13BT to 13REW Front Cover Swap

#27

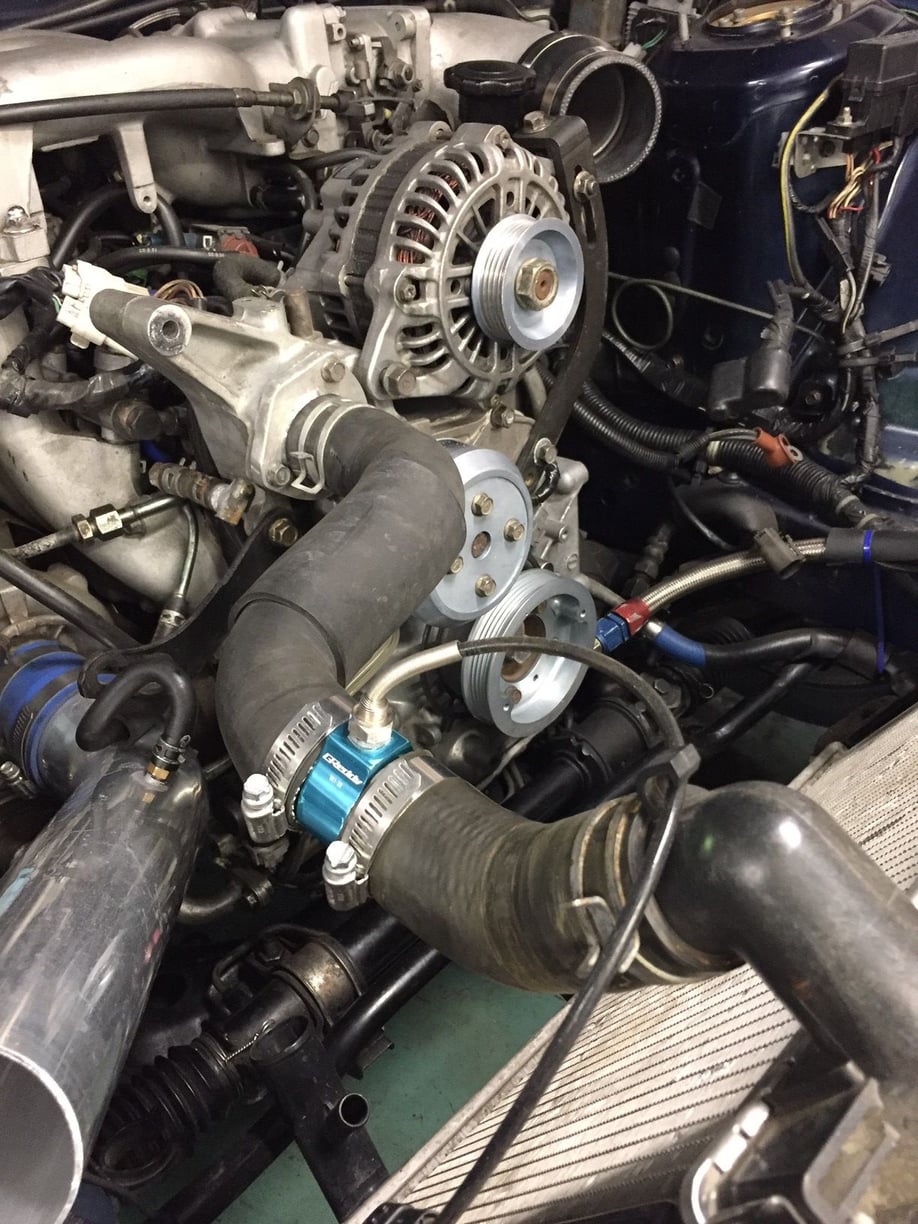

Ok, I have finally reached this part of my RESTOMOD project, since I started this thread a while back I will post my results here, and link it to my Build thread.

Now there are three ways to accomplish getting serpentine belts on the 13BT using FD (13b-REW) parts

Method 1 keeps the 13BT Front Cover and CAS Trigger but uses the 13B-REW accessory bracket and compressor.

Method 2 uses the 13B-REW Front Cover, Trigger, accessory bracker, and compressor (this is the approach I chose)

Method 3 is the same as method 2 but you will need an 13BT oil Pan and a 13B-REW oil pan.

