Electric water pump benefits

#26

Daily Used and Abused

Thread Starter

iTrader: (1)

Join Date: Dec 2008

Location: South Florida

Posts: 290

Likes: 0

Received 0 Likes

on

0 Posts

I wouldn't deactivate the stock waterpump, but an electric water pump would be a much wiser idea if you have the alternator to support it.

Pele you really think 12-13 seconds without a waterpump is gonna fry his engine? I don't know if dragsters really do turn off their waterpumps during their run, but I imagine you could leave it running until you pull up to the line, switch it off, make your run and switch it back on at the finish line. idk, I wouldn't try it myself, but I would like to know how it would turn out, so lets get swkiller to be our guinnea pig

either way, I don't think I would do this mod just to gain power, as pele mentioned there are so many other things to do first. like setting a brick on the throttle and jumping out. hahaha.

Pele you really think 12-13 seconds without a waterpump is gonna fry his engine? I don't know if dragsters really do turn off their waterpumps during their run, but I imagine you could leave it running until you pull up to the line, switch it off, make your run and switch it back on at the finish line. idk, I wouldn't try it myself, but I would like to know how it would turn out, so lets get swkiller to be our guinnea pig

either way, I don't think I would do this mod just to gain power, as pele mentioned there are so many other things to do first. like setting a brick on the throttle and jumping out. hahaha.

#27

Daily Used and Abused

Thread Starter

iTrader: (1)

Join Date: Dec 2008

Location: South Florida

Posts: 290

Likes: 0

Received 0 Likes

on

0 Posts

I keep asking myself "why do I bother coming to the 2nd gen section (It used to be a great place with knowledgeable guys and good technical discussions years ago, but now it's idiotic kids with repeated idiotic questions and ghetto fabulous MaD TyGhT DoRiFtO AcTiOn wanna-bes with horrid fitting wheels, tires and SHITTY fitting and SHITTY LOOKING body kits and a complete and total lack of common sense)" and now I remember why........ for a few chuckles!

~Mike............

~Mike............

#28

Junior Member

Join Date: Oct 2008

Location: Oak Harbor, Washington

Posts: 37

Likes: 0

Received 0 Likes

on

0 Posts

So how is that no thermostat thing working out for you?

#29

Love Thy Rotor

Join Date: Nov 2006

Location: Yuba City, Ca

Posts: 93

Likes: 0

Received 0 Likes

on

0 Posts

I have 140K on my water pump! Still going strong.

Isnt hard to get you engine up to opperating temp. with out a thermostat??

If your engine didnt need one, why does virtually every combustion engine have a thermostat? Just a question.Lol Felix Wankel was a smart guy. lol

Isnt hard to get you engine up to opperating temp. with out a thermostat??

If your engine didnt need one, why does virtually every combustion engine have a thermostat? Just a question.Lol Felix Wankel was a smart guy. lol

#30

Daily Used and Abused

Thread Starter

iTrader: (1)

Join Date: Dec 2008

Location: South Florida

Posts: 290

Likes: 0

Received 0 Likes

on

0 Posts

[QUOTE=Alucard454;9794573]So how is that no thermostat thing working out for you?[/QUOTE

with stock ecu its a bit rich on idle but no problem its always cool even on the hottest days here in miami (its always hot here so it works out fine). my dads first gen also has no thermostat but with standalone everythings good.

with stock ecu its a bit rich on idle but no problem its always cool even on the hottest days here in miami (its always hot here so it works out fine). my dads first gen also has no thermostat but with standalone everythings good.

#32

I agree with swkiller that I doubt the car will overheat in 8 seconds, it sounds to me that it's ridiculous to think that it would. Although personally i'd be scared of creating a hot spot near the spark plugs or exhaust so I'd keep it running (as there isn't much gained otherwise when using electric pump on/off).

However, check out this link I'm pasting below of a corvette that gains 13 hp from just adding an electric water pump. I didn't read the whole article but it seems pretty legit. Of course 13 hp on a 450 hp car is probably worth, what 5 hp on a 300hp car? Either way it is A LOT more than fractional as mentioned above.

