Found out why my engine was losing compression

#1

Found out why my engine was losing compression

This is not a "complain" thread or a "feel sorry for me" thread. I want to share with you why you shouldn't reuse old parts that are critical to an engine's reliability and long term use.

Back Story

In June I purchased another FD. This would be my second FD. This FD had the motor built in 2013, was professionally tuned, made good numbers, and had 10,000km on the rebuilt engine. At the time of purchase, everything checked out and I was happy with the car. Compression was acceptable for a large street ported motor.

Shortly after I bought the FD, the motor started losing compression very quickly. First hot starts were hard. Then hot starts were impossible. Finally cold starts also became very difficult. At the time I assumed that this was from the previous owner's lack of rotary knowledge and from not using enough premix (He bought the car in 2014 and did not build the engine).

Side note: I found out, through the grape vine, after I had purchased the car that the previous owner knew about the engine losing compression over time but neglected to inform me of it.

No big deal. I wanted to tear out the motor anyways and check over the work that was originally done to it. Winter is long and the car would be in storage for 6-8 months, giving me plenty of time to go over the car and the engine.

I drove the car for 2,500km during the summer and by late August, the engine was in very rough shape. Cold starts were hard, hot starts were impossible, but everything ran well when the engine was warm.

Some more digging

After I had bought the car I got in contact with the original owner and builder of the engine. He's a pretty nice guy and seems to know a thing or two about rotaries. I wanted to know exactly what had been done to the car so that I did not look like a chump if someone asked me about it.

I found out that the engine was removed, rebuilt, and installed in eight hours. This guy must be extremely skilled or a wizard.

The original owner also said that he reused the old corner seals... Could this be the cause of the compression loss? Maybe they were loose after 12,500km or were worn out.

Fast forward to this weekend

I took the car off the road last week. Winter is close and the car's seasonal registration runs out at the end of October. I then began to pull & disassemble the engine over the weekend. I was shocked by what I saw. All I could think of was

"How was this thing still running"

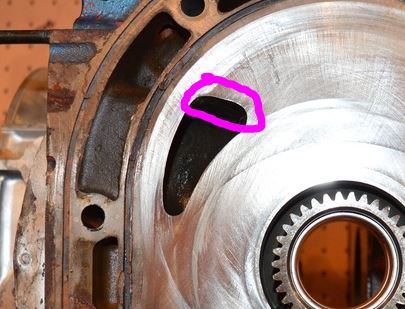

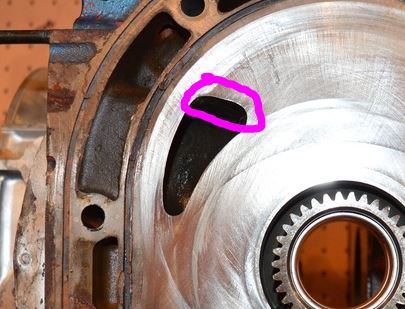

The rear rotor:

I assume that the rotor was installed like this. This was not caused by a lose piece in the combustion chamber of this engine. Clearances are within spec. The housing surfaces show no sign of something "dragging" on them. I believe that this was done by an earlier engine.

The Front iron. Notice the orange RTV gasket sealant all around the outside and on both water jackets. Yes, this engine was coated in RTV sealant between each housing & iron. We found RTV sealant remnants in one of the combustion chambers, in the water channels, and on all the water jackets.

