GSL vs GSL-SE fuel hardlines

#1

GSL vs GSL-SE fuel hardlines

Looks like my 85 GSL has 5/16" feed and 1/4" return (and another 1/4" vent). Is it the same for the SE or did they upgrade to a larger return for the EFI setup?

I'm converting my GSL to EFI and I was planning to just use the original lines with 6AN fittings on them, which is what I did on my REPU, but now I'm wondering if I need to at least upgrade the return line to a larger diameter to prevent too much pressure during off throttle transients. The plan is to use a 255lph walbro pump with power goals around 180-200 whp, so nothing crazy, just a big street port.

I'm converting my GSL to EFI and I was planning to just use the original lines with 6AN fittings on them, which is what I did on my REPU, but now I'm wondering if I need to at least upgrade the return line to a larger diameter to prevent too much pressure during off throttle transients. The plan is to use a 255lph walbro pump with power goals around 180-200 whp, so nothing crazy, just a big street port.

#2

ancient wizard...

SE has 8 mm feed and return lines1/4Ē vent line. Suggest 3/8Ē or 6-an feed and supply lines if using a pump of that volume for a balanced fuel system. If your engine had fuel requirements similar to 13B SE engine you could just run larger return line and be ok.

With what iíve read of your thread,your engine,intake,injectors are capable of more horsepower. Youíre using a higher volume pump to feed it,should upgrade feed/return lines to complement the engine and rest of fuel system. Am not saying it wonít run with 8mm feed and return,but it will run better with the recommended line size and be easier to tune with less possibility of hiccups.

With what iíve read of your thread,your engine,intake,injectors are capable of more horsepower. Youíre using a higher volume pump to feed it,should upgrade feed/return lines to complement the engine and rest of fuel system. Am not saying it wonít run with 8mm feed and return,but it will run better with the recommended line size and be easier to tune with less possibility of hiccups.

#3

Ok, so they did add a larger return line on the SE. I guess I should rethink the setup then. I don't really expect more than 200hp, but I'd rather overbuild things than come up short. At some point I may consider turbo, and I know I'd have to upgrade the lines then....but it sounds like I should just do it now, order some tubing, get a few bending tools, and figure it out.

I do have my REPU running with the same configuration, similar pump, 4 425cc injectors, and the factory feed/return lines. The shop just finished tuning it but I haven't driven it since they did the work. Prior to sending it to them it actually ran pretty decent on my road tune but had a few issues that turned out to be a vacuum leak from one of the fittings. Anyway, the REPU is just a cruiser while the RX7 will see track time and getting the throttle response right is very important.

I do have my REPU running with the same configuration, similar pump, 4 425cc injectors, and the factory feed/return lines. The shop just finished tuning it but I haven't driven it since they did the work. Prior to sending it to them it actually ran pretty decent on my road tune but had a few issues that turned out to be a vacuum leak from one of the fittings. Anyway, the REPU is just a cruiser while the RX7 will see track time and getting the throttle response right is very important.

#4

Banned

iTrader: (40)

Go with the 3/8 on supply and return like GSLSEforme said... you wont be disappointed...

Trending Topics

#8

ancient wizard...

You can benefit from my prior experience here...Several years ago owned an 84GSL with a 13B i converted to standalone FI run by Megasquirt. I used 3/8" nickle/copper fuel line for feed and return and modified fuel pickup/return in tank by cutting off original lines and enlarging holes in mounting plate for tank to accommodate 3/8" lines. Had to move 1/4" vent line to do so. Welded up original hole and drilled a new one and made new vent line from 1/4" steel tube. Bent all lines 90 degrees and flared all three lines and soldered into mounting plate.Put a 3/8" pickup screen from a big block Dodge B body car and bent feed and return lines to mimic SE configuration.

