What would cause an extremely low idle?

#1

Senior Member

Thread Starter

Join Date: Sep 2008

Location: Seattle, WA

Posts: 622

Likes: 0

Received 0 Likes

on

0 Posts

What would cause an extremely low idle?

Like 300 RPM or below.

BTW, it's a GSL-SE, but I figured 2nd gen people are more familiar with fuel injected 13B, so might offer a different perspective.

New engine, built with S4 components and a mild street port, compression is decent. Using stock '85 GSL-SE ECU.

Idle screw is all the way out, but it still idles really low. If I screw it in more than a turn, engine dies.

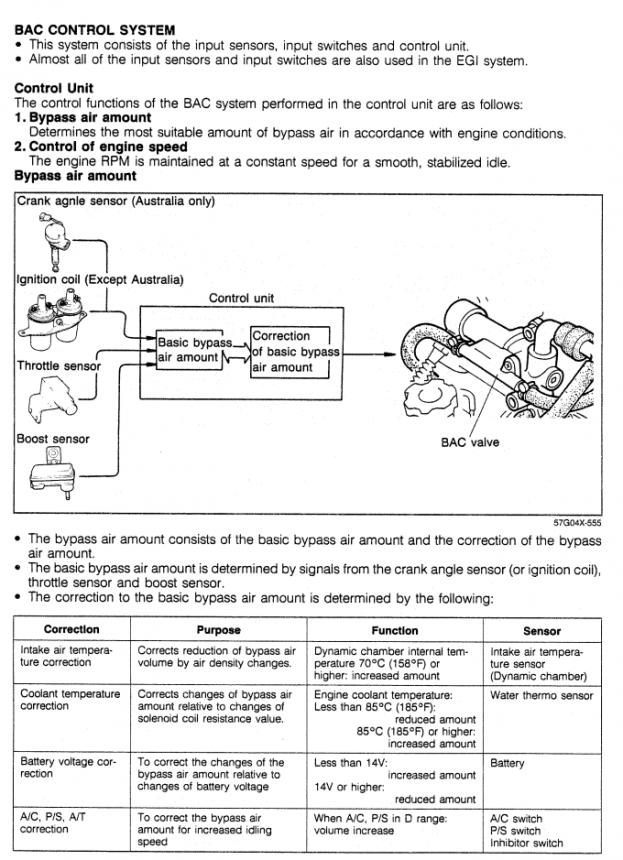

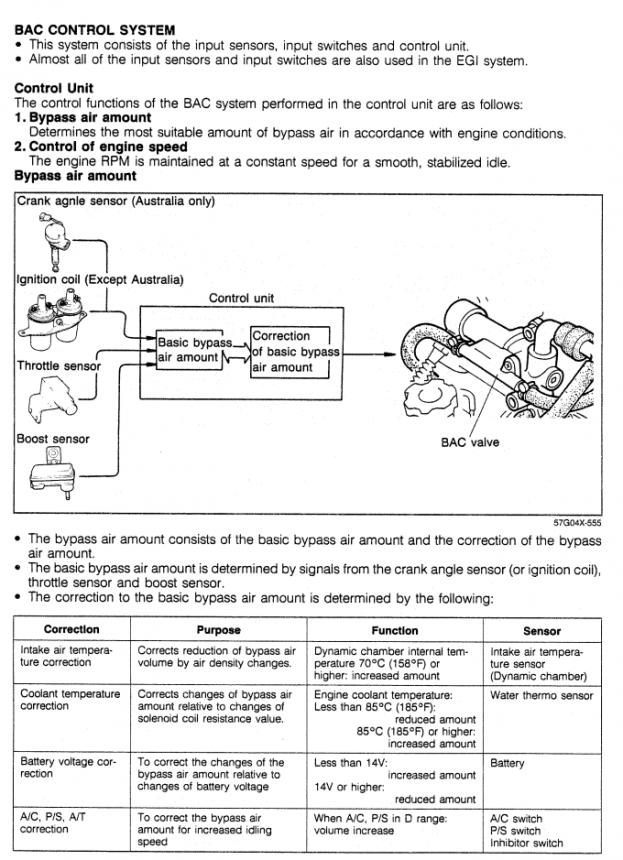

I double and triple checked my BAC valve and solenoids, and everything seems to be in order. Also my secondary Intake Air Temp sensor (one in the back of the dynamic chamber) broke off today, well the wires did, but I don't think that would cause such a low idle all by itself.

Suggestions?

Thanks.

