Fuel System Design

#1

Fuel System Design

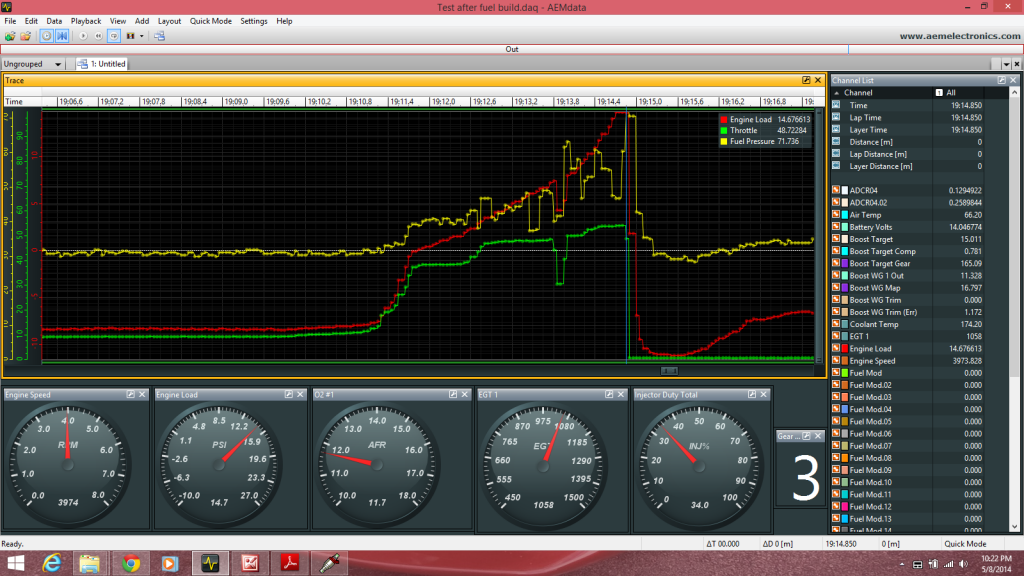

When I dynoed my car, I knew I was at the ragged edge of my fuel delivery system. I did make it through the dyno session with no problems. Fuel pressure was stable, AFRs were on target, and max injector duty was 75%. The car made 512 WHP at 24psi. When I was driving home, I noticed that if I floor it in second gear below 3K RPM and let the boost build there is a loud bang and the car stalls. It feels a lot like fuel cut. This happens even on my low boost setting of 15psi. I pulled the ECU data from the AEM and saw that fuel pressure dropped to 25 psi at 15 psi of boost.

The current setup is:

KG primary and secondary fuel rails (with a bung welded in the secondary for the fuel temp sensor)

-6AN stainless steel braided fuel lines (engine bay only)

2 Bosch EV14 750 cc/min primaries

2 Bosch EV14 2150 cc/min secondaries

1 Bosch 044 Fuel pump

40 PSI Base Pressure

I was thinking of changing my fuel setup to add a second Bosch 044 and run one fuel line from each pump to each fuel rail. I am not fixed on that and open to alternatives.

The current setup is:

KG primary and secondary fuel rails (with a bung welded in the secondary for the fuel temp sensor)

-6AN stainless steel braided fuel lines (engine bay only)

2 Bosch EV14 750 cc/min primaries

2 Bosch EV14 2150 cc/min secondaries

1 Bosch 044 Fuel pump

40 PSI Base Pressure

I was thinking of changing my fuel setup to add a second Bosch 044 and run one fuel line from each pump to each fuel rail. I am not fixed on that and open to alternatives.

#2

First thing that comes to mind is the fuel tank sloshing. Fill it all the way up and there's a good chance it will go away. Most people are aware that this is a problem during cornering but it's also a problem in a straight line once you start making serious power. When you were on the dyno, the car was strapped down so there was less opportunity for the fuel to shift around.

If that really is the cause, you've got two options: modify the fuel system further with more pumps, sub-tanks and such, or just keep more gas in it.

