She Followed Me Home, Honest

#1851

That air pump looks pretty sweet. Curious how you will mount it. I need one to pass smog, and have no ACV, or spot to mount the stock air pump. So I'll need to find a way to step down the voltage/blower speed that way I can conveniently flip a switch while waiting in line at the DMV. Delaware is the WORST....The inspection lanes are all state run so theres no way to slip someone a benny under the table and get a sticker

#1852

Have you looked at any potential electric pumps to use?

Beginning a project like this I typically first look at how easy the part would be to mount/locate.

Some parts are just to weird/unit specific to fit anything but the original, others are more "generic" and simpler to work with.

That's what attracted me to the Volvo pump.

I'm back at the yard today, I'll look at it more closely.

Beginning a project like this I typically first look at how easy the part would be to mount/locate.

Some parts are just to weird/unit specific to fit anything but the original, others are more "generic" and simpler to work with.

That's what attracted me to the Volvo pump.

I'm back at the yard today, I'll look at it more closely.

#1853

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,832

Received 2,603 Likes

on

1,847 Posts

there seem to be about 2 electric air pumps. the Rx8, and all the german stuff use a Bosch pump, the Rx8 pig tail even has a mercedes star on it, and uses a circa 1939 electrical connector. the second pump is the GM one.

the Bosch pump, as you would expect has a high failure rate (it says Bosch on it!), but the bearings are actually serviceable (same as a skateboard), so its rebuildable. i think the GM one just melts, although GM doesn't export cars here, so i can't say i've ever seen one

the Bosch pump, as you would expect has a high failure rate (it says Bosch on it!), but the bearings are actually serviceable (same as a skateboard), so its rebuildable. i think the GM one just melts, although GM doesn't export cars here, so i can't say i've ever seen one

#1855

I looked at the Volvo pump again and like it even more.

Unfortunately, my discretionary income must be allocated to finishing the airbox, so it'll be a few weeks till I go further.

But it's moved right to the top of the list.

A big day on the airbox front, oh yes indeedy.

I went to the yard primarily to find some 90° elbows but my heart just wasn't in it.

The idea of a hard right angle just before the AFM upset my rudimentary technical sensibilities but I picked up two possibilities just to try.

Ugh.

Much smoking and pondering ensued. Many different boot configs were attempted.

And then it just came together.

Here is the first test fit.

There are obvious further steps necessary but this is the first fully complete box that fits the space and the intake and doesn't appear glaringly out of place.

AND it gives me a fighting chance at an air source external to the bay.

Namely this:

See that stock hole tucked right in the corner?

I'm not exactly sure where it goes, it's part of the upper fender structure (on Z cars Datsun uses that structure as a fresh air intake for the cabin) and that's where I'm hoping to source the intake air.

This will be extremely easy to do because I have a trick up my sleeve and am not afraid to use it.

But that comes a bit later.

First I must block off the original in/out ports that are no longer useful.

Then a bit of paint.

Then we shall see.

Unfortunately, my discretionary income must be allocated to finishing the airbox, so it'll be a few weeks till I go further.

But it's moved right to the top of the list.

A big day on the airbox front, oh yes indeedy.

I went to the yard primarily to find some 90° elbows but my heart just wasn't in it.

The idea of a hard right angle just before the AFM upset my rudimentary technical sensibilities but I picked up two possibilities just to try.

Ugh.

Much smoking and pondering ensued. Many different boot configs were attempted.

And then it just came together.

Here is the first test fit.

There are obvious further steps necessary but this is the first fully complete box that fits the space and the intake and doesn't appear glaringly out of place.

AND it gives me a fighting chance at an air source external to the bay.

Namely this:

See that stock hole tucked right in the corner?

I'm not exactly sure where it goes, it's part of the upper fender structure (on Z cars Datsun uses that structure as a fresh air intake for the cabin) and that's where I'm hoping to source the intake air.

This will be extremely easy to do because I have a trick up my sleeve and am not afraid to use it.

But that comes a bit later.

First I must block off the original in/out ports that are no longer useful.

Then a bit of paint.

Then we shall see.

#1857

Yes, and your car also had nipples on the hatch glass, an inspiration to us all.

Late at night or early in the morning, I like to spend time staring at pics because sometimes details/concepts are easier to see than in real life.

Although it's taken seven years, I'm pleased that the bay is finally looking like I always thought it should; there's a logic/tidiness that makes sense to me.

All the uncountable hours in the junkyard, searching for the perfect molded hose, boot or bracket have really paid off and the concept of completely reorganizing the bay while keeping it looking OEM (nothing polished or billet or obviously custom) is close to reality.

Which means the parts that are left are that much more glaring/irritating.

Specifically, the damn upper radiator hose, which drunkenly wanders around for no apparent reason. It made perfect sense in the original context but with all the impediments removed (fan shroud, airbox, intake snorkel), it just looks stupid and weird.

Spurred on by welfare's creative airpump delete solution and j9's info about electric airpumps, that area (basically, the front of the engine) has become my next target...conceptualizing as I finish off the airbox.

In the past I've tried the side alternator relocate (no longer possible because of the newly positioned leading coil) and even made a different upper hose fitting (I think jackhild has it now), so I've made attempts at this before.

This time I'm serious.

I've done no measuring, so this is all total blue sky dreaming but I wonder if the alternator could be moved to the airpump location and if so, what the waterpump would think about that. Could I get away with the one belt?

Hmmm.

Actually, moving the alt is a pretty low priority, it doesn't offend me as is and this was a new idea I just began to think about but it's something I will look into.

Removing the stock airpump opens a lot of possibilities I had not previously considered but I should get deeper into the e-pump conversion before going too much further.

That thermostat cover/hose bung though can be dealt with immediately.

I can think of a couple different approaches but my preference is to start in the yard and see what I can find.

So that's on the burner.