BTW, it's a GSL-SE, but I figured 2nd gen people are more familiar with fuel injected 13B, so might offer a different perspective.

New engine, built with S4 components and a mild street port, compression is decent. Using stock '85 GSL-SE ECU.

Idle screw is all the way out, but it still idles really low. If I screw it in more than a turn, engine dies.

I double and triple checked my BAC valve and solenoids, and everything seems to be in order. Also my secondary Intake Air Temp sensor (one in the back of the dynamic chamber) broke off today, well the wires did, but I don't think that would cause such a low idle all by itself.

Suggestions?

Thanks.

#4

Senior Member

Thread Starter

Join Date: Sep 2008

Location: Seattle, WA

Posts: 622

Likes: 0

Received 0 Likes

on

0 Posts

AFAIK stock ECU should be able to handle mild street porting. I mean, it drives and everything. It's when you go big with bridge or peripheral that you need a stand-alone. Plus, as I understand, if it's using stock maps on a port, the car should idle higher, not lower. I may be wrong, though.

#5

Like 300 RPM or below.

BTW, it's a GSL-SE, but I figured 2nd gen people are more familiar with fuel injected 13B, so might offer a different perspective.

New engine, built with S4 components and a mild street port, compression is decent. Using stock '85 GSL-SE ECU.

Idle screw is all the way out, but it still idles really low. If I screw it in more than a turn, engine dies.

I double and triple checked my BAC valve and solenoids, and everything seems to be in order. Also my secondary Intake Air Temp sensor (one in the back of the dynamic chamber) broke off today, well the wires did, but I don't think that would cause such a low idle all by itself.

Suggestions?

Thanks.

BTW, it's a GSL-SE, but I figured 2nd gen people are more familiar with fuel injected 13B, so might offer a different perspective.

New engine, built with S4 components and a mild street port, compression is decent. Using stock '85 GSL-SE ECU.

Idle screw is all the way out, but it still idles really low. If I screw it in more than a turn, engine dies.

I double and triple checked my BAC valve and solenoids, and everything seems to be in order. Also my secondary Intake Air Temp sensor (one in the back of the dynamic chamber) broke off today, well the wires did, but I don't think that would cause such a low idle all by itself.

Suggestions?

Thanks.

