How to tear down a 12A without a shop

#26

Thanks for posting the "before" photo James, I forgot to take one of those!

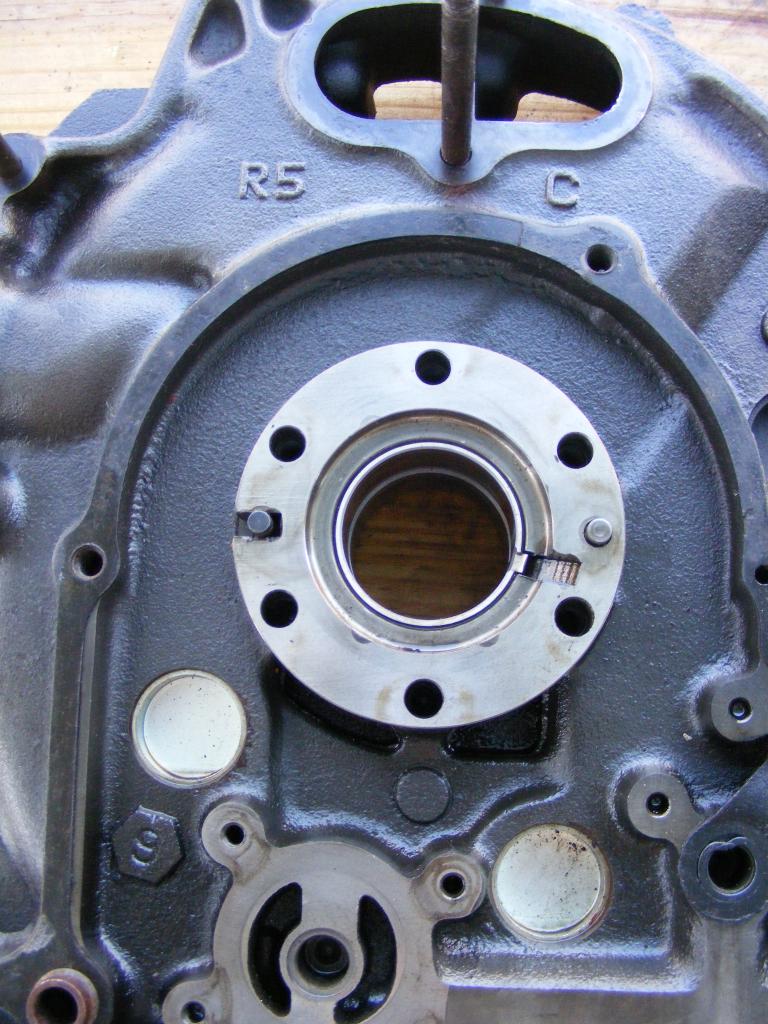

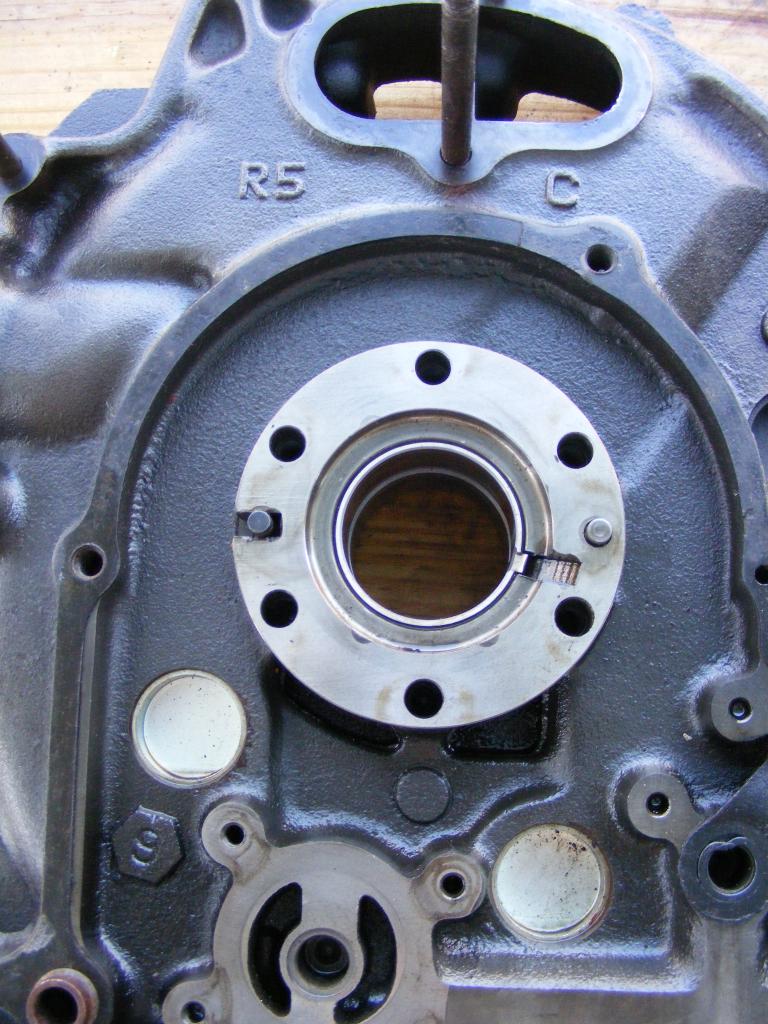

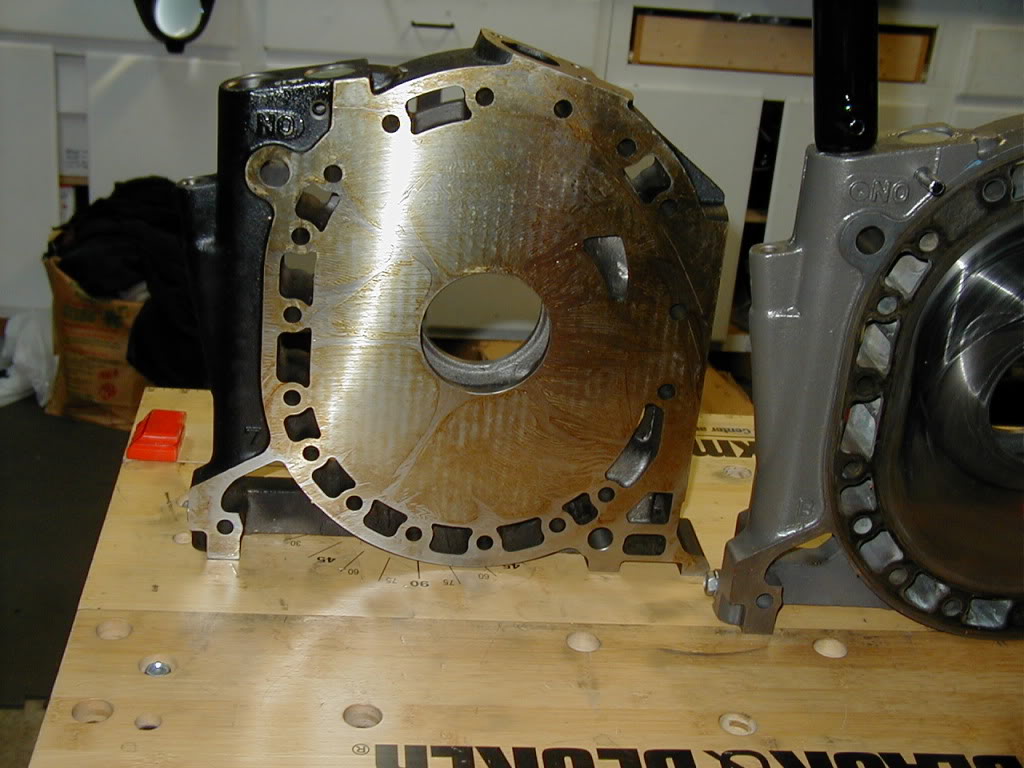

Jeff, the oil pump that came out of the R5 engine looks exactly like the ones I've pulled from the other 4 12As, which were all from FBs. The R5 one is on the left, an FB unit is on the right

