How to make your own aluminum or carbon driveshaft

#1

How to make your own aluminum or carbon driveshaft

So I just pieced together my own carbon fiber driveshaft from a universal CF driveshaft and rx7 type pinion yokes so I thought I'd share how to do it...

This is more or less exactly what mazdatrix does to make their aluminum driveshafts.

You need 4 things:

1) A driveshaft that is the right length and u-joint type

2) front slip yoke (slips into transmission)

3) rear flange yoke (bolts to diff)

4) u-joints

1. the drive shaft:

This part is pretty simple, you need a aluminum driveshaft with either 7260 u-joints (not very common) or the much more common 1310 u-joints. (more on this latter)

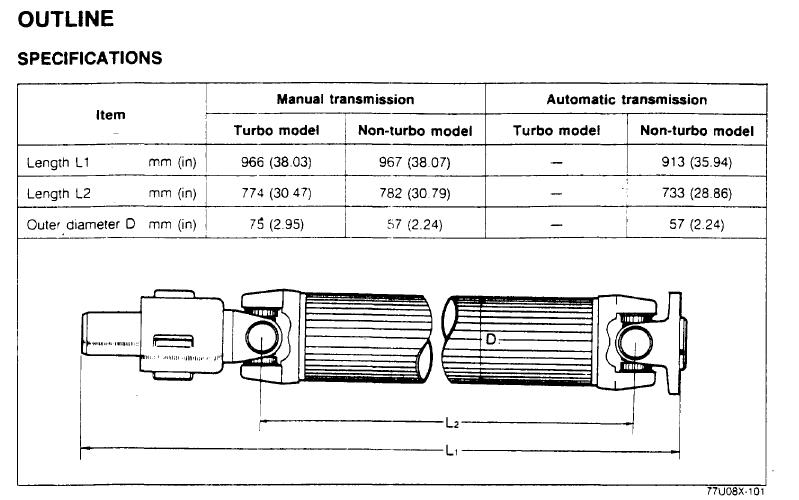

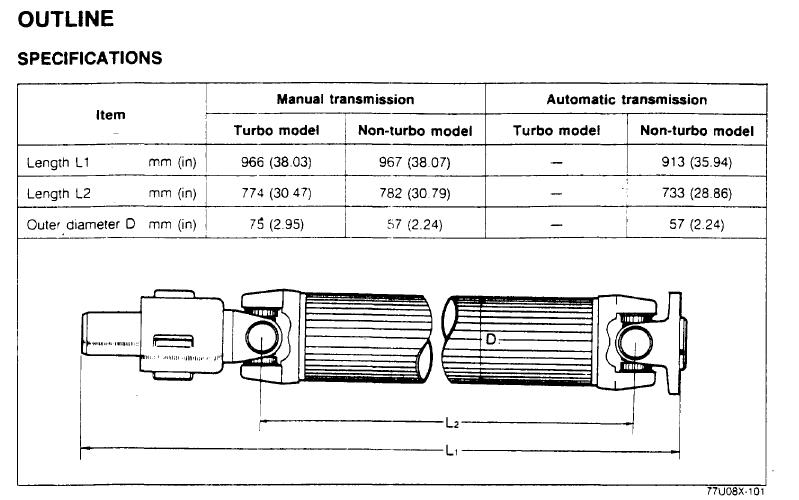

It needs to be the right length. Driveshaft lengths are measured from u-joint center to u-joint center so use the L2 length from this graphic:

for the diameter, 3" is probably going to be fine for most people. that's what the mazdatrix shaft is.

I built mine with a quartermaster carbon driveshaft:

Carbon Fiber 1310 Driveshafts

http://www.quartermasterusa.com/qm/c...riveshafthtml/

but there are tons of other options:

Precision Shaft Technologies

Dennys Driveshafts > 1310 Series 3 inch Aluminum Driveshaft up to 52 inch CL

Carbon Fiber Driveshafts | QA1 Drive Shaft

Custom Aluminum & Composite Driveshaft - Driveshaft Shop | Dynotech Engineering Services

you get the idea...