The road down to the yard is quite rutted and bumpy and I'm using it to test airbox stabilty. If you look at the pics you'll notice the box is simply wedged into position with foam blocks. I originally thought this was a temporary way to get the box where it wanted to be so I could figure out brackets but it's much more secure and yet forgiving (remember, I still have to account for engine movement, so this can't be too rigid) and also means no bracket making or hardware.

If the airbox stays secure I'll keep this mounting method.

Still considering options for the box's intake. There are two obvious options, I'm exploring the easiest first and we'll see how it goes.

It's a process.

Sad as I am that the Z is languishing, at least it freed up time for me to fiddle with my own car for a change and I'm happy about that.

So is Sprocket, apparently.

Late at night or early in the morning, I like to spend time staring at pics because sometimes details/concepts are easier to see than in real life.

Although it's taken seven years, I'm pleased that the bay is finally looking like I always thought it should; there's a logic/tidiness that makes sense to me.

All the uncountable hours in the junkyard, searching for the perfect molded hose, boot or bracket have really paid off and the concept of completely reorganizing the bay while keeping it looking OEM (nothing polished or billet or obviously custom) is close to reality.

Which means the parts that are left are that much more glaring/irritating.

Specifically, the damn upper radiator hose, which drunkenly wanders around for no apparent reason. It made perfect sense in the original context but with all the impediments removed (fan shroud, airbox, intake snorkel), it just looks stupid and weird.

Spurred on by welfare's creative airpump delete solution and j9's info about electric airpumps, that area (basically, the front of the engine) has become my next target...conceptualizing as I finish off the airbox.

In the past I've tried the side alternator relocate (no longer possible because of the newly positioned leading coil) and even made a different upper hose fitting (I think jackhild has it now), so I've made attempts at this before.

This time I'm serious.

I've done no measuring, so this is all total blue sky dreaming but I wonder if the alternator could be moved to the airpump location and if so, what the waterpump would think about that. Could I get away with the one belt?

Hmmm.

Actually, moving the alt is a pretty low priority, it doesn't offend me as is and this was a new idea I just began to think about but it's something I will look into.

Removing the stock airpump opens a lot of possibilities I had not previously considered but I should get deeper into the e-pump conversion before going too much further.

That thermostat cover/hose bung though can be dealt with immediately.

I can think of a couple different approaches but my preference is to start in the yard and see what I can find.

So that's on the burner.

The road down to the yard is quite rutted and bumpy and I'm using it to test airbox stabilty. If you look at the pics you'll notice the box is simply wedged into position with foam blocks. I originally thought this was a temporary way to get the box where it wanted to be so I could figure out brackets but it's much more secure and yet forgiving (remember, I still have to account for engine movement, so this can't be too rigid) and also means no bracket making or hardware.

If the airbox stays secure I'll keep this mounting method.

Still considering options for the box's intake. There are two obvious options, I'm exploring the easiest first and we'll see how it goes.

It's a process.

Sad as I am that the Z is languishing, at least it freed up time for me to fiddle with my own car for a change and I'm happy about that.

So is Sprocket, apparently.

#1858

Senior Member

iTrader: (1)

The road down to the yard is quite rutted and bumpy and I'm using it to test airbox stabilty. If you look at the pics you'll notice the box is simply wedged into position with foam blocks. I originally thought this was a temporary way to get the box where it wanted to be so I could figure out brackets but it's much more secure and yet forgiving (remember, I still have to account for engine movement, so this can't be too rigid) and also means no bracket making or hardware.

If the airbox stays secure I'll keep this mounting method.

Still considering options for the box's intake. There are two obvious options, I'm exploring the easiest first and we'll see how it goes.

It's a process.

If the airbox stays secure I'll keep this mounting method.

Still considering options for the box's intake. There are two obvious options, I'm exploring the easiest first and we'll see how it goes.

It's a process.

#1859

I disagree about the suitability of foam but my projects seem to morph daily, so no telling what will hold the box next.

I blocked off the unused top hole, installed the filter element and went to the yard.

This was basically a worst case scenario, the box is now drawing from the bottom, facing the exhaust manifold but I wanted to see how she did with the filter restriction and small inlet (@2 3/4").

Drove fine.

As I contemplate the cosmetics (and wait for 70° weather to return), the intake can run as is.

Which sets me up for the next stage...the front of the engine.

