Running like limp mode, but no codes

#1

Running like limp mode, but no codes

Last night a pleasant top down drive was interrupted by my engine suddenly running like poop.

The engine did a little hesitation and backfire (which it has been doing very sporadically for a little bit). And then a few minutes later the engine went to ****. Running very rough, barely able to keep it idling, very poor acceleration. I limped it back home. Checked CELs last night and this morning with nothing out of the ordinary. No codes for OMP/MOP.

I've always had codes so these were expected, I've had them since I went JDM swapped turbo in my vert:

30 Solenoid, Split Air Valve

33 Solenoid, Port Air Valve

38 Solenoid, Accelerated Warm-up System (AWS)

Oil pressure is fine, coolant temps were fine, voltage was fine.

AFR on the limp home might have been leaner than normal. At 20mph and maybe 2500rpms in probably 2nd gear I had AFR of 15-16. But the AFR was all over the place as I was giving it gas and letting it off trying to give it as little throttle as possible. So on decel it would start leaning out.

I started the engine this morning and it barely wants to turn over, idling rough and is definitely leaner than it used to be, but ironically probably closer to where it should be, at 12.7 at 1k rpm.

It's a rebuilt JDM 13B N370 Rtek 1.7 (rest of the build is in my signature) which I have been fighting electrical issues (as many of you know). I ditched my Taurus fan and modded S5 alt. Went back to clutch fan and an OEM S5 alt. For the last few days I've been driving it for short distances with no issues beyond my normal issues of idling rich. Wideband would read 10.7ish at idle.

I don't think it's limp mode

I checked resistances on my OMP/MOP and it has tested good. Though the FSM for testing the 6pin harness is a little confusing. This is what I boiled it down to through trial and error and checking with a spare OMP/MOP pump I have.

Upper B+ to SM4

Upper B+ to SM2

Lower B+ to SM3

Lower B+ to SM1

All mine are in spec between 19-23ohms

3 pin harness checked out was a touch out of spec on (Vo-E2) + (Vo-Vc), mine added up was 2.1K ohms. Is 100ohms enough to cause problems?

I should have more time tomorrow to mess with it. I guess I'll start with FSM and see what it suggests I start with. Regardless of what FSM tells me I'm to checking spark, tps, compression (if I can get a helper).

Any suggestions?

The engine did a little hesitation and backfire (which it has been doing very sporadically for a little bit). And then a few minutes later the engine went to ****. Running very rough, barely able to keep it idling, very poor acceleration. I limped it back home. Checked CELs last night and this morning with nothing out of the ordinary. No codes for OMP/MOP.

I've always had codes so these were expected, I've had them since I went JDM swapped turbo in my vert:

30 Solenoid, Split Air Valve

33 Solenoid, Port Air Valve

38 Solenoid, Accelerated Warm-up System (AWS)

Oil pressure is fine, coolant temps were fine, voltage was fine.

AFR on the limp home might have been leaner than normal. At 20mph and maybe 2500rpms in probably 2nd gear I had AFR of 15-16. But the AFR was all over the place as I was giving it gas and letting it off trying to give it as little throttle as possible. So on decel it would start leaning out.

I started the engine this morning and it barely wants to turn over, idling rough and is definitely leaner than it used to be, but ironically probably closer to where it should be, at 12.7 at 1k rpm.

It's a rebuilt JDM 13B N370 Rtek 1.7 (rest of the build is in my signature) which I have been fighting electrical issues (as many of you know). I ditched my Taurus fan and modded S5 alt. Went back to clutch fan and an OEM S5 alt. For the last few days I've been driving it for short distances with no issues beyond my normal issues of idling rich. Wideband would read 10.7ish at idle.

I don't think it's limp mode

I checked resistances on my OMP/MOP and it has tested good. Though the FSM for testing the 6pin harness is a little confusing. This is what I boiled it down to through trial and error and checking with a spare OMP/MOP pump I have.

Upper B+ to SM4

Upper B+ to SM2

Lower B+ to SM3

Lower B+ to SM1

All mine are in spec between 19-23ohms

3 pin harness checked out was a touch out of spec on (Vo-E2) + (Vo-Vc), mine added up was 2.1K ohms. Is 100ohms enough to cause problems?