Those gains are only among the other benefits offered. You also get consistent and better coolant flow, and I'd imagine it's a bit lighter weight? albeit that might be fractional.

http://www.vetteweb.com/tech/vemp_08...mps/index.html

whats up with all the hating on body kits and putting stickers on your car and this that and the other? Some say there is a problem with 2nd gen section becoming ignorant which may be the case sometimes, but man, i see there is a problem with people jumping to this conclusion.

I think there is a difference between drift and drag, and although switching off the wp may not be the best idea at first glance, either way an electric wp conversion is definitely worth considering imo. then again thats just my honest $.02 cents.

However, check out this link I'm pasting below of a corvette that gains 13 hp from just adding an electric water pump. I didn't read the whole article but it seems pretty legit. Of course 13 hp on a 450 hp car is probably worth, what 5 hp on a 300hp car? Either way it is A LOT more than fractional as mentioned above.

Those gains are only among the other benefits offered. You also get consistent and better coolant flow, and I'd imagine it's a bit lighter weight? albeit that might be fractional.

http://www.vetteweb.com/tech/vemp_08...mps/index.html

whats up with all the hating on body kits and putting stickers on your car and this that and the other? Some say there is a problem with 2nd gen section becoming ignorant which may be the case sometimes, but man, i see there is a problem with people jumping to this conclusion.

I think there is a difference between drift and drag, and although switching off the wp may not be the best idea at first glance, either way an electric wp conversion is definitely worth considering imo. then again thats just my honest $.02 cents.

#33

Rotary Enthusiast

iTrader: (1)

Join Date: Mar 2008

Location: VA Beach

Posts: 797

Likes: 0

Received 0 Likes

on

0 Posts

Not exactly sure where you are thinking you are going to get massive hp? This the same argument as with an e-fan over the stock clutch fan.

The stock fan is a direct mechanical coupling. The energy from the engine turning to the fan spinning does not have to be converted.

An electric fan has mechanical energy (engine turning) converted to electrical energy (spinning alternator) back to mechanical energy (spin the e-fan). No conversion of energy is 100% efficient. You will always lose some to heat and friction.

An electric water pump would have the same issues. It's only perks are optimal water flow rates (no cavitating) and the ability to run while the car is off.

What you should design is a water pump that has cvt style clutch/gear to keep it in an optimal range at all times. Think something like a clutch on a moped. Notice how all mopeds stay at about the same engine speed but can vary wheel speeds?

All this seems like an awful lot of work for a minimal gain on all but the most extreme of vehicles.

The stock fan is a direct mechanical coupling. The energy from the engine turning to the fan spinning does not have to be converted.

An electric fan has mechanical energy (engine turning) converted to electrical energy (spinning alternator) back to mechanical energy (spin the e-fan). No conversion of energy is 100% efficient. You will always lose some to heat and friction.

An electric water pump would have the same issues. It's only perks are optimal water flow rates (no cavitating) and the ability to run while the car is off.

What you should design is a water pump that has cvt style clutch/gear to keep it in an optimal range at all times. Think something like a clutch on a moped. Notice how all mopeds stay at about the same engine speed but can vary wheel speeds?

All this seems like an awful lot of work for a minimal gain on all but the most extreme of vehicles.

#34

Right near Malloy

iTrader: (28)

Join Date: Dec 1999

Location: Behind a workbench, repairing FC Electronics.

Posts: 7,841

Received 510 Likes

on

345 Posts

Also there are several threads throughout the forum regarding the water jacket mods to increase coolant flow to this area.

If you're **** enough, you can consider the engine to be overheating in normal conditions with stock cooling system parts.

#35

Stock, there is localized coolant boiling near the spark plugs... Notice how there are SEVERAL posts in here regarding that area.

Also there are several threads throughout the forum regarding the water jacket mods to increase coolant flow to this area.

If you're **** enough, you can consider the engine to be overheating in normal conditions with stock cooling system parts.

Also there are several threads throughout the forum regarding the water jacket mods to increase coolant flow to this area.