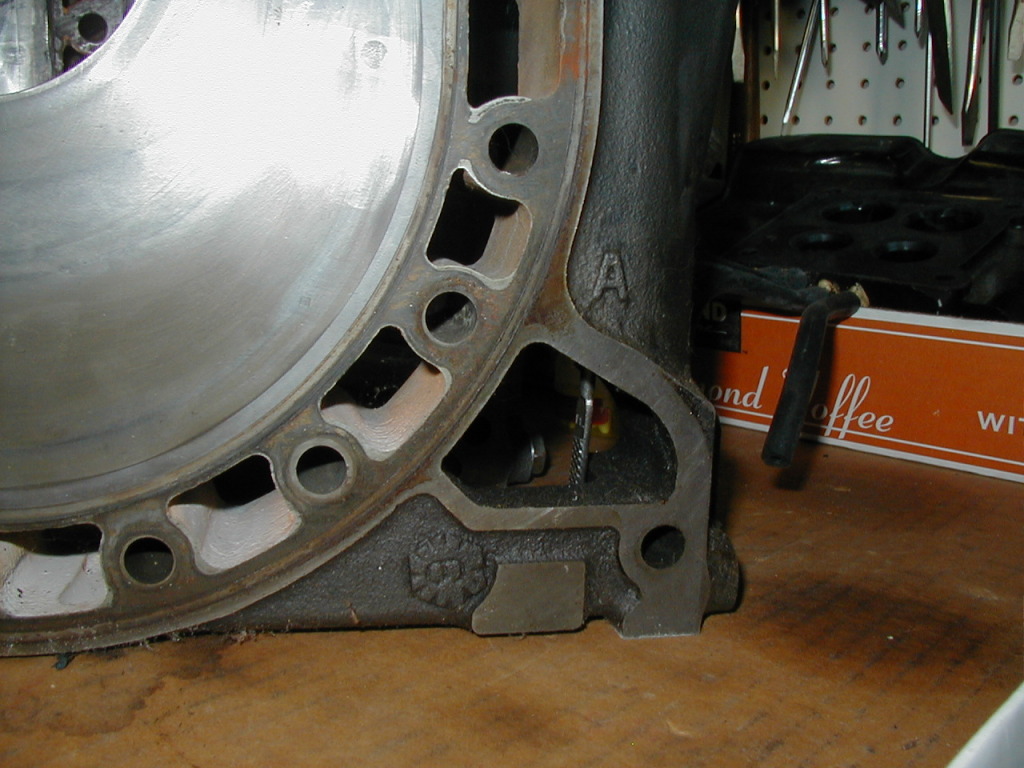

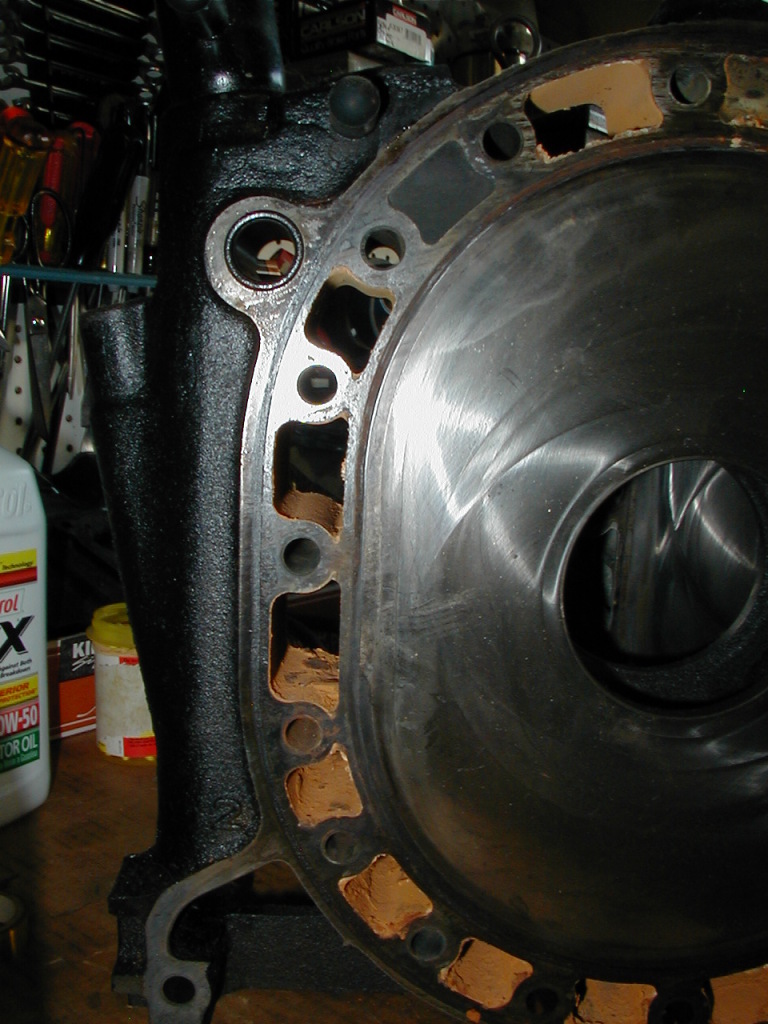

Here's a shot from the back

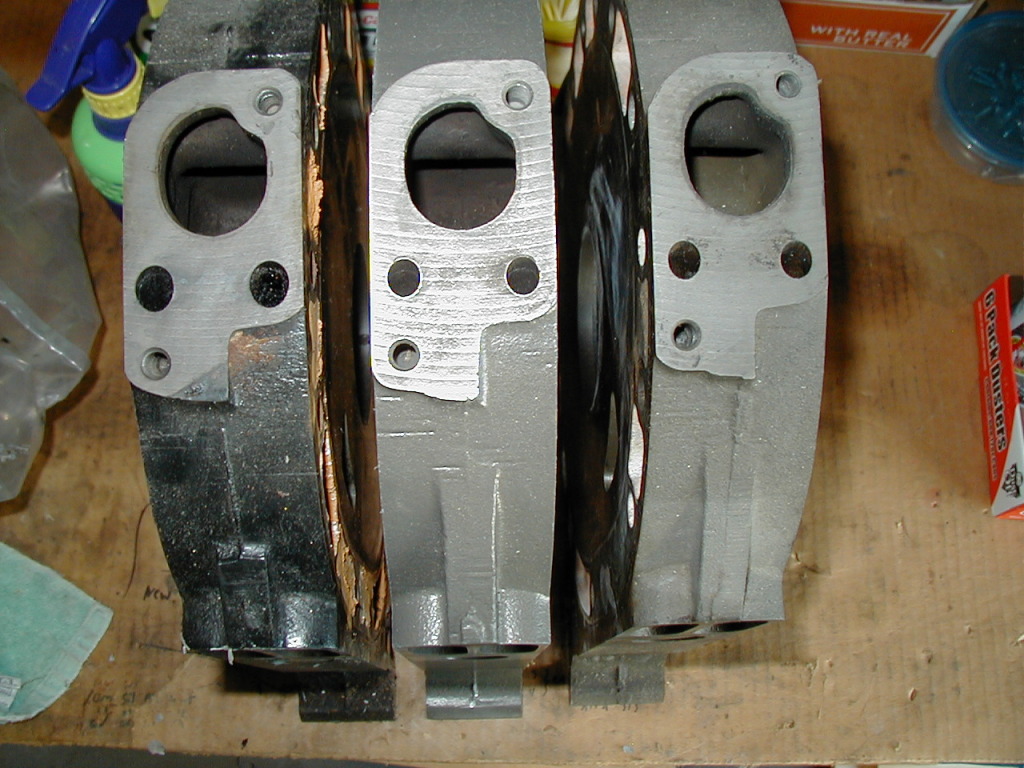

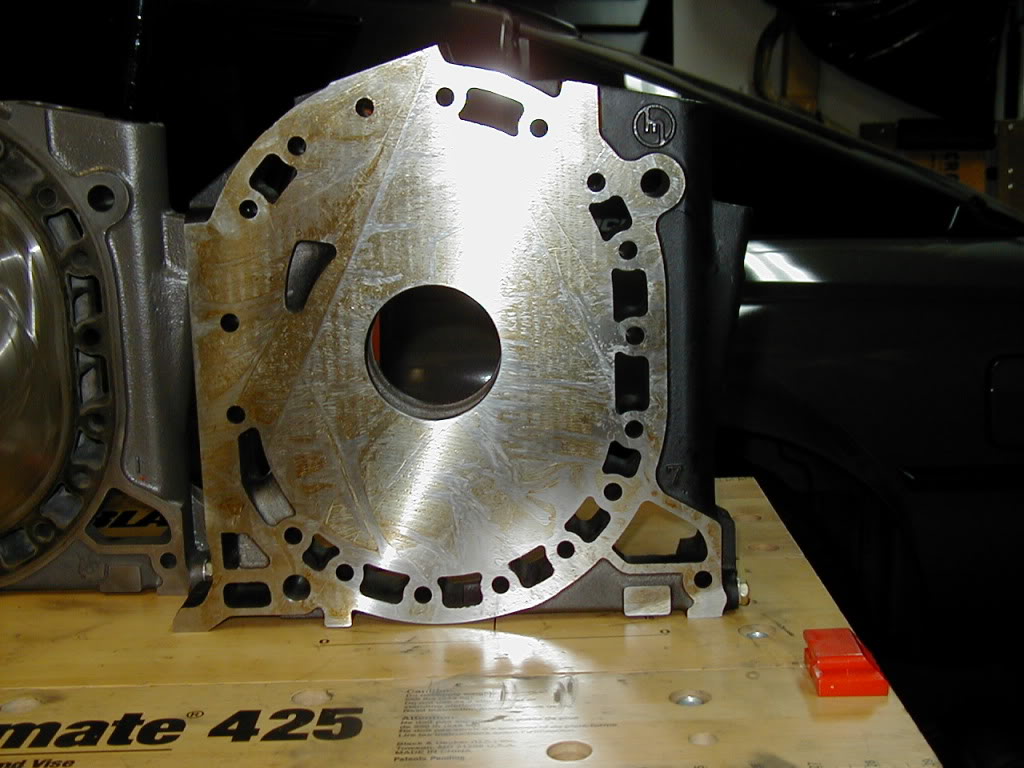

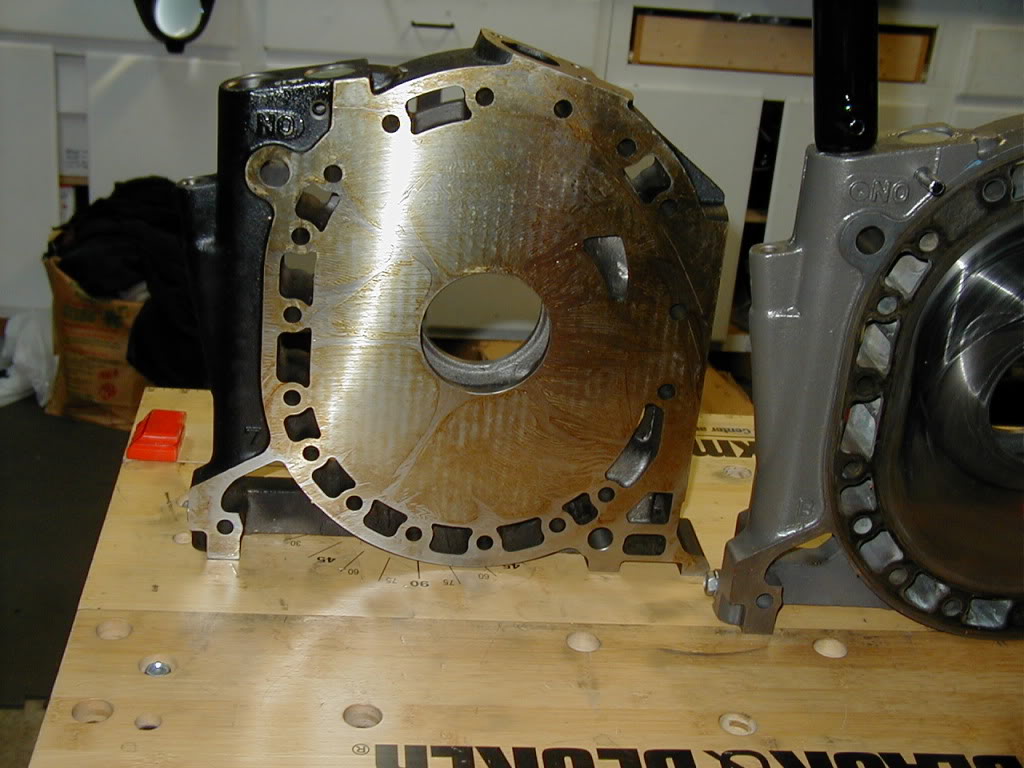

I took some more close up shots of the ports, comparing the R5 midplate (on the right) with one from an 84 FB (on the left)

I also took some better pictures of the flat plate markings

Comparison with the FB midplate

So, hopefully this is enough info to give a proper diagnosis of where this engine came from?

Jeff, I'm currently researching this statement of yours:

"since this engine has an R5 rear plate with an undrilled oil pressure boss, I'm 99% sure you have full flow oil squirters. You know what to do about that"

Oil pressure bosses and oil squirters are new to me, but it sounds like something I should probably know.

Jeff, the oil pump that came out of the R5 engine looks exactly like the ones I've pulled from the other 4 12As, which were all from FBs. The R5 one is on the left, an FB unit is on the right

Here's a shot from the back

I took some more close up shots of the ports, comparing the R5 midplate (on the right) with one from an 84 FB (on the left)

I also took some better pictures of the flat plate markings

Comparison with the FB midplate

So, hopefully this is enough info to give a proper diagnosis of where this engine came from?

Jeff, I'm currently researching this statement of yours:

"since this engine has an R5 rear plate with an undrilled oil pressure boss, I'm 99% sure you have full flow oil squirters. You know what to do about that"

Oil pressure bosses and oil squirters are new to me, but it sounds like something I should probably know.

#27

Oh also Jeff, I was looking back at your comments on the housings so I took another look at those.

Here's what you said:

"Those rotor housings have Atkins apex seals written all over them. Nice big stock porting in those too. My guess is it's GSL-SE spec (late opening and T2 closing edges - very good for low end torque but can be ported to T2 spec to drive a turbo). I don't think these have 12AT spec, which open early (at T2 spec) but close earlier than T2. Still better than tiny US-spec exhaust ports. Do you have any US-spec housings to compare port timing differences?"

