basic mods dyno'd at 321rwhp and i drove it for years! Where one before it with a 1/2 bridge port and playing with higher rev's wouldn't even get past a reading 45.

I take knock readings with a grain of salt, it doesn't seem like a very accurate measurement. I'm very interested on you input on this.

#14

Howard,

When you talk about knock numbers on the PFC. What exactly do those numbers mean? Such as, a knock reading of 9, whats a 9 vs 80? Is a 9 perfect? bad? good?

The reason why I'm asking is I've had 3 FD's with a power FC in them(four fd's total). They all had different knock numbers for each car. Each one of them were different, but not consistent knock numbers. My last one I just recently sold would knock to 134 while backing out of the garage. Nothing wrong with that car, just basic mods dyno'd at 321rwhp and i drove it for years! Where one before it with a 1/2 bridge port and playing with higher rev's wouldn't even get past a reading 45.

I take knock readings with a grain of salt, it doesn't seem like a very accurate measurement. I'm very interested on you input on this.

When you talk about knock numbers on the PFC. What exactly do those numbers mean? Such as, a knock reading of 9, whats a 9 vs 80? Is a 9 perfect? bad? good?

The reason why I'm asking is I've had 3 FD's with a power FC in them(four fd's total). They all had different knock numbers for each car. Each one of them were different, but not consistent knock numbers. My last one I just recently sold would knock to 134 while backing out of the garage. Nothing wrong with that car, just basic mods dyno'd at 321rwhp and i drove it for years! Where one before it with a 1/2 bridge port and playing with higher rev's wouldn't even get past a reading 45.

I take knock readings with a grain of salt, it doesn't seem like a very accurate measurement. I'm very interested on you input on this.

thewird

#15

BRAP BRAP BRAP...

Join Date: Mar 2008

Location: Plano, Texas

Posts: 424

Likes: 0

Received 0 Likes

on

0 Posts

Every car has a different so called, base knock reading. It's like background noise. If your regular reading is 10, 60 would be real knock. If regular is 60, 100 would be real knock. (Those numbers are examples only. ANY variation from normal should be taken seriously.)

Although from what I hear, any real knock on a rotary is probably just the sound of your apex seals hitting you're turbine. If you know what I mean...

If you know what I mean...

Although from what I hear, any real knock on a rotary is probably just the sound of your apex seals hitting you're turbine.

If you know what I mean...

If you know what I mean...

#16

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

while primary focus of this thread is an analysis of what AI can do for the rotary i also would be delighted if it included anything material and relevant re the rotary.

re what "9" means as far as my knock readings... most of the above posts are correct but i would like to add a couple of points. the factory knock sensor is no toy. i respect it but understand it's limitations.

when i developed a low to medium rpm knock, in the middle of a dyno session i ended the session and spent a week looking for an answer. interestlingly i tried 4 factory knock sensors and they all generated the same numbers. that impressed me. i have yet to find the item making the noise that the factory sensor is reading but it appears to not be life threatening. the real reason i have assumed an i don't care attitude is that the knock readings go to almost zero under boost and high output.

i also run a J&S knock sensor. it employs a more expensive Bosch sensor. the lights indicating knock have flashed twice in two years, under no or low boost at lowish rpms. i absolutely believe in the J&S and should it ever light up under real boost it would really get my attention. it is set up to drop my lead timing 10 degrees under serious knock.

the takeaway here is the Mazda knock sensor combined with the Power FC and Datalogit are the real thing under boost. probably you look at it as a relative thing. if you generally get X and you start to see 1.5X you should look immediately for answers while lifting your right foot.

perhaps the greatest single body of AI knowledge is to be found on the Turbobuick.com forum. 87 pages containing 3461 threads!!!! yes it is piston, yes it is drag racing but the Buick guys have been doing it for many many years and it really is the same dynamics . if you actually commence reading at page one you will be in on the start of the AI process as it relates to present day turbo'd motors. TurboBuick evolved to all methanol and pump gas. 236 cu inch 2 valve V6s making 800 rwhp on pumpgas and meth. daily driven.

anyway, the reason i bring it up is because they tune almost mostly off knock. since rotaries are a bit fragile so we need to tiptoe around knock but it still, along w EGTs, is really important.