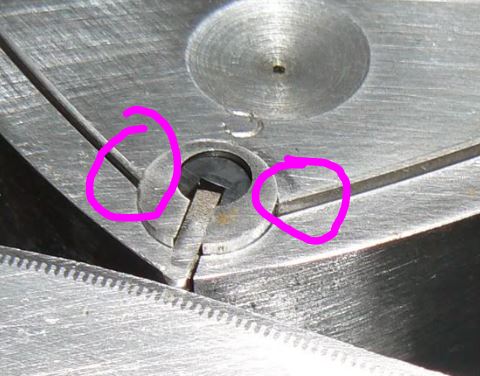

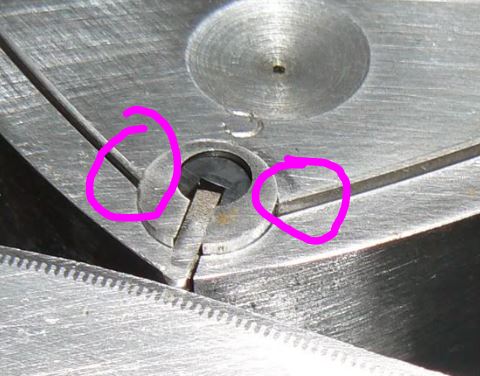

Finally, the corner seals. These are the OEM two piece Mazda corner seals that were reused by the original owner of the car and builder of the engine. TEN of the 12 corner seals were split and broken in to multiple pieces. This, in my opinion is what caused the rapid loss of combustion. The apex seals were loose and sliding side-to-side in the corner seals when we took the engine apart.

I am amazed that this engine still ran and did not blow an apex seal. I think that I got very lucky on this one and that damage was not more.

Now it's time to build it right.

Back Story

In June I purchased another FD. This would be my second FD. This FD had the motor built in 2013, was professionally tuned, made good numbers, and had 10,000km on the rebuilt engine. At the time of purchase, everything checked out and I was happy with the car. Compression was acceptable for a large street ported motor.

Shortly after I bought the FD, the motor started losing compression very quickly. First hot starts were hard. Then hot starts were impossible. Finally cold starts also became very difficult. At the time I assumed that this was from the previous owner's lack of rotary knowledge and from not using enough premix (He bought the car in 2014 and did not build the engine).

Side note: I found out, through the grape vine, after I had purchased the car that the previous owner knew about the engine losing compression over time but neglected to inform me of it.

No big deal. I wanted to tear out the motor anyways and check over the work that was originally done to it. Winter is long and the car would be in storage for 6-8 months, giving me plenty of time to go over the car and the engine.

I drove the car for 2,500km during the summer and by late August, the engine was in very rough shape. Cold starts were hard, hot starts were impossible, but everything ran well when the engine was warm.

Some more digging

After I had bought the car I got in contact with the original owner and builder of the engine. He's a pretty nice guy and seems to know a thing or two about rotaries. I wanted to know exactly what had been done to the car so that I did not look like a chump if someone asked me about it.

I found out that the engine was removed, rebuilt, and installed in eight hours. This guy must be extremely skilled or a wizard.

The original owner also said that he reused the old corner seals... Could this be the cause of the compression loss? Maybe they were loose after 12,500km or were worn out.

Fast forward to this weekend

I took the car off the road last week. Winter is close and the car's seasonal registration runs out at the end of October. I then began to pull & disassemble the engine over the weekend. I was shocked by what I saw. All I could think of was

"How was this thing still running"

The rear rotor:

I assume that the rotor was installed like this. This was not caused by a lose piece in the combustion chamber of this engine. Clearances are within spec. The housing surfaces show no sign of something "dragging" on them. I believe that this was done by an earlier engine.

The Front iron. Notice the orange RTV gasket sealant all around the outside and on both water jackets. Yes, this engine was coated in RTV sealant between each housing & iron. We found RTV sealant remnants in one of the combustion chambers, in the water channels, and on all the water jackets.

Finally, the corner seals. These are the OEM two piece Mazda corner seals that were reused by the original owner of the car and builder of the engine. TEN of the 12 corner seals were split and broken in to multiple pieces. This, in my opinion is what caused the rapid loss of combustion. The apex seals were loose and sliding side-to-side in the corner seals when we took the engine apart.

I am amazed that this engine still ran and did not blow an apex seal. I think that I got very lucky on this one and that damage was not more.

Now it's time to build it right.

Last edited by H_M; 10-10-16 at 03:34 PM.

#3

Housings are In OK shape. No gouges in the chrome. There are small imperfections if I carefully run my fingernail over the chrome (can't see them with the naked eye). I could use them as they are but want to get them resurfaced.

I thought Mazda only used two piece corner seals on the 13B REW. My other FD's engine had the exact same two piece corner seals and it had never been opened until I rebuilt it. By "two piece" I mean the corner seal and the plug.