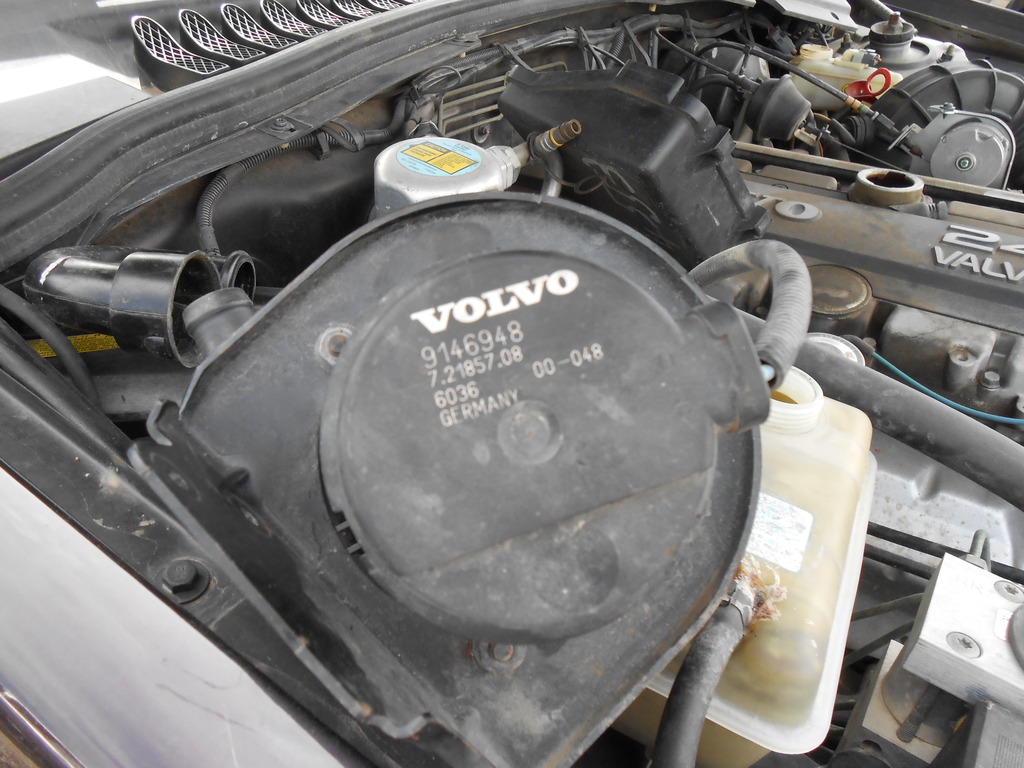

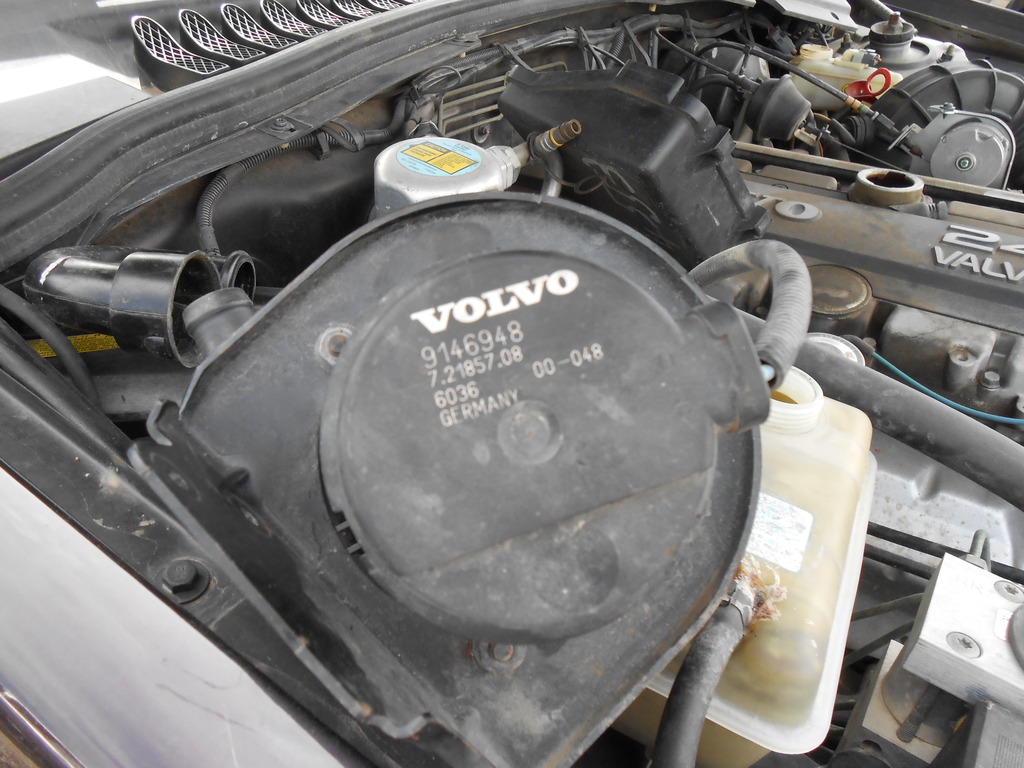

I went to the yard (fifth time this week!) specifically to hunt for a rad hose/thermostat fitting and to take a closer look at the Volvo airpump.

These pics were shot in the yard:

The unit is 8" long and about 6" in diameter.

A quick google search says it's used in several Volvo and BMW models.

I love the steampunkish rubber suspension and the simple bracket.

I really couldn't afford to get it.

An hour later, after the hose fitting search (possibly successful, btw), I'd talked myself into it.

Too many times I've held parts in my hands and then decided to wait, only to find them gone a few days later. Sometimes never to be seen again.

Despite my total lack of knowledge, this seemed like too good a deal to pass up, so I folded and bought it.

Jeez, I hope this works out.

I blocked off the unused top hole, installed the filter element and went to the yard.

This was basically a worst case scenario, the box is now drawing from the bottom, facing the exhaust manifold but I wanted to see how she did with the filter restriction and small inlet (@2 3/4").

Drove fine.

As I contemplate the cosmetics (and wait for 70° weather to return), the intake can run as is.

Which sets me up for the next stage...the front of the engine.

I went to the yard (fifth time this week!) specifically to hunt for a rad hose/thermostat fitting and to take a closer look at the Volvo airpump.

These pics were shot in the yard:

The unit is 8" long and about 6" in diameter.

A quick google search says it's used in several Volvo and BMW models.

I love the steampunkish rubber suspension and the simple bracket.

I really couldn't afford to get it.

An hour later, after the hose fitting search (possibly successful, btw), I'd talked myself into it.

Too many times I've held parts in my hands and then decided to wait, only to find them gone a few days later. Sometimes never to be seen again.

Despite my total lack of knowledge, this seemed like too good a deal to pass up, so I folded and bought it.

Jeez, I hope this works out.

#1860

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,832

Received 2,603 Likes

on

1,847 Posts

Late at night or early in the morning, I like to spend time staring at pics because sometimes details/concepts are easier to see than in real life.

Although it's taken seven years, I'm pleased that the bay is finally looking like I always thought it should; there's a logic/tidiness that makes sense to me.

I've done no measuring, so this is all total blue sky dreaming but I wonder if the alternator could be moved to the airpump location and if so, what the waterpump would think about that. Could I get away with the one belt?

Hmmm.\.

Although it's taken seven years, I'm pleased that the bay is finally looking like I always thought it should; there's a logic/tidiness that makes sense to me.