If that really is the cause, you've got two options: modify the fuel system further with more pumps, sub-tanks and such, or just keep more gas in it.

#4

Thanks for the input. I wanted to eliminate a few possible causes, so I changed the fuel pump sock, fuel filter, and topped off the gas tank. I repeated the scenario and the same thing happen.

I have the fuel pump rewired so it draws directly from the battery.

This only happens in second gear. I can accelerate in 3rd, 4th, and 5th running about 10 more psi of boost and there is no problem. I think this is because the rate of acceleration in second is greater. It is changing cells so rapidly in the fuel map that the single pump and stock hard lines just don't have enough volume to keep up.

I have the fuel pump rewired so it draws directly from the battery.

This only happens in second gear. I can accelerate in 3rd, 4th, and 5th running about 10 more psi of boost and there is no problem. I think this is because the rate of acceleration in second is greater. It is changing cells so rapidly in the fuel map that the single pump and stock hard lines just don't have enough volume to keep up.

#6

I'm running 6an feed and 6an return on 340l stealth pump. 22psi on a 68mm custom BW turbo. No fuel pressure issues. Base fuel pressure is 50psi with 990's and 2375's (that's the flow rate at 50psi). I'm not sure on the duty cycle off hand but I tune quite "lean" so it's still safe.

Might hit the rollers in a couple weeks and go 28psi which is absolute max for the gm 3bar.

If I were you I would route 6an feed/return and get a walbro 400...

Might hit the rollers in a couple weeks and go 28psi which is absolute max for the gm 3bar.

If I were you I would route 6an feed/return and get a walbro 400...

#7

I tested the fuel pressure regulator by connecting a hand pump to the reference line and changing pressure while the car was running. It functioned normally.

The Walbro 400 looks promising as the best single pump solution it will flow around 320LPH at the boost I am running which is 50 more LPH that my single Bosch. If I go with an extra Bosch in the CJ hanger each pump having it's own designated 6AN line I would more than double the flow and have around 540 LPH capable system at 25psi of boost. The downside would be the extra current draw of having a second fuel pump, and I have heard of issues fitting the dual Bosch configuration in the tank.

Trending Topics

#9

I was thinking of going with something like this

Last edited by agent004; 11-15-13 at 07:30 PM. Reason: Attachment too small

#10

Brap..

iTrader: (2)

Avoiding a retune is a big part of this. I think as long as I maintain the same base pressure, increasing the fuel flow through the return system should not affect the tune. Fuel temperature will probably increase a bit tho..

I was thinking of going with something like this

I was thinking of going with something like this

I would tee the line after the pumps and split them before the rails again. If one pump fails even momentarily, it's kapow for your engine. Is it likely? not really but with two pumps run like that you effectively double your chances of failure.