I should have more time tomorrow to mess with it. I guess I'll start with FSM and see what it suggests I start with. Regardless of what FSM tells me I'm to checking spark, tps, compression (if I can get a helper).

Any suggestions?

#2

Just a few ideas:

Besides the things you mentioned you might want to make sure the primary injectors are connected properly.

Exhaust system is in good condition (not clogged). If it runs better w/the oxygen sensor removed that would be a heads up.

AFM is operating properly. You could jumper the fuel check connector to see if it makes any difference.

Fuel pressure is good and filter is clean.

Possible deflood necessary.

Check plugs.

Unplug TPS.

Vacuum leak.

Besides the things you mentioned you might want to make sure the primary injectors are connected properly.

Exhaust system is in good condition (not clogged). If it runs better w/the oxygen sensor removed that would be a heads up.

AFM is operating properly. You could jumper the fuel check connector to see if it makes any difference.

Fuel pressure is good and filter is clean.

Possible deflood necessary.

Check plugs.

Unplug TPS.

Vacuum leak.

#3

Thanks Satch, A few of those you suggested are on my list, a few I hadn't thought of.

I'm curious what unplugging the TPS will accomplish? If it doesn't run any worse with it unplugged it's a good indication TPS is the issue?

Something related I thought of, how important is it to have the engine warmed up for checking TPS? The engine is running so poorly that I'd rather not make it run if it doesn't want to.

I'm curious what unplugging the TPS will accomplish? If it doesn't run any worse with it unplugged it's a good indication TPS is the issue?

Something related I thought of, how important is it to have the engine warmed up for checking TPS? The engine is running so poorly that I'd rather not make it run if it doesn't want to.

#5

Quick question, what is best to use for capping unused vacuum ports on throttlebody, intakes, rats nest?

I did find one split cap on the upper intake, I use the caps you can buy at any parts store and they don't last. I don't really want to JB Weld the ports in case I ever want to use them. Can I smear RTV in them and inject it in a cap then put the cap on?

The vac cap was not the problem. It did idle a little better but that wasn't the smoking gun. What with the heat I'll probably run errands while it's hot and work on it tonight when the sun isn't so cruel.

I did find one split cap on the upper intake, I use the caps you can buy at any parts store and they don't last. I don't really want to JB Weld the ports in case I ever want to use them. Can I smear RTV in them and inject it in a cap then put the cap on?

The vac cap was not the problem. It did idle a little better but that wasn't the smoking gun. What with the heat I'll probably run errands while it's hot and work on it tonight when the sun isn't so cruel.

#6

Well, didn't take long to find my problem, or at least one of my problems.

MAF appears to have taken a crap on me.

E2 to Vs readings should be:

E2 - Vs closed = 200-1000ohms

E2 - Vs open = 20-800 ohms

Mine reads incorrectly once it opened, in fact my meter drops to 0 ohms, so it shorts out is how I'm reading that.

Already have a replacement paid for, so in a week or so I'll have that in hand.

Between now and then I'm going to start going over my sensors, test as many of them as I can on a non-running engine. While doing that I want to clean up all my connectors and spray some dielectric grease on them.

I've got one concern about one of my solenoids that mounts on the driver side of the engine. One of them is clicking loudly when it's energized but the engine not running, not sure if it does it once the engine turns over. Before anyone says it, it's NOT the BAC. It's clearly coming from one of those solenoids on the driver side of the engine, and it wasn't chattering like it does before. If it turns into anything I'll start a different thread (if I don't find one while researching) so that others can learn from what I'm learning).

MAF appears to have taken a crap on me.

E2 to Vs readings should be:

E2 - Vs closed = 200-1000ohms

E2 - Vs open = 20-800 ohms

Mine reads incorrectly once it opened, in fact my meter drops to 0 ohms, so it shorts out is how I'm reading that.

Already have a replacement paid for, so in a week or so I'll have that in hand.

Between now and then I'm going to start going over my sensors, test as many of them as I can on a non-running engine. While doing that I want to clean up all my connectors and spray some dielectric grease on them.

