How do i make my 5th/6th ports work on S4 N/A?

#1

Full Member

Thread Starter

Join Date: Mar 2012

Location: Toronto

Posts: 47

Likes: 0

Received 0 Likes

on

0 Posts

i recently deleted my air pump and blocked off my Air Control & Check Valve. i got a RacingBeat Road Race Header http://www.racingbeat.com/RX7-1986-1...ers/16127.html

im trying to figure out how to get my 5th/ 6th ports working since i deleted my exhaust back pressure tube because i have a custom true dual. ive read a couple threads about making them work but i was wondering if there's any other way of doing this without keeping the air pump?

what if i dont even have my 5/6th ports working?

also the headers i got does not come with a O2 sensor bung. is an O2 really needed with the S4 N/A? if it does im thinking of getting a WideBand O2 any commments on that?

thanks any help is appreciated

im trying to figure out how to get my 5th/ 6th ports working since i deleted my exhaust back pressure tube because i have a custom true dual. ive read a couple threads about making them work but i was wondering if there's any other way of doing this without keeping the air pump?

what if i dont even have my 5/6th ports working?

also the headers i got does not come with a O2 sensor bung. is an O2 really needed with the S4 N/A? if it does im thinking of getting a WideBand O2 any commments on that?

thanks any help is appreciated

#2

Full Member

iTrader: (1)

Join Date: Apr 2012

Location: Phoenix

Posts: 93

Likes: 0

Received 0 Likes

on

0 Posts

There really isn't to many practical ways of making them work without the airpump. Some people use compressors but you would have to find a switch that opened them at the correct rpms. Or you could toggle it at 3800! I just kept my airpump and made a device that opens them from the egr hose out of plumbing parts. As far as the o2 sensor, yes it would be wise to have a bung put in or you will lose performance and mpg. And a wideband isn't gonna do you a whole lot of good in a n/a assuming its virtually stock even with exhaust and intake. Removing emissions is great for more room but really doesn't do a whole lot for performance. I would just leave the airpump considering your ports account for about 25hp!

#3

Keep the airpump, removing it saves no meaningful weight.

Not sure what he's talking about with the EGR, but what you want is airpump output to a T, put a valve on one side and adapters down to vacuum hose on the other side. Adjust the valve so that when you hit ~3850RPM they open.

WARNING! Make sure you have rubber hose that can take at least a bit of heat and not Home Depot "braided water hose" [it's plastic and melts - I would know ]

]

Not sure what he's talking about with the EGR, but what you want is airpump output to a T, put a valve on one side and adapters down to vacuum hose on the other side. Adjust the valve so that when you hit ~3850RPM they open.

WARNING! Make sure you have rubber hose that can take at least a bit of heat and not Home Depot "braided water hose" [it's plastic and melts - I would know

]

]

#4

Full Member

Thread Starter

Join Date: Mar 2012

Location: Toronto

Posts: 47

Likes: 0

Received 0 Likes

on

0 Posts

so do i need to put my air control valve back in ? what if i drill a hole in my exhaust and put the tube back in to get back pressure?

so the wideband wouldn't help with performance at all in a N/A?

i really dont want to put my air pump back in but if really really have too

so the wideband wouldn't help with performance at all in a N/A?

i really dont want to put my air pump back in but if really really have too

#5

Full Member

Thread Starter

Join Date: Mar 2012

Location: Toronto

Posts: 47

Likes: 0

Received 0 Likes

on

0 Posts

There really isn't to many practical ways of making them work without the airpump. Some people use compressors but you would have to find a switch that opened them at the correct rpms. Or you could toggle it at 3800! I just kept my airpump and made a device that opens them from the egr hose out of plumbing parts. As far as the o2 sensor, yes it would be wise to have a bung put in or you will lose performance and mpg. And a wideband isn't gonna do you a whole lot of good in a n/a assuming its virtually stock even with exhaust and intake. Removing emissions is great for more room but really doesn't do a whole lot for performance. I would just leave the airpump considering your ports account for about 25hp!

can u explain how u got it working with the EGR?