I thought Mazda only used two piece corner seals on the 13B REW. My other FD's engine had the exact same two piece corner seals and it had never been opened until I rebuilt it. By "two piece" I mean the corner seal and the plug.

Last edited by H_M; 10-09-16 at 09:54 PM.

#4

H_M,

1. intake and exhaust porting doesn't affect compression. a "big street port" will compress the same as a stock port engine.

the intake, compression, and exhaust are separate "strokes" unless the porting is way overdone and there's huge overlap into the compression stroke.

2. it's perfectly OK to reuse the corners with new rubber plugs. also, that rotor damaged in your pic is reusable if the scratches don't interfere with the apex slot and don't protrude "up" toward the housing chrome.

3. as for the corner seals, I will bet you $1 the corners broke because the irons are over-ported and the side seal was falling into the intake port, also maybe part of the corner seal was unsupported as well. please post a pic of the irons and a pic of the sides of the rotors. a closeup of the intake ports would be good too, so we can help you verify what happened.

it would really suck to reuse those irons and have the same thing happen again, after "doing it right."

my paypal address is jacob.cartmill@gmail.com

i'm sorry to hear about your misfortune here. I've *definitely* been there before (a few times)

1. intake and exhaust porting doesn't affect compression. a "big street port" will compress the same as a stock port engine.

the intake, compression, and exhaust are separate "strokes" unless the porting is way overdone and there's huge overlap into the compression stroke.

2. it's perfectly OK to reuse the corners with new rubber plugs. also, that rotor damaged in your pic is reusable if the scratches don't interfere with the apex slot and don't protrude "up" toward the housing chrome.

3. as for the corner seals, I will bet you $1 the corners broke because the irons are over-ported and the side seal was falling into the intake port, also maybe part of the corner seal was unsupported as well. please post a pic of the irons and a pic of the sides of the rotors. a closeup of the intake ports would be good too, so we can help you verify what happened.

it would really suck to reuse those irons and have the same thing happen again, after "doing it right."

my paypal address is jacob.cartmill@gmail.com

i'm sorry to hear about your misfortune here. I've *definitely* been there before (a few times)

Last edited by jacobcartmill; 10-09-16 at 11:37 PM.

#6

Sponsor

iTrader: (41)

Stock 93-95 corner seals are 2 piece, if you count the rubber insert.

The most common way to break a stock corner seal is from detonation if running stronger apex seals. Something has to go so the corners usually go next. The engine will still usually run to some degree because the cracked corner seal will stay put. I would still check the port to make sure there is no side seal interference.

The iron pictured looks to have significant scoring from the broken corner seal pieces dragging. It could be lapped and re-nitride if the damage isn't deeper than .002.

The marks on the rotor are most likely from a previous engine failure. As long as the seal clearances aren't affected and there is no significant denting of the rotor face, it is acceptable to continue using that rotor.

It looks like silicone rtv was used to hold the coolant seals in place. I prefer using hylomar. I would clean all the rtv and carefully inspect the iron to make sure the water jacket isn't broken anywhere.

Personally I never re-use any seals, springs, gaskets, or bearings during a build. They are wear items.

The most common way to break a stock corner seal is from detonation if running stronger apex seals. Something has to go so the corners usually go next. The engine will still usually run to some degree because the cracked corner seal will stay put. I would still check the port to make sure there is no side seal interference.

The iron pictured looks to have significant scoring from the broken corner seal pieces dragging. It could be lapped and re-nitride if the damage isn't deeper than .002.

The marks on the rotor are most likely from a previous engine failure. As long as the seal clearances aren't affected and there is no significant denting of the rotor face, it is acceptable to continue using that rotor.

It looks like silicone rtv was used to hold the coolant seals in place. I prefer using hylomar. I would clean all the rtv and carefully inspect the iron to make sure the water jacket isn't broken anywhere.

Personally I never re-use any seals, springs, gaskets, or bearings during a build. They are wear items.