1) Procure an FD Aircon compressor, and accessory bracket, Now this needs to be drilled and a specific washer procured for it to match the accessory bolt locations on the 13BT block. Then a washer to ensure that it is completely true to the block. Now the FD has a trigger wheel on the pulley, you will need space out the pulley the same spacing otherwise your serpentine belt will be off by that margin. Once you have bolted on your accessory bracket, and bolted on the new front pulley spaced out by the spacer that replaced the trigger wheel, you will be good to go, if you do not use the power steering pump you will have to figure out some way to tension the AirCon belt, you can use the OEM one if you choose, but the routing will be wrong (the ribs will be against the pulley instead of the back side). You will also need either an FD alternator pulley, or an FD alternator.

2) This is one involved as it requires welding cutting both steel and aluminum, as well as a machine operation or two depending.

- Remove 13BT Engine Mount (the one that bolts to the bottom of the oil pan) I removed both for ease of working around the engine.

- Remove the 13BT oil pan

- Remove 13BT Water Pump

- Remove 13BT Front Pulley, and pulley hub front eccentric shaft

- Remove the FC Front Cover, place on the FD front cover so you can see the extra bolt hole that needs to be cut off, and then welded and machined (see next post with details)

- Bolt FD (13B-REW) front cover with an FC gasket in place

- I chose to integrate an oil pan brace and oil pan flange into one as no-one would have made a brace for my hybrid engine. I cut the flange of the FC oil pan off so that it would be easy to transpose the bolt hole pattern to create my new flange. I plasma cut my flange by making a wooden template and cutting it out and trimming it. The oil pan needed to be sectioned and worked a little bit to conform to the much shorter 13B-REW front cover. Once that was complete I bolted the flange to the block aligned my modified 13BT oil pan and welded them together. once all cleaned up I will have it powder coated and ready for install.

- Install front cover permanently (you will need to procure some 13B-REW front cover bolts as not all of them are the same length as the 13BT front cover.

- Re-install the Pulley hub, followed by the Trigger wheel, and pulley.

- Install your modified oil Pan using black gasket maker don't forget to let the gasket maker set up for the prescribed amount of time before bolting down your oil pan.

- Re-install your water pump and alternator, and Engine mounts

- Once you have installed your engine or have removed it from the engine stand you can install the accessory bracket and air conditioning compressor

- Fabricate a belt tensioner for the air conditioning belt

- Install alternator belt, then install the air conditioning belt

- You will have to bring your air conditioning lines into a shop to have the ends changed or new hose sections made to match the FD air conditioning compressor (there are 2 types of systems)

- wire into your stand alone EMS the trigger either hall or mag whichever you choose. the air conditioning clutch OEM wiring connectors are the same in the FC as FD so no problem here.

3) is the same as 2 with 1 notable exception, the oil pan. The method I used was a GIANT pain in the ***, it took me three days to cut weld grind drill and weld again. This can be accomplished by sectioning the oil pans across the same two bolt holes the ones in the centre of the front iron. If you section them equally then bolt the 13BT one to the Rear portion of the block, and the FD section to the front cover, tack weld it sufficiently as to avoid warpage, remove and then weld, paint and install. You won't get an engine oil pan brace this way but would only take an afternoon to accomplish if you know what you are doing.

I will follow up with another post detailing with pictures how I accomplished method number 2.

Now there are three ways to accomplish getting serpentine belts on the 13BT using FD (13b-REW) parts

Method 1 keeps the 13BT Front Cover and CAS Trigger but uses the 13B-REW accessory bracket and compressor.

Method 2 uses the 13B-REW Front Cover, Trigger, accessory bracker, and compressor (this is the approach I chose)

Method 3 is the same as method 2 but you will need an 13BT oil Pan and a 13B-REW oil pan.

1) Procure an FD Aircon compressor, and accessory bracket, Now this needs to be drilled and a specific washer procured for it to match the accessory bolt locations on the 13BT block. Then a washer to ensure that it is completely true to the block. Now the FD has a trigger wheel on the pulley, you will need space out the pulley the same spacing otherwise your serpentine belt will be off by that margin. Once you have bolted on your accessory bracket, and bolted on the new front pulley spaced out by the spacer that replaced the trigger wheel, you will be good to go, if you do not use the power steering pump you will have to figure out some way to tension the AirCon belt, you can use the OEM one if you choose, but the routing will be wrong (the ribs will be against the pulley instead of the back side). You will also need either an FD alternator pulley, or an FD alternator.

2) This is one involved as it requires welding cutting both steel and aluminum, as well as a machine operation or two depending.

- Remove 13BT Engine Mount (the one that bolts to the bottom of the oil pan) I removed both for ease of working around the engine.