thanks

#6

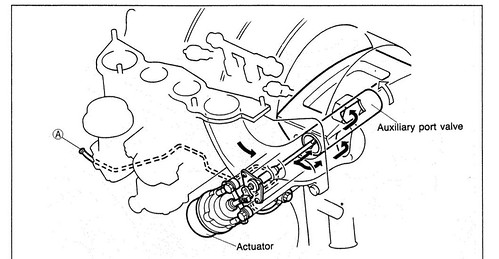

Adialup78 is confusing the ACV with the EGR. The EGR is underneath the manifold on an S4 NA and sees nothing but vacuum on the line to it. The actuators function via positive pressure. The ACV is where the air pump dumps all of its air & it gets directed to the exhaust ports, main cat and out the side to the silencer tube above 3500 RPM.

RPM switch method: https://www.rx7club.com/2nd-generation-specific-1986-1992-17/activating-aux-ports-vdi-rpm-switches-907824/. This can also be done with an electric air pump.

Some headers have a small diameter pick up tube that you can use for backpressure activation of the S4 actuators. The simplest route for you is to get an muffler shop to weld one on & they can add a bung for the 02 sensor too. For the tube, keep it small (~1/8" to 1/4").

The 02 sensor is used purely for mixture under cruise conditions, so it is used to improve mileage.

RPM switch method: https://www.rx7club.com/2nd-generation-specific-1986-1992-17/activating-aux-ports-vdi-rpm-switches-907824/. This can also be done with an electric air pump.

Some headers have a small diameter pick up tube that you can use for backpressure activation of the S4 actuators. The simplest route for you is to get an muffler shop to weld one on & they can add a bung for the 02 sensor too. For the tube, keep it small (~1/8" to 1/4").

The 02 sensor is used purely for mixture under cruise conditions, so it is used to improve mileage.

#7

so do i need to put my air control valve back in ? what if i drill a hole in my exhaust and put the tube back in to get back pressure?

so the wideband wouldn't help with performance at all in a N/A?

i really dont want to put my air pump back in but if really really have too

so the wideband wouldn't help with performance at all in a N/A?

i really dont want to put my air pump back in but if really really have too

You could drill a hole in the exhaust... But I'd recommend against it, getting the right position and size for the hole and tubing would be difficult, I believe the exhaust gasses also help gunk up the actuators.. Also if you do that method you can NOT check the 5th/6th ports functionality without doing the grease test or watching under the hood while it's on a dyno... But the other methods will work if you just free rev the car.

Do either the analog way that I described or RotaryRocket's digital method. Analog is cheaper and a bit less accurate, digital would be easier to use with an electric air pump.

The wideband could help you tune more performance out of your car... But without a standalone engine computer the gains would be harder to achieve and be much more of a compromise. Simply bolting up a wideband wont do anything for the car.. Though it could be interesting to watch while you drive. [I believe you would still need a narrow band for the stock engine computer to read]

Why are you adverse to putting the air pump back on? And related, do you have a Yoohoo belt or double belt alternator pulley? If not you need to put it back on anyway! Your water pump will slip without one of those three.

Trending Topics

#8

Full Member

iTrader: (1)

Join Date: Apr 2012

Location: Phoenix

Posts: 93

Likes: 0

Received 0 Likes

on

0 Posts

Yes acv is what i meant sorry was just posting a comment about it! And definitley dont go with rubber i used metal braded line and it seems to hold well. There is a writeup on it somewhere.

#9

Full Member

Thread Starter

Join Date: Mar 2012

Location: Toronto

Posts: 47

Likes: 0

Received 0 Likes

on

0 Posts

Adialup78 is confusing the ACV with the EGR. The EGR is underneath the manifold on an S4 NA and sees nothing but vacuum on the line to it. The actuators function via positive pressure. The ACV is where the air pump dumps all of its air & it gets directed to the exhaust ports, main cat and out the side to the silencer tube above 3500 RPM.

RPM switch method: https://www.rx7club.com/showthread.php?t=907824. This can also be done with an electric air pump.

Some headers have a small diameter pick up tube that you can use for backpressure activation of the S4 actuators. The simplest route for you is to get an muffler shop to weld one on & they can add a bung for the 02 sensor too. For the tube, keep it small (~1/8" to 1/4").

The 02 sensor is used purely for mixture under cruise conditions, so it is used to improve mileage.