I've done no measuring, so this is all total blue sky dreaming but I wonder if the alternator could be moved to the airpump location and if so, what the waterpump would think about that. Could I get away with the one belt?

Hmmm.\.

imo, i think the radiator hose is ok, but the air pump filter bugs me, it might be a real life vs picture thing...

putting the alternator where the air pump went is theoretically really simple. the alt uses a 10mm bolt, and the air pump is an 8mm, simple fix, there is enough meat to drill the bracket, or the 8mm bolt should actually be ok, the wiring probably wont reach, but its simple.

the deal breaker is the intake manifold, my PP can't have the alt over there because it hits the intake, just barely. it can still be done, probably, but you'd have to switch to the turbo air pump brackets, which put the pump i think higher, and further out.

shouldn't the electric air pump go where the old air pump silencer was?

#1861

At this point I have no idea.

I have an idea for relocating the just installed washer reservoir, which will free up space at the strut tower and open up options for the airpump. Then I'll pull the old airpump and see what the area looks like.

Now please allow for my ignorance...

If I power the pump through a relay, is this as easy as sending the two signals from the check connector to the relay coil?

I have an idea for relocating the just installed washer reservoir, which will free up space at the strut tower and open up options for the airpump. Then I'll pull the old airpump and see what the area looks like.

Now please allow for my ignorance...

If I power the pump through a relay, is this as easy as sending the two signals from the check connector to the relay coil?

#1862

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,832

Received 2,603 Likes

on

1,847 Posts

At this point I have no idea.

I have an idea for relocating the just installed washer reservoir, which will free up space at the strut tower and open up options for the airpump. Then I'll pull the old airpump and see what the area looks like.

Now please allow for my ignorance...

If I power the pump through a relay, is this as easy as sending the two signals from the check connector to the relay coil?

I have an idea for relocating the just installed washer reservoir, which will free up space at the strut tower and open up options for the airpump. Then I'll pull the old airpump and see what the area looks like.

Now please allow for my ignorance...

If I power the pump through a relay, is this as easy as sending the two signals from the check connector to the relay coil?

#1863

I can't believe it's so easy, guess I'll find out.

In a while.

Last night I spent a few hours employing my favorite design strategy- getting ripped and staring at pics and sure enough, **** changed again.

This time I got to the finished stage.

Sorta.

I found another washer bottle that fits into the very corner (most of my "washer bottles" are actually radiator overflow tanks that I fit the pump to), it holds less than a quart but I don't really care.

On a side note: after cruising the yard for potential washer reservoirs, I'm amazed at how big modern reservoirs are, some of 'em look like they hold over a gallon. I'm surprised they have fill caps- big as they are they could be factory sealed and sold as a lifetime supply.