If you're **** enough, you can consider the engine to be overheating in normal conditions with stock cooling system parts.

Not exactly sure where you are thinking you are going to get massive hp? This the same argument as with an e-fan over the stock clutch fan.

The stock fan is a direct mechanical coupling. The energy from the engine turning to the fan spinning does not have to be converted.

An electric fan has mechanical energy (engine turning) converted to electrical energy (spinning alternator) back to mechanical energy (spin the e-fan). No conversion of energy is 100% efficient. You will always lose some to heat and friction.

An electric water pump would have the same issues. It's only perks are optimal water flow rates (no cavitating) and the ability to run while the car is off.

All this seems like an awful lot of work for a minimal gain on all but the most extreme of vehicles.

The stock fan is a direct mechanical coupling. The energy from the engine turning to the fan spinning does not have to be converted.

An electric fan has mechanical energy (engine turning) converted to electrical energy (spinning alternator) back to mechanical energy (spin the e-fan). No conversion of energy is 100% efficient. You will always lose some to heat and friction.

An electric water pump would have the same issues. It's only perks are optimal water flow rates (no cavitating) and the ability to run while the car is off.

All this seems like an awful lot of work for a minimal gain on all but the most extreme of vehicles.

Finally some real advice!! Thanks for restoring my faith in the 2nd gen sections, and thanks for saving me the energy from typing exactly what you both wrote.

~Mike..............

#36

Quality pumps have a seal life expectancy of 2000 hours or higher, about the same as the mechanical pumps. The electric motors driving them are typically rated for a higher lifespan, so I should say comparable to that of mechanical pump.

As for belts breaking from wear versus just breaking... belts do just snap. I've gotten a belt that lasted a month. Manufacturing defects can and do happen, its a part of life. I'll give you the 2 belt-thing, but I was doing a direct mechanical vs. electrical comparison, as most vehicles set-ups do not use 2 belts in contact with the water pump.

As for belts breaking from wear versus just breaking... belts do just snap. I've gotten a belt that lasted a month. Manufacturing defects can and do happen, its a part of life. I'll give you the 2 belt-thing, but I was doing a direct mechanical vs. electrical comparison, as most vehicles set-ups do not use 2 belts in contact with the water pump.

and on to the boiling of water in the engine, yes it happens but it is also not a huge issue. the only thing it really helps is to reduce the pitting in the rotor housings around those areas. it also happens around the exhaust ports as well, not just the spark plug bosses in the cooling passages.

#37

I wish I was driving!

and on to the boiling of water in the engine, yes it happens but it is also not a huge issue. the only thing it really helps is to reduce the pitting in the rotor housings around those areas. it also happens around the exhaust ports as well, not just the spark plug bosses in the cooling passages.

As for localized boiling... It may not be an issue on a stock engine, but it ure as hell can lead to a blown engine on anything modified. Personally, I don't give a **** about cooling my exhaust ports; as long as the rotor housing isn't warping, I don't care. But I do care about localized over-heating at the spark plugs, causing rotor housing warping, housing cracking, preignition, and detonation. This is why it is common to cut grooves into the rotor housing in this area; to provide additional surface area for the coolant to be in contact with. A better solution is to increase the mass coolant flow rate, which can only be accomplished with an aftermarket pump... its money far better spent on a cooling system modification than an aluminum rad.

#38

i think we're now getting a bit far beyond what the original post had in mind, now we're talking about 2 rotors pushing 700+ wheel horsepower issues. and you will still need a larger aluminum radiator even with the cooling system modifications unless you think cutting grooves into the rotor housings get rid of the additional 50% more heat that rotaries generate.

#39

Not exactly sure where you are thinking you are going to get massive hp? This the same argument as with an e-fan over the stock clutch fan.

The stock fan is a direct mechanical coupling. The energy from the engine turning to the fan spinning does not have to be converted.

An electric fan has mechanical energy (engine turning) converted to electrical energy (spinning alternator) back to mechanical energy (spin the e-fan). No conversion of energy is 100% efficient. You will always lose some to heat and friction.