#7

H_M,

2. it's perfectly OK to reuse the corners with new rubber plugs. also, that rotor damaged in your pic is reusable if the scratches don't interfere with the apex slot and don't protrude "up" toward the housing chrome.

3. as for the corner seals, I will bet you $1 the corners broke because the irons are over-ported and the side seal was falling into the intake port, also maybe part of the corner seal was unsupported as well. please post a pic of the irons and a pic of the sides of the rotors. a closeup of the intake ports would be good too, so we can help you verify what happened.

it would really suck to reuse those irons and have the same thing happen again, after "doing it right."

2. it's perfectly OK to reuse the corners with new rubber plugs. also, that rotor damaged in your pic is reusable if the scratches don't interfere with the apex slot and don't protrude "up" toward the housing chrome.

3. as for the corner seals, I will bet you $1 the corners broke because the irons are over-ported and the side seal was falling into the intake port, also maybe part of the corner seal was unsupported as well. please post a pic of the irons and a pic of the sides of the rotors. a closeup of the intake ports would be good too, so we can help you verify what happened.

it would really suck to reuse those irons and have the same thing happen again, after "doing it right."

3. I have takes some pictures of the irons and the housings and have posted them below. I can take some pictures of the rotors next time that I go out to the garage. I also want to get o the bottom of why this happened so that I can make sure that something like this does not happen again.

Stock 93-95 corner seals are 2 piece, if you count the rubber insert.

The most common way to break a stock corner seal is from detonation if running stronger apex seals. Something has to go so the corners usually go next. The engine will still usually run to some degree because the cracked corner seal will stay put. I would still check the port to make sure there is no side seal interference.

The iron pictured looks to have significant scoring from the broken corner seal pieces dragging. It could be lapped and re-nitride if the damage isn't deeper than .002.

It looks like silicone rtv was used to hold the coolant seals in place. I prefer using hylomar. I would clean all the rtv and carefully inspect the iron to make sure the water jacket isn't broken anywhere.

The most common way to break a stock corner seal is from detonation if running stronger apex seals. Something has to go so the corners usually go next. The engine will still usually run to some degree because the cracked corner seal will stay put. I would still check the port to make sure there is no side seal interference.

The iron pictured looks to have significant scoring from the broken corner seal pieces dragging. It could be lapped and re-nitride if the damage isn't deeper than .002.

It looks like silicone rtv was used to hold the coolant seals in place. I prefer using hylomar. I would clean all the rtv and carefully inspect the iron to make sure the water jacket isn't broken anywhere.

Yes, the builder did use RTV sealant. You can see it under the water jackets (the ones that are removed) and in some of the water tunnels.

I have takes pictures of the irons and housings and have posted them below.

Front iron

Front housing. The housing has even wear marks in the chrome. The wear marks go evenly around the entire housing. There are no chatter marks to be seen. I can feel small grooves in the surface when I run my fingernail across it.

Front Housing. Cracks around the leading and trailing plugs

Front Housing. Exhaust port

Centre iron. Front. RTV sealant in the cooling passages.

Centre iron. Rear

Rear housing. Same exact grooves as the front housing.

Rear housing. No cracks around spark plugs

Rear housing. exhaust port

Rear iron

I can get more close up pictures of the ports, rotors, or anything else if someone wants a closer look.

Trending Topics

#8

H_M, i am starting to agree with Ihor after taking a second look at your pictures. also i am surprised your housings are that scored.

can you post closeups of the closing edge of the intake ports? also, it looks like your primary ports are stock, but the secondary ports are ported...

something like this:

can you post closeups of the closing edge of the intake ports? also, it looks like your primary ports are stock, but the secondary ports are ported...

something like this:

#10

H_M, i am starting to agree with Ihor after taking a second look at your pictures. also i am surprised your housings are that scored.

can you post closeups of the closing edge of the intake ports? also, it looks like your primary ports are stock, but the secondary ports are ported...

can you post closeups of the closing edge of the intake ports? also, it looks like your primary ports are stock, but the secondary ports are ported...