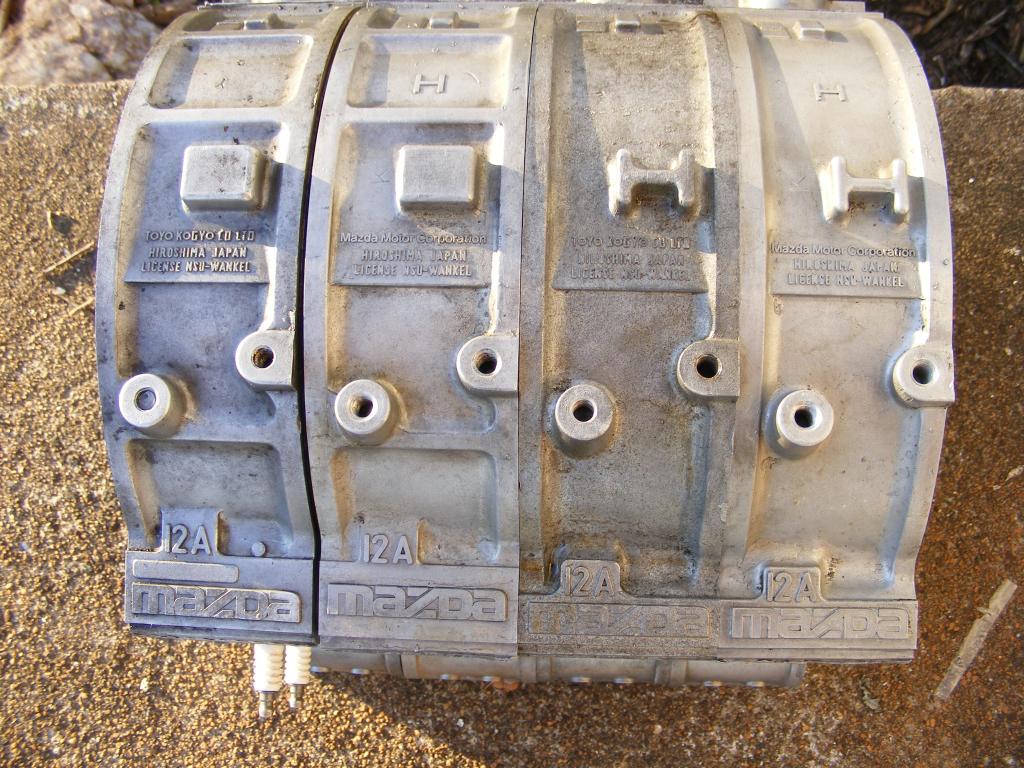

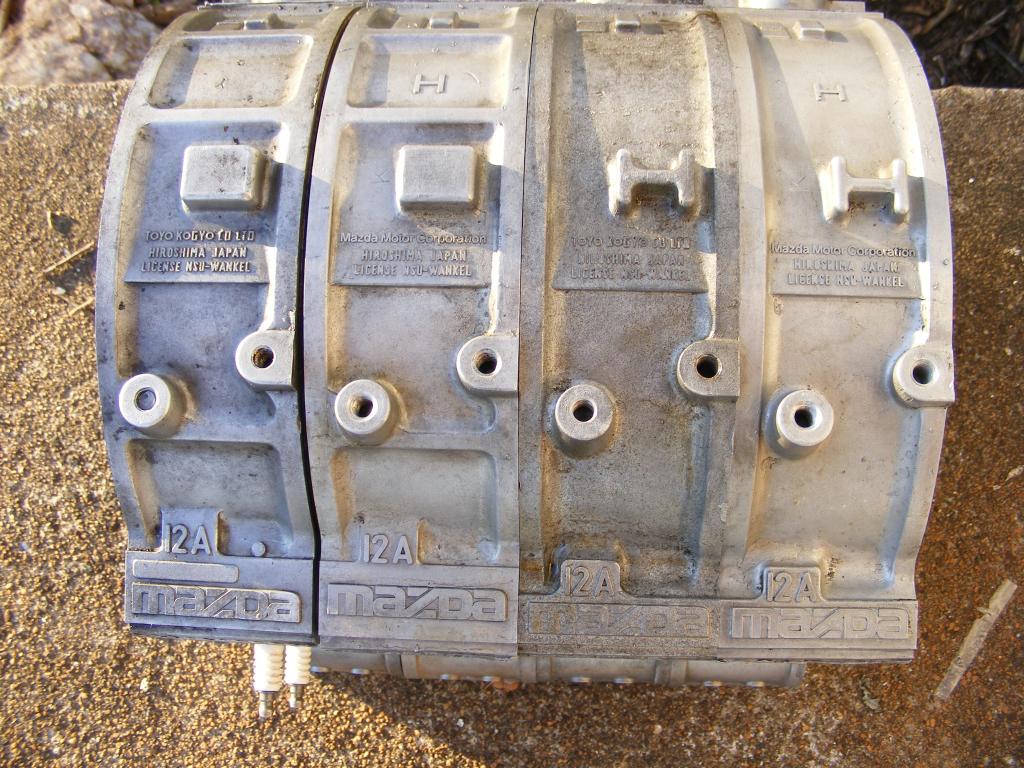

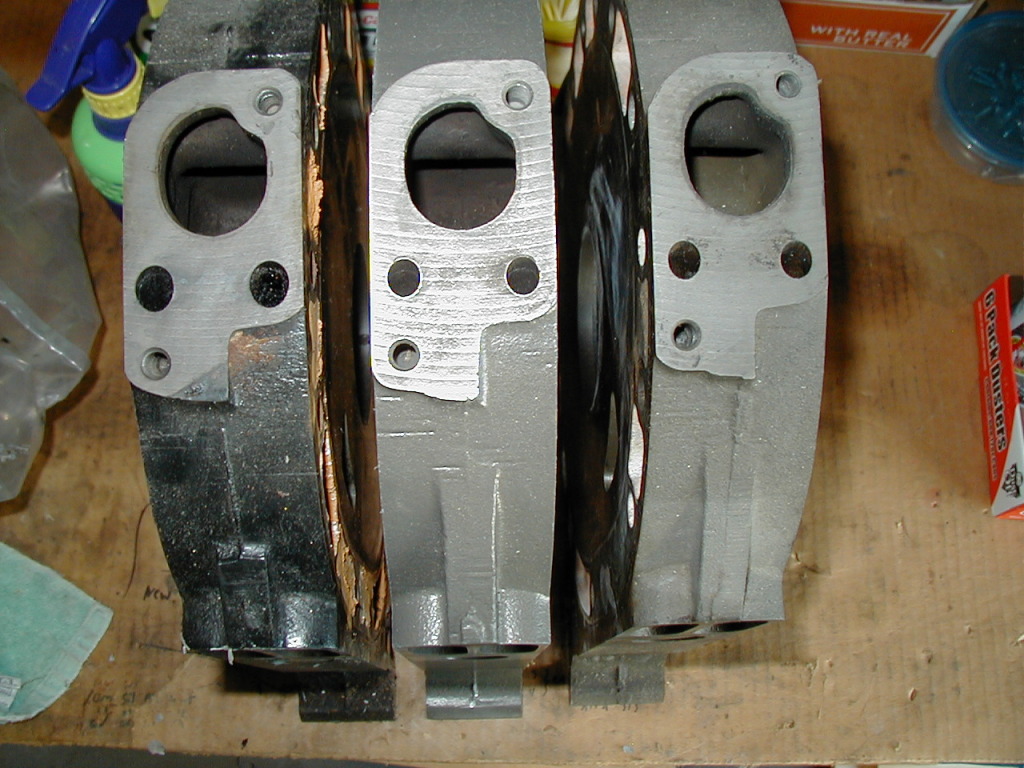

So I got out different 12A housings from my collection and put the big port R5 one in the front (to the left) and progressing to the newer housings to the back:

Here they are from the back

and from the top, R5 on the left

Weird thing, it looks like the cooling channels have changed with time, the ones in the back have more divisions and flow holes. (Same order as in the photos above, R5 in front)

Are these later versions? What year did they start doing that?

And here's the Big Question. Can you mix and match rotor housings in a rebuild?

Here's what you said:

"Those rotor housings have Atkins apex seals written all over them. Nice big stock porting in those too. My guess is it's GSL-SE spec (late opening and T2 closing edges - very good for low end torque but can be ported to T2 spec to drive a turbo). I don't think these have 12AT spec, which open early (at T2 spec) but close earlier than T2. Still better than tiny US-spec exhaust ports. Do you have any US-spec housings to compare port timing differences?"

So I got out different 12A housings from my collection and put the big port R5 one in the front (to the left) and progressing to the newer housings to the back:

Here they are from the back

and from the top, R5 on the left

Weird thing, it looks like the cooling channels have changed with time, the ones in the back have more divisions and flow holes. (Same order as in the photos above, R5 in front)

Are these later versions? What year did they start doing that?

And here's the Big Question. Can you mix and match rotor housings in a rebuild?

#28

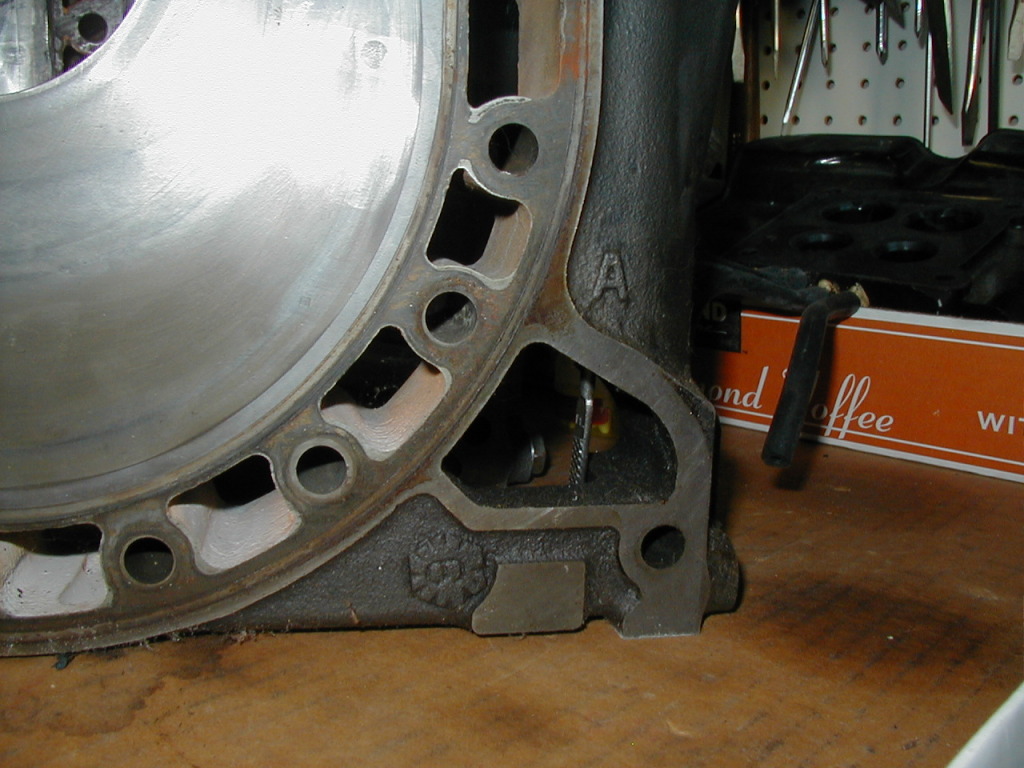

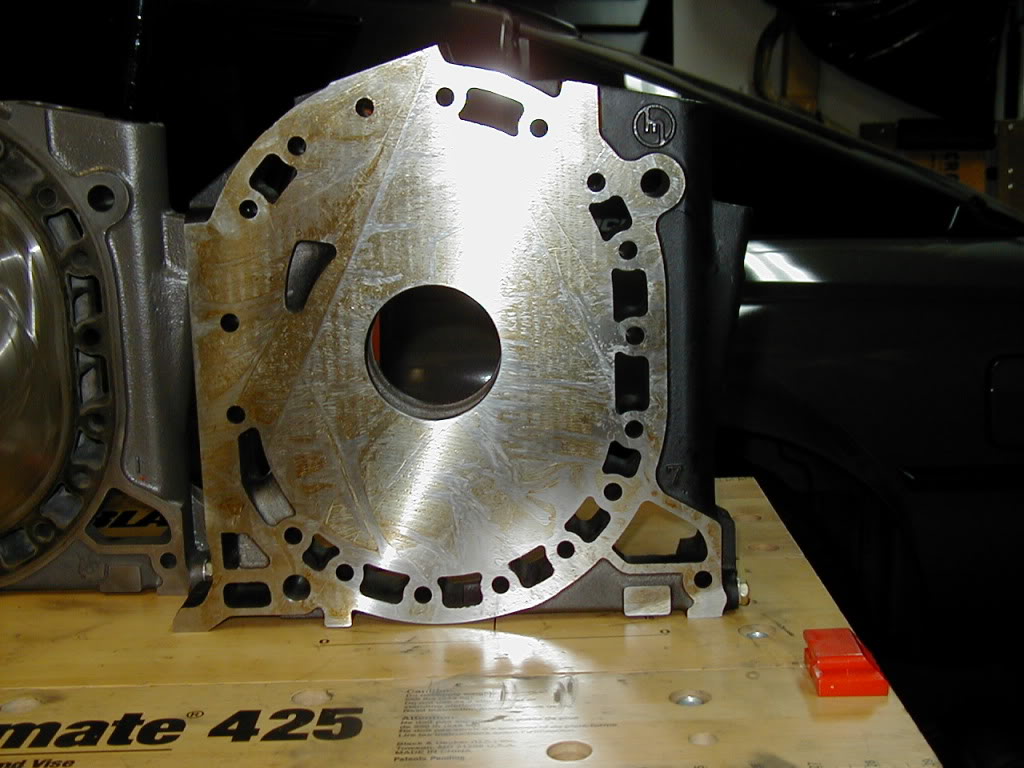

OK, here's what I have in my "used up but may work if I'm desperate someday" midplate stack.

Working from Right to Left, here we have:

#1 the midplate from the engine that was original to my car when I got it; all signs plus statements of PO said it had never been out of the car.

