tips on replacing whole clutch

#1

Junior Member

Thread Starter

Join Date: Nov 2014

Location: Washington

Posts: 42

Likes: 0

Received 0 Likes

on

0 Posts

tips on replacing whole clutch

Hey guys, so I have a bit of a dilemma, I recently swapped a S5 13B into my 1983 RX-7, the guy who sold me the engine used it for racing and had installed a super light flywheel and twin disk clutch set up, though he assured me that it was streetable, well yesterday I finally got everything working and tried to drive it for the first time, I could not get it to move, the clutch would grab almost instantly and stall the engine, I also thing i might have damaged my diff, because there was a loud thunk on one of my attempts and the car has been jerky since then. what I need to know is what will I need in order to put a whole new stage 1 clutch set up onto the engine, I have never done this before so any info is appreciated, im looking at this clutch kit Exedy Clutch Kit - Stage 1 for 83-92 12A & 13B Non-Turbo RX-7 - Racing Beat thanks for the help

#2

Rotory United RU.

iTrader: (1)

Join Date: Oct 2008

Location: Bronx, NY

Posts: 284

Likes: 0

Received 0 Likes

on

0 Posts

The Haynes manual will walk you through the installation of your new clutch. Its pretty straight forward almost like any other clutch swap. Only Special tool you really need is a bearing puller for the ring that goes at the end of the transmission shaft. Id recommend a transmission jack if you don't want to bench press the tranny after you have unbolted it.

#5

Junior Member

Thread Starter

Join Date: Nov 2014

Location: Washington

Posts: 42

Likes: 0

Received 0 Likes

on

0 Posts

so is it possible to remove the area where the clutch disk contacts the flyqheel (if that makes sense, im not sure what its called) because the current clutch uses two small disks they are about half in diameter of the original clutch disk so the contact area is much smaller.

#7

84SE-EGI helpy-helperton

You really need to find out what kind of flywheel was installed, as the double-disk clutches may use a different flywheel design whoch would prevent use of a standard 225mm clutch disk, pressure plate, and possibly the counterweight - if lightweight aluminum. The factory flywheels were cast steel, machined to shape and then balanced dynamically to include the needed counterweight function without needing a separate counterweight.

Point being that until you know what kind of flywheel, you won't know how much work will be involved to install a regular clutch disk and pressure plate. Engine removal may be the best course, as ot will allow you to do everything you might need, including flywheel removal and replacement with the necessary tools. Also, if this is your first time doing this, it will make it all a LOT easier. Some guys here could do this from under the car without pulling anything but the tranny, in the dark, and in their sleep, but new guys would quickly get into trouble. Throw in the usual needle pilot bearing removal/replacement, and you have hours of anguish and tool-throwing ahead of you.

Have a look at the flywheel and current pressure plate if you can remove the transmission from the bottom, get some clear pictures and we can help you out. Good luck,

Point being that until you know what kind of flywheel, you won't know how much work will be involved to install a regular clutch disk and pressure plate. Engine removal may be the best course, as ot will allow you to do everything you might need, including flywheel removal and replacement with the necessary tools. Also, if this is your first time doing this, it will make it all a LOT easier. Some guys here could do this from under the car without pulling anything but the tranny, in the dark, and in their sleep, but new guys would quickly get into trouble. Throw in the usual needle pilot bearing removal/replacement, and you have hours of anguish and tool-throwing ahead of you.

Have a look at the flywheel and current pressure plate if you can remove the transmission from the bottom, get some clear pictures and we can help you out. Good luck,

Trending Topics

#8

Junior Member

Thread Starter

Join Date: Nov 2014

Location: Washington

Posts: 42

Likes: 0

Received 0 Likes

on

0 Posts

ok thanks guys, im still in touch with the guy who built the engine so im waiting on his reply that way i know what flywheel and clutch he used, once i find that out ill post the info on here

#10

I've replaced clutches both ways -- by pulling the engine and by dropping the trans. They both have their pros and cons but I usually lean more towards dropping the trans because it seems like there are fewer steps to it. I have an engine hoist, so pulling the engine isn't especially difficult. On the other hand, I put the car on tall jack stands and use my floor jack to drop the trans, which isn't particularly difficult either. (If you center the weight of the trans on the jack saddle, it's easy to tilt it and get the angle right.)