- Remove the 13BT oil pan

- Remove 13BT Water Pump

- Remove 13BT Front Pulley, and pulley hub front eccentric shaft

- Remove the FC Front Cover, place on the FD front cover so you can see the extra bolt hole that needs to be cut off, and then welded and machined (see next post with details)

- Bolt FD (13B-REW) front cover with an FC gasket in place

- I chose to integrate an oil pan brace and oil pan flange into one as no-one would have made a brace for my hybrid engine. I cut the flange of the FC oil pan off so that it would be easy to transpose the bolt hole pattern to create my new flange. I plasma cut my flange by making a wooden template and cutting it out and trimming it. The oil pan needed to be sectioned and worked a little bit to conform to the much shorter 13B-REW front cover. Once that was complete I bolted the flange to the block aligned my modified 13BT oil pan and welded them together. once all cleaned up I will have it powder coated and ready for install.

- Install front cover permanently (you will need to procure some 13B-REW front cover bolts as not all of them are the same length as the 13BT front cover.

- Re-install the Pulley hub, followed by the Trigger wheel, and pulley.

- Install your modified oil Pan using black gasket maker don't forget to let the gasket maker set up for the prescribed amount of time before bolting down your oil pan.

- Re-install your water pump and alternator, and Engine mounts

- Once you have installed your engine or have removed it from the engine stand you can install the accessory bracket and air conditioning compressor

- Fabricate a belt tensioner for the air conditioning belt

- Install alternator belt, then install the air conditioning belt

- You will have to bring your air conditioning lines into a shop to have the ends changed or new hose sections made to match the FD air conditioning compressor (there are 2 types of systems)

- wire into your stand alone EMS the trigger either hall or mag whichever you choose. the air conditioning clutch OEM wiring connectors are the same in the FC as FD so no problem here.

3) is the same as 2 with 1 notable exception, the oil pan. The method I used was a GIANT pain in the ***, it took me three days to cut weld grind drill and weld again. This can be accomplished by sectioning the oil pans across the same two bolt holes the ones in the centre of the front iron. If you section them equally then bolt the 13BT one to the Rear portion of the block, and the FD section to the front cover, tack weld it sufficiently as to avoid warpage, remove and then weld, paint and install. You won't get an engine oil pan brace this way but would only take an afternoon to accomplish if you know what you are doing.

I will follow up with another post detailing with pictures how I accomplished method number 2.

#28

REW Cover Modification

So here you can see the extra bolt hole that the REW front cover has that the 13BT does not. Now you could try to just run a 13BT gasket and hope it does not leak. However there has bee some people in Japan that do this and report sweating of the gasket at that particular spot. Seeing as how much of a pain in the *** it is to remove the front cover to replace this particular gasket I figured that I would make it right.

You can see that I cut the bolt hole ear off and ground the profile smooth with a sanding disc.

I then followed up with the TIG welder and filled in the area that was left over.

Finally it will be sent to the machine shop to have the surface touched up to ensure a smooth mating surface.

There you Have it the Front Cover is modified to fit the 13BT engine.

So here you can see the extra bolt hole that the REW front cover has that the 13BT does not. Now you could try to just run a 13BT gasket and hope it does not leak. However there has bee some people in Japan that do this and report sweating of the gasket at that particular spot. Seeing as how much of a pain in the *** it is to remove the front cover to replace this particular gasket I figured that I would make it right.

You can see that I cut the bolt hole ear off and ground the profile smooth with a sanding disc.

I then followed up with the TIG welder and filled in the area that was left over.

Finally it will be sent to the machine shop to have the surface touched up to ensure a smooth mating surface.

There you Have it the Front Cover is modified to fit the 13BT engine.

#29

13BT with REW Front cover oil pan Fabrication;

So the first four photos show how the 13BT with an REW front Cover installed do not work so well together

The 5th photo shows you how I traced the flange and REW cover together in order to make a cutout out of 3/16" Mild Steel which would double as the oil pan flange and engine brace to resist twisting of the engine.

The 6th photo shows me laying out the pattern on some plywood, which I then traced an outline inside and outside equal to 1/2 the diameter of my plasma cutting tip so that when finished the flange would be the correct size.

The 7th photo shows the wood template all trimmed out and touched up so as to make a smooth correct flange.

The 8th photo shows the plasma cut flange rough cut and placed on the block with the REW front cover to see how the fitment was.

The 9th somewhat blurry photo shows the 13BT oil pan basin cut from it's flange.

The 10th photo shows how the front of the 13BT oil pan basin was sectioned and bent to match the new 3/16" flange.

The 9th photo shows

So the first four photos show how the 13BT with an REW front Cover installed do not work so well together

The 5th photo shows you how I traced the flange and REW cover together in order to make a cutout out of 3/16" Mild Steel which would double as the oil pan flange and engine brace to resist twisting of the engine.