I used 3/8" Fuel injection hose to run from pump down to frame rail (at spot where SE pump would have been) and used a Walbro 255lph pump with a GM FI filter before pump and transitioned to 3/8" copper nickle feed/return line to go from there up to firewall by booster like original SE design. At that point transitioning to 3/8" to -6AN couplers and Earl's stainless braided fuel hoses to Fuel rail/regulator. Worked real good,with a full tank of fuel...less than 1/2 tank of fuel was plagued by bucking/hesitation/stalling from fuel slosh in hard cornering,braking,accelerating,uncovering pickup tube. This is not a problem when this happens to carbed cars as the fuel in the bowls will allow the fuel system to recover from intermittent cavitation without car momentarily running out of gas.

I had a prospective buyer for the car and needed a quick solution for the problem. I ended up using an SE fuel tank as they have a slosh cup welded to floor of tank around fuel pickup that keeps it submerged in fuel at all times,it worked and i sold the car. Subsequently discovered others were cutting slosh cups out of FC cars and welding them into FB tanks to address this issue,so there's another option to address fuel slosh issue.

I'm restoring a Dodge Ramcharger that originally had a carb based fuel system and repowering with a larger 2nd gen Magnum engine with FI. Truck has a 36 gallon poly unbaffled tank. After a lot of research trying to address inevitable fuel slosh/starvation issues,i intend to retrofit the tank with an intank high pressure pump. I want to keep the original sender in place for an operational fuel gauge. Best case solution and route i'm taking is an Aeromotive Phantom 340lph stealth intank fuel pump system. The original application is for updating musclecars to modern fuel injected engines. It requires cutting a hole in top of tank to install it,the top of pump has a bulkhead with -6an feed/return fittings and a vent fitting cast into bulkhead. Wires for pump come out of bulkhead thru rubber grommets. The fuel pickup is surrounded by a foam collar that goes all the way to tank floor keeping pickup submerged and held there by hardware that attaches pump to top of tank. The foam is identical to what is used in fuel cells,for the same purpose,to eliminate fuel slosh issues.

About $500,not inexpensive but will solve fuel slosh problems and have enough volume to feed the modified engine that will have bigger than oe fuel demands that's going in truck.

I looked at offerings from Tanks INC. who have something similar(for considerably less) and Holley with their intank setup with what they call a hydromat that unrolls and lays across bottom of tank that's supposed to pick up fuel anywhere along the mat( not much feedback review wise on this as of yet).

Chuyler,if i were in your position i would go the Aeromotive route in your original tank,which will allow you to use -6AN braided hose down to frame rail and transition cleanly to 3/8" steel line(i'd use copper/nickle,easier to work with and not much more than steel tubing of same size) to front of car/firewall and transition to braided hose to connect to rail/regulator. Also allows keeping your original fuel sender unit. Trying to post pics of Pump i'm describing but still having problems uploading pics to site. Google "Aeromotive Stealth Fuel Systems to get a visual for what i'm recommending.

I used 3/8" Fuel injection hose to run from pump down to frame rail (at spot where SE pump would have been) and used a Walbro 255lph pump with a GM FI filter before pump and transitioned to 3/8" copper nickle feed/return line to go from there up to firewall by booster like original SE design. At that point transitioning to 3/8" to -6AN couplers and Earl's stainless braided fuel hoses to Fuel rail/regulator. Worked real good,with a full tank of fuel...less than 1/2 tank of fuel was plagued by bucking/hesitation/stalling from fuel slosh in hard cornering,braking,accelerating,uncovering pickup tube. This is not a problem when this happens to carbed cars as the fuel in the bowls will allow the fuel system to recover from intermittent cavitation without car momentarily running out of gas.

I had a prospective buyer for the car and needed a quick solution for the problem. I ended up using an SE fuel tank as they have a slosh cup welded to floor of tank around fuel pickup that keeps it submerged in fuel at all times,it worked and i sold the car. Subsequently discovered others were cutting slosh cups out of FC cars and welding them into FB tanks to address this issue,so there's another option to address fuel slosh issue.