#11

Adam,

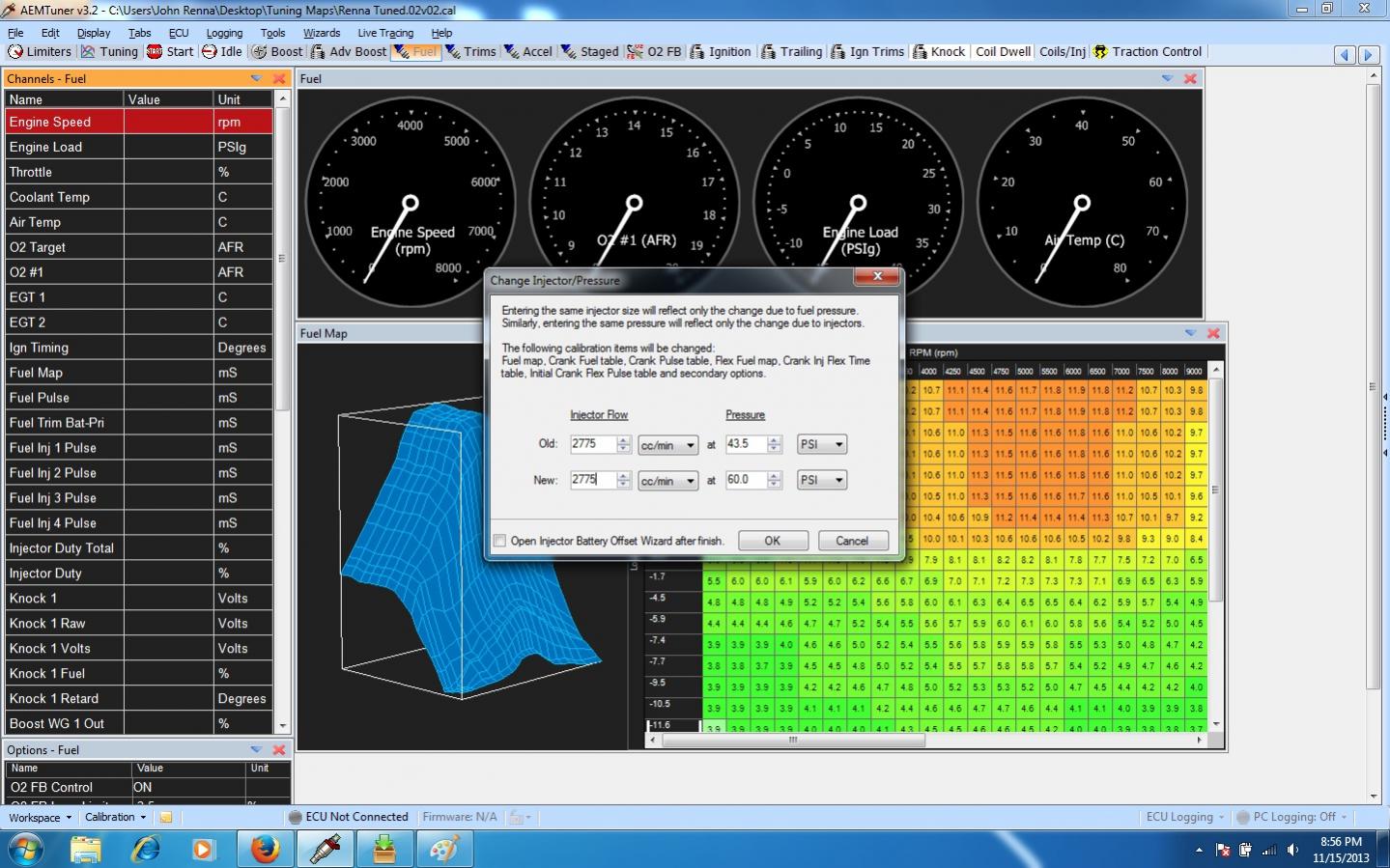

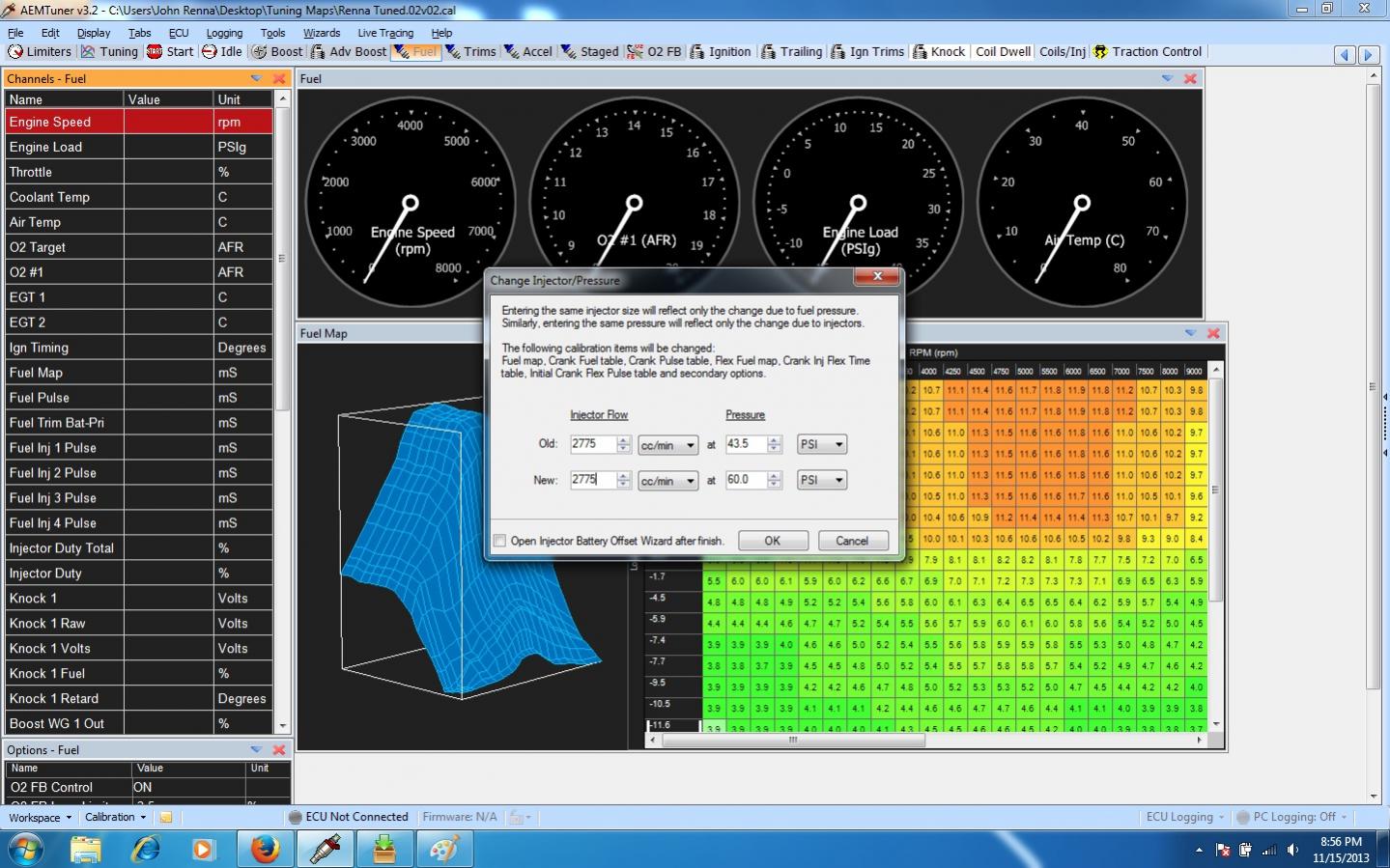

Your AEM has a wizard that will automatically adjust your fuel map for any changes in injector size or fuel pressure.

Go to: Wizards > Change Injector Flow/Pressure

You will need to enter in the combined value of your primary and secondary injectors into both old and new injector flow columns (this can really be any non zero number as long as they are both the same). Then enter in your original base fuel pressure in the old pressure column, and your new base pressure in the new column.

It is worth a shot. Just be sure to save your map prior to making any changes and make note of your original fuel pressure so you can go back. Once you make the changes you should know right away if the AFR's are the same or not.

I have yet to try this, however theoretically there is no reason it should not work. If you do this, don't forget to adjust the injector dead times based on the info provided by ID for 60psi base pressure.

That said, I still feel you should oversize your fuel system a bit so you are not running the system at its upper limit.

Your AEM has a wizard that will automatically adjust your fuel map for any changes in injector size or fuel pressure.

Go to: Wizards > Change Injector Flow/Pressure

You will need to enter in the combined value of your primary and secondary injectors into both old and new injector flow columns (this can really be any non zero number as long as they are both the same). Then enter in your original base fuel pressure in the old pressure column, and your new base pressure in the new column.