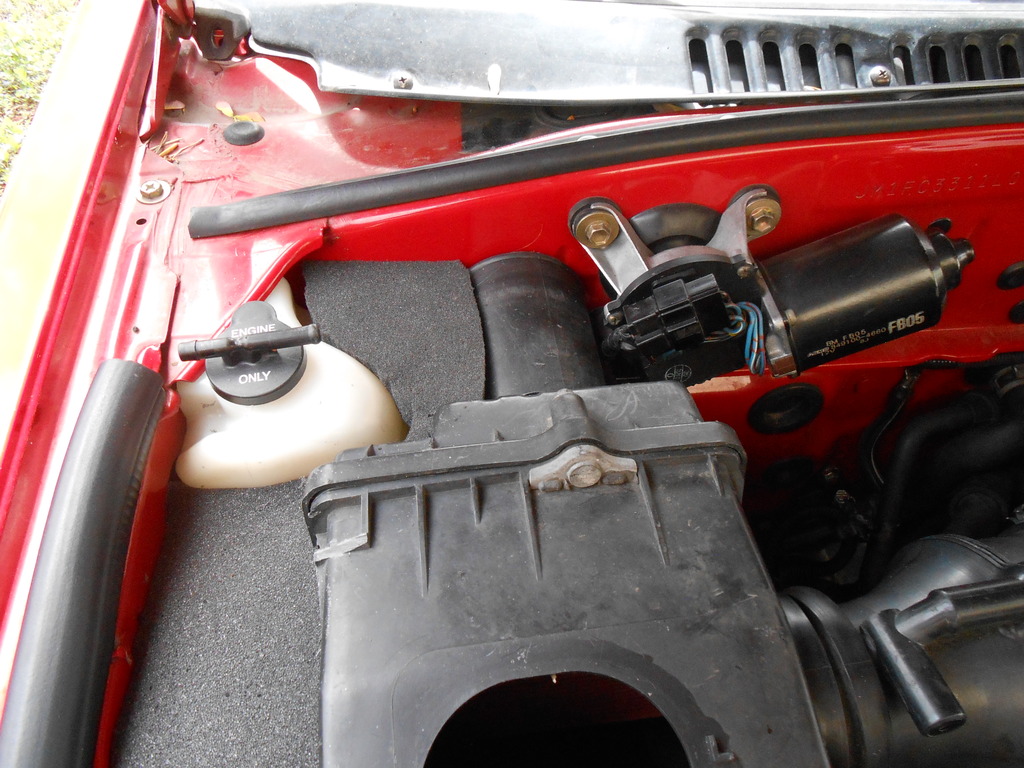

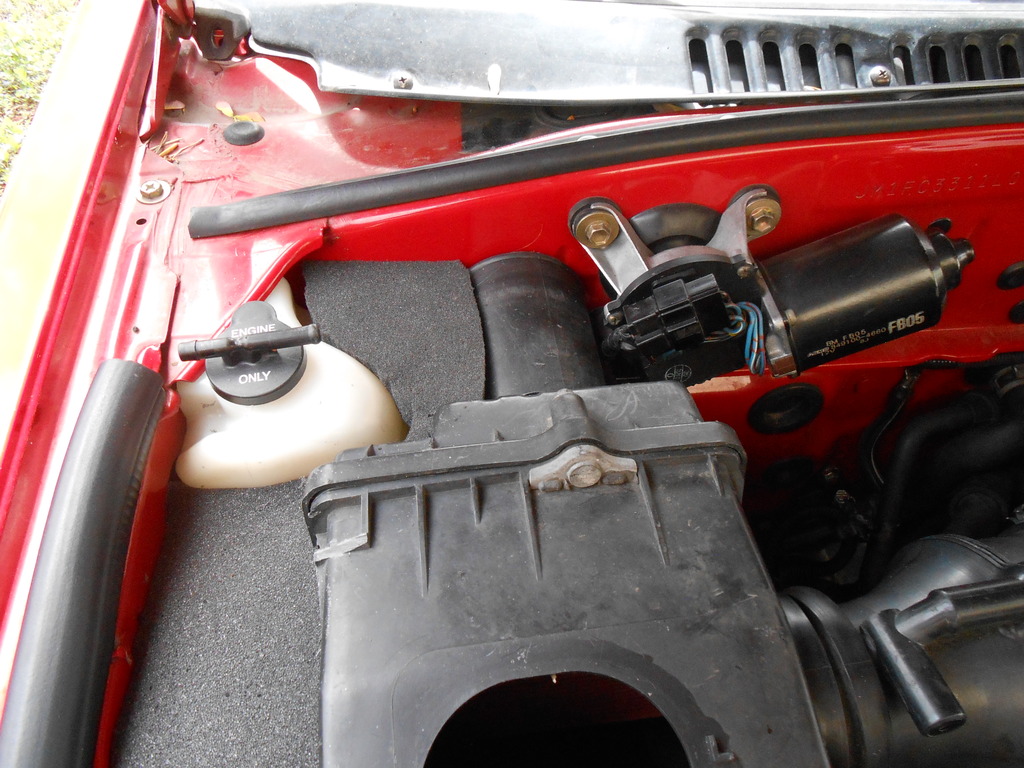

And the airbox intake from the wiper cavity is in place. It's the 2 1/2" tube right next to the wiper motor.

No, I haven't yet cut metal...this is still in the "considering" stage, but it's just what I envisioned.

I need to pull the wiper motor and see whats behind the firewall there, I know the HVAC intake is somewhere in that area and I don't want to **** with it.

This is the best packaging in that corner yet, getting the airbox and reservoir into the same space was an ideal I didn't think would be achieved but it looks like it really can happen.

Goody.

I was very happy with the last rez arrangement and had the bay been complete, probably would have kept it but the electric airpump changed the situation a lot.

Currently, I have no idea where it's going to be sited and clearing the strut tower gave me more options, so I decided to see what I could do.

I hope to mount the pump to the engine but if that doesn't pan out I know I have space to work with.

All my relays and electrical stuffs are at Sigfrids or I'd have this wired (temporarily)

to test right now.

Instead, I'll try to finish up the airbox install and then remove the airpump and see what's what...but it'll have to go back on till all the required parts are in hand. I haven't even begun to look for the MPV tensioner pulley to deal with the loss of the airpump...pretty sure there aren't any in the yard, so it might be a bit.

I guess I can go on without it and see if the waterpump bitches.

Or, I'm still thinking of relocating the alternator to the airpump mount...that's another thing to look into. If that were to happen, the airpump would have to move somewhere up front.

So there are still a lot of moving parts to decide on.

And j9...I see your point about the upper rad hose, maybe it is the little filter that makes it stand out/look weird.

I have the piece necessary to mod the thermostat cover/hose bung but I'll leave it be for now and decide after the next round of changes.

In a while.

Last night I spent a few hours employing my favorite design strategy- getting ripped and staring at pics and sure enough, **** changed again.

This time I got to the finished stage.

Sorta.

I found another washer bottle that fits into the very corner (most of my "washer bottles" are actually radiator overflow tanks that I fit the pump to), it holds less than a quart but I don't really care.

On a side note: after cruising the yard for potential washer reservoirs, I'm amazed at how big modern reservoirs are, some of 'em look like they hold over a gallon. I'm surprised they have fill caps- big as they are they could be factory sealed and sold as a lifetime supply.

And the airbox intake from the wiper cavity is in place. It's the 2 1/2" tube right next to the wiper motor.

No, I haven't yet cut metal...this is still in the "considering" stage, but it's just what I envisioned.

I need to pull the wiper motor and see whats behind the firewall there, I know the HVAC intake is somewhere in that area and I don't want to **** with it.

This is the best packaging in that corner yet, getting the airbox and reservoir into the same space was an ideal I didn't think would be achieved but it looks like it really can happen.

Goody.

I was very happy with the last rez arrangement and had the bay been complete, probably would have kept it but the electric airpump changed the situation a lot.

Currently, I have no idea where it's going to be sited and clearing the strut tower gave me more options, so I decided to see what I could do.

I hope to mount the pump to the engine but if that doesn't pan out I know I have space to work with.

All my relays and electrical stuffs are at Sigfrids or I'd have this wired (temporarily)

to test right now.

Instead, I'll try to finish up the airbox install and then remove the airpump and see what's what...but it'll have to go back on till all the required parts are in hand. I haven't even begun to look for the MPV tensioner pulley to deal with the loss of the airpump...pretty sure there aren't any in the yard, so it might be a bit.

I guess I can go on without it and see if the waterpump bitches.

Or, I'm still thinking of relocating the alternator to the airpump mount...that's another thing to look into. If that were to happen, the airpump would have to move somewhere up front.

So there are still a lot of moving parts to decide on.

And j9...I see your point about the upper rad hose, maybe it is the little filter that makes it stand out/look weird.

I have the piece necessary to mod the thermostat cover/hose bung but I'll leave it be for now and decide after the next round of changes.

#1864

Denver just suffered through three uncharacteristic days of cold rain and grim, grey skies.

Really dampened my enthusiasm for spending time in the driveway.