The 6th photo shows me laying out the pattern on some plywood, which I then traced an outline inside and outside equal to 1/2 the diameter of my plasma cutting tip so that when finished the flange would be the correct size.

The 7th photo shows the wood template all trimmed out and touched up so as to make a smooth correct flange.

The 8th photo shows the plasma cut flange rough cut and placed on the block with the REW front cover to see how the fitment was.

The 9th somewhat blurry photo shows the 13BT oil pan basin cut from it's flange.

The 10th photo shows how the front of the 13BT oil pan basin was sectioned and bent to match the new 3/16" flange.

The 9th photo shows

#30

The 1st photo shows the 13BT oil pan basin mocked up on the new flange bolted to the block so as to resist warping when it was welded.

The 2nd photo shows the 13BT oil pan basin all welded up to the new flange the welds and flange ground to clean it up.

I did not take a photo of my using the old oil pan flange to punch the centre marks for the main part of the block excluding the front cover. The front cover was transferred using a paper template , then drilled on the drill press using a cobalt drill bit.

I tig welded my flange on so as to control the amount of heat I placed into the part to avoid distortion. I also did 1 inch long welds around the pan alternating 1 at a time on opposing sides of the pan so as not to heat up the piece. You can do it with a mig welder but make sure you follow the same 1 inch welds alternating opposite sides of the piece to control heat. Also if using a mig make sure to focus the heat of the mig to the flange and let the heat of the weld work up to the much thinner oil pan basin.

So in the end this was a huge PITA due to several factors having to pattern the piece, then match the drilling of the flange so that the oil pan sits square and to avoid warpage to the flange as I welded it. all though it is the right way to do it, I wished I had taken time and measured the parts and drew them on CAD and had them waterjet, laser cut, or plasma cut flange which would result in a much much cleaner piece that requires much less dress up, and more precise whole locations. But that being said this piece will be powder coated and will serve very well as both an engine brace and an expanded oil pan by expanding the capacity slightly of the oil pan by 1/8" over the entire area of the oil pan basin.

The 2nd photo shows the 13BT oil pan basin all welded up to the new flange the welds and flange ground to clean it up.

I did not take a photo of my using the old oil pan flange to punch the centre marks for the main part of the block excluding the front cover. The front cover was transferred using a paper template , then drilled on the drill press using a cobalt drill bit.

I tig welded my flange on so as to control the amount of heat I placed into the part to avoid distortion. I also did 1 inch long welds around the pan alternating 1 at a time on opposing sides of the pan so as not to heat up the piece. You can do it with a mig welder but make sure you follow the same 1 inch welds alternating opposite sides of the piece to control heat. Also if using a mig make sure to focus the heat of the mig to the flange and let the heat of the weld work up to the much thinner oil pan basin.

So in the end this was a huge PITA due to several factors having to pattern the piece, then match the drilling of the flange so that the oil pan sits square and to avoid warpage to the flange as I welded it. all though it is the right way to do it, I wished I had taken time and measured the parts and drew them on CAD and had them waterjet, laser cut, or plasma cut flange which would result in a much much cleaner piece that requires much less dress up, and more precise whole locations. But that being said this piece will be powder coated and will serve very well as both an engine brace and an expanded oil pan by expanding the capacity slightly of the oil pan by 1/8" over the entire area of the oil pan basin.

Last edited by jreynish; 10-03-17 at 09:51 PM. Reason: TYPO

#31

Now to summarize the options depend on what you want to achieve;

I want to convert my 13BT to serpentine belt and want to keep at least airconditioning, and stock alternator location, as well as powersteering if you so desire. Then Method 1 described above is best for you.

I want to convert my 13BT to use the REW trigger wheel and ditch the CAS as well as convert to the serpentine belt and airconditioning and possibly powersteering but not planning on making more than about 350 WHP then method 3 would be for you.

I want to convert my 13BT to use the REW trigger wheel and ditch the CAS as well as convert the serpentine belt and airconditioning and possibly powersteering and plan on making more than about 350 WHP at some point. Then method 2 would be best for you.

Please note that ALL of the above options require an electric water pump. There might be a way to use the REW water pump but I would not suggest it as it requires many more custom parts and pieces to make that all work out.

I want to convert my 13BT to serpentine belt and want to keep at least airconditioning, and stock alternator location, as well as powersteering if you so desire. Then Method 1 described above is best for you.

I want to convert my 13BT to use the REW trigger wheel and ditch the CAS as well as convert to the serpentine belt and airconditioning and possibly powersteering but not planning on making more than about 350 WHP then method 3 would be for you.

