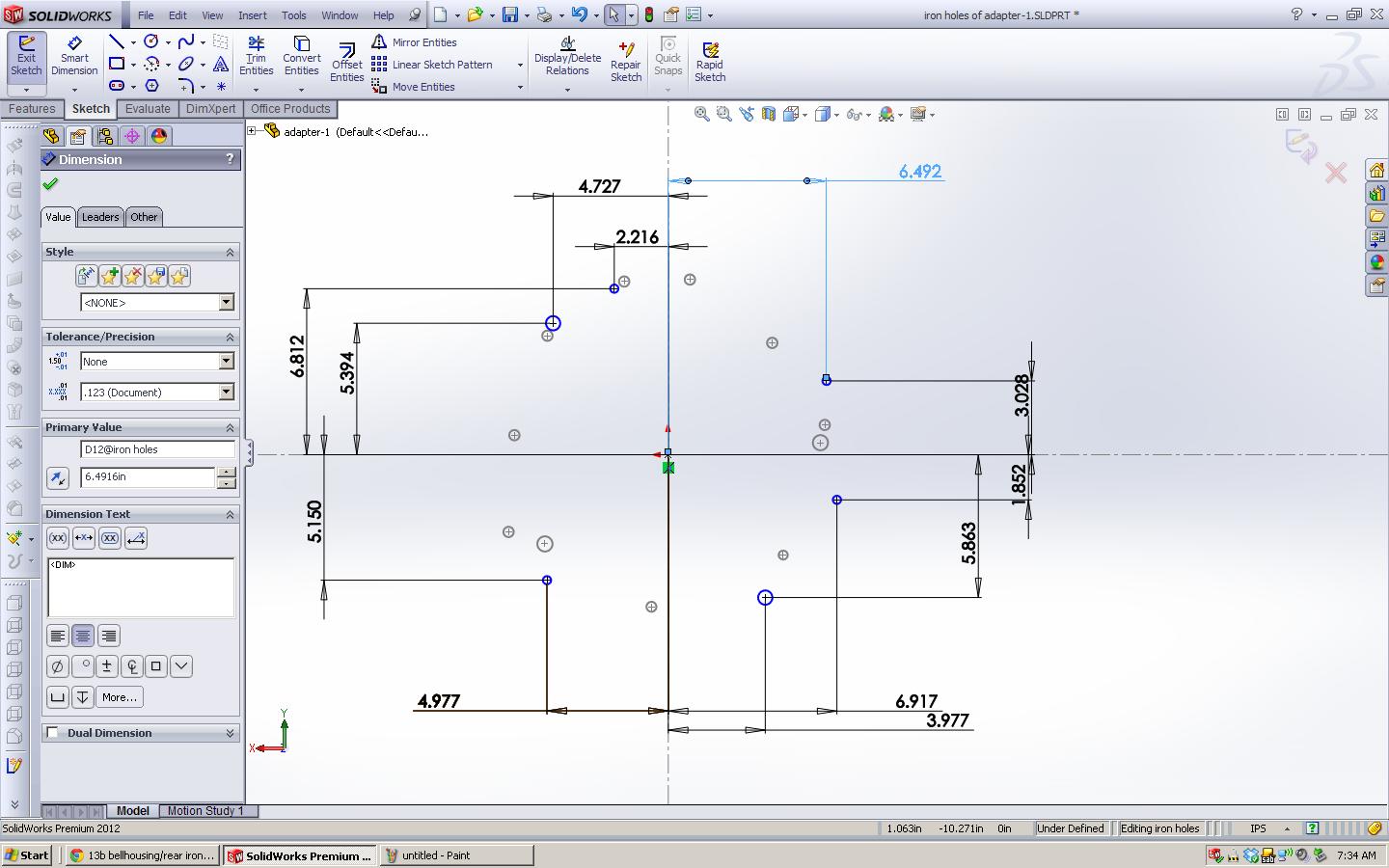

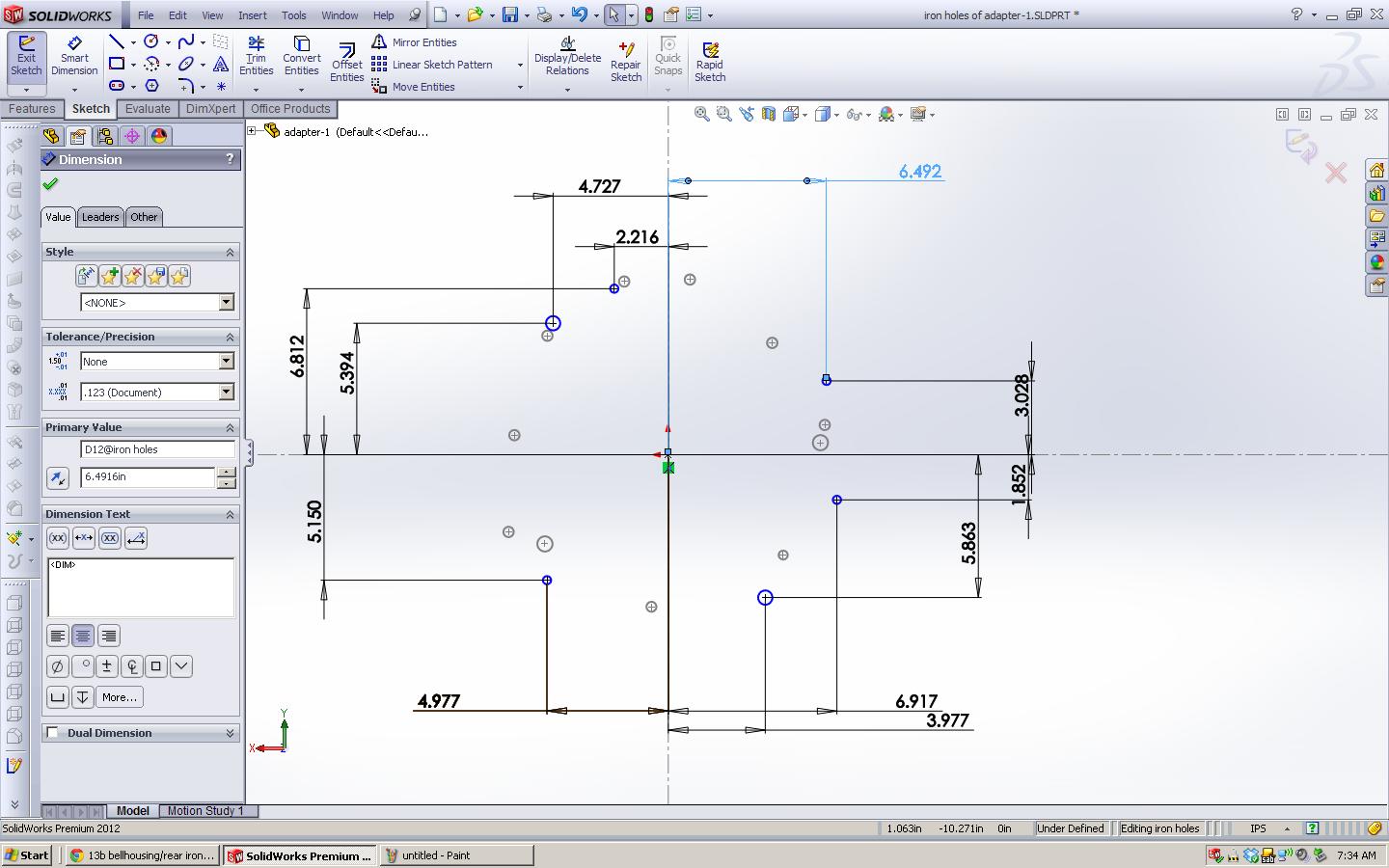

13b bellhousing/rear iron bolt pattern w/ dimensions

#3

Learned alot | Alot to go

iTrader: (2)

Join Date: Apr 2002

Location: Rotaryland, New Hampshire

Posts: 4,232

Likes: 0

Received 0 Likes

on

0 Posts

I havent double checked these yet, so id pull some measurements yourself before making anything

Ignore the grey holes, they are for a non-mazda transmission

They were pulled from a s4 t2 rear iron.

-Jacob

Ignore the grey holes, they are for a non-mazda transmission

They were pulled from a s4 t2 rear iron.

-Jacob

Last edited by CrackHeadMel; 01-01-13 at 06:36 AM.

#4

Sen, yup, for an adapter plate. I already have one made but it could be considered a prototype at best and I want a much cleaner, and easier to make one this time around. I don't have a set of calipers large enough to get measurements.

Jacob, thanks very much! If you don't mind my asking, what did you use to get the measurements?

I also sent Mazda USA an e-mail asking for this information, if/when I get a response I'll post what they say.

Jacob, thanks very much! If you don't mind my asking, what did you use to get the measurements?

I also sent Mazda USA an e-mail asking for this information, if/when I get a response I'll post what they say.