RPM switch method: https://www.rx7club.com/showthread.php?t=907824. This can also be done with an electric air pump.

Some headers have a small diameter pick up tube that you can use for backpressure activation of the S4 actuators. The simplest route for you is to get an muffler shop to weld one on & they can add a bung for the 02 sensor too. For the tube, keep it small (~1/8" to 1/4").

The 02 sensor is used purely for mixture under cruise conditions, so it is used to improve mileage.

ohh now i understand the system. that RPM switch is a good way to do it but that exhaust sounds a lot simpler and easier. but im running no CAT and no presilencer just dual to the stock mufflers. i probably wont have much back pressure , so i dont know if that will work in my situation. i guess my best bet is the rpm switch.

also witch exhaust runner do u recommend i weld the bung on to?

#10

Full Member

Thread Starter

Join Date: Mar 2012

Location: Toronto

Posts: 47

Likes: 0

Received 0 Likes

on

0 Posts

No, you don't need the ACV.

You could drill a hole in the exhaust... But I'd recommend against it, getting the right position and size for the hole and tubing would be difficult, I believe the exhaust gasses also help gunk up the actuators.. Also if you do that method you can NOT check the 5th/6th ports functionality without doing the grease test or watching under the hood while it's on a dyno... But the other methods will work if you just free rev the car.

Do either the analog way that I described or RotaryRocket's digital method. Analog is cheaper and a bit less accurate, digital would be easier to use with an electric air pump.

The wideband could help you tune more performance out of your car... But without a standalone engine computer the gains would be harder to achieve and be much more of a compromise. Simply bolting up a wideband wont do anything for the car.. Though it could be interesting to watch while you drive. [I believe you would still need a narrow band for the stock engine computer to read]

Why are you adverse to putting the air pump back on? And related, do you have a Yoohoo belt or double belt alternator pulley? If not you need to put it back on anyway! Your water pump will slip without one of those three.

You could drill a hole in the exhaust... But I'd recommend against it, getting the right position and size for the hole and tubing would be difficult, I believe the exhaust gasses also help gunk up the actuators.. Also if you do that method you can NOT check the 5th/6th ports functionality without doing the grease test or watching under the hood while it's on a dyno... But the other methods will work if you just free rev the car.

Do either the analog way that I described or RotaryRocket's digital method. Analog is cheaper and a bit less accurate, digital would be easier to use with an electric air pump.

The wideband could help you tune more performance out of your car... But without a standalone engine computer the gains would be harder to achieve and be much more of a compromise. Simply bolting up a wideband wont do anything for the car.. Though it could be interesting to watch while you drive. [I believe you would still need a narrow band for the stock engine computer to read]

Why are you adverse to putting the air pump back on? And related, do you have a Yoohoo belt or double belt alternator pulley? If not you need to put it back on anyway! Your water pump will slip without one of those three.

would the analog way still work if i barley have any back pressure because i have no cats or silencer just stock straight threw mufflers with a true dual? would it be very inaccurate?

yah i guess ill skipp the wideband till i get a different computer

i dont want any powerloss by the air pump and it saves weight and frees up space but yess i been looking into a under drive pulley set with dual belt also electric fan

#11

Full Member

Thread Starter

Join Date: Mar 2012

Location: Toronto

Posts: 47

Likes: 0

Received 0 Likes

on

0 Posts

what do u guys think of it being mechanically actuated by a dual servo motor connected to both ports by linkages that open together. i could hook it up to a RPM switch or have it manually operated threw a 3 way switch of some sort some where on the steering wheel or shifter. so basically i decide when they open and how fast they open ... just an idea .. any thoughts?

#12

A small tube close to the exhaust ports should see enough pressure to move the actuators. But there are no guarantees and they may not actuate at 3800 RPM. I've never liked the S4 method. The S5 setup was much better.

It doesn't matter which runner you place the 02 sensor bung on. You could also have it attached at the collection point and extend the wiring a couple feet. Just be sure is located between 3 and 9 o'clock (not on the bottom).

It doesn't matter which runner you place the 02 sensor bung on. You could also have it attached at the collection point and extend the wiring a couple feet. Just be sure is located between 3 and 9 o'clock (not on the bottom).