BTW, if you really want to learn the AI game spend a few days reading at Turbobuick. the section is entitled "Alcohol, Nitrous & Propane Tech." but it is all about alcohol/AI. lots of tuning procedural info. link: http://www.turbobuick.com/forums/alc.../?daysprune=-1

Carbon deposits and the External Oil Pump

the short take here is crankcase oil has no business in your combustion chamber.

crankcase oil is filled w carbon deposits. consider what it looks like coming out of your drainplug. crankcase oil, unlike 2 cycle oil, is prone to leave deposits when burned. it is not formulated to endure under combustion chamber temperature.

the compression (side and apex) seals. apex seal to groove clearance should be no more than 3 thousandths. that's 1 and a half thou per side! how much carbon does it take to muck it up? carbon diluted crankcase oil is being sprayed on the apex seal which is very hot. as you know the apex seal rides on top of a spring and it moves up and down in it's slot on every compression event. half of the failed motors i take apart have stuck carboned apex seals. the same goes for side seals

there are two fixes. Rotary Aviation sells a neat relatively inexpensive piece that converts your external pump so it doesn't draw from the oilpan but draws from a small reservoir tank. you fill it w any (i buy mine at Walmart) TC3 rated 2 cycle oil. case closed.

or

disconnect your pump and add one half ounce 2 cycle per gallon to your gas ( 1 oz for track/dyno) to your gas. that's what i did with my 14,000 mile 4 year motor and it looks happy.

re alcohol, water or a mix....

it depends on your objectives.

if you are content with 400 or less rwhp it is easier to go with water.

the only negative is it freezes so no road racing in alaska in december. almost everyone on this board using water is just in it for the cooling... although it also steam cleans your motor...

water, due to it's chemical properties delivers AI benefits differently than alcohol. water cools the intake charge very little. water cools the combustion chamber big time. water's primary measurable temperature benefit is measured at the EGT level.

water may also be able to deliver major hp gains if properly fixtured. RiceRacing/Australia is forging new frontiers with water and the rotary by going after and attaining 600 rwhp. i am very interested to see how this might work w the new generation HD-AI and it's precise tunable delivery. i have had no direct experience with water and high hp rotaries. perhaps others who actually have had will chime in.

it is my experience, and the experience of most on the Buick board, that if you are after higher hp that alcohol WORKS. ( not saying water doesn't, i just don't have first hand experience with water and high hp). alcohol and high hp rotaries are no strangers. alcohol, unlike water GREATLY reduces intake air temperatures as well as works in the combustion chamber and it also cleans the engine interior.

then there is the MIX option. Snowperformance is the biggest player in the AI world in terms of units sold and they sell a mix of water and meth. obviously you need to always use the same ratio or your tune will be off. a couple of benefits... the mixture doesn't freeze and doesn't burn. Snow does not to my knowledge offer HD-AI.

lightly modded FD and AI?

it is really easy to blow a "lightly modded" engine. our engines are 2.6 liters or 159 cubic inches. they are 9 to one compression yet make 255 hp. lightly modded call it 300 hp. that's about two hp per cubic inch at only 9 to 1. there's alot of CCP (combustion chamber pressure) going on inside. things can go slightly awry... say, bad gas. if you have a properly setup AI system working in boost you are not going to have a problem. further, your engine will be devoid of carbon from the cleaning action.

carbon coats the rotor faces. carbon is capable of acting like a diesel glow plug and preigniting the charge before the plug fires. AI loses the carbon.

with the advent of the new precise tunable AI i believe it becomes a more rational system for most FD owners.

hc

re what "9" means as far as my knock readings... most of the above posts are correct but i would like to add a couple of points. the factory knock sensor is no toy. i respect it but understand it's limitations.

when i developed a low to medium rpm knock, in the middle of a dyno session i ended the session and spent a week looking for an answer. interestlingly i tried 4 factory knock sensors and they all generated the same numbers. that impressed me. i have yet to find the item making the noise that the factory sensor is reading but it appears to not be life threatening. the real reason i have assumed an i don't care attitude is that the knock readings go to almost zero under boost and high output.