I want to convert my 13BT to use the REW trigger wheel and ditch the CAS as well as convert the serpentine belt and airconditioning and possibly powersteering and plan on making more than about 350 WHP at some point. Then method 2 would be best for you.

Please note that ALL of the above options require an electric water pump. There might be a way to use the REW water pump but I would not suggest it as it requires many more custom parts and pieces to make that all work out.

The following users liked this post:

jreynish (10-02-17)

#33

Important update

Well as it turns out I have discovered something a little unexpected. Due to not having the parts around I did not pre-fit it before I wrote the previous write up. So here is an Update:

Now on the REW front cover there is a pointer that points to Pulley marks for timing just like the FC, however it is in a different position. As such it interferes with both the S4 and S5 water pump housings. Since I am running the FFE FD Mag trigger setup which comes with it's own pointer I have decided to cut the OEM pointer off to eliminate the interference with the water pump housing. I only cut the amount I needed and profiled it to look as close to a casting feature as I could so it would appear stock. (it came that way).

in either event here are a few pictures to show how the front cover was further modified to eliminate the interference.

Cheers,

Now on the REW front cover there is a pointer that points to Pulley marks for timing just like the FC, however it is in a different position. As such it interferes with both the S4 and S5 water pump housings. Since I am running the FFE FD Mag trigger setup which comes with it's own pointer I have decided to cut the OEM pointer off to eliminate the interference with the water pump housing. I only cut the amount I needed and profiled it to look as close to a casting feature as I could so it would appear stock. (it came that way).

in either event here are a few pictures to show how the front cover was further modified to eliminate the interference.

Cheers,

#34

Finally there is one last piece that needs to be considered. I am set on using an S4 Water Pump housing on this project. But there is a bit of a problem in that the OEM 13b-REW Alternator pulley does not align with the REW pulley when placed on an S4/S5 Waterpump. It is best if you use a 13b-REW water pump. But if you can not you will have to have a custom pulley made up to space out the plane of the belt in line with the 13b-REW Pulley.

I used the SAE Standard J1459 and J2432 specifications to design the pulley to accommodate the PK style belt. Here is an image of the solid model;

I used the SAE Standard J1459 and J2432 specifications to design the pulley to accommodate the PK style belt. Here is an image of the solid model;

#35

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,774

Received 2,563 Likes

on

1,823 Posts

Finally there is one last piece that needs to be considered. I am set on using an S4 Water Pump housing on this project. But there is a bit of a problem in that the OEM 13b-REW Alternator pulley does not align with the REW pulley when placed on an S4/S5 Waterpump. It is best if you use a 13b-REW water pump. But if you can not you will have to have a custom pulley made up to space out the plane of the belt in line with the 13b-REW Pulley.

I used the SAE Standard J1459 and J2432 specifications to design the pulley to accommodate the PK style belt. Here is an image of the solid model;

I used the SAE Standard J1459 and J2432 specifications to design the pulley to accommodate the PK style belt. Here is an image of the solid model;

with the FC water pump you can run the 13B Cosmo water pump pulley, the FD main pulley, but it need to go backwards, and the little spacer thing needs to go in there. on an S4 it looks like the FD alternator will still work if you put the spacer on the other side. the JC cosmo belt looks close to working, its a 5PK815.

with the S5 water pump the alternator spacer is built in, so it needs to be cut down, or you'd need a pulley with a different offset or something.

The following users liked this post:

KNONFS (12-22-21)

#36

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,774

Received 2,563 Likes

on

1,823 Posts

#37

https://www.rx7club.com/build-thread.../#post11323291

Defined Autoworks thermostat housing:

https://www.definedautoworks.com/maz...r-pump-FD.html

Shameless plug, got a used defined autoworks thermostat housing like the one above, for sale lol

For those using the OEM FD water pump/pulleys, I found the following radiator hoses that are almost a perfect fit with the FC radiator:

Dayco 71863 (upper) <--- Only if you are using a defined autoworks thermostat housing

Dayco 71526 (lower) - Had to trim about 1/2 from the hose

Dayco 71863 (upper) <--- Only if you are using a defined autoworks thermostat housing

Dayco 71526 (lower) - Had to trim about 1/2 from the hose

https://www.definedautoworks.com/maz...r-pump-FD.html

Shameless plug, got a used defined autoworks thermostat housing like the one above, for sale lol

#38

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,774

Received 2,563 Likes

on

1,823 Posts

The following users liked this post:

KNONFS (12-22-21)

Thread

Thread Starter

Forum

Replies

Last Post

caredden

3rd Generation Specific (1993-2002)

7

03-30-16 11:49 AM