I've got one concern about one of my solenoids that mounts on the driver side of the engine. One of them is clicking loudly when it's energized but the engine not running, not sure if it does it once the engine turns over. Before anyone says it, it's NOT the BAC. It's clearly coming from one of those solenoids on the driver side of the engine, and it wasn't chattering like it does before. If it turns into anything I'll start a different thread (if I don't find one while researching) so that others can learn from what I'm learning).

#7

Update, MAF was not the problem.

I had a helper who was pushing in the "plunger" on the MAF while I held the leads on the terminals. Turns out the helper was not pushing the plunger all the way in. Once the plunger is all the way in/open my thought to be bad MAF reads correctly.

I haven't touched the car to test anything else, I had to temporarily move it for some construction work.

I had a helper who was pushing in the "plunger" on the MAF while I held the leads on the terminals. Turns out the helper was not pushing the plunger all the way in. Once the plunger is all the way in/open my thought to be bad MAF reads correctly.

I haven't touched the car to test anything else, I had to temporarily move it for some construction work.

Trending Topics

#8

MECP Certified Installer

Update, MAF was not the problem.

I had a helper who was pushing in the "plunger" on the MAF while I held the leads on the terminals. Turns out the helper was not pushing the plunger all the way in. Once the plunger is all the way in/open my thought to be bad MAF reads correctly.

I haven't touched the car to test anything else, I had to temporarily move it for some construction work.

I had a helper who was pushing in the "plunger" on the MAF while I held the leads on the terminals. Turns out the helper was not pushing the plunger all the way in. Once the plunger is all the way in/open my thought to be bad MAF reads correctly.

I haven't touched the car to test anything else, I had to temporarily move it for some construction work.

I would be testing sensors at the ECU.

#9

FYI to make backprobe leads simply take some sewing "tee" needles and solder some wire leads onto them. I like the ones with a "tee" on the end because it makes it easy to insert and remove them. Dull the points so your not cutting the insulation on the wires by accident and BOOM you have backprobe leads.

I'm suspicious of one of the solenoids on the driver side of the engine. One of them chatters real loud. It's much louder than the BAC usually chatters and the noise isn't coming from the BAC, it's clearly coming from one of the other solenoids.

#10

I'm going down the line for the FSM "flowchart" for diagnosing rough idle. With Idle Speed Control next on the list, my BAC tests correctly at the BAC. I didn't check AWS or AVS as my JDM engine does not have them.

Here's where things get curious, Testing pins at the ECU are listed:

Voltage at my battery is 11.75v

Per the service manual flowchart, tomorrow I'll test fuel system.

Here's where things get curious, Testing pins at the ECU are listed:

- 1B - Main Relay -should see 0v OFF and 12v ON

- 3J - AWS - didn't bother looking it up as I don't have it

- 3Q - BAC - 0v OFF, 8v ON, and 8v Idle

Voltage at my battery is 11.75v

- 1B - .598-.614v OFF, 11.33v ON

- 3Q - .614v OFF, 8.98-9.2v ON (BUT the first time I put my meter on that pin it read 10.98v ON). I never idled the engine as I have the TMIC off.

- Should I be concerned that I am seeing voltage at the ECU when IGN is OFF? Possibly a grounding problem at the ECU?

- Should I be concerned that I have a voltage drop between what I see at the battery terminals (11.75v)and what I see at the Main Relay pin (11.33v) on my ECU.

Per the service manual flowchart, tomorrow I'll test fuel system.

#11

You can use the mounting bolts of the ECU for the meter grounding point.

The BAC works for a period of time after the engine has been running and the key to off, as so will some other circuits, so you need to check the ECU after the car has been off for at least 20 minutes or so.

And since the main relay receives voltage on a constant basis it is probably not uncommon for some of that voltage to bleed through.

The BAC works for a period of time after the engine has been running and the key to off, as so will some other circuits, so you need to check the ECU after the car has been off for at least 20 minutes or so.

And since the main relay receives voltage on a constant basis it is probably not uncommon for some of that voltage to bleed through.

#12

You can use the mounting bolts of the ECU for the meter grounding point.

The BAC works for a period of time after the engine has been running and the key to off, as so will some other circuits, so you need to check the ECU after the car has been off for at least 20 minutes or so.