An electric water pump would have the same issues. It's only perks are optimal water flow rates (no cavitating) and the ability to run while the car is off.

All this seems like an awful lot of work for a minimal gain on all but the most extreme of vehicles.

The stock fan is a direct mechanical coupling. The energy from the engine turning to the fan spinning does not have to be converted.

An electric fan has mechanical energy (engine turning) converted to electrical energy (spinning alternator) back to mechanical energy (spin the e-fan). No conversion of energy is 100% efficient. You will always lose some to heat and friction.

An electric water pump would have the same issues. It's only perks are optimal water flow rates (no cavitating) and the ability to run while the car is off.

All this seems like an awful lot of work for a minimal gain on all but the most extreme of vehicles.

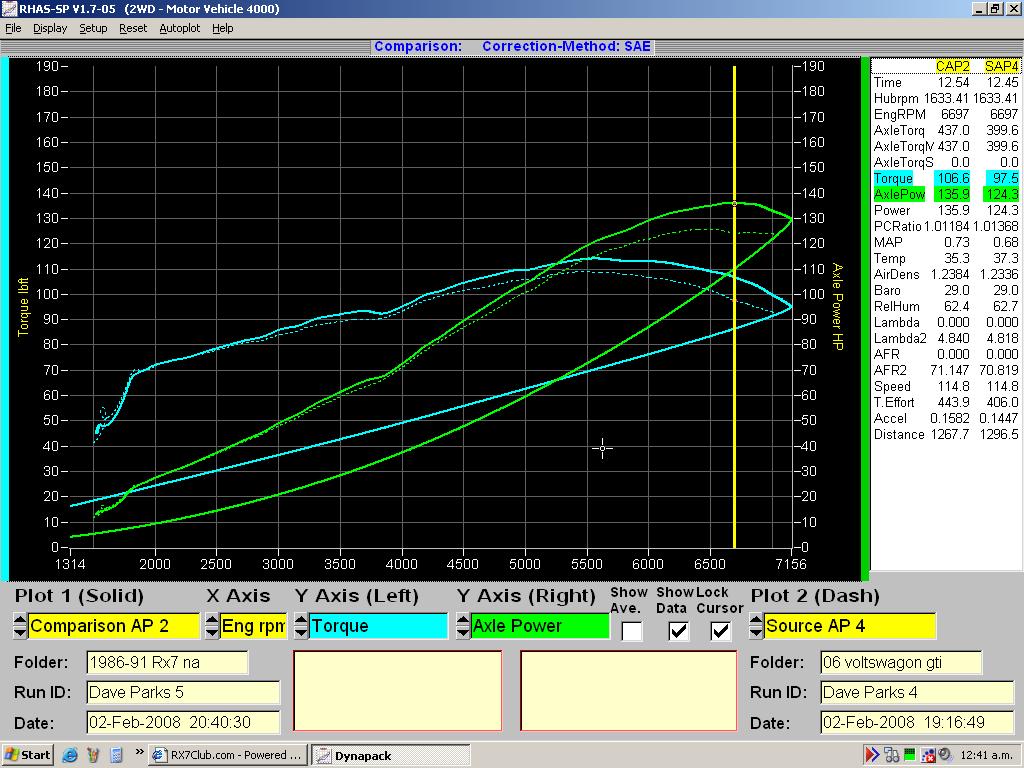

Maybe the electric pump is just more efficient and requires less energy so it draws less? However you put the theories in words, the dyno sheet shows the truth to the matter. There are gains to be had with this mod and I don't see the point in many of the above comments. Honestly I'm quite surprised to find this thread turned out this way, and I feel like I'm losing faith in the 2nd gen section.

And to say that electric waterpumps are not good because so many products are made with shitty quality. I just see that as quite a conclusion to jump to, that could be the case with any new part you change.

#40

I wish I was driving!

i think we're now getting a bit far beyond what the original post had in mind, now we're talking about 2 rotors pushing 700+ wheel horsepower issues. and you will still need a larger aluminum radiator even with the cooling system modifications unless you think cutting grooves into the rotor housings get rid of the additional 50% more heat that rotaries generate.