I'm restoring a Dodge Ramcharger that originally had a carb based fuel system and repowering with a larger 2nd gen Magnum engine with FI. Truck has a 36 gallon poly unbaffled tank. After a lot of research trying to address inevitable fuel slosh/starvation issues,i intend to retrofit the tank with an intank high pressure pump. I want to keep the original sender in place for an operational fuel gauge. Best case solution and route i'm taking is an Aeromotive Phantom 340lph stealth intank fuel pump system. The original application is for updating musclecars to modern fuel injected engines. It requires cutting a hole in top of tank to install it,the top of pump has a bulkhead with -6an feed/return fittings and a vent fitting cast into bulkhead. Wires for pump come out of bulkhead thru rubber grommets. The fuel pickup is surrounded by a foam collar that goes all the way to tank floor keeping pickup submerged and held there by hardware that attaches pump to top of tank. The foam is identical to what is used in fuel cells,for the same purpose,to eliminate fuel slosh issues.

About $500,not inexpensive but will solve fuel slosh problems and have enough volume to feed the modified engine that will have bigger than oe fuel demands that's going in truck.

I looked at offerings from Tanks INC. who have something similar(for considerably less) and Holley with their intank setup with what they call a hydromat that unrolls and lays across bottom of tank that's supposed to pick up fuel anywhere along the mat( not much feedback review wise on this as of yet).

Chuyler,if i were in your position i would go the Aeromotive route in your original tank,which will allow you to use -6AN braided hose down to frame rail and transition cleanly to 3/8" steel line(i'd use copper/nickle,easier to work with and not much more than steel tubing of same size) to front of car/firewall and transition to braided hose to connect to rail/regulator. Also allows keeping your original fuel sender unit. Trying to post pics of Pump i'm describing but still having problems uploading pics to site. Google "Aeromotive Stealth Fuel Systems to get a visual for what i'm recommending.

#9

What about just leaving everything completely stock out back, and installing a surge tank in the engine bay. Plenty of space on the passenger side.

This FiTech model has the pump submerged. Stock fuel pump via stock hard line feeds one of the -6AN fittings while another connects to the stock return line. The other two connect to the fuel rail. It makes for a quick install, no modifications to the hard lines or fuel tank, no risk of slosh causing problems. I'm not sure how big this is, but perhaps it could fit near the stock fuel pump location. The manual does say it still works if mounted horizontal, albeit not as well. It looks like that's basically how PeeJay did it back in '14.

https://www.rx7club.com/naturally-as...1067346/page2/

But I actually do like the Aeromotive setup, one less pump to fail, plus the pump stays submerged in fuel which is cooler and quieter. What's involved with installation of the Aeromotive kit. Just cutting a bigger hole? Oh wait...google is my friend. Sorry for going through this but since I've never pulled the tank I need to go by the wealth of knowledge on this site...

Below is what someone said is an '84 SE tank next to an '83 (non-SE) tank.

What am I going to find when I drop my '85 non-SE? I suppose if it looks like the '83 I just cap the 3 lines and drill a hole for the Aeromotive kit. If it looks like the '85 SE, is the hole already the right size?

This FiTech model has the pump submerged. Stock fuel pump via stock hard line feeds one of the -6AN fittings while another connects to the stock return line. The other two connect to the fuel rail. It makes for a quick install, no modifications to the hard lines or fuel tank, no risk of slosh causing problems. I'm not sure how big this is, but perhaps it could fit near the stock fuel pump location. The manual does say it still works if mounted horizontal, albeit not as well. It looks like that's basically how PeeJay did it back in '14.

https://www.rx7club.com/naturally-as...1067346/page2/

But I actually do like the Aeromotive setup, one less pump to fail, plus the pump stays submerged in fuel which is cooler and quieter. What's involved with installation of the Aeromotive kit. Just cutting a bigger hole? Oh wait...google is my friend. Sorry for going through this but since I've never pulled the tank I need to go by the wealth of knowledge on this site...