And since the main relay receives voltage on a constant basis it is probably not uncommon for some of that voltage to bleed through.

The BAC works for a period of time after the engine has been running and the key to off, as so will some other circuits, so you need to check the ECU after the car has been off for at least 20 minutes or so.

And since the main relay receives voltage on a constant basis it is probably not uncommon for some of that voltage to bleed through.

I'm a little confused on how the main relay can see voltage constantly but not be a bleed/drain on the system? If there is voltage leaving the battery, isn't that the same as a parasitic draw? Also, should I expect to see that same trace amount of voltage on all the ECU pins that it's simply being fed into the ECU by the Main Relay and that same voltage will be across all the ECU pins?

#13

The EGI fuse always has voltage, as do all the engine box fuses (the main fuse always delivers voltage to the ignition switch for if it didn't you would never have voltage w/key to on) and it is this fuse which powers the relay via the White/Red and White/Blue wires. I suppose you need a new relay.

#14

The EGI fuse always has voltage, as do all the engine box fuses (the main fuse always delivers voltage to the ignition switch for if it didn't you would never have voltage w/key to on) and it is this fuse which powers the relay via the White/Red and White/Blue wires. I suppose you need a new relay.

My hopes had been that I sufficiently repaired the short damage. I've been trying to avoid replacing that harness because the dash has to come out to do it and I have temporarily lost my garage to work on my car. I used to store my parts and work on my car someplace other than where I live. It'll probably next spring before I have a garage to work on my car, but I may have to make do with what I have.

#15

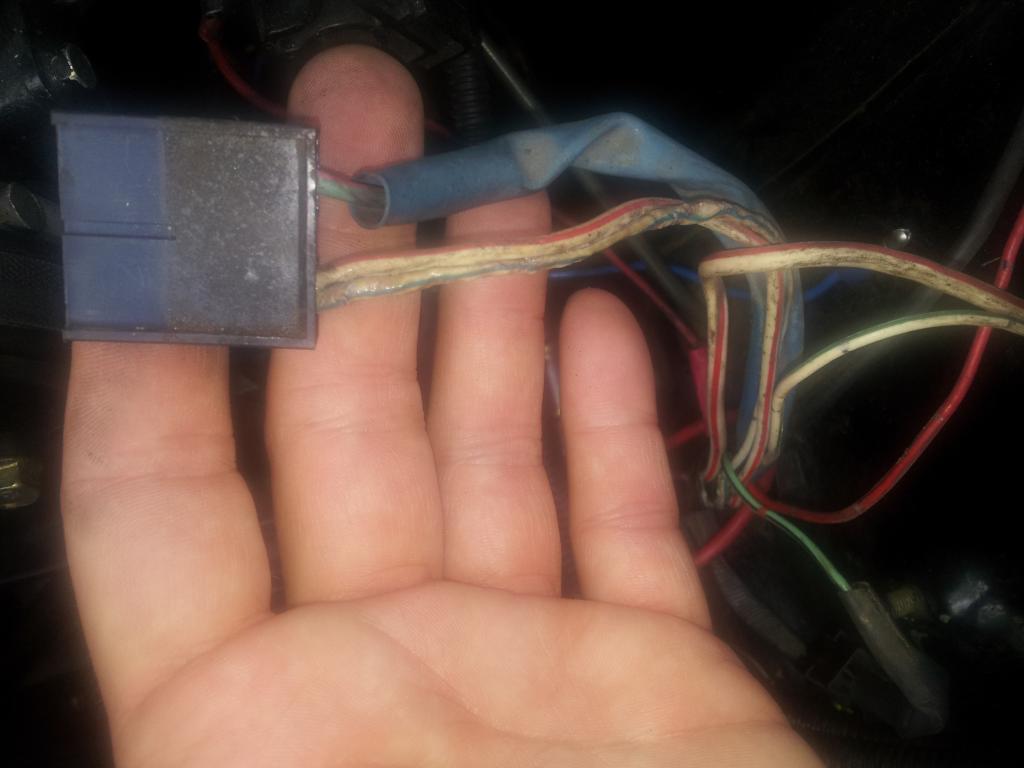

This may be coming back to my driver side main harness. I had a short which melted insulation at the 6pin connector at the battery. That short smoked the 12v switched wire off that connector going to the Main Relay and to the main fuse box in the engine compartment. I replaced the 6pin connector and wiring as far back into the harness as I could get. I'd have to look at the wiring for it to jog my memory, but I had to replace one of the wires you refer to and reinsulate the other. I can't remember right now if I spliced in and replaced W/R or W/BL. But one was replaced the other reinsulated. I also replaced the Main Relay while doing that.