In a way I suppose it was a good time to take a break because I was at the point where an irrevocable move (cutting into the firewall) was at hand. I hemmed and hawed, changed my mind multiple times and finally decided this project had come too far not to see if the final step worked.

I backstopped the go-decision by digging up a nice 2 1/2" body plug, so I could cover the hole in case it didn't work out.

Today dawned sunny and warmer...it was now or never.

Unlike spectre, after removing the wipers and garnish plate I didn't find the cavity packed with mulch. I must have cleaned it when I built the car but don't really remember specifically doing so.

Anyway, it wasn't bad and there was nothing visible behind the area I'd be cutting, so we were a go.

Took about five minutes with a bimetallic hole saw in a drill.

Then I spent a few hours fiddling with different rubber boot configs, foam blocks and assembly sequence changes before finally getting it all in place. Probably not final but all there and functional.

Then the first drive.

She was fine.

Remember, at the beginning of this project I said the main point was aesthetics; as long as performance didn't degrade, I was happy.

So, I'll not be making any claims of increased horsepower or better throttle response or anything.

I kinda think she IS better but maybe spectre is better positioned to tell.

We'll see.

I picked up some screen door material and tomorrow will remove the garnish plate again and see about covering the cavity openings with it, try to minimize vegetable matter intrusion. There are a few minor adjustments needed also and I'll take some pics then.

I want to put some miles on the setup before tearing it out for final cleanup and paint(?)...I tend to change things a lot, so the "look" can just chill out for a few days while I see if any other ideas come to mind.

Which is fine because it allows me to start exploring the electric airpump swap.

Really dampened my enthusiasm for spending time in the driveway.

In a way I suppose it was a good time to take a break because I was at the point where an irrevocable move (cutting into the firewall) was at hand. I hemmed and hawed, changed my mind multiple times and finally decided this project had come too far not to see if the final step worked.

I backstopped the go-decision by digging up a nice 2 1/2" body plug, so I could cover the hole in case it didn't work out.

Today dawned sunny and warmer...it was now or never.

Unlike spectre, after removing the wipers and garnish plate I didn't find the cavity packed with mulch. I must have cleaned it when I built the car but don't really remember specifically doing so.

Anyway, it wasn't bad and there was nothing visible behind the area I'd be cutting, so we were a go.

Took about five minutes with a bimetallic hole saw in a drill.

Then I spent a few hours fiddling with different rubber boot configs, foam blocks and assembly sequence changes before finally getting it all in place. Probably not final but all there and functional.

Then the first drive.

She was fine.

Remember, at the beginning of this project I said the main point was aesthetics; as long as performance didn't degrade, I was happy.

So, I'll not be making any claims of increased horsepower or better throttle response or anything.

I kinda think she IS better but maybe spectre is better positioned to tell.

We'll see.

I picked up some screen door material and tomorrow will remove the garnish plate again and see about covering the cavity openings with it, try to minimize vegetable matter intrusion. There are a few minor adjustments needed also and I'll take some pics then.

I want to put some miles on the setup before tearing it out for final cleanup and paint(?)...I tend to change things a lot, so the "look" can just chill out for a few days while I see if any other ideas come to mind.

Which is fine because it allows me to start exploring the electric airpump swap.

#1865

Rotary Enthusiast

iTrader: (1)

Join Date: Nov 2012

Location: bloomington, mn

Posts: 1,100

Likes: 0

Received 0 Likes

on

0 Posts

take a look at the mark 4 jetta (probably the same for golf) 2.0 8v engine. The electric air pump on mine appears smaller then that Volvo unit with what appears to be the same connector.

#1866

Hi arch, your garage is looking good.

The airpump project begins today as I survey the area and start imagining the path.

As I said before, I have no clue really how this system works and so have no idea if size matters.

I'd assume that the amount of air moved somewhat correlates to size but have no idea how much air I need.

Volume of air isn't my biggest question though.

What I'm first wondering about is lag.

As I understand it, with the stock mechanical pump air is always available, mostly being dumped out the muffler but always there when needed. This e-pump setup seems to activate the pump only on demand and I wonder if it will suffer from "turbo lag" as the pump spins up.

I may be overthinking this.

Whatever.

The first thing I'll try is moving the alternator to the airpump mount, see how the belt wrap on the waterpump looks. Unless it's convincingly good (which I sorta doubt), that idea will get shitcanned. Can't say I'm interested in extending/rerouting the alt wiring for a new position if I really don't have to.

Depending on that outcome, identifying airpump mount options is next and that's the primary stage where size might matter. I've cleared out the bay to the extent that again, aesthetics will be a major factor because I have space everywhere these days.

Everything is so fluid at the moment because there is still an intake issue that's been nagging me and although I've been resisting, still appeals.

After all this futzing with the intake, the most unwieldy component turns out to be the AFM, which is objectively gigantic, especially compared to a hot wire MAF sensor.

I wonder if anyone has found a compatible swap that the stock ECU can work with.

And if not, is it because it's fundamentally not possible or just that no one with a NA ever bothered to look?

Welfare's recent discovery of the MPV dual belt solution gives me hope that there are still undiscovered options out there for the lowliest rotaries.

That's cooking in the background because it would change everything (I can already see what might result) but it'd be smarter I think to leave it be for now and deal with the airpump by itself.

I have a fully functional intake, so that can be ignored for the nonce.

Once the e-pump is up and running, I can go from there.

But...if anyone has thoughts about the AFM/MAF, I'd like to hear them.

The airpump project begins today as I survey the area and start imagining the path.

As I said before, I have no clue really how this system works and so have no idea if size matters.

I'd assume that the amount of air moved somewhat correlates to size but have no idea how much air I need.

Volume of air isn't my biggest question though.

What I'm first wondering about is lag.

As I understand it, with the stock mechanical pump air is always available, mostly being dumped out the muffler but always there when needed. This e-pump setup seems to activate the pump only on demand and I wonder if it will suffer from "turbo lag" as the pump spins up.