#13

adialup78 >> Rubber is fine so long as it's meant for car applications.. My issue was a plastic braided water hose from Home Depot - the end melted off one day... Switched to high temp rubber and it's been fine ever since. ^_^

Back pressure doesn't matter at all with the analog method, it's based off engine and air pump speed.

Yeah.... Don't even try the exhaust method. I am nearly certain that it wont open anywhere near the correct timing. I've heard even fresh from the factory the S4 [exhaust] method wasn't very reliable... Hence Mazda's changeover to ECU control for the S5/RX-8.

The analog method is quite reliable, I've had it on my car for a couple years and aside from that plastic Home Depot water heater hose, it's always worked perfectly [mine's opening within ~150RPM of the ideal, which is to say, about 4000RPM]

Try turning the air pump by hand, there's almost no resistance. It will save exactly ZERO measurable power to remove it. [likewise, the weight savings is so insignificant as to be meaningless on a street car]

[likewise, the weight savings is so insignificant as to be meaningless on a street car]

I've thought about having servos actuate the ports... But I haven't tried it for a few reasons: analog works well enough and reliably, extra cost of an RPM switch and servo[s] and logic to control them, and because I'm afraid that the heat that destroyed the plastic hose would harm either the servo's casing/wiring/motor. Actuating it via a switch inside the car is far from ideal.. For the same work it would be MUCH better to use the RPM switch.

would the analog way still work if i barley have any back pressure because i have no cats or silencer just stock straight threw mufflers with a true dual? would it be very inaccurate?

yah i guess ill skipp the wideband till i get a different computer

i dont want any powerloss by the air pump and it saves weight and frees up space but yess i been looking into a under drive pulley set with dual belt also electric fan

yah i guess ill skipp the wideband till i get a different computer

i dont want any powerloss by the air pump and it saves weight and frees up space but yess i been looking into a under drive pulley set with dual belt also electric fan

Yeah.... Don't even try the exhaust method. I am nearly certain that it wont open anywhere near the correct timing. I've heard even fresh from the factory the S4 [exhaust] method wasn't very reliable... Hence Mazda's changeover to ECU control for the S5/RX-8.

The analog method is quite reliable, I've had it on my car for a couple years and aside from that plastic Home Depot water heater hose, it's always worked perfectly [mine's opening within ~150RPM of the ideal, which is to say, about 4000RPM]

Try turning the air pump by hand, there's almost no resistance. It will save exactly ZERO measurable power to remove it.

[likewise, the weight savings is so insignificant as to be meaningless on a street car]

[likewise, the weight savings is so insignificant as to be meaningless on a street car]I've thought about having servos actuate the ports... But I haven't tried it for a few reasons: analog works well enough and reliably, extra cost of an RPM switch and servo[s] and logic to control them, and because I'm afraid that the heat that destroyed the plastic hose would harm either the servo's casing/wiring/motor. Actuating it via a switch inside the car is far from ideal.. For the same work it would be MUCH better to use the RPM switch.

#14

Full Member

Thread Starter

Join Date: Mar 2012

Location: Toronto

Posts: 47

Likes: 0

Received 0 Likes

on

0 Posts

Try turning the air pump by hand, there's almost no resistance. It will save exactly ZERO measurable power to remove it.  [likewise, the weight savings is so insignificant as to be meaningless on a street car]

[likewise, the weight savings is so insignificant as to be meaningless on a street car]

I've thought about having servos actuate the ports... But I haven't tried it for a few reasons: analog works well enough and reliably, extra cost of an RPM switch and servo[s] and logic to control them, and because I'm afraid that the heat that destroyed the plastic hose would harm either the servo's casing/wiring/motor. Actuating it via a switch inside the car is far from ideal.. For the same work it would be MUCH better to use the RPM switch.