Below is what someone said is an '84 SE tank next to an '83 (non-SE) tank.

What am I going to find when I drop my '85 non-SE? I suppose if it looks like the '83 I just cap the 3 lines and drill a hole for the Aeromotive kit. If it looks like the '85 SE, is the hole already the right size?

#10

ancient wizard...

Personal opinion here...been doing a lot of research on aftermarket FI systems and while initially i liked a lot of features of Fitech's systems and their price,i have found enough repetitive negative reviews of their systems after very short periods after install and their horrible customer service,their command control center that allows you to keep your carb fuel system to feed their throttle body system that repeatedly vapor locks,has flooding problems from the carb style needle seat/float switch,has its own slew of negative feedback and again pitiful customer support.

I see a lot of people happy with their Fitech systems,also see a lot that go back to carbs or switch to another brand of retrofit FI from repeated component failures in their systems and lack of customer support/service after the sale from them. Not hard to find reviews online,lots of forums with info good and bad.

Have not followed up on Fitech's Hyperfuel surge tank systems,but being jaded about what i've already learned about their products/customer service,personally wouldn't consider it for that reason and another which is not wanting any more fuel related connections/components in engine compartment than necessary-especially over top of hot exhaust components. At the very least durability/vaporlock/tuning/driveability issues,at worst concerns of fire.

I think the Aeromotive in tank route would be the cleanest,most like oe regarding durability and silent operation and having enough reserve to supply later turbo upgrades for the money. Only thing you need to do is give it enough current to work properly like i outlined in your other thread. I believe the mounting hole is 3.5" and several holes need to be drilled around the circumference of drilled hole for mounting pump assembly. Appears to be pretty easy install to non SE tank,not sure of dimension of exposed part of pump assembly on top of tank when considering clearance for tank mounting,but it would be very close to dimension of original SE pickup tube mounting plate/lines and maybe not an issue at all. Non SE tank is dimensionally same as SE tank and removing/capping existing feed/return lines is not difficult.

I see a lot of people happy with their Fitech systems,also see a lot that go back to carbs or switch to another brand of retrofit FI from repeated component failures in their systems and lack of customer support/service after the sale from them. Not hard to find reviews online,lots of forums with info good and bad.

Have not followed up on Fitech's Hyperfuel surge tank systems,but being jaded about what i've already learned about their products/customer service,personally wouldn't consider it for that reason and another which is not wanting any more fuel related connections/components in engine compartment than necessary-especially over top of hot exhaust components. At the very least durability/vaporlock/tuning/driveability issues,at worst concerns of fire.

I think the Aeromotive in tank route would be the cleanest,most like oe regarding durability and silent operation and having enough reserve to supply later turbo upgrades for the money. Only thing you need to do is give it enough current to work properly like i outlined in your other thread. I believe the mounting hole is 3.5" and several holes need to be drilled around the circumference of drilled hole for mounting pump assembly. Appears to be pretty easy install to non SE tank,not sure of dimension of exposed part of pump assembly on top of tank when considering clearance for tank mounting,but it would be very close to dimension of original SE pickup tube mounting plate/lines and maybe not an issue at all. Non SE tank is dimensionally same as SE tank and removing/capping existing feed/return lines is not difficult.

Last edited by GSLSEforme; 01-30-19 at 12:45 PM.

#11

This was bugging me, and if I'm going to order more parts I needed to know, so I dropped the tank. Sure enough, inlet/outlet match the diameter of the lines in the engine bay so there must just be a different SE cap to the tank. Hoses were sealed up, but looked pretty dry so I'm glad I at least dropped it to inspect.

Not sure if I can just drill more holes for the Aeromotive kit or what... maybe an adapter plate?

Not sure if I can just drill more holes for the Aeromotive kit or what... maybe an adapter plate?

#12

ancient wizard...