It is worth a shot. Just be sure to save your map prior to making any changes and make note of your original fuel pressure so you can go back. Once you make the changes you should know right away if the AFR's are the same or not.

I have yet to try this, however theoretically there is no reason it should not work. If you do this, don't forget to adjust the injector dead times based on the info provided by ID for 60psi base pressure.

That said, I still feel you should oversize your fuel system a bit so you are not running the system at its upper limit.

#12

I don't like that setup at all.

I would tee the line after the pumps and split them before the rails again. If one pump fails even momentarily, it's kapow for your engine. Is it likely? not really but with two pumps run like that you effectively double your chances of failure.

I would tee the line after the pumps and split them before the rails again. If one pump fails even momentarily, it's kapow for your engine. Is it likely? not really but with two pumps run like that you effectively double your chances of failure.

But now the AEM ECU has a definable fuel pressure curve for every given load. If a pump fails and pressure falls below the value defined in the curve, failsafe actions will be triggered.

#15

I decided that I am going to go with two Bosch 044s for sure now. I weighed the pros and cons. I realize that fitting the CJ hanger with two bosch pumps is a PITA but worth it for combination the flow advantage at higher pressure and relatively low current draw. I was considering using two Aermotive 340s, but there are a few reliability issues with those overheating posted in the supra and evo forums. The Bosch 044 is a solid performer with proven reliability.

I was also considering wiring the relay for my second pump to one of the lowside outputs from the AEM ECU. This way the pump would not be running all the time when I don't need it. I can set up the lowside trigger to activate the second pump based on load, throttle, RPM or a combination.

Any thoughts on this?

I was also considering wiring the relay for my second pump to one of the lowside outputs from the AEM ECU. This way the pump would not be running all the time when I don't need it. I can set up the lowside trigger to activate the second pump based on load, throttle, RPM or a combination.

Any thoughts on this?

#16

I am starting to round up the parts to actually build this fuel system. I am planning on using two of these inline fuel filters.

[IMG] [/IMG]

[/IMG]

There are two options for these;

1. -8AN 10 micron rated for 300psi

2. -6AN 40 micron rated for 75psi

I am planning on going with option #2. I realize that #1 has better performance characteristics, but it is 1/2 inch fatter, -8AN where my lines are -6AN, and more expensive. Option #2 more than meets my flow requirements and should be easier to tuck away since it is 2 inches shorter and 1/2 inch skinnier, and will not require extra AN adapter fittings to go from 6 to 8AN.

My only concern is, will 40 microns provide enough protection?

[IMG]

[/IMG]

[/IMG]There are two options for these;

1. -8AN 10 micron rated for 300psi

2. -6AN 40 micron rated for 75psi

I am planning on going with option #2. I realize that #1 has better performance characteristics, but it is 1/2 inch fatter, -8AN where my lines are -6AN, and more expensive. Option #2 more than meets my flow requirements and should be easier to tuck away since it is 2 inches shorter and 1/2 inch skinnier, and will not require extra AN adapter fittings to go from 6 to 8AN.

My only concern is, will 40 microns provide enough protection?

#17

Started making progress today now that most parts are on hand.

I came across this picture of hardlines used to connect the bosch pumps to the bulkhead fittings. I am going to attempt to recreate this. I wonder if this person used stainless steel or aluminum?

I came across this picture of hardlines used to connect the bosch pumps to the bulkhead fittings. I am going to attempt to recreate this. I wonder if this person used stainless steel or aluminum?

#19

I have finally installed the CJ hanger, wired everything up, and began running the fuel lines. Some of those fittings are over $20 each so this is really adding up to be expensive. I have about $1200 into this setup already and that is with reusing my existing single Bosch 044, KG fuel rails, injectors, and as many of the fittings from my RX7 Store ultimate fuel system as I could.

If I had to do it over again, I would not have gone with this setup. I would have modified the stock hanger to hold a Walbro 400 and welded an -8AN bulkhead fitting, to run a single -8AN feed through a high flow filter and to the -8AN connection on the secondary fuel rail. Unused fuel would return via a -6AN line. The Walbro 400 would be controlled with a PWM voltage controller.