[likewise, the weight savings is so insignificant as to be meaningless on a street car]

[likewise, the weight savings is so insignificant as to be meaningless on a street car]I've thought about having servos actuate the ports... But I haven't tried it for a few reasons: analog works well enough and reliably, extra cost of an RPM switch and servo[s] and logic to control them, and because I'm afraid that the heat that destroyed the plastic hose would harm either the servo's casing/wiring/motor. Actuating it via a switch inside the car is far from ideal.. For the same work it would be MUCH better to use the RPM switch.

yah i see what ur saying bout the heat. im gonna ceramic coat and header wrap my headers to keep engine bay temperatures down. also i deleted my passenger side head light and put a velocity stack air duct going right into my cone air filter. so there is air flow. if i heat reflective tape on my servos and its components will help. but whats so wrong with it being actuated by a switch? id like to controll when it hits to play around with it

also what do u think about a MSD Digital DIS-2? its a 2 channel is it compatible with my S4 N/A?

thank for ur help thou

#15

Ahhh.. Still, for a fraction of a second you save $45+ [$45 for the RPM switch and then whatever the electric airpump cost is if you want that too]

That might make it safe enough to use the servos, but I'm not an expert on them..

The reason that an RPM switch is better than a manual switch is because you can still play with the timing, but you don't have to remember to switch back and forth depending on your engine speed, automagically giving you the best power/torque over the range.

Or if you really don't want to loose that fraction of a second by having the airpump on, you could always do the S5 intake swap so you have VDI to make much more power than the airpump weight costs you.

Not sure about the MSD box... No experience with those yet.

No problem! ^_^

That might make it safe enough to use the servos, but I'm not an expert on them..

The reason that an RPM switch is better than a manual switch is because you can still play with the timing, but you don't have to remember to switch back and forth depending on your engine speed, automagically giving you the best power/torque over the range.

Or if you really don't want to loose that fraction of a second by having the airpump on, you could always do the S5 intake swap so you have VDI to make much more power than the airpump weight costs you.

Not sure about the MSD box... No experience with those yet.

No problem! ^_^

#16

troubleshooting sucks

bit of a shot in the dark here but im hoping someones still subscribed to this thread.

i have deleted the emissions on my s4 n/a and have an rb header. i just cant seem to get my head around how i should activate my auxiliary ports.

can i fit a 1/8 fitting like the one on the left..

into the middle of this block-off plate..

and connect it via a hose to the pipe on my rb header

to activate my auxiliary ports?

i have deleted the emissions on my s4 n/a and have an rb header. i just cant seem to get my head around how i should activate my auxiliary ports.

can i fit a 1/8 fitting like the one on the left..

into the middle of this block-off plate..

and connect it via a hose to the pipe on my rb header

to activate my auxiliary ports?

#17

s4 and s5 use different porting, so anyone asking would have to specify. the s4 has it's own spider to feed pressure to the actuators, all that one pipe needs is pressure.

the s5 has 2 individual ports, one for each actuator so a tee off your pressure line to those is what you need.

there's no need to feed anything back through the lower intake manifold.

i'm not a huge fan of using raw hot exhaust as a pressure source but sometimes you just have to use what is available.

the s5 has 2 individual ports, one for each actuator so a tee off your pressure line to those is what you need.

there's no need to feed anything back through the lower intake manifold.

i'm not a huge fan of using raw hot exhaust as a pressure source but sometimes you just have to use what is available.

Last edited by RotaryEvolution; 03-25-14 at 05:37 PM.

The following users liked this post:

alejo13 (10-19-23)

#18

troubleshooting sucks

s4 and s5 use different porting, so anyone asking would have to specify. the s4 has it's own spider to feed pressure to the actuators, all that one pipe needs is pressure.

the s5 has 2 individual ports, one for each actuator so a tee off your pressure line to those is what you need.

there's no need to feed anything back through the lower intake manifold.

i'm not a huge fan of using raw hot exhaust as a pressure source but sometimes you just have to use what is available.

the s5 has 2 individual ports, one for each actuator so a tee off your pressure line to those is what you need.

there's no need to feed anything back through the lower intake manifold.

i'm not a huge fan of using raw hot exhaust as a pressure source but sometimes you just have to use what is available.

i would prefer to just do it the analogue way out of pure laziness but if it doesnt work i will have to use the electric pump method instead.

thanks for the tips!

#20

troubleshooting sucks

ok i attached the split air pipe on the rb header directly to the solenoids using a hose and a t-fitting. like so..