I think that the cooling system should be upgraded as a whole. Upgrading the rad alone makes about as much sense as upgrading the turbo and keeping the stock intercooler.

In total, you should:

- Prevent pump cavitation

- Increase mass coolant flow

- Increase coolant quantity

- Increase radiator capapcity and efficiency

- Increase heat transfer efficiency

#41

I wish I was driving!

This would be true if and only if your were driving the stock water pump with an electric motor. You can't compare a pump designed for constant-rpm to that of variable for energy consumtion; the variable rpm pump will always fall far short.

#42

Here's a link to a seemingly very high quality WP made for the 13b as a bolt on (well besides the wiring i'm sure). Albeit it's a little expensive, but so are most of the other parts we use to make our cars better. Scroll down a little.

http://estore.websitepros.com/163642...y=Rotary+Parts

http://estore.websitepros.com/163642...y=Rotary+Parts

#43

Rotary Enthusiast

iTrader: (1)

Join Date: Mar 2008

Location: VA Beach

Posts: 797

Likes: 0

Received 0 Likes

on

0 Posts

Are you kidding me? Find me a dyno sheet where someone gained hp from an e-fan? I couldn't find one in my minute of searching. Did you look at the link I posted that kinda disproves your proposed idea that the alternator is going to take from the engine just as much energy as the original mechanical pump?

Maybe the electric pump is just more efficient and requires less energy so it draws less? However you put the theories in words, the dyno sheet shows the truth to the matter. There are gains to be had with this mod and I don't see the point in many of the above comments. Honestly I'm quite surprised to find this thread turned out this way, and I feel like I'm losing faith in the 2nd gen section.

Maybe the electric pump is just more efficient and requires less energy so it draws less? However you put the theories in words, the dyno sheet shows the truth to the matter. There are gains to be had with this mod and I don't see the point in many of the above comments. Honestly I'm quite surprised to find this thread turned out this way, and I feel like I'm losing faith in the 2nd gen section.

Just because an electric pump has 92% efficiency or whatever doesn't mean it will make horsepower versus the stock pump. The stock pump has no conversion of energy from mechanical energy of the engine spinning to the pumps blades spinning in the coolant. Did you forget that fact that every time you change energy from one form to another (IE mechanical to electrical) you lose some energy to heat and friction. You also seem to forget the stock alternator is pretty much crap when it comes to turning mechanical energy to electrical energy.

If you want to make more horsepower with the stock pump find a way to replace it's bearing with some sort of ball bearing. Then put an under-drive pulley on it and call it a day.

#45

I wish I was driving!

I have no idea what you are babbling about. Read and learn please http://www.uwsp.edu/cnr/wcee/keep/Mo...Conversion.htm

Second, don't post on a subject you have no education in, and more importantly, ZERO experience in, becuase really, it just makes you look ignorant.

#46

Rotary Enthusiast

iTrader: (1)

Join Date: Mar 2008

Location: VA Beach

Posts: 797

Likes: 0

Received 0 Likes

on

0 Posts

Also read again. http://www.superchevy.com/technical/...ump/index.html

In the above quoted article they stated that you did gain approximately 4-6hp granted this is on a big torque v8 so there may be some differences. But they also stated that this setup is not suitable for the street due to the greatly reduced flow rates of the electric pump.

I am going to guess that 90% of the readers of the 2nd gen forum drive their cars on the street more than they do the track. And when do you see your average 2nd gen owner spend $400+ for 4-6hp? That's right....never

#47

scathcart I'm actually going to school for Mechanical Engineering myself, although I'm just a sophomore I definitely understand some of the basic concepts like that mentioned by solareon about conversion of energy. I know about these energy losses when converting forms of energy. But...

Really when you look at dyno sheets before and after there is no reason to argue about the theory of it, at least in this case. Even with your arguments about conversion of energy their is proven power gain, so stop trying to use that as a point, obviously there is more to it than that.

Electric waterpumps can be an effective modification that increase power and cooling system efficiency. The $400 dollar pump was just an example and a full race part at that. There are other options and many mustang guys I've seen run them everyday on the street for years with no problems.