#2 a bonafide 1980 CA "NO" midplate purchased used from Racing Beat a long itime back, which was then run until used up. It got chewed up in my build disaster earlier this year.

#3 The strange one; This came out of an engine I was told was a rebuilt but all-80 CA motor, & which turned out on inspection to have a lot of problems, including mismatched rotors, huge rust buildup in the cooling channels, thrashed bearings, and broken seal marks on the rear endplate. It was busted down for parts.

Intake side; all identical, all "tall" runners

Inner ports; All identical in dimension & timing

EGR pads; only oddball thing here is #3 (leftmost) has considerably larger-diameter gas channels down to the intakes.

Housing #1's markings: It's an NO housing with a raised 2 at the bottom, raised A opposite, with a cast-in "6" indent in the oil gallery area

Housing #2: NO housing, raised B @ bottom, raised I opposite, indented 6

Housing 3: Mutant! There is NO "NO" mark, or even a pad space for it - yet it's an EGR housing. Raised 2 @ bottom, raised P opposite top, raised 2 below... indent mark appears to have been ground off during resurfiacing in the past

Now, my current midplate in the engine, which was NOS but pre-RX-7 & non-nitrided, part number was 8736-23-070. But it was nonetheless an NO housing with EGR. It has SMALLER than normal EGR passages, but the ports and runners are identical to the plates above -- I checked that very carefully before I bought it, as even though I got a magnificent deal it was still an expensive part.

It has raised NO with raised 7 below, and the old-school raised Circled M Mazda logo on the face with another raised 7 below, and no nex pad with intented number.

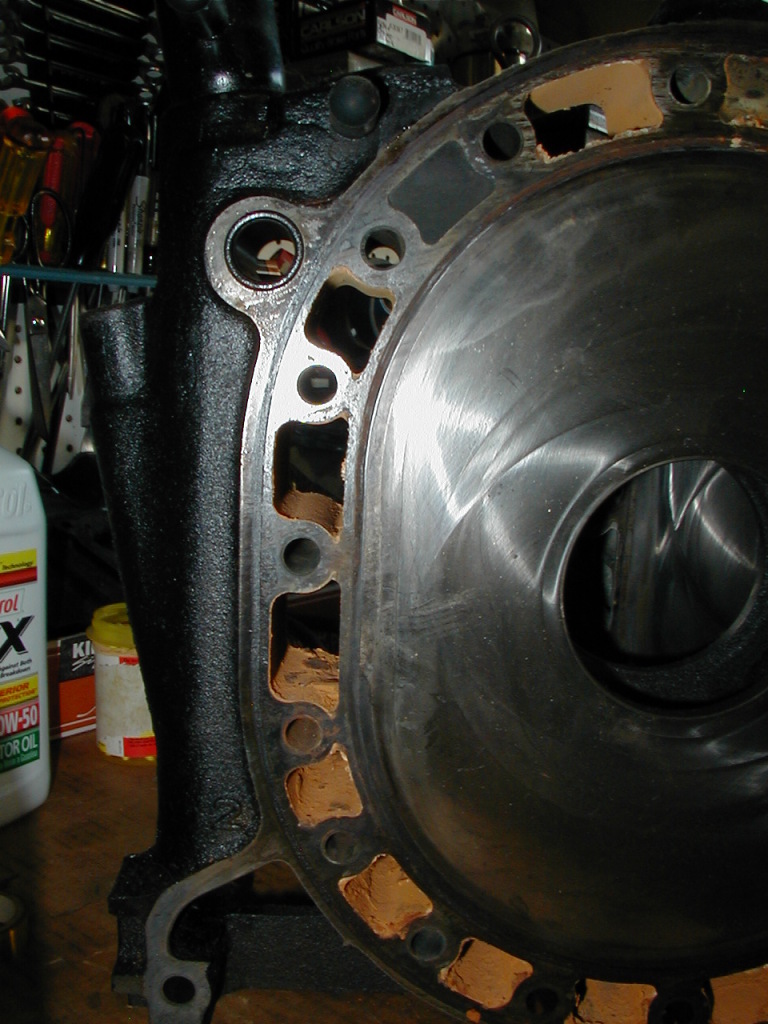

Here are what pix I have of it prior to installing it: Comparison to #2, above:

Working from Right to Left, here we have:

#1 the midplate from the engine that was original to my car when I got it; all signs plus statements of PO said it had never been out of the car.

#2 a bonafide 1980 CA "NO" midplate purchased used from Racing Beat a long itime back, which was then run until used up. It got chewed up in my build disaster earlier this year.

#3 The strange one; This came out of an engine I was told was a rebuilt but all-80 CA motor, & which turned out on inspection to have a lot of problems, including mismatched rotors, huge rust buildup in the cooling channels, thrashed bearings, and broken seal marks on the rear endplate. It was busted down for parts.

Intake side; all identical, all "tall" runners

Inner ports; All identical in dimension & timing

EGR pads; only oddball thing here is #3 (leftmost) has considerably larger-diameter gas channels down to the intakes.

Housing #1's markings: It's an NO housing with a raised 2 at the bottom, raised A opposite, with a cast-in "6" indent in the oil gallery area

Housing #2: NO housing, raised B @ bottom, raised I opposite, indented 6

Housing 3: Mutant! There is NO "NO" mark, or even a pad space for it - yet it's an EGR housing. Raised 2 @ bottom, raised P opposite top, raised 2 below... indent mark appears to have been ground off during resurfiacing in the past

Now, my current midplate in the engine, which was NOS but pre-RX-7 & non-nitrided, part number was 8736-23-070. But it was nonetheless an NO housing with EGR. It has SMALLER than normal EGR passages, but the ports and runners are identical to the plates above -- I checked that very carefully before I bought it, as even though I got a magnificent deal it was still an expensive part.

It has raised NO with raised 7 below, and the old-school raised Circled M Mazda logo on the face with another raised 7 below, and no nex pad with intented number.

Here are what pix I have of it prior to installing it: Comparison to #2, above:

#29

love the braaaap

This is an interesting thread. I just got the engine out of my 79 today. Definitely have R5 front and rear plates, will have to see what the intermediate is when I clean off all the grime. Its got fairly significant internal and external oil leakage which is why I will be tearing it down for a soft seal kit. I think all the hard seals will be decent since the engine was able to produce 105-110 psi on my compression test, but time will tell.

#30

Ray, thanks for the pics of the oil pumps. They are indeed "high volume". Have you checked them for scoring and play? The FSM explains how to do it.

One of your rear stationary gear bolts is pretty smashed looking. Someone's been prying a little.

The black rear stationary seals always harden and leak. Always swap in a new orange one.

As for your rotor housings, your J-spec R5 housing has GSL-SE spec exhaust port timing. It opens late and closes late compared with US-spec FB housings.

In a nut shell, FB spec opens at T2 spec and J-spec closes at T2 spec. So if you wanted to, you could mimic the port timing of a T2 engine to drive a turbo based on what you have in front of you without access to a real T2 rotor housing. Pretty neat huh?

But what does this mean to you? Well, if you want to drive a turbo, there you go. But if you don't, I'd say leave the GSL-SE port tinming alone. According to Paul Yaw, late opening ports have better low end torque up to 4k. After that it's better to have larger ports, but you then start to hurt low RPM.

The extra bracing in the water jacket is something Mazda introduced with the 12A turbo in 1983.

Some housings can be mixed. Make sure spark plugs and exhaust ports are in the same location.

One of your rear stationary gear bolts is pretty smashed looking. Someone's been prying a little.

The black rear stationary seals always harden and leak. Always swap in a new orange one.

As for your rotor housings, your J-spec R5 housing has GSL-SE spec exhaust port timing. It opens late and closes late compared with US-spec FB housings.

In a nut shell, FB spec opens at T2 spec and J-spec closes at T2 spec. So if you wanted to, you could mimic the port timing of a T2 engine to drive a turbo based on what you have in front of you without access to a real T2 rotor housing. Pretty neat huh?

But what does this mean to you? Well, if you want to drive a turbo, there you go. But if you don't, I'd say leave the GSL-SE port tinming alone. According to Paul Yaw, late opening ports have better low end torque up to 4k. After that it's better to have larger ports, but you then start to hurt low RPM.

The extra bracing in the water jacket is something Mazda introduced with the 12A turbo in 1983.

Some housings can be mixed. Make sure spark plugs and exhaust ports are in the same location.

#31

Nice pics DD, you're right, those midhousings don't look like the one I pulled from this engine, the intake ports are much smaller on my plate. Yours look more my other midhousings, just with those annoying blockages of the cooling ports up there by the EGR port. Now I'm curious if your rotor housings have the big exhaust ports like the ones pulled from this engine or the smaller "US" versions like in all the rest of my rotor housings.

You know, we don't have emissions here in GA and real estate and cost of living expenses are way lower than CA. The rotaries are more numerous too. Just a thought, we could always use another engineer in the Atlanta area.

Thanks for the feedback Jeff! I'll check those oil pumps according to the FSM, they all look fine and I'm sure with 5 to choose from at least one is serviceable.

Yep, I bashed that stationary gear bolt pretty good with my special method for removing flywheels (see "The Trick" in the photos on page 1). Next time I'll be a little more careful about where I put those pry dogs.