But I am committed to this now. The CJ hanger is almost impossible with the lines looped, so I had to modify it like this

[IMG] [/IMG]

[/IMG]

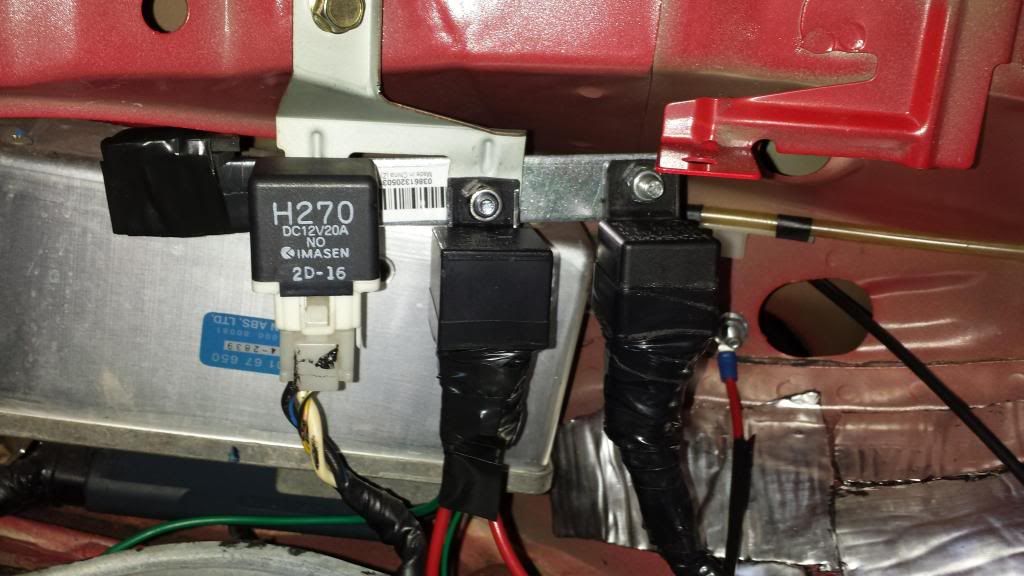

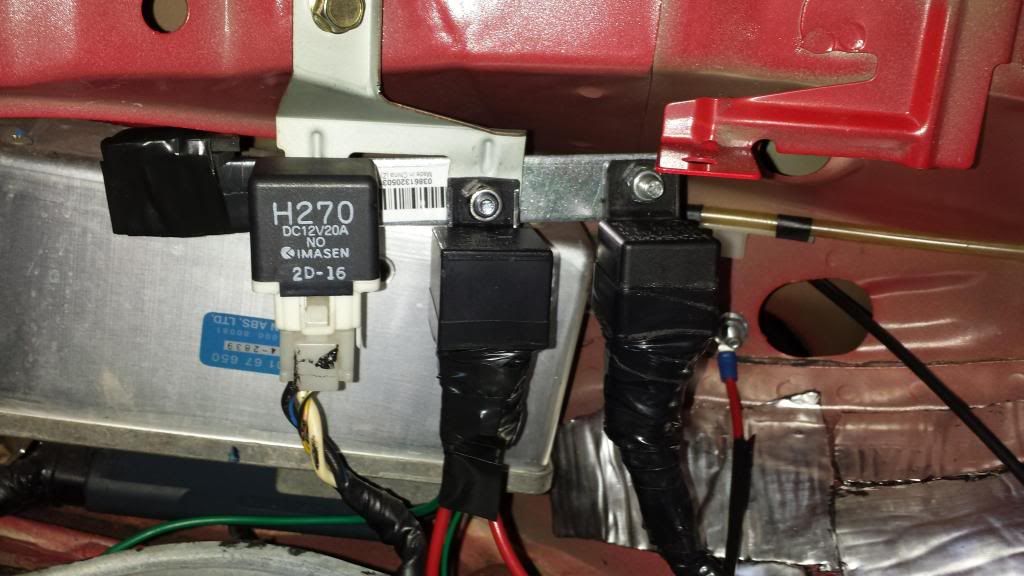

I fabricated a bracket to neatly mount the relays that run straight off the battery to the fuel pumps.