Here are the pictures:

Front iron secondary port (one pic without flash and one with flash)

Rear iron secondary port (one pic without flash and one with flash)

Front rotor

#12

Racing Rotary Since 1983

iTrader: (6)

built in 8 hours

built in 8 hours

generally, most corner seals break due to detonation. your irons do not look "overported." overported irons break the leading edge of the sideseal.

my guess is the engine detonated.

while it might have been tuned by an excellent tuner there are a million other causes than tune to cause detonation. check your corner seal springs height. often corner seal springs are the first to go as detonation can be 3500F V normal combustion around half of that.

spring height should be around .15

while some like OE corners i prefer Atkins as they are beefier.

the housings look like the motor was either run on E85 or someone wasn't premixing. be extremely careful if you have them honed that they really come back flat.

since your apex seal is the mirror image of the housing it will look really trashy.

i bet you will spend a bit more than 8 hours on the assembly.

add//////////////

as just saw your apex seal groove pics after i posted... the rotary does tend to open the apex seal groove clearances at the rotor sides. the opened groove does create slop between the corner seal and the CS well. this could have caused the CS breakage. it is not difficult to re-adjust the groove. if your CS springs are around .15/.16 chances are no detonation, just CSs rattling around in the well.

good luck,

Howard

built in 8 hours

generally, most corner seals break due to detonation. your irons do not look "overported." overported irons break the leading edge of the sideseal.

my guess is the engine detonated.

while it might have been tuned by an excellent tuner there are a million other causes than tune to cause detonation. check your corner seal springs height. often corner seal springs are the first to go as detonation can be 3500F V normal combustion around half of that.

spring height should be around .15

while some like OE corners i prefer Atkins as they are beefier.

the housings look like the motor was either run on E85 or someone wasn't premixing. be extremely careful if you have them honed that they really come back flat.

since your apex seal is the mirror image of the housing it will look really trashy.

i bet you will spend a bit more than 8 hours on the assembly.

add//////////////

as just saw your apex seal groove pics after i posted... the rotary does tend to open the apex seal groove clearances at the rotor sides. the opened groove does create slop between the corner seal and the CS well. this could have caused the CS breakage. it is not difficult to re-adjust the groove. if your CS springs are around .15/.16 chances are no detonation, just CSs rattling around in the well.

good luck,

Howard

Last edited by Howard Coleman; 10-10-16 at 02:18 PM.

#13

built in 8 hours

built in 8 hours

generally, most corner seals break due to detonation. your irons do not look "overported." overported irons break the leading edge of the sideseal.

my guess is the engine detonated.

while it might have been tuned by an excellent tuner there are a million other causes than tune to cause detonation. check your corner seal springs height. often corner seal springs are the first to go as detonation can be 3500F V normal combustion around half of that.

spring height should be around .15

while some like OE corners i prefer Atkins as they are beefier.

the housings look like the motor was either run on E85 or someone wasn't premixing. be extremely careful if you have them honed that they really come back flat.

since your apex seal is the mirror image of the housing it will look really trashy.

i bet you will spend a bit more than 8 hours on the assembly.

add//////////////

as just saw your apex seal groove pics after i posted... the rotary does tend to open the apex seal groove clearances at the rotor sides. the opened groove does create slop between the corner seal and the CS well. this could have caused the CS breakage. it is not difficult to re-adjust the groove. if your CS springs are around .15/.16 chances are no detonation, just CSs rattling around in the well.

good luck,

Howard

built in 8 hours

generally, most corner seals break due to detonation. your irons do not look "overported." overported irons break the leading edge of the sideseal.

my guess is the engine detonated.

while it might have been tuned by an excellent tuner there are a million other causes than tune to cause detonation. check your corner seal springs height. often corner seal springs are the first to go as detonation can be 3500F V normal combustion around half of that.

spring height should be around .15

while some like OE corners i prefer Atkins as they are beefier.

the housings look like the motor was either run on E85 or someone wasn't premixing. be extremely careful if you have them honed that they really come back flat.

since your apex seal is the mirror image of the housing it will look really trashy.

i bet you will spend a bit more than 8 hours on the assembly.

add//////////////

as just saw your apex seal groove pics after i posted... the rotary does tend to open the apex seal groove clearances at the rotor sides. the opened groove does create slop between the corner seal and the CS well. this could have caused the CS breakage. it is not difficult to re-adjust the groove. if your CS springs are around .15/.16 chances are no detonation, just CSs rattling around in the well.

good luck,

Howard

You are right about the apex seals. They are a mirror image of the housings. I have attached an image showing the Goopy apex seals that were in the engine.