My hopes had been that I sufficiently repaired the short damage. I've been trying to avoid replacing that harness because the dash has to come out to do it and I have temporarily lost my garage to work on my car. I used to store my parts and work on my car someplace other than where I live. It'll probably next spring before I have a garage to work on my car, but I may have to make do with what I have.

My hopes had been that I sufficiently repaired the short damage. I've been trying to avoid replacing that harness because the dash has to come out to do it and I have temporarily lost my garage to work on my car. I used to store my parts and work on my car someplace other than where I live. It'll probably next spring before I have a garage to work on my car, but I may have to make do with what I have.

#18

It idles better after finding the one split vacuum cap but still needs gas applied to keep running. Point being anything that requires the engine to be idling during testing I need a helper. If a helper can't get to me in the next couple days I may pull the UIM and start checking the rats nest for other leaks and pull other sensors to test.

#19

you don't need a helper, make sure the car is in Neutral, ebrake set,( id leave key in off position) run a jumper wire from the starter solenoid ( the small wire on the starter) to near the + of the battery, one hand on the tester other hand connect the jumper wire. bam its cranking and your in the engine bay. if u want to do it right with throttle plate open u could zip tie it at w0t also.

I allways recommend a comp test before most troubleshooting just to rule it out.

also when it was running do u have an aftermarket boost gauge? if so was the gauge reading steady, before and after this problem occurred... if the gauge is very shaky it can be a sign of lost compression also.

I allways recommend a comp test before most troubleshooting just to rule it out.

also when it was running do u have an aftermarket boost gauge? if so was the gauge reading steady, before and after this problem occurred... if the gauge is very shaky it can be a sign of lost compression also.

#20

you don't need a helper, make sure the car is in Neutral, ebrake set,( id leave key in off position) run a jumper wire from the starter solenoid ( the small wire on the starter) to near the + of the battery, one hand on the tester other hand connect the jumper wire. bam its cranking and your in the engine bay. if u want to do it right with throttle plate open u could zip tie it at w0t also.

I allways recommend a comp test before most troubleshooting just to rule it out.

also when it was running do u have an aftermarket boost gauge? if so was the gauge reading steady, before and after this problem occurred... if the gauge is very shaky it can be a sign of lost compression also.

I allways recommend a comp test before most troubleshooting just to rule it out.

also when it was running do u have an aftermarket boost gauge? if so was the gauge reading steady, before and after this problem occurred... if the gauge is very shaky it can be a sign of lost compression also.

I've got an AEM boost gauge and it was reading just fine.

I might have some time tomorrow to do some work on the car, we'll see.

#21

Well it appears that the fuel system is operating correctly. I didn't check pressures at the fuel filter like some of the tests in the FSM showed. What I did do was put my fuel pressure tee after the fuel filter and just before it goes into the rats nest.

FSM for fuel line pressures:

Mine results

Should I be concerned that my hold pressure and pressure regulators were so much higher than specs? I'm assuming that it holding more pressure is more of a good thing? My test results were rock solid because they are higher...or am I missing something?

I also tested resistance on my TPS with a cold engine and those read correctly. I didn't do a voltage test simply because my battery is getting drained from testing. I may take the battery and have it topped off (I don't own an AGM charger).

FSM for fuel line pressures:

- Hold Pressure on pg. F2-46 - 18 psi (after 5 min)

- Fuel Line Pressure on pg F2-46 - 34.1- 39.8 psi

- Pressure Regulator on pg F2-49 and 50 - 21 psi (after 5 min)

Mine results

- Hold Pressure - 35 psi (after 5 min)

- Fuel Line Pressure - 39-40 psi

- Pressure Regulator - 50 psi(after 5 min)

Should I be concerned that my hold pressure and pressure regulators were so much higher than specs? I'm assuming that it holding more pressure is more of a good thing? My test results were rock solid because they are higher...or am I missing something?