[IMG] [/IMG]

[/IMG]

I found a spot where I could mount the two Fuel Lab 10 micron filters where they will fit underneath the plastic shielding.

[IMG] [/IMG]

[/IMG]

I modified the stock fuel line holders to hold a single -6AN line, So now I can run my return line along the stock lines underneath the stock plastic fuel line protector. This also makes for less hole drilling and tapping in my car.

[IMG] [/IMG]

[/IMG]

This is the low-profile check valve/AN adapter I am using on the outlet of each of the Bosch 044s. These are very expensive, but give the most clearance in the CJ hanger.[IMG] [/IMG]

[/IMG]

CJ Hanger installed with both feed lines run. It is very important to use the low-profile 90 degree fittings. I have seen some pics where people have used regular 90 degree fittings and have had to cut the body of the car to get the lines to clear. The low-profile fittings also allow the metal cover above the hanger with the wire grommet to fit back on.[IMG] [/IMG]

[/IMG]

This may be the best tool I have ever bought. I used to cut the Steel AN lines with a carbon cutoff disc then fight the frayed hose ends into the AN fittings. Life is so much easier with this, and it was only $50[IMG] [/IMG]

[/IMG]

I just ordered another $200 of AN hose and fittings to run the return line and finish up with the plumbing under the manifold. Hopefully that should be all I need to finish up and start driving again.

If I had to do it over again, I would not have gone with this setup. I would have modified the stock hanger to hold a Walbro 400 and welded an -8AN bulkhead fitting, to run a single -8AN feed through a high flow filter and to the -8AN connection on the secondary fuel rail. Unused fuel would return via a -6AN line. The Walbro 400 would be controlled with a PWM voltage controller.

But I am committed to this now. The CJ hanger is almost impossible with the lines looped, so I had to modify it like this

[IMG]

[/IMG]

[/IMG]I fabricated a bracket to neatly mount the relays that run straight off the battery to the fuel pumps.

[IMG]

[/IMG]

[/IMG]I found a spot where I could mount the two Fuel Lab 10 micron filters where they will fit underneath the plastic shielding.

[IMG]

[/IMG]

[/IMG]I modified the stock fuel line holders to hold a single -6AN line, So now I can run my return line along the stock lines underneath the stock plastic fuel line protector. This also makes for less hole drilling and tapping in my car.

[IMG]

[/IMG]

[/IMG]This is the low-profile check valve/AN adapter I am using on the outlet of each of the Bosch 044s. These are very expensive, but give the most clearance in the CJ hanger.[IMG]

[/IMG]

[/IMG]CJ Hanger installed with both feed lines run. It is very important to use the low-profile 90 degree fittings. I have seen some pics where people have used regular 90 degree fittings and have had to cut the body of the car to get the lines to clear. The low-profile fittings also allow the metal cover above the hanger with the wire grommet to fit back on.[IMG]

[/IMG]

[/IMG]This may be the best tool I have ever bought. I used to cut the Steel AN lines with a carbon cutoff disc then fight the frayed hose ends into the AN fittings. Life is so much easier with this, and it was only $50[IMG]

[/IMG]

[/IMG]I just ordered another $200 of AN hose and fittings to run the return line and finish up with the plumbing under the manifold. Hopefully that should be all I need to finish up and start driving again.

#21

I made some good progress this weekend; removed the old KG Fuel rails

[IMG] [/IMG]

[/IMG]

Bought the new FFE fuel rails

[IMG] [/IMG]

[/IMG]

These actually didn't fit right in the 60mm configuration. The spacers were too long, so that when I pulled up on an injector it would completely pop out of the LIM. The primaries also had some travel but not as bat as

So I bought this machine to take 3.3mm off the spacers, and not everything fits perfectly.