2) Front slip yoke

PTI is the only company that makes them. They all take a 7260 u-joint. These are the same yokes mazdatrix uses.

www.powertrainindustries.com

Turbo2 trans: 2603-25

NA trans: 2603-22

3) rear flange yoke

PTI is the only company that makes them. They all take a 7260 u-joint. These are the same yokes mazdatrix uses.

www.powertrainindustries.com

turbo2 rear: 2602-41

NA rear: 2602-37

4) U joints.

This is where it gets tricky.

If you have a 7260 driveshaft, just buy a 7260 u-joint (easy, but un-likely)

If you have a 1310 driveshaft you need to get a conversion joint.

usually everyone in the world would recommend a Spicer joint... but

IMPORTANT: The spicer 5-788x 1310->7260 joint doesn't fit in PTI 7260 yokes:

you have 2 options here.

- have PTI custom clearance your yokes (they will do this)

- get any other u-joint

up to you.

I used a Neapco 2-3100:

NEAPCO 2-3100 Dodge 7260 series Mopar to 1310 series combination universal joint.

next up, assembly

This is more or less exactly what mazdatrix does to make their aluminum driveshafts.

You need 4 things:

1) A driveshaft that is the right length and u-joint type

2) front slip yoke (slips into transmission)

3) rear flange yoke (bolts to diff)

4) u-joints

1. the drive shaft:

This part is pretty simple, you need a aluminum driveshaft with either 7260 u-joints (not very common) or the much more common 1310 u-joints. (more on this latter)

It needs to be the right length. Driveshaft lengths are measured from u-joint center to u-joint center so use the L2 length from this graphic:

for the diameter, 3" is probably going to be fine for most people. that's what the mazdatrix shaft is.

I built mine with a quartermaster carbon driveshaft:

Carbon Fiber 1310 Driveshafts

http://www.quartermasterusa.com/qm/c...riveshafthtml/

but there are tons of other options:

Precision Shaft Technologies

Dennys Driveshafts > 1310 Series 3 inch Aluminum Driveshaft up to 52 inch CL

Carbon Fiber Driveshafts | QA1 Drive Shaft

Custom Aluminum & Composite Driveshaft - Driveshaft Shop | Dynotech Engineering Services

you get the idea...

2) Front slip yoke

PTI is the only company that makes them. They all take a 7260 u-joint. These are the same yokes mazdatrix uses.

www.powertrainindustries.com

Turbo2 trans: 2603-25

NA trans: 2603-22

3) rear flange yoke

PTI is the only company that makes them. They all take a 7260 u-joint. These are the same yokes mazdatrix uses.

www.powertrainindustries.com

turbo2 rear: 2602-41

NA rear: 2602-37

4) U joints.

This is where it gets tricky.

If you have a 7260 driveshaft, just buy a 7260 u-joint (easy, but un-likely)

If you have a 1310 driveshaft you need to get a conversion joint.

usually everyone in the world would recommend a Spicer joint... but

IMPORTANT: The spicer 5-788x 1310->7260 joint doesn't fit in PTI 7260 yokes:

you have 2 options here.

- have PTI custom clearance your yokes (they will do this)

- get any other u-joint

up to you.

I used a Neapco 2-3100:

NEAPCO 2-3100 Dodge 7260 series Mopar to 1310 series combination universal joint.

next up, assembly

#2

Assembly:

There are tons of youtube videos on how to assemble u-joints so I'm not going to go over this in a lot of detail.... but here are the basics.

First you'll want to press out the u-joints that came with your driveshaft (probably 1310s)

take the side clips out:

and use a press (ideal), a vise, or a socket and hammer (least ideal) to push the u-joints over to one side and take the cap off:

then you press it over to the other side to take the other cap out and then you can remove the cross of the u-joint.

assembly is the reverse of removal

press the u-joint into the yoke:

the 7260 u-joints have the clips on the inside:

then you do it again with the driveshaft:

1310 clips (driveshaft side) are going to be on the outside:

do it again on the other side and you're done!

complete driveshaft:

This carbon driveshaft is 9.3 lbs

- 4.7 lbs lighter than the stock TII driveshaft

- 1.5 lbs lighter than mazdatrix's aluminum shaft

note: if you're confused by some of my pictures, my rear flange is actually a 1310 rear flange because it's getting bolted to a Ford 8.8

There are tons of youtube videos on how to assemble u-joints so I'm not going to go over this in a lot of detail.... but here are the basics.