i also run a J&S knock sensor. it employs a more expensive Bosch sensor. the lights indicating knock have flashed twice in two years, under no or low boost at lowish rpms. i absolutely believe in the J&S and should it ever light up under real boost it would really get my attention. it is set up to drop my lead timing 10 degrees under serious knock.

the takeaway here is the Mazda knock sensor combined with the Power FC and Datalogit are the real thing under boost. probably you look at it as a relative thing. if you generally get X and you start to see 1.5X you should look immediately for answers while lifting your right foot.

perhaps the greatest single body of AI knowledge is to be found on the Turbobuick.com forum. 87 pages containing 3461 threads!!!! yes it is piston, yes it is drag racing but the Buick guys have been doing it for many many years and it really is the same dynamics . if you actually commence reading at page one you will be in on the start of the AI process as it relates to present day turbo'd motors. TurboBuick evolved to all methanol and pump gas. 236 cu inch 2 valve V6s making 800 rwhp on pumpgas and meth. daily driven.

anyway, the reason i bring it up is because they tune almost mostly off knock. since rotaries are a bit fragile so we need to tiptoe around knock but it still, along w EGTs, is really important.

BTW, if you really want to learn the AI game spend a few days reading at Turbobuick. the section is entitled "Alcohol, Nitrous & Propane Tech." but it is all about alcohol/AI. lots of tuning procedural info. link: http://www.turbobuick.com/forums/alc.../?daysprune=-1

Carbon deposits and the External Oil Pump

the short take here is crankcase oil has no business in your combustion chamber.

crankcase oil is filled w carbon deposits. consider what it looks like coming out of your drainplug. crankcase oil, unlike 2 cycle oil, is prone to leave deposits when burned. it is not formulated to endure under combustion chamber temperature.

the compression (side and apex) seals. apex seal to groove clearance should be no more than 3 thousandths. that's 1 and a half thou per side! how much carbon does it take to muck it up? carbon diluted crankcase oil is being sprayed on the apex seal which is very hot. as you know the apex seal rides on top of a spring and it moves up and down in it's slot on every compression event. half of the failed motors i take apart have stuck carboned apex seals. the same goes for side seals

there are two fixes. Rotary Aviation sells a neat relatively inexpensive piece that converts your external pump so it doesn't draw from the oilpan but draws from a small reservoir tank. you fill it w any (i buy mine at Walmart) TC3 rated 2 cycle oil. case closed.

or

disconnect your pump and add one half ounce 2 cycle per gallon to your gas ( 1 oz for track/dyno) to your gas. that's what i did with my 14,000 mile 4 year motor and it looks happy.

re alcohol, water or a mix....

it depends on your objectives.

if you are content with 400 or less rwhp it is easier to go with water.

the only negative is it freezes so no road racing in alaska in december. almost everyone on this board using water is just in it for the cooling... although it also steam cleans your motor...

water, due to it's chemical properties delivers AI benefits differently than alcohol. water cools the intake charge very little. water cools the combustion chamber big time. water's primary measurable temperature benefit is measured at the EGT level.

water may also be able to deliver major hp gains if properly fixtured. RiceRacing/Australia is forging new frontiers with water and the rotary by going after and attaining 600 rwhp. i am very interested to see how this might work w the new generation HD-AI and it's precise tunable delivery. i have had no direct experience with water and high hp rotaries. perhaps others who actually have had will chime in.

it is my experience, and the experience of most on the Buick board, that if you are after higher hp that alcohol WORKS. ( not saying water doesn't, i just don't have first hand experience with water and high hp). alcohol and high hp rotaries are no strangers. alcohol, unlike water GREATLY reduces intake air temperatures as well as works in the combustion chamber and it also cleans the engine interior.

then there is the MIX option. Snowperformance is the biggest player in the AI world in terms of units sold and they sell a mix of water and meth. obviously you need to always use the same ratio or your tune will be off. a couple of benefits... the mixture doesn't freeze and doesn't burn. Snow does not to my knowledge offer HD-AI.

lightly modded FD and AI?

it is really easy to blow a "lightly modded" engine. our engines are 2.6 liters or 159 cubic inches. they are 9 to one compression yet make 255 hp. lightly modded call it 300 hp. that's about two hp per cubic inch at only 9 to 1. there's alot of CCP (combustion chamber pressure) going on inside. things can go slightly awry... say, bad gas. if you have a properly setup AI system working in boost you are not going to have a problem. further, your engine will be devoid of carbon from the cleaning action.

carbon coats the rotor faces. carbon is capable of acting like a diesel glow plug and preigniting the charge before the plug fires. AI loses the carbon.

with the advent of the new precise tunable AI i believe it becomes a more rational system for most FD owners.

hc

Last edited by Howard Coleman; 12-19-08 at 09:29 AM.