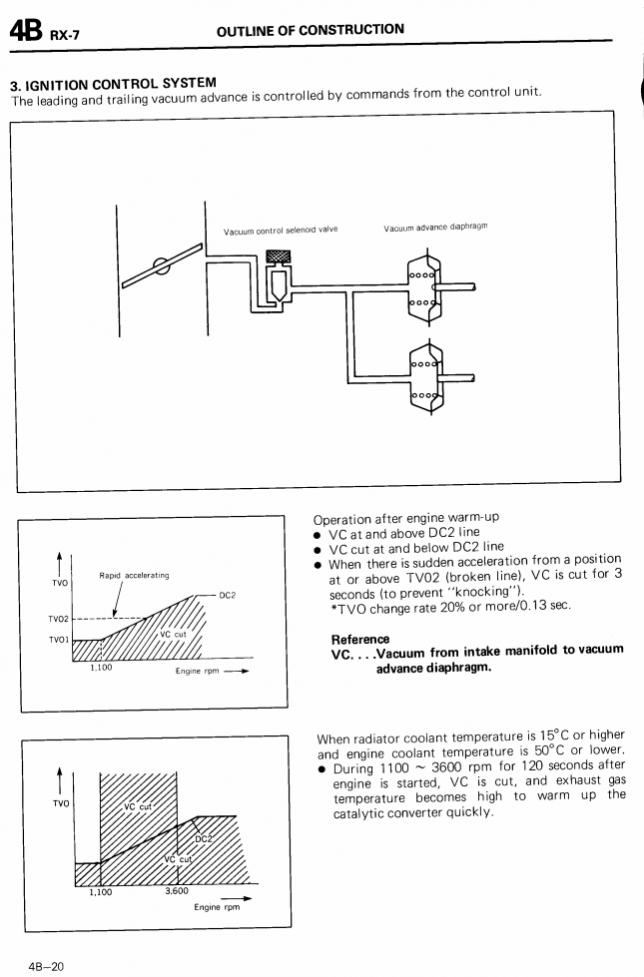

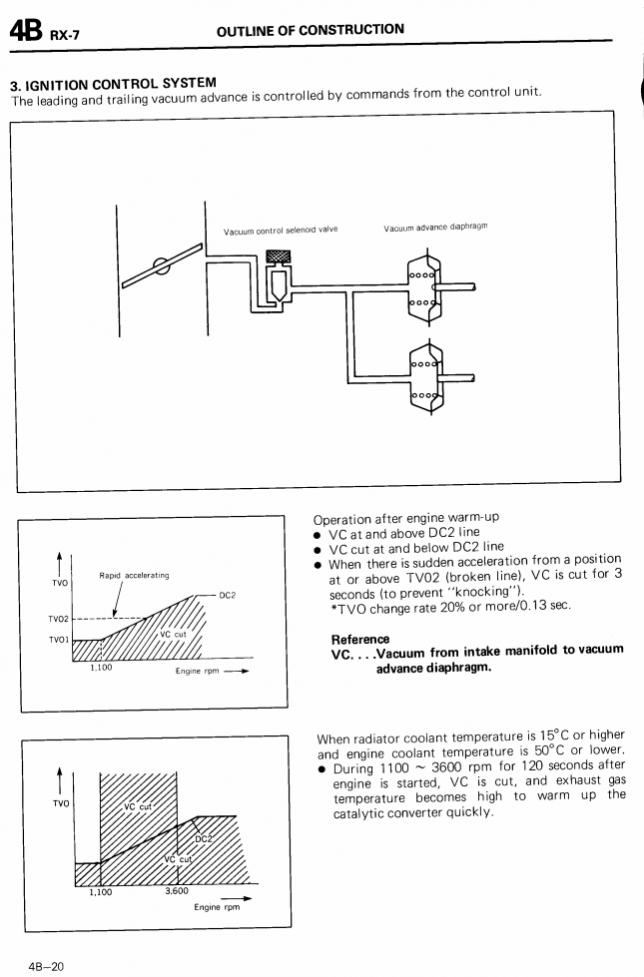

Do you have the s3 dizzy or s4 coilpacks?

#6

Just to clarify the differences between s3 and s4 nonturbo:

The s3 is a really really old design, something you would see in the early Bosch EFI from the 70s. It's an orifice that is opened and closed by engine vacuum, and the solenoids either increase or decrease that vacuum. Then the air supply valve adds in more air for A/C loads etc.

The s4 is more modern. It's the same basic design as the s5 and later Rx-7 valve. It's like the Ford and Honda valved. It's a plunger-type solenoid that's cycled on and off rapidly using duty control. The air supply valve is only on s4 Turbo engine if I remember correctly.

In either case though there is still the throttle plate opening angle (throttle stop screw on TB and fast idle cam during cold weather) as well as the bypass air amount (through the air adjusting screw on the plenum) to affect idle speed. And idle timing can affect idle speed as well.

On the s3 there is just a distributor (like the old 280Z's) and a solenoid for the ECU to cut vacuum. Everything ok with that system? What do you see when you put a timing light on the engine?

The s3 is a really really old design, something you would see in the early Bosch EFI from the 70s. It's an orifice that is opened and closed by engine vacuum, and the solenoids either increase or decrease that vacuum. Then the air supply valve adds in more air for A/C loads etc.

The s4 is more modern. It's the same basic design as the s5 and later Rx-7 valve. It's like the Ford and Honda valved. It's a plunger-type solenoid that's cycled on and off rapidly using duty control. The air supply valve is only on s4 Turbo engine if I remember correctly.

In either case though there is still the throttle plate opening angle (throttle stop screw on TB and fast idle cam during cold weather) as well as the bypass air amount (through the air adjusting screw on the plenum) to affect idle speed. And idle timing can affect idle speed as well.

On the s3 there is just a distributor (like the old 280Z's) and a solenoid for the ECU to cut vacuum. Everything ok with that system? What do you see when you put a timing light on the engine?

#7

Senior Member

Thread Starter

Join Date: Sep 2008

Location: Seattle, WA

Posts: 622

Likes: 0

Received 0 Likes

on

0 Posts

Ok can you clarify what exactly you have that is s4? The s3 BAC valve is an orifice controlled by a vacuum solenoid and vacuum relief solenoid, it is not a duty controlled solenoid valve. Also the s4 n/a plenum has the air bypass screw on the top, but I don't remember if the s3 does. What is your TPS voltage with the engine completely warm (fast idle down)? Does the car idle ok when it is cold (fast idle engaged) ? Has the throttle plate stop screw been adjusted at all from its factory setting? And is this an s4 or s3 throttlebody? The IAT sensor on the plenum is for BAC valve control, while the IAT in the AFM is for the airflow calculation.