First you'll want to press out the u-joints that came with your driveshaft (probably 1310s)

take the side clips out:

and use a press (ideal), a vise, or a socket and hammer (least ideal) to push the u-joints over to one side and take the cap off:

then you press it over to the other side to take the other cap out and then you can remove the cross of the u-joint.

assembly is the reverse of removal

press the u-joint into the yoke:

the 7260 u-joints have the clips on the inside:

then you do it again with the driveshaft:

1310 clips (driveshaft side) are going to be on the outside:

do it again on the other side and you're done!

complete driveshaft:

This carbon driveshaft is 9.3 lbs

- 4.7 lbs lighter than the stock TII driveshaft

- 1.5 lbs lighter than mazdatrix's aluminum shaft

note: if you're confused by some of my pictures, my rear flange is actually a 1310 rear flange because it's getting bolted to a Ford 8.8

#3

Special Ronin Ford swap section:

I actually built this driveshaft to be a bit longer than the stock one to reach my Ronin Ford 8.8 conversion:

FC Ford 8.8 IRS Mounting Kit

Everything is the same except I used a spicer ford small pattern flange yoke (2-2-939) instead of the mazda rear flange yoke to go with the smaller mustang flange required on the 8.8 diff

Dana Spicer 2-2-939 Mustang Driveshaft Flange Yoke fits 7.5 and 8.8 inch Rear Ends 1310 Series with small Ford bolt pattern

and of course the rear u-joint is just a normal 1310 joint.

I actually built this driveshaft to be a bit longer than the stock one to reach my Ronin Ford 8.8 conversion:

FC Ford 8.8 IRS Mounting Kit

Everything is the same except I used a spicer ford small pattern flange yoke (2-2-939) instead of the mazda rear flange yoke to go with the smaller mustang flange required on the 8.8 diff

Dana Spicer 2-2-939 Mustang Driveshaft Flange Yoke fits 7.5 and 8.8 inch Rear Ends 1310 Series with small Ford bolt pattern

and of course the rear u-joint is just a normal 1310 joint.

#5

Red Pill Dealer

iTrader: (10)

Originally Posted by eage8

then you press it over to the other side to take the other cap out and then you can remove the cross of the u-joint.

assembly is the reverse of removal

assembly is the reverse of removal

Trending Topics

#8

front yoke: $43

rear flange: $39

driveshaft: $289, and it appears you can request 7260 hybrid joints?

so $371 total compared to mazdatrix's $432

#9

Rotary Enthusiast

iTrader: (1)

not necessarily

front yoke: $43

rear flange: $39

driveshaft: $289, and it appears you can request 7260 hybrid joints?

so $371 total compared to mazdatrix's $432

front yoke: $43

rear flange: $39

driveshaft: $289, and it appears you can request 7260 hybrid joints?

so $371 total compared to mazdatrix's $432

#17

UPDATE:

I had Powertrain industries clearance my transmission yoke for a Spicer lifetime u-joint (no grease fitting)

Spicer lifetime 7260 -> 1310 conversion joint: 5-788X

At the same time I ordered a Spicer lifetime coated u-joint for aluminum driveshafts yokes: 5-3613X

I took 2 of the caps off the coated u-joint to swap them onto the 1310->7260 conversion u-joint so I would have coated caps on both u-joints that go into the driveshaft (the aluminum parts)

I had Powertrain industries clearance my transmission yoke for a Spicer lifetime u-joint (no grease fitting)

Spicer lifetime 7260 -> 1310 conversion joint: 5-788X

At the same time I ordered a Spicer lifetime coated u-joint for aluminum driveshafts yokes: 5-3613X

I took 2 of the caps off the coated u-joint to swap them onto the 1310->7260 conversion u-joint so I would have coated caps on both u-joints that go into the driveshaft (the aluminum parts)

Thread

Thread Starter

Forum

Replies

Last Post