#17

Hey Howard, I've watched you progress through the AI systems. First being with Alky control and now to the digital FJO system. My question is besides having the PRECISE control of digital injection why did you switch? I'm looking at going with Devils Own injection because it's much more simple for me to work with. I know the primitive surflow injection is just a pump and a nozzle at the end but as long as it doesn't clog up I see no problems. I'm shooting for 650+whp with this current setup I have before I build my P-Port motor. I guess I'm asking should I really shell out the extra money for the digital injection that I'll have to pay someone to learn on? Thanks again for enlightening us with your progress and the realistic approach toward a high powered/more reliable FD.

#18

Banned. I got OWNED!!!

Join Date: Jul 2008

Location: NC

Posts: 529

Likes: 0

Received 0 Likes

on

0 Posts

question, Howard: most pump gas these days already contains 10% ethanol, does that help these engines run cooler, or is auxillary injection required to see the benefit?

#19

apeiron

iTrader: (2)

Join Date: Oct 2002

Location: Boulder, CO

Posts: 1,773

Likes: 0

Received 0 Likes

on

0 Posts

If anyone gets an AI kit in the Texas region during Christmas time and needs some help installing it let me know - I just installed mine last month and it took less than 3 hours to do the whole installation.

I have my pump located in the bin behind the drivers seat - the pump it self is surrounded by a dense foam padding enclosure to help absorb some of the vibration noise and buzzing noise that they make when the pump engages.

I purchased the AEM AI kit, it is the basic kit that runs off psi (u set a minimum and maximum setting) and the kit comes with 3 jets so you can choose how much water/methanol you want to be sprayed.

I have a question that I would like Howard to consider and answer --- I currently have my AI Jet tapped into the bend on my Greddy Elbow to give even distribution to both front and rear rotors.

My question is..... would the AI be more effective if I were to tap into the piping BEFORE the intercooler?

//////answer from howard: NO. generally speaking the best place to inject is between the intercooler and the elbow. water does very little as to cooling the intake charge due to the charge being hot and pressurized. water works in the combustion chamber. methanol cools the charge air so rapidly it does not have to be further upstream. see Kento comments.////////////////////

I have my pump located in the bin behind the drivers seat - the pump it self is surrounded by a dense foam padding enclosure to help absorb some of the vibration noise and buzzing noise that they make when the pump engages.

I purchased the AEM AI kit, it is the basic kit that runs off psi (u set a minimum and maximum setting) and the kit comes with 3 jets so you can choose how much water/methanol you want to be sprayed.

I have a question that I would like Howard to consider and answer --- I currently have my AI Jet tapped into the bend on my Greddy Elbow to give even distribution to both front and rear rotors.

My question is..... would the AI be more effective if I were to tap into the piping BEFORE the intercooler?

//////answer from howard: NO. generally speaking the best place to inject is between the intercooler and the elbow. water does very little as to cooling the intake charge due to the charge being hot and pressurized. water works in the combustion chamber. methanol cools the charge air so rapidly it does not have to be further upstream. see Kento comments.////////////////////

Last edited by Howard Coleman; 12-19-08 at 09:43 AM.

#20

2/4 wheel cornering fiend

Because the water droplets are not vaporizing in the intake tract, they're not lowering intake charge temps (they lower combustion chamber temps)-- this is the common myth that is continually perpetuated with water injection. Methanol vaporizes at a much lower temperature, but ounce for ounce it doesn't have near the capability to absorb as much heat as water.

Last edited by Howard Coleman; 12-19-08 at 09:45 AM.