Do you have the s3 dizzy or s4 coilpacks?

Do you have the s3 dizzy or s4 coilpacks?

I've tested the vacuum solenoids that control the BAC valve per FSM and they check out ok. There's no air bypass screw on the S3. Don't know the TPS voltage, but resistance is about 1K at idle with fast idle cam disengaged, which I believe is pretty much to spec. I have a brand new TPS, and I set it per FSM, using the 2-LED method. Cold idle seems alright. Around 2000 RPM. Maybe some roughness in it, not perfectly smooth, like it has a bit of engine shake now and then, but it's quite steady.

Throttle plate stop screw looks like it hasn't been touched in decades, so I'm gonna assume nobody has ever messed with it. It is my understanding that once the wax rod has expanded and fast idle cam disengages the throttle plates should be closed all the way at idle, and full control is handed over to BAC valve. When I apply vacuum to BAC by hand, it closes as it should and upon releasing vacuum it opens, so I think it operates properly, and definitely has the capacity to keep the idle, if it wanted to.

Now I'm hoping that fixing or replacing the IAT sensor might correct the problem (btw, can I use a second gen one? or are they not the same?), but I broke the wires when I was messing with the solenoids AFTER the car was already idling too low. It's possible the wires were already hanging by a thread, and the signal was wrong, but it seems even with the sensor broken, the ECU should default to some pre-set temperature to keep the car running at least.

Oh, and I'm using the S3 dizzy. New cap and rotor. I have a 2nd gen coil, and I tried it, but it made no difference. Timing light shows steady firing on all wires and the timing is pretty much spot on.

Trending Topics

#8

Only engine parts are from the second gen. Rotor housings are S4, e-shaft, rotors, and counterweights I believe are S5. I also went to the junk yard and got me a second gen pulley, with offset bolt pattern. Donno if it's S4 or S5, it was in a box of pulleys, but the marks match TDC: 5 and 20 after. All the bolt-ons, such as intake manifolds, TB, BAC, etc are stock S3. I should also mention that I do not have ACV or air pump. It's blocked off, vacuum hoses disconnected and split air solenoids removed.

And yes, there is an air adjusting screw on the s3 13B:

try following this procedure. But there is another procedure which involves adjusting the variable resistor, see 1985 FSM page 4B-65. These are almost the exact same procedures as for the FC and FD except instead of disconnecting the two vacuum solenoids you jumper a diagnostic connector to set the pulsewidth modulated BAC valve to a fixed duty cycle.

#9

Senior Member

Thread Starter

Join Date: Sep 2008

Location: Seattle, WA

Posts: 622

Likes: 0

Received 0 Likes

on

0 Posts

Thanks for staying with me, I used a few different methods to find TDC and they all agreed on the same spot, which happened to be right at the mark +/- 1 degree. Well, not the actual "mark" mark, but the TDC mark from which I measured 5 degrees to find the "mark" mark, you know what I mean. But yeah, I'm not boosting, so it's not crucial.

About that screw - it's not really a bypass. It offers fine adjustments to an already decent idle and has a range of maybe 200 RPM at most. Mine is turned out all the way, and it's probably the only thing that keeps the car running. If I turn it in at all the engine dies. I feel like I'm running mostly on the air it's supplying, instead of BAC air. There's no way I can gain another 600 RPM with it. It's strange, because I can hear the BAC solenoids clicking, so obviously ECU is trying to do something... but somehow it's not doing anything. Could it be an electrical issue? Bad ground somewhere?

Variable resistor is useless at this point, because it only has a range of about 50 RPM. I obviously have a much bigger issue here.

What else could it be? Bad ECU? Bad AFM? Bad coolant temp sensor?

About that screw - it's not really a bypass. It offers fine adjustments to an already decent idle and has a range of maybe 200 RPM at most. Mine is turned out all the way, and it's probably the only thing that keeps the car running. If I turn it in at all the engine dies. I feel like I'm running mostly on the air it's supplying, instead of BAC air. There's no way I can gain another 600 RPM with it. It's strange, because I can hear the BAC solenoids clicking, so obviously ECU is trying to do something... but somehow it's not doing anything. Could it be an electrical issue? Bad ground somewhere?

Variable resistor is useless at this point, because it only has a range of about 50 RPM. I obviously have a much bigger issue here.

What else could it be? Bad ECU? Bad AFM? Bad coolant temp sensor?

Thread

Thread Starter

Forum

Replies

Last Post

83revival

New Member RX-7 Technical

4

09-03-15 10:42 PM