The previous owner of the car (not the builder) premixed 50ml/10L. About 0.66oz/gal

I will spend 6-8 months on the assembly. We're scheduled to get a long and snowy winter.

Goopy apex seal. Lots of scoring

#14

i'm with the other guys now. it doesnt look like the side seals were dipping into the intake port.

and H_M, you're into single turbo, high HP, aftermarket EMS rotary cars. you can't go by "the previous owner said it was tuned." when you buy a single turbo FD with EMS, you verify the tuning immediately after purchasing (if it blows up on the first pull of a test drive it's not your fault!)

my advice is to find a few people who know what they're talking about (like ihor and HC), and follow them around like genital herpes until you know what you're doing.

and H_M, you're into single turbo, high HP, aftermarket EMS rotary cars. you can't go by "the previous owner said it was tuned." when you buy a single turbo FD with EMS, you verify the tuning immediately after purchasing (if it blows up on the first pull of a test drive it's not your fault!)

my advice is to find a few people who know what they're talking about (like ihor and HC), and follow them around like genital herpes until you know what you're doing.

#15

Thanks for the info and advice guys.

We have a very small and spread out amateur rotary community here. None of us are experts. The closest expert is about 16 hours away but I will get in contact with a few more knowledgeable people and come up with a plan.

We have a very small and spread out amateur rotary community here. None of us are experts. The closest expert is about 16 hours away but I will get in contact with a few more knowledgeable people and come up with a plan.

#16

Sponsor

iTrader: (41)

I also noticed the apex seal slots look out of spec from the pics. They appear to be vd out. Either those rotors have really high mileage or the seals were not clearance properly and chattered.

The irons look hosed from the pics. Can you feel the scratches with your fingernail? It almost looks like someone sanded them.

If you have the means to measure the irons, wear at .002 or less can be lapped out. The irons will then need to be re-nitrided.

The irons look hosed from the pics. Can you feel the scratches with your fingernail? It almost looks like someone sanded them.

If you have the means to measure the irons, wear at .002 or less can be lapped out. The irons will then need to be re-nitrided.

#17

^i noticed the seal V spec looking bad as well, but thought maybe it was a photo illusion.

and M_H, i'd do a rebuild with different rotors, irons, and housings, personally -- but that's just me. you should check out my previous build thread (of 94 white FD) in which i did a teardown and had a similar issue to yours.

or maybe at least for the housings you could check into the "resurfacing" that people seem to have good results with. i'm not totally sold on it, as i haven't read about long term results (ie, does removing a bit of chrome to smooth the surface reduce longevity?)

Ihor, can you comment on this? sorry to threadjack BTW, if you could consider it that.

and M_H, i'd do a rebuild with different rotors, irons, and housings, personally -- but that's just me. you should check out my previous build thread (of 94 white FD) in which i did a teardown and had a similar issue to yours.

or maybe at least for the housings you could check into the "resurfacing" that people seem to have good results with. i'm not totally sold on it, as i haven't read about long term results (ie, does removing a bit of chrome to smooth the surface reduce longevity?)

Ihor, can you comment on this? sorry to threadjack BTW, if you could consider it that.

#18

Sponsor

iTrader: (41)

I use a local machine shop to resurface housings. I take off .002 at the most. Any more I feel takes too much chrome off. Remember you are not putting any material back. If there is a gouge or flaking, it won't come out if its deeper than .002. If a housing has light scratching or chatter, it is usually a good candidate for resurfacing if new isn't in the budget. I don't use any of the other guys as I feel they remove too much material, leave too rough of a surface with takes excessive mileage to break in, and the tooling they use does not machine the entire surface across at one time. I have found uneven wear as one side of the housing can be higher than the other because of this. Pricing is $150 per housing and includes cleaning and measuring the housing.