Iím looking at your pics from my phone and canít see a lot of detail. I will look at them on my pc when I get home later. What is the depth from opening to floor of tank? What is the height of lines coming out from top of tank?

#13

I couldn't find the diameter of the Aeromotive unit in their documentation but I did read that you need to cut a 3-1/4" hole. I guessed that it was maybe 4.5" in diameter which is too big to fit anywhere but the factory location. There is plenty of clearance below and I think enough above. The problem is just that lip that is on the factory opening which will likely cause problems with drilling the holes and sealing it up. It looks like it is spot welded on and if I can get it off without introducing any holes, the new hole I need to cut is larger than the current opening and the lip.

Last edited by chuyler1; 01-30-19 at 02:55 PM.

#15

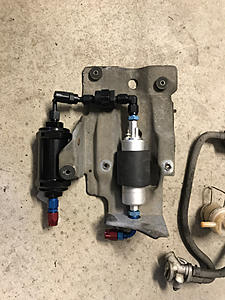

Some more thoughts. The Aeromotive kit is not going to soak up all the gas in the tank, even with its baffle I'm guessing it will run dry at 1/8 tank under normal driving. The bottom of the tank is toward the front which is why the pipes on the OEM unit have a bend in them. I think the best approach is to just make my own plate for the OEM hole, add in some AN fittings, bend some hard line and get an in-tank pump right where the original pickup was. Maybe use one of those Holley mats on the end. Basically duplicate what these kits do but tailored for my application. I'll use the in-line filter and check valve I already have and place those where the original fuel pump was. Then hard lines to the front. Is that nickel/copper line you suggested good for inside the tank? I just gotta add up what fittings I would need and see how much that will cost.

#16

ancient wizard...

Yes,nickel copper line suitable for inside tank. You'd need to put a stabilizing bracket to mount pump to,recommend using 3/16" aluminum or anodized steel plate to minimize wobbling and possible cracking from weight of pump/wiring/pickup on it. Look at Tanks Inc. GPA-4 pump for ideas. Look at Holley 12-130 retrofit pump module with hydramat. It's 255 lph which would be enough for NA,maybe not for turbo retrofit. Not sure if it can be specd with 340lph pump that would give your system some reserve for turbocharging.

#17

The pump needs to be offset quite a bit, if the two lines are hard lines except for a small rubber hose to link the pump to the line, and the other side of the line is connected with AN hardline adapters, would i still need a stabilizing rod?

I'm thinking, cutting a piece of aluminum that matches the original cover (or just hacking up the original). Attaching 3 -6AN bulkhead fittings with PTFE washers and a 2-wire bulkhead connector. On the bottom side, 2 -6AN to 3/8 hardline adaptors to connect two pipes that snake down to the original pickup location. The one for the pump will be shorter so I can attach the pump and pickup sleeve.

Or I can just duplicate the exact original pickup with 3/8 line and keep the pump in the factory location like I originally planned, just with 3/8 line all the way.

I'm thinking, cutting a piece of aluminum that matches the original cover (or just hacking up the original). Attaching 3 -6AN bulkhead fittings with PTFE washers and a 2-wire bulkhead connector. On the bottom side, 2 -6AN to 3/8 hardline adaptors to connect two pipes that snake down to the original pickup location. The one for the pump will be shorter so I can attach the pump and pickup sleeve.

Or I can just duplicate the exact original pickup with 3/8 line and keep the pump in the factory location like I originally planned, just with 3/8 line all the way.

#18

Just started looking at the Holley kit. I had seen it before in my searching but didn't go through all the specs. I like the hydra mat better than the Aeromotive silo simply because the mat will reach down to the lower part of the tank. I've been known to run my cars until 10-20 miles past the low fuel light. I can also probably bend the support bracket or make a new one to get the pump even closer to the right spot. The Holley setup also looks pretty low profile and doesn't require cutting holes, so there will be no issue getting it to seal against the OEM location. I'll double check the dimensions, then the hard part is going to be making a 3-1/4" round hole out of that factory opening without a center point to guide a hole saw.