That one superchevy article you linked can't possibly represent all electric water pumps can it? Not all pumps are designed the same, and they surely can be designed to flow for street and track applications I'm sure, definitely better than the cavitation and power loss of the stock pump.

Your guess, solareon, that 90% of the readers on the 2nd gen forum blah blah blah, wait you left out the other 10% and some like me, that do NOT use their 7 as a daily driver (gas is so much cheaper in the Tercel) and are NOT the 'average' 2nd gen owner. I drive my car street and track, and may eventually go with an e-pump.

Honestly I was just trying to clear the air of misinformation and misleading advice.

Comparing an electric WP to a body kit and rims...ridiculous. (oh, I know, not you solareon, I know you might say something about my spelling or some other low blow instead of truthfully discussing the technical aspects of the conversation and trying to educate each other).

Oh and thanks for posting the dyno sheet jackchild, makes me want to further investigate this dilemma.

Really when you look at dyno sheets before and after there is no reason to argue about the theory of it, at least in this case. Even with your arguments about conversion of energy their is proven power gain, so stop trying to use that as a point, obviously there is more to it than that.

Electric waterpumps can be an effective modification that increase power and cooling system efficiency. The $400 dollar pump was just an example and a full race part at that. There are other options and many mustang guys I've seen run them everyday on the street for years with no problems.

That one superchevy article you linked can't possibly represent all electric water pumps can it? Not all pumps are designed the same, and they surely can be designed to flow for street and track applications I'm sure, definitely better than the cavitation and power loss of the stock pump.

Your guess, solareon, that 90% of the readers on the 2nd gen forum blah blah blah, wait you left out the other 10% and some like me, that do NOT use their 7 as a daily driver (gas is so much cheaper in the Tercel) and are NOT the 'average' 2nd gen owner. I drive my car street and track, and may eventually go with an e-pump.

Honestly I was just trying to clear the air of misinformation and misleading advice.

Comparing an electric WP to a body kit and rims...ridiculous. (oh, I know, not you solareon, I know you might say something about my spelling or some other low blow instead of truthfully discussing the technical aspects of the conversation and trying to educate each other).

Oh and thanks for posting the dyno sheet jackchild, makes me want to further investigate this dilemma.

#48

I am an efan guy. The gains feel real on the butt-dyno. Additionally, I can tell you that with the efan *off* there is a reduction of rotating mass effect similar to using a lightweight flywheel. This means quick revving. This effect is very noticeable and is probably what most efan users identify as the horsepower gains.

The downside is if the efan is on at idle, the additional alternator load on the engine is significant and noticeable. This slightly bogs the engine when starting up from a stop, especially if the fan kicks on right as you are letting out the clutch. This effect is probably what efan naysayers notice and dislike.

I would like to see a dyno on an efan car with the efan turned off and then with the efan turned on. The gain from mech fan to efan would shrink. Like everyone else, I would like to see it but I wouldn't pay for it.

Since my efan is off most of the time, for me it is a net benefit. Additionally, I get *great* A/C due to maximum airflow across the condenser in traffic.

I don't see any of these efan type advantages to the electric water pump.

#49

Can Post Only in New Member Section

iTrader: (2)

Join Date: Jul 2004

Location: Calgary, Canada

Posts: 930

Likes: 0

Received 0 Likes

on

0 Posts

so i was going through some old pictures from some cars at the drag strip. I noticed one guys has no alternator. not uncommon, he charges his battery every pass and runs of it. he also was using an electric motor belt driving his mechanical water pump. i'm sure something like that would free up some HP. and if you looking for some daily drivability that clutch pulley on the alternator switch would sound good but finding one small enough that would severely underdrive the alternator would be challenging

#50

To those that keep bringing up the "it takes mechanical energy to make electrical energy:

Unless you have to upgrade your alternator, it will have the same resistance or "mechanical energy" required to turn no matter how much current you attempt to draw off of it.

Unless you have to upgrade your alternator, it will have the same resistance or "mechanical energy" required to turn no matter how much current you attempt to draw off of it.