I especially appreciate the info on the rotor housings, clears up some questions about what year the various 12As I've been tearing down were (apparently only one was 83 or later). I'll match the good ones I have according to your specs.

Pretty much everything else you say is way beyond my feeble mind, I don't understand SEs and I sure don't like turbos (too expensive and exotic, not what the Mazda engineers intended when they created the 12A or the FB).

So if anybody is looking for some "J-spec R5 housing has GSL-SE spec exhaust port timing" or "T2 spec and J-spec closes at T2 spec" performance, I've got the parts for you!

You know, we don't have emissions here in GA and real estate and cost of living expenses are way lower than CA. The rotaries are more numerous too. Just a thought, we could always use another engineer in the Atlanta area.

Thanks for the feedback Jeff! I'll check those oil pumps according to the FSM, they all look fine and I'm sure with 5 to choose from at least one is serviceable.

Yep, I bashed that stationary gear bolt pretty good with my special method for removing flywheels (see "The Trick" in the photos on page 1). Next time I'll be a little more careful about where I put those pry dogs.

I especially appreciate the info on the rotor housings, clears up some questions about what year the various 12As I've been tearing down were (apparently only one was 83 or later). I'll match the good ones I have according to your specs.

Pretty much everything else you say is way beyond my feeble mind, I don't understand SEs and I sure don't like turbos (too expensive and exotic, not what the Mazda engineers intended when they created the 12A or the FB).

So if anybody is looking for some "J-spec R5 housing has GSL-SE spec exhaust port timing" or "T2 spec and J-spec closes at T2 spec" performance, I've got the parts for you!

#32

Georgia... I spent the better part of a year in the Augusta area back in '83 (taking training in crypto gear repair at Ft. Gordon) and have been in Atlanta many many weeks on business, as both past and current employers have had offices in the northern suburbs there, around Roswell / Alpharetta. In general, I liked the place & the people.

Not a lot of diving opportunities, though, unless you get closer to Savannah.

On the other hand, the Carib is a lot closer from there.

On the other hand, the Carib is a lot closer from there.

#33

Ray, I use the Mazdatrix method to take off flywheels. No prybars, just a mini sledge.

As for the housings, glad I could help. Since you won't go turbo, leave the R5 housings alone. You'll love the GSL-SE port timing. That's what I've got in the blue car. Its low end torque is amazing to drive, and it pulls well up to 7k. Perfect for 3mm apex seals and heavy R5 rotors!

As for the housings, glad I could help. Since you won't go turbo, leave the R5 housings alone. You'll love the GSL-SE port timing. That's what I've got in the blue car. Its low end torque is amazing to drive, and it pulls well up to 7k. Perfect for 3mm apex seals and heavy R5 rotors!

#34

Divin, I honestly didn't know but suspected the US-spec engines would have tall primary runners. Thanks for the confirmation. This further vindicates my position that only J-spec R5 engines came with those pathetically small ports and short runners. And only some models while others did come with tall runners and normal 12A ports - without the crappy EGR casting. I hope to use one of these somewhat rare tall port R5 intermediate plates in my next build.

Just some trivia for you. The short small NO ports are the same port timing and size as GSL-SE and S4 NA. Well, GSL-SE anyway as I believe S4 moved the position of the runners up a little on ther iron, but kept the port timing small. This was to keep incoming air velocity up for the fuel injectors located in the upper edge of the iron. I'm sure you've seen SE and S4 stuff at some point. Incidentally the FD moved the runners up even higher and way more curved so when you look at them from the outside they look tall but you're really seeing a steeply angled slice through a u-bend. So it looks oval and tall, but it;s really fairly short and small to keep velocity up. Works well enough for that, but hurts high end flow a little if you run an FD NA. They were meant to be boosted - just referncing something Ray said how Mazda never intended to boost the 12A... but they did in the 1983 - 85 12A turbo.

Wow, a P casting? Never seen that before!

Wow, a non nitrided tall port NO? Never seen that before.

I did once see a non nitrided short runner R5. That was strange. It had the little GSL-SE size intake port timing like a J-spec NO but no EGR casting. It came with "Automobiles" housings with GSL-SE exhaust port timing. I used the housings in my REPU for better low end torque. But now I'd like to use them in a turbo build. So that means porting them out to T2 spec. I'll also swap to a thick rib 18 tension bolt R5 rear plate like the one you used in your recent build. This is going to be a fun rebuild. Maybe I can get it together over the winter.

This is going to be a fun rebuild. Maybe I can get it together over the winter.

Just some trivia for you. The short small NO ports are the same port timing and size as GSL-SE and S4 NA. Well, GSL-SE anyway as I believe S4 moved the position of the runners up a little on ther iron, but kept the port timing small. This was to keep incoming air velocity up for the fuel injectors located in the upper edge of the iron. I'm sure you've seen SE and S4 stuff at some point. Incidentally the FD moved the runners up even higher and way more curved so when you look at them from the outside they look tall but you're really seeing a steeply angled slice through a u-bend. So it looks oval and tall, but it;s really fairly short and small to keep velocity up. Works well enough for that, but hurts high end flow a little if you run an FD NA. They were meant to be boosted - just referncing something Ray said how Mazda never intended to boost the 12A... but they did in the 1983 - 85 12A turbo.

Wow, a P casting? Never seen that before!

Wow, a non nitrided tall port NO? Never seen that before.

I did once see a non nitrided short runner R5. That was strange. It had the little GSL-SE size intake port timing like a J-spec NO but no EGR casting. It came with "Automobiles" housings with GSL-SE exhaust port timing. I used the housings in my REPU for better low end torque. But now I'd like to use them in a turbo build. So that means porting them out to T2 spec. I'll also swap to a thick rib 18 tension bolt R5 rear plate like the one you used in your recent build.

This is going to be a fun rebuild. Maybe I can get it together over the winter.

This is going to be a fun rebuild. Maybe I can get it together over the winter.

#35

DD, I work in Atlanta, let me know next time you're in town and we can get together for lunch. I'll send that NO midplate home with you.

So Jeff, you are saying rebuild that same motor, using all the same parts, except ditch the NO midplate and substitute one of my Y midplates?

This is an intriguing idea because I could do the entire rebuild from recycled parts and a soft seal kit, for about $130. The rotor housings are the weak link, they do have a bit of chrome flaking but otherwise are in good shape.

I have two other pairs of the FB rotor housings that are in better shape, ready to go, the plan being to replace anything that isn't in very good condition with new parts (that's where my $900 estimate for the rebuild kit comes in).

But being my first rotary rebuild, I like the idea of doing a "practice run" first with all recycled parts, less risk if I screw up and I can use the experience to do an even better job on the next one with my best rotor housings (maybe even do a little porting).

I might even have a decent set of used apex seals, I'll have to gather all those together next and see if there's a usable set.

You mentioned earlier that the rotor housings that came out of this engine "have the mark of Atkins apex seals all over them" and you said that a set of Atkins seals would do a good job of sealing to those lightly flaked rotor housings.

Can you tell from this picture if the seals that were in the engine are Atkins seals and if they are still usable? Or would you recommend either buying new Atkins seals or maybe reusing some of the other recycled apex seals I've got (pictures coming on those a bit later).

I really appreciate all the help on this, if I go with with the SA housings and upgraded midplate, we will do a Rainbow Dash paint job on the housings in your honor. I'm just learning about rotary rebuilds, but when it comes to finishes I know my stuff. It will look great.

So Jeff, you are saying rebuild that same motor, using all the same parts, except ditch the NO midplate and substitute one of my Y midplates?

This is an intriguing idea because I could do the entire rebuild from recycled parts and a soft seal kit, for about $130. The rotor housings are the weak link, they do have a bit of chrome flaking but otherwise are in good shape.

I have two other pairs of the FB rotor housings that are in better shape, ready to go, the plan being to replace anything that isn't in very good condition with new parts (that's where my $900 estimate for the rebuild kit comes in).

But being my first rotary rebuild, I like the idea of doing a "practice run" first with all recycled parts, less risk if I screw up and I can use the experience to do an even better job on the next one with my best rotor housings (maybe even do a little porting).

I might even have a decent set of used apex seals, I'll have to gather all those together next and see if there's a usable set.

You mentioned earlier that the rotor housings that came out of this engine "have the mark of Atkins apex seals all over them" and you said that a set of Atkins seals would do a good job of sealing to those lightly flaked rotor housings.

Can you tell from this picture if the seals that were in the engine are Atkins seals and if they are still usable? Or would you recommend either buying new Atkins seals or maybe reusing some of the other recycled apex seals I've got (pictures coming on those a bit later).

I really appreciate all the help on this, if I go with with the SA housings and upgraded midplate, we will do a Rainbow Dash paint job on the housings in your honor. I'm just learning about rotary rebuilds, but when it comes to finishes I know my stuff. It will look great.

#36

Full Member

I really appreciate the time and effort of documenting these tear downs and rebuilds. I've got a 12a in a parts car that I plan on tearing into this winter to see what the status is. Whether or not to use a capital letter lube seems to be debatable, however, the general consensus on mandatory beer breaks - unanimous.

#37

Yes, reuse as many parts as you can. It's a better choice than grabbing other parts from other engines with unknown wear, Well, you measure stuff but it's best to keep original parts in original places.