Do you have recommendations on affordable tube bending tools? I was reading reviews on Amazon and Summit Racing and cannot decide what would be a good investment that won't break the bank.

Do you have recommendations on affordable tube bending tools? I was reading reviews on Amazon and Summit Racing and cannot decide what would be a good investment that won't break the bank.

#19

ancient wizard...

I always err on more stout side of things when it comes to electrical circuits and fabrication. Prefer to do things once,with my mind's eye on how things are designed and constructed from an oem standpoint to last as long as possible. I hate having to go back and revisit something for a 2nd time. I'm one and done oriented.

I've been doing research on converting my trucks fuel tank from carb to FI and still considering building pump/pickup for it. For your application i think the lines/pump would have to be reinforced with at least a 90 degree bracket running the majority of length of the pump pickup to mounting plate,and more likely a C channel bracket to contain the attaching points for feed/return lines and solid mounting of fuel pump and a place to zip tie power supply wires for the pump. When you consider vibration from rough roads,G forces imparted from turning,braking,accelerating and the multidirectional push of 13 gallons of fuel(36 gallons in my truck),i feel that's too much stress and strain on metal fuel lines alone. First point of failure would be where they are soldered in place in your cover plate ,there may be harmonics set up at some rpm or road speed point that could lead to cracking any where along the unsupported assembly. Look at Tanks Inc. GPA-4 setup to see what i mean. There is also the concern of getting power/ground wires thru and sealed in mounting plate of pump/pickup.

I have enough skills to fabricate pretty much what i need but sometimes it's more expedient to plunk down your money for a well designed/built product(with a warranty?) that's real close to what you need and massage it to suit your application. In my case i would love to use the Aeromotive pump in my tank but my tank is too deep to use it without buying their extender kit for almost $200 more for a ball park of @$700. I have time to sort thru a solution i'm sure to come up with without spending that type of coin.In your case i think the Holley 12-130 pump/hydramat combo would be your best bet for a near bolt in setup.

Even better would be their 12-131 pump/with hydramat. This is a returnless system meaning you only need 1 supply line from pump to Fuel rail on engine,the regulator is in the pump unit. This technology is used on most modern cars and cuts down on fuel system complexity and cost. In your case,you could do away with your underhood fuel regulator and associated plumbing and cost for those components. You would actually save time and money this way,even though pump costs@$50 more,you don't have the extra cost of running 2 fuel lines from back to front of car and cost of regulator,more fuel line and fittings...much cleaner setup. Holley's system is regulated at 60 PSI,see what the system requirements you're using are and see if you can use this system.

As far as tubing benders,one of a couple reasons i like to use the copper/nickle tubing is it's more friendly to bending/routing than steel tubing is,easier to work with,a lot of bends can be done by hand. It comes in 25' rolls for about $35 depending where you're located. Tubing benders,one made by Lisle #44000,about $19 is handy. Another i use can be found at Jegs #80089 @ $20. Mine,i got from Snap-On,most likely made by Lisle for them. The one at Jegs looks identical,so likely Lisle too. I have used different size sockets and pieces of sched 40 PCV pipe to make particular radius bends

I've been doing research on converting my trucks fuel tank from carb to FI and still considering building pump/pickup for it. For your application i think the lines/pump would have to be reinforced with at least a 90 degree bracket running the majority of length of the pump pickup to mounting plate,and more likely a C channel bracket to contain the attaching points for feed/return lines and solid mounting of fuel pump and a place to zip tie power supply wires for the pump. When you consider vibration from rough roads,G forces imparted from turning,braking,accelerating and the multidirectional push of 13 gallons of fuel(36 gallons in my truck),i feel that's too much stress and strain on metal fuel lines alone. First point of failure would be where they are soldered in place in your cover plate ,there may be harmonics set up at some rpm or road speed point that could lead to cracking any where along the unsupported assembly. Look at Tanks Inc. GPA-4 setup to see what i mean. There is also the concern of getting power/ground wires thru and sealed in mounting plate of pump/pickup.