#11

Regarding the flywheel -- most aftermarket flywheels bolt to an automatic transmission (ATX) counterweight. This makes it much easier for the flywheel manufacturer because now they don't have to worry about the various counterweight options for each individual engine version.

You'll probably want to remove the whole twin disc flywheel/disc/pressure plate assembly from the ATX counterweight and replace it with a lightweight flywheel designed for a single plate clutch and the Exedy Stage 1 clutch. Twin disc setups are valuable, so you will be able to recoup a lot of $$ by selling it in the racing section if it's in good shape.

You'll probably want to remove the whole twin disc flywheel/disc/pressure plate assembly from the ATX counterweight and replace it with a lightweight flywheel designed for a single plate clutch and the Exedy Stage 1 clutch. Twin disc setups are valuable, so you will be able to recoup a lot of $$ by selling it in the racing section if it's in good shape.

#12

Junior Member

Thread Starter

Join Date: Nov 2014

Location: Washington

Posts: 42

Likes: 0

Received 0 Likes

on

0 Posts

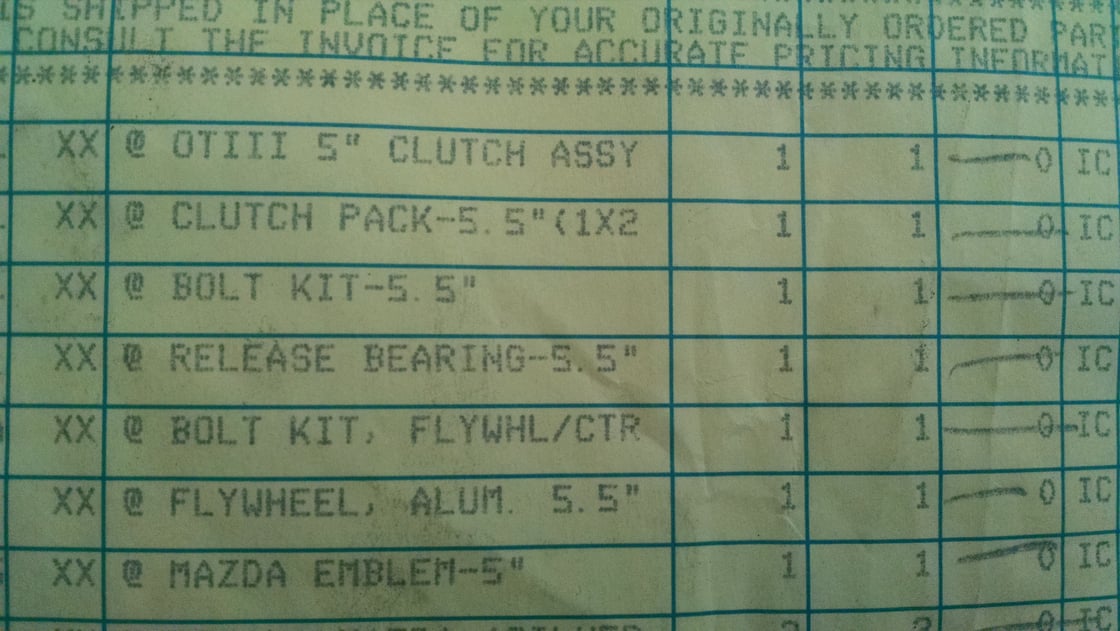

so I found the old invoice of the things that he bought including the clutch set up, the invoice is from Mazda so im guessing these are genuine parts, I do remember him telling me that the flywheel was about 3 pounds, im still waiting for him to email me back so I know exactly what kind of set up he had put on the engine

Thread

Thread Starter

Forum

Replies

Last Post