TII swap questions (searched)

#1

TII swap questions (searched)

http://s307.photobucket.com/albums/n...-Brunson/Rx-7/

I just bought a TII engine and trans from a guy who is installing an Ls1, so he sold me the entire thing for $400. Now, I have the driveshaft for both the turbo and non-turbo. From what I've read, the driveshaft can be made custom to fit the N/A differential. Can the differential-end yoke from the N/A fit on the TII driveshaft (i.e. pop the u-joint and replace with N/A yoke), or is there some other customizing involved?

Also, can I use the N/A ecu (S4 N/A and S4 TII) with an Apex'i SAFC to modify the fuel mapping, or do I HAVE to get the TII ecu? I've already replaced the fuel pump, pressure sensor, air flow meter, and variable resistor as well.

Does the S4 N/A thermal pellet I bought from Atkins fit the S4 TII engine?

And lastly, what kind of things (aside from the obvious belts, hoses, spark plugs, etc) should SPECIFICALLY be looked/considered at when doing this swap. I already had to adjust the dashpot, found a cracked turbo pipe, and broken oil metering lines. Anything else I should keep an eye out for?

Thanks alot

-Terrence

I just bought a TII engine and trans from a guy who is installing an Ls1, so he sold me the entire thing for $400. Now, I have the driveshaft for both the turbo and non-turbo. From what I've read, the driveshaft can be made custom to fit the N/A differential. Can the differential-end yoke from the N/A fit on the TII driveshaft (i.e. pop the u-joint and replace with N/A yoke), or is there some other customizing involved?

Also, can I use the N/A ecu (S4 N/A and S4 TII) with an Apex'i SAFC to modify the fuel mapping, or do I HAVE to get the TII ecu? I've already replaced the fuel pump, pressure sensor, air flow meter, and variable resistor as well.

Does the S4 N/A thermal pellet I bought from Atkins fit the S4 TII engine?

And lastly, what kind of things (aside from the obvious belts, hoses, spark plugs, etc) should SPECIFICALLY be looked/considered at when doing this swap. I already had to adjust the dashpot, found a cracked turbo pipe, and broken oil metering lines. Anything else I should keep an eye out for?

Thanks alot

-Terrence

#2

Full Member

iTrader: (2)

Join Date: Mar 2008

Location: Fort Collins

Posts: 219

Likes: 0

Received 0 Likes

on

0 Posts

In your case I believe you can use your NA ecu. There is rumor that 88 vert ecu's can control a stock tii engine. Thermal pellet is the same.

As for the drive shaft I don't think you can swap the yoke. Your options would be get a tii rear end, custom drive shaft, or put your na flywheel on the tii motor since they are the same series and run the NA transmission.

As for the drive shaft I don't think you can swap the yoke. Your options would be get a tii rear end, custom drive shaft, or put your na flywheel on the tii motor since they are the same series and run the NA transmission.

#3

Hmm.. that's cool. I have 2 88 convertible ecu's.

I was hoping that the turbo II U-joint was the same size as the N/A, but after doing alot more searching, I guess it's not going to happen.

http://www.rockforddriveline.com/New...0In%20Page.pdf

Looks like the Turbo U-joints are larger. Not by much, but enough.

How would a driveshaft shop do this? It looks as if the N/A yoke is so small, and it would be very difficult to weld on to the turbo driveshaft.

edit: Upon further investigation, you're right about the 88 vert ecu. It apparently can run a TII.

I was hoping that the turbo II U-joint was the same size as the N/A, but after doing alot more searching, I guess it's not going to happen.

http://www.rockforddriveline.com/New...0In%20Page.pdf

Looks like the Turbo U-joints are larger. Not by much, but enough.

How would a driveshaft shop do this? It looks as if the N/A yoke is so small, and it would be very difficult to weld on to the turbo driveshaft.

edit: Upon further investigation, you're right about the 88 vert ecu. It apparently can run a TII.

Last edited by AGreen; 12-07-08 at 07:20 PM.

#4

well rested,buffet o food

http://mazdatrix.com/g9.htm

288.00 for their d-shaft is not horrible.

Dont know how much a shop is gonna cost though.

john

288.00 for their d-shaft is not horrible.