I have enough skills to fabricate pretty much what i need but sometimes it's more expedient to plunk down your money for a well designed/built product(with a warranty?) that's real close to what you need and massage it to suit your application. In my case i would love to use the Aeromotive pump in my tank but my tank is too deep to use it without buying their extender kit for almost $200 more for a ball park of @$700. I have time to sort thru a solution i'm sure to come up with without spending that type of coin.In your case i think the Holley 12-130 pump/hydramat combo would be your best bet for a near bolt in setup.

Even better would be their 12-131 pump/with hydramat. This is a returnless system meaning you only need 1 supply line from pump to Fuel rail on engine,the regulator is in the pump unit. This technology is used on most modern cars and cuts down on fuel system complexity and cost. In your case,you could do away with your underhood fuel regulator and associated plumbing and cost for those components. You would actually save time and money this way,even though pump costs@$50 more,you don't have the extra cost of running 2 fuel lines from back to front of car and cost of regulator,more fuel line and fittings...much cleaner setup. Holley's system is regulated at 60 PSI,see what the system requirements you're using are and see if you can use this system.

As far as tubing benders,one of a couple reasons i like to use the copper/nickle tubing is it's more friendly to bending/routing than steel tubing is,easier to work with,a lot of bends can be done by hand. It comes in 25' rolls for about $35 depending where you're located. Tubing benders,one made by Lisle #44000,about $19 is handy. Another i use can be found at Jegs #80089 @ $20. Mine,i got from Snap-On,most likely made by Lisle for them. The one at Jegs looks identical,so likely Lisle too. I have used different size sockets and pieces of sched 40 PCV pipe to make particular radius bends

#20

ancient wizard...

Is that last pic with the "template" on tank opening,is that 3.25" id ? If so i would mark that outline with a sharpie and cut out what's not needed. Perfect tool for this would be an air powered zipsaw/hacksaw with 1/4" metal cutting blade and a fine metal burr in a die grinder or dremel tool. Being able to leave that spot welded collar on the tank will make finished product more rigid.

#21

Everything you said makes sense. Thanks for hashing things out for me. I've been searching on and off for a few days looking for others that have made similar modifications but can't really find good info on the internet. The Holley kits seem well sorted and I'm going to double check the measurements more carefully when I get home and make a decision.

As far as a return-less system goes, I suppose that is an option too and I did poke around on Holley's website and saw that kit too. I already have a bunch of fittings and a regulator I was going to install, but not having all that stuff in the engine bay does clean things up significantly. I researched return-less setups when I was working on my REPU because space at the end of the fuel rail was tight. The regulator had two high pressure ports and one return port. I ended up using one of those as the feed line, the other is a line that dead ends at the fuel rail. It works, as both ports see the same pressure regardless of what the return is doing. The only fuel that doesn't get cycled through the system is a small amount in the hose that runs from the regulator to the rail. Anyway, my reading on the return-less vs return system led me toward it being a cost reduction solution more than a performance solution. For me right now, the only cost savings would be a few fittings and another run of 3/8 hard line. I've got plenty of fittings and enough 6an hose to complete the job. So I don't know.

The last pic is a 3.25" I.D. cutout with a 4.5" O.D. diameter. Holley documentation says their module is 4.8" total (if I'm reading the right spec). It should be fine, even if it goes over the edge a bit, the bolts are inset compared to the Aeromotive unit and have those cam style lobes that will just stop if they hit something in the way. I don't think I can leave that lip on the opening. If I were to cut out the right size opening, the unit would have trouble sealing since there are notches in the ring where the spot welds were made. It seems best to just drill out the welds, take the ring off, then cut a hole. Perhaps a hole saw will actually work if I balance it against the protruding lip and start slow. Once it bites, it should stay in it's track.