#5

Old [Sch|F]ool

Those gray holes look a little bit like the VWAG dual bolt pattern transaxles built starting in 1988 or so.

If that's the case, this is really relative to my interests

I personally took a dead smoothcase trans, cut the front housing off just aft of the front bulkhead, removed the input shaft from the remains of the geartrain, and re-inserted it into the case. Plan is/was to adapt the smoothcase to a VW four for RWD conversion of something else. There are certain synchronicities that make this a viable project. I was just going to dial-indicate the mockup against an engine and build the adapter in place.

If that's the case, this is really relative to my interests

I personally took a dead smoothcase trans, cut the front housing off just aft of the front bulkhead, removed the input shaft from the remains of the geartrain, and re-inserted it into the case. Plan is/was to adapt the smoothcase to a VW four for RWD conversion of something else. There are certain synchronicities that make this a viable project. I was just going to dial-indicate the mockup against an engine and build the adapter in place.

#6

Learned alot | Alot to go

iTrader: (2)

Join Date: Apr 2002

Location: Rotaryland, New Hampshire

Posts: 4,232

Likes: 0

Received 0 Likes

on

0 Posts

Vally,

I took the measurements with a mitatoyo digital height gauge that's in current iso calibration. Im going to do it one more time just to be sure.

Peejay,

your close.. its more of the 2001 era. Now if i could only find a way to make a starter fit without cutting anything.

Ill post pics when i actualy machine something. Right now its just a block of 7075 hanging around

-Jacob

I took the measurements with a mitatoyo digital height gauge that's in current iso calibration. Im going to do it one more time just to be sure.

Peejay,

your close.. its more of the 2001 era. Now if i could only find a way to make a starter fit without cutting anything.

Ill post pics when i actualy machine something. Right now its just a block of 7075 hanging around

-Jacob

#7

Old [Sch|F]ool

Again, relevant to my interests

I've been steadily amassing much four- and five-cylinder performance hardware. But you're thinking of going the OTHER direction, of course.

I've been steadily amassing much four- and five-cylinder performance hardware. But you're thinking of going the OTHER direction, of course.Two questions - are you planning on a 225 or 240mm clutch disc? If 225, do you think you'd have room to cut out part of the top-left of the transmission to clear the topmount starter? They stopped using them in '73 but all engines up to 1992 are machined to use it. I THINK the 016's slave cylinder is lower than that, but you're not using an 016...

Trending Topics

#8

Learned alot | Alot to go

iTrader: (2)

Join Date: Apr 2002

Location: Rotaryland, New Hampshire

Posts: 4,232

Likes: 0

Received 0 Likes

on

0 Posts

Wow! Nice. Same thing actually, it's a combination of the inline four and inline fove bolt patterns. Nutshell - the 016 transmissions (everything up to 1991) (in North America) were only made with the five/V6/V8 pattern, while the 01A ('88-up small chassis) and 01E (S-car heavy duty big mammajamma) were dual pattern.

Again, relevant to my interests I've been steadily amassing much four- and five-cylinder performance hardware. But you're thinking of going the OTHER direction, of course.

I've been steadily amassing much four- and five-cylinder performance hardware. But you're thinking of going the OTHER direction, of course.

Two questions - are you planning on a 225 or 240mm clutch disc? If 225, do you think you'd have room to cut out part of the top-left of the transmission to clear the topmount starter? They stopped using them in '73 but all engines up to 1992 are machined to use it. I THINK the 016's slave cylinder is lower than that, but you're not using an 016...

Again, relevant to my interests

I've been steadily amassing much four- and five-cylinder performance hardware. But you're thinking of going the OTHER direction, of course.

I've been steadily amassing much four- and five-cylinder performance hardware. But you're thinking of going the OTHER direction, of course.Two questions - are you planning on a 225 or 240mm clutch disc? If 225, do you think you'd have room to cut out part of the top-left of the transmission to clear the topmount starter? They stopped using them in '73 but all engines up to 1992 are machined to use it. I THINK the 016's slave cylinder is lower than that, but you're not using an 016...