I may be overthinking this.

Whatever.

The first thing I'll try is moving the alternator to the airpump mount, see how the belt wrap on the waterpump looks. Unless it's convincingly good (which I sorta doubt), that idea will get shitcanned. Can't say I'm interested in extending/rerouting the alt wiring for a new position if I really don't have to.

Depending on that outcome, identifying airpump mount options is next and that's the primary stage where size might matter. I've cleared out the bay to the extent that again, aesthetics will be a major factor because I have space everywhere these days.

Everything is so fluid at the moment because there is still an intake issue that's been nagging me and although I've been resisting, still appeals.

After all this futzing with the intake, the most unwieldy component turns out to be the AFM, which is objectively gigantic, especially compared to a hot wire MAF sensor.

I wonder if anyone has found a compatible swap that the stock ECU can work with.

And if not, is it because it's fundamentally not possible or just that no one with a NA ever bothered to look?

Welfare's recent discovery of the MPV dual belt solution gives me hope that there are still undiscovered options out there for the lowliest rotaries.

That's cooking in the background because it would change everything (I can already see what might result) but it'd be smarter I think to leave it be for now and deal with the airpump by itself.

I have a fully functional intake, so that can be ignored for the nonce.

Once the e-pump is up and running, I can go from there.

But...if anyone has thoughts about the AFM/MAF, I'd like to hear them.

#1867

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,832

Received 2,603 Likes

on

1,847 Posts

its been done, you need a little electronic box as the signal needs some translation. HKS used to offer something called the VPC, and it removed the AFM for a map sensor and magic box. also Jackson racing had a hotwire setup for the miata, which is essentially the same as the Rx7.

so its possible, and its been done, but its not plug and play

so its possible, and its been done, but its not plug and play

#1868

I am both dismayed and relieved by this info.

Will look into it anyway.

Spectre6000 has discussed something similar and lives next to an electronics Brainiac, almost anything could (but probably won't) happen.

Weather continues to improve, today's mid-70s approach the "getting too damn hot" stage. That and too much sun glare.

Bitch, bitch, bitch.

Do I long for Jan/Feb?

Ah, no.

Just like to bitch.

Despite the physical hardship, work happened...basically all the stuff I said this morning.

I'd originally thought to put the screen on the bulkhead, not the garnish trim, but that area is all convoluted and weird, the garnish looked easier. No idea how it will hold up but it was worth a try and is easily reversed. This is the perfect time of year to test as the Chinese maple over the driveway sheds billions of these wing-like seed pods and they get everywhere, so in a few days I can crack the airbox and see if any made their way to the filter. Kinda doubt it.