[IMG] [/IMG]

[/IMG]

And the fuel rails are securely mounted with a good seal on both upper and lower o-rings.

[IMG] [/IMG]

[/IMG]

I also flow tested my system and at 12V each fuel rail is receiving 300 LPH. This is at 0psi, so I know that number will go down once the system is closed and operating with a 40psi base pressure. But this is a good open system reference point.

Just waiting for what I hope is my last batch of fittings from summit, and I will be able to fully close the system and run the car again!

[IMG]

[/IMG]

[/IMG]Bought the new FFE fuel rails

[IMG]

[/IMG]

[/IMG]These actually didn't fit right in the 60mm configuration. The spacers were too long, so that when I pulled up on an injector it would completely pop out of the LIM. The primaries also had some travel but not as bat as

So I bought this machine to take 3.3mm off the spacers, and not everything fits perfectly.

[IMG]

[/IMG]

[/IMG]And the fuel rails are securely mounted with a good seal on both upper and lower o-rings.

[IMG]

[/IMG]

[/IMG]I also flow tested my system and at 12V each fuel rail is receiving 300 LPH. This is at 0psi, so I know that number will go down once the system is closed and operating with a 40psi base pressure. But this is a good open system reference point.

Just waiting for what I hope is my last batch of fittings from summit, and I will be able to fully close the system and run the car again!

#23

Registered User

iTrader: (13)

Just wanted to chime in about the spacer height. We originally designed our rails around the ID injectors and their spacers have a lip so that they can't be raised into the rail like your video shows. However, it's just for installation as once there is rail pressure applied the injectors will stay firmly in their seat.

#24

The guys at FFE are top notch and their products are of the highest quality. I can't wait for them to make a rear brake upgrade that works with the parking brake. The extra space in the fuel rail is just something that to keep in mind if you use bosch EV14 injectors in the 60mm configuration.

I closed up the fuel system today and have the car running.

[IMG]

[/IMG]

[/IMG]https://www.youtube.com/watch?v=sfMy...ature=youtu.be

I had one leak from a line that I reused from my old setup. I guess it is okay to reuse the fittings, but if you install a fitting on a line that was previously used and already stretched from the old fitting, it will not seal properly.

I like how I tucked both filters under the stock undershield with minimal cutting necessary. Just that section was over $100 in AN fittings to make it fit nicely.

[IMG]

[/IMG]

[/IMG]I put everything back together and drove the car around the block. The only problem I noticed is that when I go into boost, my second pump comes on, and I get some nasty fuel pressure spikes.

[IMG]

[/IMG]

[/IMG]I am thinking that the bypass valve in my fuel pressure regulator is too small and I need to upgrade the FPR. The only other thing I can think of would be that my single -6AN return can not keep up with my 2 -6AN feed lines. It is a little funny how I started this build because I was getting fuel pressure drops and now I am getting spikes.

#25

Full Member

iTrader: (3)

Join Date: May 2009

Location: Montreal

Posts: 192

Likes: 0

Received 0 Likes

on

0 Posts

Please tell me if you had hard time putting in the Bosch 044 into the plastic rings that hold the pump on the CJ rail, I used Vaseline, oil, etc etc and then I had to stop because I felt like it was going to break the plastic rings. What did you do to get them in the plastic loops? What I ended up doing is I changed the O-rings in the plastic rings for thinner ones, but they ended up being too thin and the pumps don't hold very solid.

Also I tried to use hard lines but the pumps are so close to the top of the CJ rail that the hardline can't seem to be able to bend two different bends and then fare them on each end... But if you managed and have a picture I would love for you to share the info

Thank you!

Also I tried to use hard lines but the pumps are so close to the top of the CJ rail that the hardline can't seem to be able to bend two different bends and then fare them on each end... But if you managed and have a picture I would love for you to share the info

Thank you!