I also tested resistance on my TPS with a cold engine and those read correctly. I didn't do a voltage test simply because my battery is getting drained from testing. I may take the battery and have it topped off (I don't own an AGM charger).

#22

Finally got to compression test it and the result couldn't be much worse. ZERO compression on the front rotor!!

All kinds of confused on why/how I could have lost every face of my front rotor while still in break in and driving it like I'm supposed to. When the engine started running like crap I was going maybe 35mph at maybe 3500 rpm. Not an environment where it would have detonated.

When I pulled the leading front plug to do the test it was covered in fuel and grit. My AFR have been idling low, 10.7. Which I haven't been able to figure out why yet. My hope is that leading plug hasn't been firing, or firing weakly and that I've got stuck seals. But i realize that's a long shot...still doesn't cost much to Seafoam it and pray to the rotary gods.

All kinds of confused on why/how I could have lost every face of my front rotor while still in break in and driving it like I'm supposed to. When the engine started running like crap I was going maybe 35mph at maybe 3500 rpm. Not an environment where it would have detonated.

When I pulled the leading front plug to do the test it was covered in fuel and grit. My AFR have been idling low, 10.7. Which I haven't been able to figure out why yet. My hope is that leading plug hasn't been firing, or firing weakly and that I've got stuck seals. But i realize that's a long shot...still doesn't cost much to Seafoam it and pray to the rotary gods.

#23

Finally got to compression test it and the result couldn't be much worse. ZERO compression on the front rotor!!

All kinds of confused on why/how I could have lost every face of my front rotor while still in break in and driving it like I'm supposed to. When the engine started running like crap I was going maybe 35mph at maybe 3500 rpm. Not an environment where it would have detonated.

When I pulled the leading front plug to do the test it was covered in fuel and grit. My AFR have been idling low, 10.7. Which I haven't been able to figure out why yet. My hope is that leading plug hasn't been firing, or firing weakly and that I've got stuck seals. But i realize that's a long shot...still doesn't cost much to Seafoam it and pray to the rotary gods.

All kinds of confused on why/how I could have lost every face of my front rotor while still in break in and driving it like I'm supposed to. When the engine started running like crap I was going maybe 35mph at maybe 3500 rpm. Not an environment where it would have detonated.

When I pulled the leading front plug to do the test it was covered in fuel and grit. My AFR have been idling low, 10.7. Which I haven't been able to figure out why yet. My hope is that leading plug hasn't been firing, or firing weakly and that I've got stuck seals. But i realize that's a long shot...still doesn't cost much to Seafoam it and pray to the rotary gods.

#24

Thanks, it was in the back of my mind also, just didn't think it was possible while driving easy. If I was boosting or driving it stupid then sure.

I haven't given up hope on stuck seals, but I'll be amazed if seafoam makes it all better.

Haven't decided what I'm doing yet. I'll at least tear the engine down, but I may be done with rotaries. Parts are getting harder to come by, nobody in my town to turn to for help/advice....kinda tired of hitting myself in the face repeatedly.

I haven't given up hope on stuck seals, but I'll be amazed if seafoam makes it all better.

Haven't decided what I'm doing yet. I'll at least tear the engine down, but I may be done with rotaries. Parts are getting harder to come by, nobody in my town to turn to for help/advice....kinda tired of hitting myself in the face repeatedly.

#25

were you boosting at all during breakin? you could of cracked a seal and it just desided to let go at that point in time.

you said you had some hesitations and backfires periodicly? maybe an injector was not operating properly at times.

was your timing set spot on?

did you build it your self?

its possible something was out of spec in the build, or bad port job, or something odd

you said you had some hesitations and backfires periodicly? maybe an injector was not operating properly at times.

was your timing set spot on?

did you build it your self?

its possible something was out of spec in the build, or bad port job, or something odd

Thread

Thread Starter

Forum

Replies

Last Post

The Shaolin

2nd Generation Specific (1986-1992)

9

09-14-15 07:50 PM