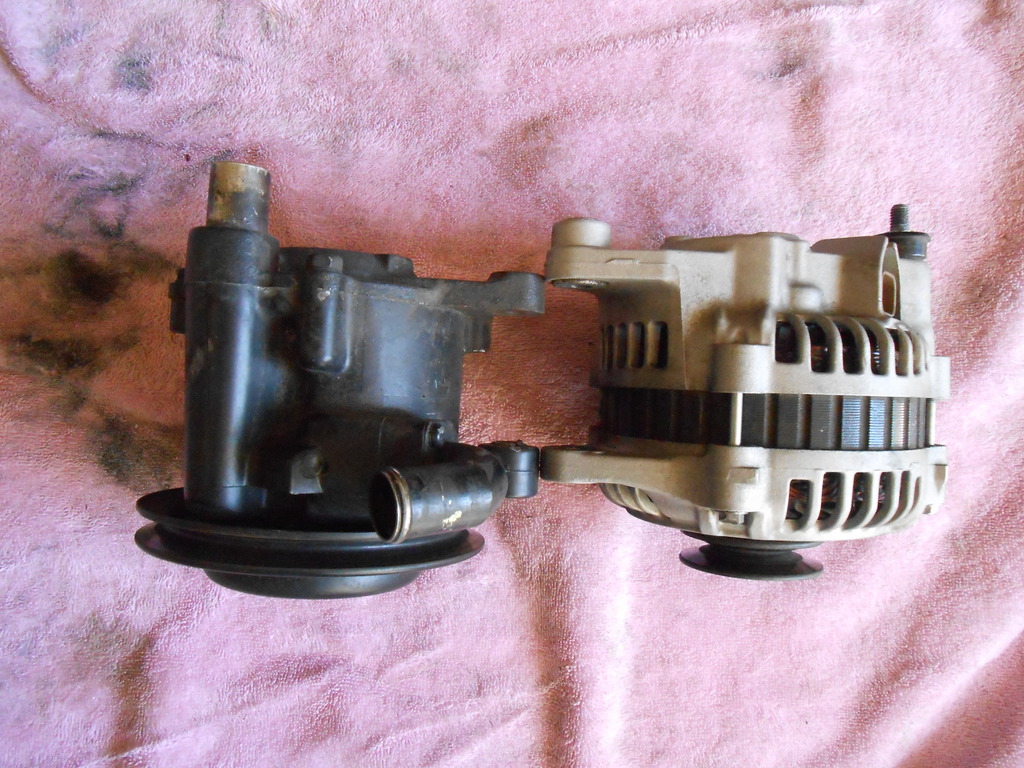

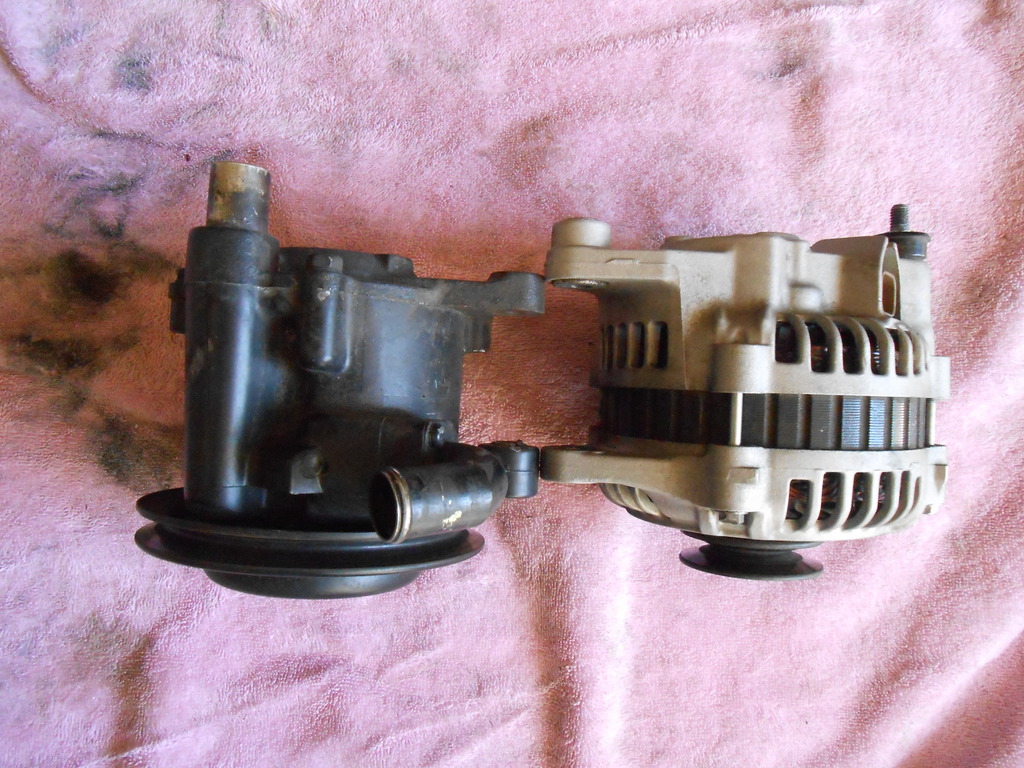

As I waited for the goop to set up, I moved to the initial airpump look-see.

In for a penny, in for a pound, I pulled the alternator too.

Sitting on the floor, there wasn't such a glaring size issue that it was decisively impossible to swap, so I tried fitting the alternator in the airpump mount.

Kinda, but no.

Different alternator with less depth and differently configured mounting ears...maybe, but not this unit.

Back to the top of the motor for you, alternator.

So I will need a second belt solution.

Also, there is no easy/good way to put the e-pump there either, it will have to go somewhere on the chassis.

Hmmm.

That's basically stage one, done.

Info gathered, now parts need to be gathered.

I'll get my favorite Volvo relay/fuse set up to power the pump (where ever it ends up) and start looking for a tensioner like welfare found.

Will look into it anyway.

Spectre6000 has discussed something similar and lives next to an electronics Brainiac, almost anything could (but probably won't) happen.

Weather continues to improve, today's mid-70s approach the "getting too damn hot" stage. That and too much sun glare.

Bitch, bitch, bitch.

Do I long for Jan/Feb?

Ah, no.

Just like to bitch.

Despite the physical hardship, work happened...basically all the stuff I said this morning.

I'd originally thought to put the screen on the bulkhead, not the garnish trim, but that area is all convoluted and weird, the garnish looked easier. No idea how it will hold up but it was worth a try and is easily reversed. This is the perfect time of year to test as the Chinese maple over the driveway sheds billions of these wing-like seed pods and they get everywhere, so in a few days I can crack the airbox and see if any made their way to the filter. Kinda doubt it.

As I waited for the goop to set up, I moved to the initial airpump look-see.

In for a penny, in for a pound, I pulled the alternator too.

Sitting on the floor, there wasn't such a glaring size issue that it was decisively impossible to swap, so I tried fitting the alternator in the airpump mount.

Kinda, but no.

Different alternator with less depth and differently configured mounting ears...maybe, but not this unit.

Back to the top of the motor for you, alternator.

So I will need a second belt solution.

Also, there is no easy/good way to put the e-pump there either, it will have to go somewhere on the chassis.

Hmmm.

That's basically stage one, done.

Info gathered, now parts need to be gathered.

I'll get my favorite Volvo relay/fuse set up to power the pump (where ever it ends up) and start looking for a tensioner like welfare found.

#1869

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,832

Received 2,603 Likes

on

1,847 Posts

oh i just thought of something, since you're an S5 the 6 ports work from the air pump, and so to do the electric one you'd need some kind of vacuum storage tank. of all things the FD has one that has a very low failure rate.

#1872

MECP Certified Installer

I am with you on that thought. I'd be concerned with eventual damage to the winding lamination due to the extreme heat and also damage to the diodes in the bridge rectifier.

#1873

MECP Certified Installer

I also wanted to add, you should have a meager but noticeable power increase at highway speeds due to the cowl effect since you plumbed your new airbox there.

#1874

Be nice if it did though.

I combined a desire to wash the bay and perform a (somewhat sketchy) "torture test" today. First, soap up the bay then hose it down.

Then, with the hood down, start car and flood the windshield with water.

Plan was to see if the airbox would ingest water and when no indication of that appeared, I quit messing around and specifically targeted the the newly meshed intake grill area...and again, nothing.

Removed the rubber boot between the box and the firewall and for all intents and purposes, it was dry. There were a few droplets but they looked more like splashage, not suckage from the box.

Fairly confident that rain won't be an issue.

Snow on the other hand...dunno.

Also examined the front of the engine for options to mount an idler pulley like welfare did (assuming the e-airpump project continues).

His solution is nearly perfect save for aesthetics...since I have no AC/PS, I'd prefer the idler low down on the driver side. That position gives much better wrap on the waterpump pulley and is less visible.

I see some junkyard time in my future.

Now to see if j9 will be more forthcoming about the need for this FD-style cannister.

#1875

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,832

Received 2,603 Likes

on

1,847 Posts

the racing engines sometimes had the alternator mounted there, so its an internet only issue.