25a7d94c-3989-488f-a4d7-9d8216c67573.jpg?t=1396141672

all this time i have been under the impression that the pressure from the exhaust pushes the solenoids open. i had read somewhere on here that they dont need much pressure to open and you can get them moving with the pressure from your lungs. i blew into the tube but nothing happened. then my buddy sugessted that i suck on it and they opened. this is what has me confounded. does the backpressure from the exhaust suck them open at 3800 rpms?

or have i done something wrong?

thanks in advance

/Anthony

25a7d94c-3989-488f-a4d7-9d8216c67573.jpg?t=1396141672

all this time i have been under the impression that the pressure from the exhaust pushes the solenoids open. i had read somewhere on here that they dont need much pressure to open and you can get them moving with the pressure from your lungs. i blew into the tube but nothing happened. then my buddy sugessted that i suck on it and they opened. this is what has me confounded. does the backpressure from the exhaust suck them open at 3800 rpms?

or have i done something wrong?

thanks in advance

/Anthony

#22

troubleshooting sucks

does this mean that i have done it wrong? i have removed the emissions on my s4 sorry i forgot to say. airpump,acv and egr are gone. do you know how i can activate them? i wish i could get my hands on the manual that specifically is for the euro six ports.

#23

Without vacuum they're going to be open all the time. Some low end torque will be lost, but it won't affect high rpm performance.

There should be a solenoid on the rat's nest that both actuators connect to. I suppose you can hook the actuators directly to vacuum and they should open at wide open throttle when there's little vacuum, but the solenoid probably does a better job of it.

Go to foxed.ca, there's a Training Manual for the 13B in the FC, section 4 is where I got those two pics from. It'll show you where that solenoid is supposed to be.

There should be a solenoid on the rat's nest that both actuators connect to. I suppose you can hook the actuators directly to vacuum and they should open at wide open throttle when there's little vacuum, but the solenoid probably does a better job of it.

Go to foxed.ca, there's a Training Manual for the 13B in the FC, section 4 is where I got those two pics from. It'll show you where that solenoid is supposed to be.

#24

sorry i didn't notice your location and once i saw your actuators i noticed they are quite different than the USDM actuators which open with a small amount of positive pressure.

i would do what j tso said and try to reintroduce the solenoid back into the system so that it can manage it better than simply attaching them to a vacuum port and having them open at lower RPM levels.

i would do what j tso said and try to reintroduce the solenoid back into the system so that it can manage it better than simply attaching them to a vacuum port and having them open at lower RPM levels.

#25

troubleshooting sucks

Without vacuum they're going to be open all the time. Some low end torque will be lost, but it won't affect high rpm performance.

There should be a solenoid on the rat's nest that both actuators connect to. I suppose you can hook the actuators directly to vacuum and they should open at wide open throttle when there's little vacuum, but the solenoid probably does a better job of it.

Go to foxed.ca, there's a Training Manual for the 13B in the FC, section 4 is where I got those two pics from. It'll show you where that solenoid is supposed to be.

There should be a solenoid on the rat's nest that both actuators connect to. I suppose you can hook the actuators directly to vacuum and they should open at wide open throttle when there's little vacuum, but the solenoid probably does a better job of it.

Go to foxed.ca, there's a Training Manual for the 13B in the FC, section 4 is where I got those two pics from. It'll show you where that solenoid is supposed to be.

FINALLY some concrete, comprehensive information about my particular model! this has explained so much more than just the 6pi system. thankyou!

sorry i didn't notice your location and once i saw your actuators i noticed they are quite different than the USDM actuators which open with a small amount of positive pressure.

i would do what j tso said and try to reintroduce the solenoid back into the system so that it can manage it better than simply attaching them to a vacuum port and having them open at lower RPM levels.

i would do what j tso said and try to reintroduce the solenoid back into the system so that it can manage it better than simply attaching them to a vacuum port and having them open at lower RPM levels.

all the work i have done on my car has been done using info on the usdm models. most of its the same but the 6pi has had me completely baffled for like a year and a half. the only thing thats a bit of a PITA is that i had already re-installed the UIM. now i have to take it off and undo my little bodge job. serves me right for being an eager beaver.. i appreciated the help all the same man

im wondering if it would be prudent for me to plug up the hole on the rb header now that i wont be using it? now its just releasing hot exhaust gas into my engine bay which im pretty sure i could do without right?