Atkins seals are the best choice on housings like those. However if your original seals that came from this engine were kept in their original slots, they could have been reused, but since you went ahead and removed all the seals to clean your rotors, you have no way of knowing which slots they came from. So go with new Atkins seals because they will break in easily to used housings where used OEMs will not.

Same goes for your side seals and corner seals. Used side seals take a while to find a slot that will allow a factory amount of clearance. The FSM tells you the specs. Again it would have been better to keep them in their original slots. But now that they're all out, you can try all of your seals in each slot until you get the right amount of clearance. Then grab other spares and keep testing clearances until all 12 are installed. The result is usaully tighter than factory spec. Does that make sense? Aim for .002" to .003".

Be sure to get NEW springs all around. Don't ever reuse springs unless they're low mileage. This engine was obviously not low mileage.

Some spring choices are available. Corner springs have three choices and oil springs have two choices.

Corner spring choices:

•old school wire type

•so called "competition" Cosmo/FD type (look for NF01 in the part number)

•RX-8 type

The old school wire type were used from 74 to 92. I'd stay away from these as they can collapse over time or get stuck easily due to carbon buildup. Not a problem if you're tuned well, but I don't use them.

The NF01 type were found in JC Cosmos (13BRE and 20B) and FDs as well. Very strong, very high lift. DO NOT use these with early non nitrided side plates EVER! Severe side plate iron wear results. Use only in nitrided boosted engines and NA if you're into high RPM and need the extra strength to keep rotors centered to prevent catstrophic rotor to side plate contact at really high RPM (example: bridge and peripheral port). Otherwise not necessary as they increase friction and heat.

The best choice for your engine are the RX-8 corner springs. They are cheaper than NF01 and have a medium amount of lift. Perfect for all 74 to 92 engines.

Oil spring choices:

•OEM inner and outer springs

•competition outer springs

I often reuse the inner OEM springs because they don't usually have too much wear as they are exposed to engine oil during operation. So to save money on my personal rebuilds, I reuse the inners. I'm sure your R5 ones could be reused if you'd like to.

I always swap in new competition outer springs because they're cheap enough and prevent smoking at startup, even if your oil seals are a bit worn. All I have to do is swap in new Atkins Viton oil o-rings (cheaper than stock and seem to work fine) and these competition outers, and I'm good to go.

That's how I build mine, and it works fine.

Atkins seals are the best choice on housings like those. However if your original seals that came from this engine were kept in their original slots, they could have been reused, but since you went ahead and removed all the seals to clean your rotors, you have no way of knowing which slots they came from. So go with new Atkins seals because they will break in easily to used housings where used OEMs will not.

Same goes for your side seals and corner seals. Used side seals take a while to find a slot that will allow a factory amount of clearance. The FSM tells you the specs. Again it would have been better to keep them in their original slots. But now that they're all out, you can try all of your seals in each slot until you get the right amount of clearance. Then grab other spares and keep testing clearances until all 12 are installed. The result is usaully tighter than factory spec. Does that make sense? Aim for .002" to .003".

Be sure to get NEW springs all around. Don't ever reuse springs unless they're low mileage. This engine was obviously not low mileage.

Some spring choices are available. Corner springs have three choices and oil springs have two choices.

Corner spring choices:

•old school wire type

•so called "competition" Cosmo/FD type (look for NF01 in the part number)

•RX-8 type

The old school wire type were used from 74 to 92. I'd stay away from these as they can collapse over time or get stuck easily due to carbon buildup. Not a problem if you're tuned well, but I don't use them.

The NF01 type were found in JC Cosmos (13BRE and 20B) and FDs as well. Very strong, very high lift. DO NOT use these with early non nitrided side plates EVER! Severe side plate iron wear results. Use only in nitrided boosted engines and NA if you're into high RPM and need the extra strength to keep rotors centered to prevent catstrophic rotor to side plate contact at really high RPM (example: bridge and peripheral port). Otherwise not necessary as they increase friction and heat.

The best choice for your engine are the RX-8 corner springs. They are cheaper than NF01 and have a medium amount of lift. Perfect for all 74 to 92 engines.

Oil spring choices:

•OEM inner and outer springs

•competition outer springs

I often reuse the inner OEM springs because they don't usually have too much wear as they are exposed to engine oil during operation. So to save money on my personal rebuilds, I reuse the inners. I'm sure your R5 ones could be reused if you'd like to.

I always swap in new competition outer springs because they're cheap enough and prevent smoking at startup, even if your oil seals are a bit worn. All I have to do is swap in new Atkins Viton oil o-rings (cheaper than stock and seem to work fine) and these competition outers, and I'm good to go.

That's how I build mine, and it works fine.

#38

What do you mean SA housings? Use the R5 housings man! No question. Better torque! More timing (the ports are open longer than US-spec). I absolutely love the torque from my two R5 engines.

What do you mean upgraded midplate? You mean swapping in a Y plate? I thought that was a given. I guess it's technically an upgrade, from the engine's perspective. But you realize you don't even have a matching intake for an NO plate, don't you? All your Nikkis are factory tuned for a Y plate anyway, right?

Oil squirters? Hello? Have you messed with them yet?

I'd like to see what a well done Rainbow Dash actually looks like. I can imagine it, with sky blue housings. But to see one in picture form would be almost as good as seeing one in real life. So get busy!

Hey, what is your rebuild time table? Maybe I can tear down and prep my R5 in parallel with yours? You already got me beat for the teardown as mine is still installed with coolant and oil in it. Intake is off it already though...

What do you mean upgraded midplate? You mean swapping in a Y plate? I thought that was a given. I guess it's technically an upgrade, from the engine's perspective. But you realize you don't even have a matching intake for an NO plate, don't you? All your Nikkis are factory tuned for a Y plate anyway, right?

Oil squirters? Hello? Have you messed with them yet?

I'd like to see what a well done Rainbow Dash actually looks like. I can imagine it, with sky blue housings. But to see one in picture form would be almost as good as seeing one in real life. So get busy!

Hey, what is your rebuild time table? Maybe I can tear down and prep my R5 in parallel with yours? You already got me beat for the teardown as mine is still installed with coolant and oil in it. Intake is off it already though...

#39

Yeah, it's a real strange one. Considering the source of that motor (at least third-hand, possibly 4th) there's no chance of tracking down provenance on it.

If I remember correctly, the part number traces it to a 1977 or 78 RX-4 with automatic trans. Was literally New In Box, and decades old. Sat on the rack at RB for well over 20 years.

Wow, a non nitrided tall port NO? Never seen that before.

#40

Very helpful as usual Jeff, thanks.

When I took out those apex and side seals, I had no intention of reusing them, most of the side seals were stuck and couldn't be removed in one piece without a whole lot of trouble so I just saved the easy ones, about half of the 60 that came from the ten rotors, the others broke.

The set from the last R5 engine were by far the best and is complete and can probably be fitted back to the original rotor slots with a little mixing and matching. Probably easier than all that fitting needed if I get new side seals.

So I'll get new Atkins apex seals, plus new springs all around, sounds like a plan.

It's just sinking in that those intake ports need to line up with my Nikki intake, obviously ruling out the NO plate, maybe even the end plates. Not a problem, I can use the same end plates that go with the Y midplate (I can chose between three sets). That should keep my intake happy.

RX8 corner springs sound like the best choice (atkins sells the FD springs in their rebuild kit, not sure why). I'll reuse the inner o ring springs and get new competition springs for the outers. A set of new Atkins Viton oil o-rings and it should be pretty much ready to go back together.

When I say "SA rotor housing" I mean the ones that came from the R5 engine, which I'm assuming came out of an SA. These are the ones with the big exhaust ports, the same as the "R5 housings". I was thinking about porting the exhaust if I had used my somewhat nicer FB housings for the rebuild, but using the SA (R5) rotor housings will save me the trouble.

Oil squirters? I'm still working on that one, not sure where to look yet.

And yes, Rainow Dash it definitely is. Check out the duck tape thread for options.

My time line is going to slow down, I have tons of work to do for the next 3 weeks, but then will have several weeks to work on it during the holidays and early January.

We could use this thread to compare notes!

When I took out those apex and side seals, I had no intention of reusing them, most of the side seals were stuck and couldn't be removed in one piece without a whole lot of trouble so I just saved the easy ones, about half of the 60 that came from the ten rotors, the others broke.

The set from the last R5 engine were by far the best and is complete and can probably be fitted back to the original rotor slots with a little mixing and matching. Probably easier than all that fitting needed if I get new side seals.

So I'll get new Atkins apex seals, plus new springs all around, sounds like a plan.

It's just sinking in that those intake ports need to line up with my Nikki intake, obviously ruling out the NO plate, maybe even the end plates. Not a problem, I can use the same end plates that go with the Y midplate (I can chose between three sets). That should keep my intake happy.

RX8 corner springs sound like the best choice (atkins sells the FD springs in their rebuild kit, not sure why). I'll reuse the inner o ring springs and get new competition springs for the outers. A set of new Atkins Viton oil o-rings and it should be pretty much ready to go back together.

When I say "SA rotor housing" I mean the ones that came from the R5 engine, which I'm assuming came out of an SA. These are the ones with the big exhaust ports, the same as the "R5 housings". I was thinking about porting the exhaust if I had used my somewhat nicer FB housings for the rebuild, but using the SA (R5) rotor housings will save me the trouble.