#21

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

"should I really shell out the extra money for the digital injection versus HD?"

it depends on usage. if you primarily drag race your FD the older style will work fine. if you drive alot under boost on the street or track i say no.

re the Kenne Bell Boost A Pump (first post)...

20 A version. run it at 20% gain. works only in boost

"most pump gas these days already contains 10% ethanol, does that help these engines run cooler, or is auxillary injection required to see the benefit?"

since ethanol is an alcohol and alcohol atomises faster tha gas and has a high (around 110+) octane rating, yes it helps.

a few problems: alcohol should be introduced into the charge airstream a distance from the combustion chamber (see the picture of my location) so it can "flash" if you note where gasoline fuel injectors are you located... they are real close to the port or intake valve. this decreases the benefit of the alcohol.

there is less energy produced from alcohol versus gasoline... so, E85 for example, delivers less MPG per gallon than a gallon of gasoline. we get around this for our applications by just injecting a bit more alcohol volume than the gas we are replacing.

don't be confused here... alcohol, due to its cooling and antiknock properties allows almost stratospheric boost and properly fixtured is capable of producing much more hp with less engine stress than gasoline. you just have to use a bit

(20%) more.

"would the AI be more effective if I were to tap into the piping BEFORE the intercooler, just after where the hot air is exiting the compressor outlet? My thoughts were that this would prove to be more effective because it would actually allow the IC to super cool the air by using the AI in conjunction with the IC. Somone told me this would be a big "no no" because water would collect at the base of the inter cooler but I do not think that would occur because #1 --- the compressor exhaust temp's would likely vaporize any of the water/methanol being injected (thats the point), and if any water did in fact collect in the base of the IC -- it would simply evaporate due to the air circulation."

i can't give you an answer based on experience. i do know that RiceRacing injects his water into the intake mouth area of the turbo compressor. i feel fairly certain that the compressor is needed/used to atomise. since it then does go thru the IC i guess you can do it. since water does not atomise as well as alcohol you might have a problem w water pre IC but post turbo. if not fully atomised it might clog up the IC. and it might not.

"would consider doing a group buy with your alcohol injection setup?"

thanks for asking but no. i will however spend some time w FJO and the various other component cos and do a post on exactly how to put it together etc. i think you will find that HD-AI is not as expensive nor as difficult to fixture and tune as you might think. my main FJO guy is out til dec 17th so i will be back to all on this subject. BTW, i have no commercial relationship to FJO other than being a beta tester.

another point is that i have a strong suspicion that FJO's Shurflow derived pump will work perfectly with my regulator and return line. i just decided to take the pump out of the picture when i redesigned the system w the return line and regulator.

Kento, as usual. is exactly correct:

The methanol maybe, but not the water droplets. Your intake temps would have to be sky high for the water droplets to actually vaporize. People say "so what, water boils at 212 degrees F"; what they're forgetting is that the intake manifold is pressurized, and at a very high level, meaning that the vaporization point rises exponentially...meaning that your intake temps would have to be so high that you'd have a lot more to worry about than just sky-high charge temps.

BTW, meth would be a no no anywhere but near the throttle body. how would you like to blow up your IC?

keep it coming,

howard

it depends on usage. if you primarily drag race your FD the older style will work fine. if you drive alot under boost on the street or track i say no.

re the Kenne Bell Boost A Pump (first post)...

20 A version. run it at 20% gain. works only in boost

"most pump gas these days already contains 10% ethanol, does that help these engines run cooler, or is auxillary injection required to see the benefit?"

since ethanol is an alcohol and alcohol atomises faster tha gas and has a high (around 110+) octane rating, yes it helps.

a few problems: alcohol should be introduced into the charge airstream a distance from the combustion chamber (see the picture of my location) so it can "flash" if you note where gasoline fuel injectors are you located... they are real close to the port or intake valve. this decreases the benefit of the alcohol.

there is less energy produced from alcohol versus gasoline... so, E85 for example, delivers less MPG per gallon than a gallon of gasoline. we get around this for our applications by just injecting a bit more alcohol volume than the gas we are replacing.

don't be confused here... alcohol, due to its cooling and antiknock properties allows almost stratospheric boost and properly fixtured is capable of producing much more hp with less engine stress than gasoline. you just have to use a bit

(20%) more.