#19

I also noticed the apex seal slots look out of spec from the pics. They appear to be vd out. Either those rotors have really high mileage or the seals were not clearance properly and chattered.

The irons look hosed from the pics. Can you feel the scratches with your fingernail? It almost looks like someone sanded them.

If you have the means to measure the irons, wear at .002 or less can be lapped out. The irons will then need to be re-nitrided.

The irons look hosed from the pics. Can you feel the scratches with your fingernail? It almost looks like someone sanded them.

If you have the means to measure the irons, wear at .002 or less can be lapped out. The irons will then need to be re-nitrided.

I also thought that the irons looked pretty bad. One of the first things that I did was run my fingernail over the iron's surface. I was super surprised that the iron felt smooth. I couldn't believe it and did it multiple times on all the irons. I could not feel any grooves or scratches at all. However, I will have the irons measured at a local shop and see what the measurements say.

#20

Sponsor

iTrader: (41)

Put a new apex seal in each slot and measure the clearance with a feeler gauge. should be .0015-.005. I clearance most of my motors to .002. If the clearance is too big the rotor is out of spec and should be replaced because it can cause the seal to chatter.

You need a dial indicator and a base that can be slid across the iron surface to properly measure it. If there is no excessive wear, someone might have block sanded those, causing the marks seen in the pics.

You need a dial indicator and a base that can be slid across the iron surface to properly measure it. If there is no excessive wear, someone might have block sanded those, causing the marks seen in the pics.

#21

The housings are being resurfaced and ported. The irons have also been checked. The grooves are between 0.002 and 0.004. You are right, they were sanded/surfaced previously (I found out on the weekend). I ordered rebuild parts last week. I will measure the rotor clearances when the new apex seals arrive.

#23

1st Gens are the Best

iTrader: (2)

Join Date: Apr 2012

Location: Virginia Beach

Posts: 560

Likes: 0

Received 0 Likes

on

0 Posts

built in 8 hours

built in 8 hours

generally, most corner seals break due to detonation. your irons do not look "overported." overported irons break the leading edge of the sideseal.

my guess is the engine detonated.

while it might have been tuned by an excellent tuner there are a million other causes than tune to cause detonation. check your corner seal springs height. often corner seal springs are the first to go as detonation can be 3500F V normal combustion around half of that.

spring height should be around .15

while some like OE corners i prefer Atkins as they are beefier.

the housings look like the motor was either run on E85 or someone wasn't premixing. be extremely careful if you have them honed that they really come back flat.

since your apex seal is the mirror image of the housing it will look really trashy.

i bet you will spend a bit more than 8 hours on the assembly.

add//////////////

as just saw your apex seal groove pics after i posted... the rotary does tend to open the apex seal groove clearances at the rotor sides. the opened groove does create slop between the corner seal and the CS well. this could have caused the CS breakage. it is not difficult to re-adjust the groove. if your CS springs are around .15/.16 chances are no detonation, just CSs rattling around in the well.

good luck,

Howard

built in 8 hours

generally, most corner seals break due to detonation. your irons do not look "overported." overported irons break the leading edge of the sideseal.

my guess is the engine detonated.

while it might have been tuned by an excellent tuner there are a million other causes than tune to cause detonation. check your corner seal springs height. often corner seal springs are the first to go as detonation can be 3500F V normal combustion around half of that.

spring height should be around .15

while some like OE corners i prefer Atkins as they are beefier.

the housings look like the motor was either run on E85 or someone wasn't premixing. be extremely careful if you have them honed that they really come back flat.

since your apex seal is the mirror image of the housing it will look really trashy.

i bet you will spend a bit more than 8 hours on the assembly.

add//////////////

as just saw your apex seal groove pics after i posted... the rotary does tend to open the apex seal groove clearances at the rotor sides. the opened groove does create slop between the corner seal and the CS well. this could have caused the CS breakage. it is not difficult to re-adjust the groove. if your CS springs are around .15/.16 chances are no detonation, just CSs rattling around in the well.

good luck,

Howard

Thread

Thread Starter

Forum

Replies

Last Post