Oil squirters? I'm still working on that one, not sure where to look yet.

And yes, Rainow Dash it definitely is. Check out the duck tape thread for options.

My time line is going to slow down, I have tons of work to do for the next 3 weeks, but then will have several weeks to work on it during the holidays and early January.

We could use this thread to compare notes!

#41

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,801

Received 2,575 Likes

on

1,830 Posts

as i recall the number doesn't show up in my parts books either, which makes it a good candidate for being non US market, as well.

#42

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,801

Received 2,575 Likes

on

1,830 Posts

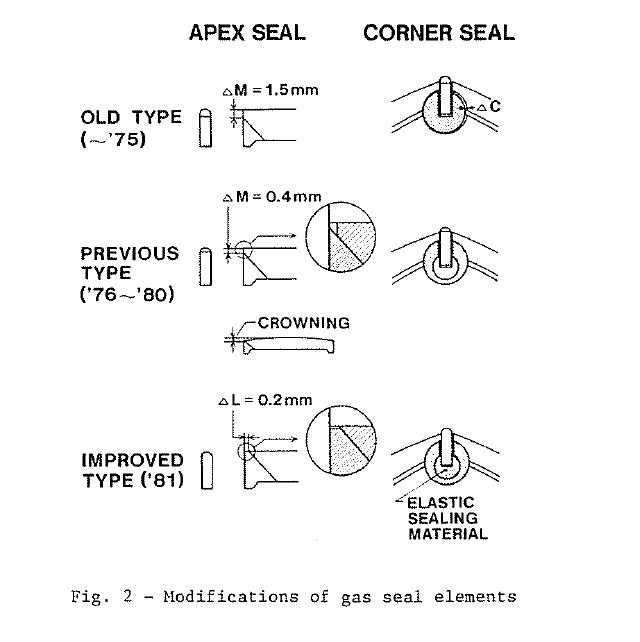

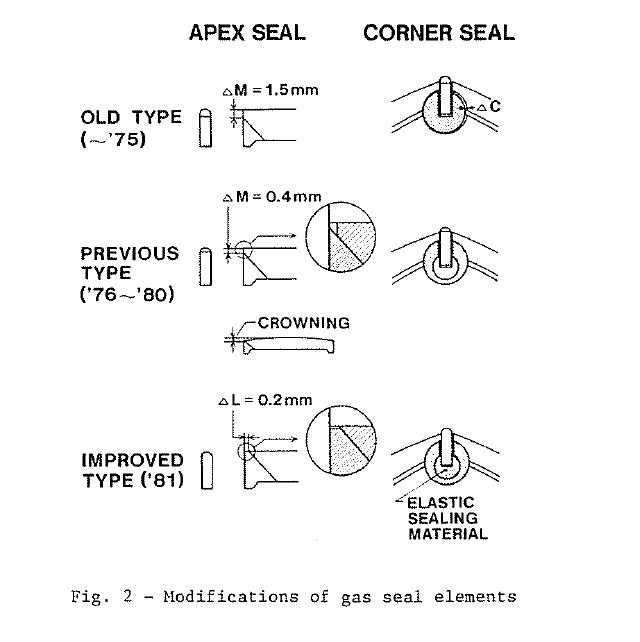

those look like the are atkins apex seals already,

this is Mazdas seal chart, they made a bunch of changes, but they never had the triangle part way in the middle like that. as you can see Mazda chooses the least leakage path, and the aftermarket chooses the less wear path.

this is Mazdas seal chart, they made a bunch of changes, but they never had the triangle part way in the middle like that. as you can see Mazda chooses the least leakage path, and the aftermarket chooses the less wear path.

#43

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,801

Received 2,575 Likes

on

1,830 Posts

the vaseline is a good for instance, really its there to keep the seals in place during assembly. half the seals are in there by gravity, and need nothing, the other half need a little dab of something, but in a shop there are tons of sticky substances that will work, like axle grease.

for things like bearings and housings i like the redline CV2 stuff, although i'll use plain motor oil, or bearing grease. most builds are for me, so i know i'm going to crank it to get oil pressure before i start it, and i don't need it to smoke for 7 hours either

#46

Thanks for the tips folks, from what I'm hearing a new set of Atkins apex seals is well advised if I use these less than perfect housings from the R5 engine, they are showing a bit of wear near the edges.

I know using rotor housings with these issues isn't great, some of the rotary builders here in the Atlanta area would advise against it, but if they're good for even 90% compression and 10,000 miles it will be a good return on the investment.

And Jeff says I'll really like those big exhaust ports combined with the heavy rotors, so I'm curious to see how that arrangement compares with the 100,000+ mile stock 12As I've been driving for the last ten years that probably had just as much housing damage but were still running pretty well.

Colin, thanks for your words of encouragement. My biggest question at this point is whether to go with these slightly damaged old school housings or move on with a proper rebuild using that really nice, newer 12A rotor housing you sent me. I have a perfect match for it in a housing that Rotospeed was kind enough to trade me for a distributor, so that pair will be the ultimate rebuild.

But for now I'm thinking going cheap, using as many recycled parts as I can (except for new apex seals, springs and soft seals) and seeing if I can get my first rotary rebuild to fire up. A great opportunity to learn from a few mistakes, it seems to me. Stay tuned, you'll see it all here.

I know using rotor housings with these issues isn't great, some of the rotary builders here in the Atlanta area would advise against it, but if they're good for even 90% compression and 10,000 miles it will be a good return on the investment.

And Jeff says I'll really like those big exhaust ports combined with the heavy rotors, so I'm curious to see how that arrangement compares with the 100,000+ mile stock 12As I've been driving for the last ten years that probably had just as much housing damage but were still running pretty well.

Colin, thanks for your words of encouragement. My biggest question at this point is whether to go with these slightly damaged old school housings or move on with a proper rebuild using that really nice, newer 12A rotor housing you sent me. I have a perfect match for it in a housing that Rotospeed was kind enough to trade me for a distributor, so that pair will be the ultimate rebuild.

But for now I'm thinking going cheap, using as many recycled parts as I can (except for new apex seals, springs and soft seals) and seeing if I can get my first rotary rebuild to fire up. A great opportunity to learn from a few mistakes, it seems to me. Stay tuned, you'll see it all here.

#48

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,801

Received 2,575 Likes

on

1,830 Posts

i'd do like Jeff suggests and sub in a better center iron.

#49

Agreed. When I found out even CA 1980 cars had tall runners, that was it for me. Ray, don't bother sending the short runner NO to Divin. Junk it instead.  Recycle! I meant recycle it. Don't want to make the Indian cry.

Recycle! I meant recycle it. Don't want to make the Indian cry.

Ray do you have any 81-82 flywheels? Do you have a matching front CW? I highly recommend swapping. You'll thank me.

Think about it. Don't use a stock 30 pound SA/R5 flywheel here. Why did Mazda use such a heavy flywyheel? Because in the early days, rotaries had no low end torque. So to make up for it, they overweighted the flywheel. This kills performance and even causes turning issues due to the gryoscopic effect (mostly in cars smaller and lighter than the 1st gen but you get my point).

The GSL-SE port timing of those R5 housings of yours increases low end torque. The heavy stock R5 rotors are already heavy enough without the insult of an overly heavy flywheel. The whole mess together in a small light 1st gen adds up to basically a tractor engine that can't rev and is wrong for the application. I'd say the stock SA barely gets away with it, but they have their own problems such as a weak ignition system (points or the less reliable fender mounted 1980-only setup) and a crappy exhaust system. So since you have an FB, do yourself a favor and use an FB flywheel!

Like I said, your Nikki and matching manifold were designed for a tall runner Y intermediate plate, right? Well, the car's gearing and everything else was designed for an FB flywheel.

Am I getting through loud and clear?

Recycle! I meant recycle it. Don't want to make the Indian cry.

Recycle! I meant recycle it. Don't want to make the Indian cry.Ray do you have any 81-82 flywheels? Do you have a matching front CW? I highly recommend swapping. You'll thank me.

Think about it. Don't use a stock 30 pound SA/R5 flywheel here. Why did Mazda use such a heavy flywyheel? Because in the early days, rotaries had no low end torque. So to make up for it, they overweighted the flywheel. This kills performance and even causes turning issues due to the gryoscopic effect (mostly in cars smaller and lighter than the 1st gen but you get my point).

The GSL-SE port timing of those R5 housings of yours increases low end torque. The heavy stock R5 rotors are already heavy enough without the insult of an overly heavy flywheel. The whole mess together in a small light 1st gen adds up to basically a tractor engine that can't rev and is wrong for the application. I'd say the stock SA barely gets away with it, but they have their own problems such as a weak ignition system (points or the less reliable fender mounted 1980-only setup) and a crappy exhaust system. So since you have an FB, do yourself a favor and use an FB flywheel!

Like I said, your Nikki and matching manifold were designed for a tall runner Y intermediate plate, right? Well, the car's gearing and everything else was designed for an FB flywheel.

Am I getting through loud and clear?

#50

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,801

Received 2,575 Likes

on

1,830 Posts

i've got some 81-82 front CW's, if anyone needs/wants

.

.