Dont know how much a shop is gonna cost though.

john

#7

Full Member

iTrader: (2)

Join Date: Mar 2008

Location: Fort Collins

Posts: 219

Likes: 0

Received 0 Likes

on

0 Posts

http://mazdatrix.com/g9.htm

288.00 for their d-shaft is not horrible.

Dont know how much a shop is gonna cost though.

john

288.00 for their d-shaft is not horrible.

Dont know how much a shop is gonna cost though.

john

I recommend that you run the NA transmission until you can source a tii rearend, then swap the drive train.

Trending Topics

#8

Banned. I got OWNED!!!

iTrader: (256)

USE the TII trans

USE the TII D-shaft

Get your hands on a TII Diff D-shaft companion flange

Swap the companion flange on your Na diff with the TII companion flange

Bot it all up and go

Eventually:

You will break the Na diff or halfshafts

Fix:

Get a TII diff and TII halfshafts

^ This is the correct way to do this...

USE the TII D-shaft

Get your hands on a TII Diff D-shaft companion flange

Swap the companion flange on your Na diff with the TII companion flange

Bot it all up and go

Eventually:

You will break the Na diff or halfshafts

Fix:

Get a TII diff and TII halfshafts

^ This is the correct way to do this...

#9

So what, maybe eventually I will break it. That's when I'll go out and buy a TII differential and halfshafts. Until then, I'll see if I can get the pinion flange for it. Thanks for the good idea!

#10

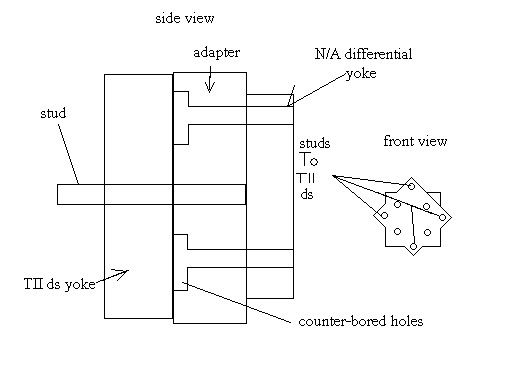

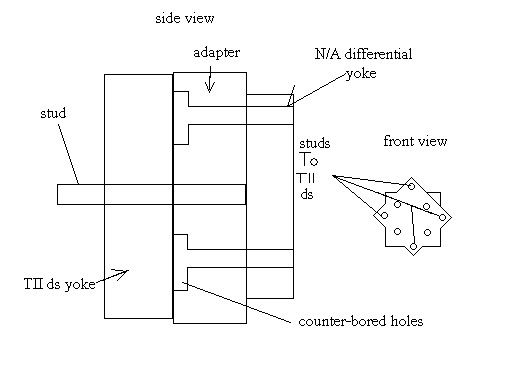

Is there any problem with having a machine shop make an adapter plate to fit the TII driveshaft to the N/A rear? I'm having trouble locating JUST the companion flange. I was thinking something like this:

The adaptor is double square-shaped, like an 8-pointed star. That way, the driveshaft is turned 45 degrees out of phase with the pinion flange. On one side, it has studs threaded all the way through it, to be bolted down on the driveshaft side by nuts. There are also 4 counter-bored holes for bolts to fit through, so the adaptor can be bolted to the flange, using the nuts that go behind the companion flange. The counter bore is large enough to fit a socket on, and deep enough to not get in the way of the driveshaft to sit flush against the adapter.

Plus, I couldn't imagine this costing too much, and would be a very effective solution to this apparently common problem.

... maybe I should have made it more simple. Umm, an 8-pointed star? Why not round? I just over think things sometimes.

The adaptor is double square-shaped, like an 8-pointed star. That way, the driveshaft is turned 45 degrees out of phase with the pinion flange. On one side, it has studs threaded all the way through it, to be bolted down on the driveshaft side by nuts. There are also 4 counter-bored holes for bolts to fit through, so the adaptor can be bolted to the flange, using the nuts that go behind the companion flange. The counter bore is large enough to fit a socket on, and deep enough to not get in the way of the driveshaft to sit flush against the adapter.

Plus, I couldn't imagine this costing too much, and would be a very effective solution to this apparently common problem.

... maybe I should have made it more simple. Umm, an 8-pointed star? Why not round? I just over think things sometimes.

Thread

Thread Starter

Forum

Replies

Last Post