BTW, I'm the same as you. I'd rather do this once the right way, even if it costs a little more. I enjoy the research just as much as the wrenching. I also get satisfaction in not cutting corners and keeping things fully functional, like the EVAP system and OMP and the Cruise Control. Sure, I could vent to air, sure I could premix, but those are little things that will get in the way of enjoying the vehicle regularly.

As far as a return-less system goes, I suppose that is an option too and I did poke around on Holley's website and saw that kit too. I already have a bunch of fittings and a regulator I was going to install, but not having all that stuff in the engine bay does clean things up significantly. I researched return-less setups when I was working on my REPU because space at the end of the fuel rail was tight. The regulator had two high pressure ports and one return port. I ended up using one of those as the feed line, the other is a line that dead ends at the fuel rail. It works, as both ports see the same pressure regardless of what the return is doing. The only fuel that doesn't get cycled through the system is a small amount in the hose that runs from the regulator to the rail. Anyway, my reading on the return-less vs return system led me toward it being a cost reduction solution more than a performance solution. For me right now, the only cost savings would be a few fittings and another run of 3/8 hard line. I've got plenty of fittings and enough 6an hose to complete the job. So I don't know.

The last pic is a 3.25" I.D. cutout with a 4.5" O.D. diameter. Holley documentation says their module is 4.8" total (if I'm reading the right spec). It should be fine, even if it goes over the edge a bit, the bolts are inset compared to the Aeromotive unit and have those cam style lobes that will just stop if they hit something in the way. I don't think I can leave that lip on the opening. If I were to cut out the right size opening, the unit would have trouble sealing since there are notches in the ring where the spot welds were made. It seems best to just drill out the welds, take the ring off, then cut a hole. Perhaps a hole saw will actually work if I balance it against the protruding lip and start slow. Once it bites, it should stay in it's track.

BTW, I'm the same as you. I'd rather do this once the right way, even if it costs a little more. I enjoy the research just as much as the wrenching. I also get satisfaction in not cutting corners and keeping things fully functional, like the EVAP system and OMP and the Cruise Control. Sure, I could vent to air, sure I could premix, but those are little things that will get in the way of enjoying the vehicle regularly.

#22

Banned

iTrader: (40)

The following users liked this post:

Richard Miller (01-31-19)

#23

ancient wizard...

What model pump did you use and how long in service,miles? Any issues with driveability with low fuel level in tank?

#24

ancient wizard...

The pump needs to be offset quite a bit, if the two lines are hard lines except for a small rubber hose to link the pump to the line, and the other side of the line is connected with AN hardline adapters, would i still need a stabilizing rod?

I'm thinking, cutting a piece of aluminum that matches the original cover (or just hacking up the original). Attaching 3 -6AN bulkhead fittings with PTFE washers and a 2-wire bulkhead connector. On the bottom side, 2 -6AN to 3/8 hardline adaptors to connect two pipes that snake down to the original pickup location. The one for the pump will be shorter so I can attach the pump and pickup sleeve.

Or I can just duplicate the exact original pickup with 3/8 line and keep the pump in the factory location like I originally planned, just with 3/8 line all the way.

I'm thinking, cutting a piece of aluminum that matches the original cover (or just hacking up the original). Attaching 3 -6AN bulkhead fittings with PTFE washers and a 2-wire bulkhead connector. On the bottom side, 2 -6AN to 3/8 hardline adaptors to connect two pipes that snake down to the original pickup location. The one for the pump will be shorter so I can attach the pump and pickup sleeve.

Or I can just duplicate the exact original pickup with 3/8 line and keep the pump in the factory location like I originally planned, just with 3/8 line all the way.

#25

I was thinking the smallest hydramat they sell on the end of a 3/8" bent tube. But I think just going with the complete holley kit is the best approach. The long hydramat will reach the same pickup point as the stock system. It has a small cutout with no additional holes to drill and is low profile.