One thing i really like about it is i don't have to flip or invert it, its already pointing the right way

I haven't decided on a clutch at all yet. The t2 flywheel will not even pretend to fit within the 012 / g86 bell-housing so I am waiting on a cosmo flex-plate to arrive and I am going to either make an adapter to mount a vw flywheel, or my preferred route will be to make a button flywheel and use whatever clutch pressure plate i want as long as its got the correct splines for the transmission. I like the button flywheel idea as I can make an aluminium one to whatever weight i want and just make a steel friction surface, no need for a ring gear as the flex-plate will do all the starting duty

I am actually hopping to use a starter in the typical rotary starter location and really hopping i can avoid notching the bell housing, sadly i got rid of all my starters in a fire sale a month or two ago, and no have none for test fitment

-Jacob

#9

I just got an e-mail from Mazda USA Customer Assistance Center. Needless to say it was less than helpful. They basically told me to purchase the FSM. I called the person to clarify my requirements and that what I'm looking for isn't in the FSM. In trying to inquire further I was more or less told that they rely on dealerships for technical data. So... I'm going to call a dealership in the next few days and see if I can find some hidden listing for something resembling an archival or engineering department.

Jacob, I made an AutoCAD drawing of the adapter plate layout using your first measurements and double checked one for its distance from center and it appears more or less correct. If by weeks end I've not heard back I'll see if I can make the new plate and report how it goes. I already made a block to reposition the slave cylinder and inch forward and trimmed the rod.

Jacob, I made an AutoCAD drawing of the adapter plate layout using your first measurements and double checked one for its distance from center and it appears more or less correct. If by weeks end I've not heard back I'll see if I can make the new plate and report how it goes. I already made a block to reposition the slave cylinder and inch forward and trimmed the rod.

#11

Follow up:

Good news, Jacob's measurements are very well done. I checked two of the holes with my smaller calipers and got about the right reading (hand calipers and only good for a ballpark figure). I remade my plate on a Mill recently and everything lined up excellently. When everything was installed on the engine with my flywheel/pilot bearing adapter the transmission spun easily by hand (I was spinning it using the output shaft) when in any gear and would continue spinning when I would give it a flick then let go in 5th (another 90 degrees or so depending).

Of note, IIRC, all of the transmission bolts are M10x1.25. The end of the input shaft is 15mm (~0.59"). The two guides for the bell housing are slightly under 15mm OD. I made two short rods that would stick out of my adapter plate ~0.4" with a rounded edge and an OD of ~0.588". I recommend (depending on what you can do or have access too) hardening the threads on the plate at a minimum. If you are able I would recommend welding nuts on the backside of the plate. Weld-in hardened threaded inserts are also good.

Good news, Jacob's measurements are very well done. I checked two of the holes with my smaller calipers and got about the right reading (hand calipers and only good for a ballpark figure). I remade my plate on a Mill recently and everything lined up excellently. When everything was installed on the engine with my flywheel/pilot bearing adapter the transmission spun easily by hand (I was spinning it using the output shaft) when in any gear and would continue spinning when I would give it a flick then let go in 5th (another 90 degrees or so depending).

Of note, IIRC, all of the transmission bolts are M10x1.25. The end of the input shaft is 15mm (~0.59"). The two guides for the bell housing are slightly under 15mm OD. I made two short rods that would stick out of my adapter plate ~0.4" with a rounded edge and an OD of ~0.588". I recommend (depending on what you can do or have access too) hardening the threads on the plate at a minimum. If you are able I would recommend welding nuts on the backside of the plate. Weld-in hardened threaded inserts are also good.

The following users liked this post:

Jamiesss (03-24-22)

#14

does anyone know if the s4 and s5 share the same rearplate/g box bolt hole pattern with a s6 rear plate.

im looking to get this

In Development: PR TREMAC T56 Magnum Adapter Plate | Pettit Racing

but i own a fc, so im hoping i can use a s5 bell housing with the pettit adaptor or at worst use the s6 bellhousing.

thanks in advance

josh

im looking to get this

In Development: PR TREMAC T56 Magnum Adapter Plate | Pettit Racing

but i own a fc, so im hoping i can use a s5 bell housing with the pettit adaptor or at worst use the s6 bellhousing.

thanks in advance

josh

#18

thanks guys, just needed some confirmation.

heres the difference between manual and auto

https://www.rx7club.com/3rd-generati...d-help-925714/

heres the difference between manual and auto

https://www.rx7club.com/3rd-generati...d-help-925714/

#19

granted most people never run into an issue with using just 4 mount bolts on swapped engines/trannies. it also leaves a gap for the flywheel to be exposed.

Last edited by RotaryEvolution; 09-02-13 at 12:33 PM.

#21

1 bolt is missing from the bellhousing mount to the rear iron(2 different rear irons). the older gen autos were direct but the later gens you could only use 4 mounting bolts as the starters bolted to the side of the engine instead of inside the bellhousing(renesis, RE and REW). this flat starter mount omitted one mount hole for the manual transmission.

Peejay, I never even gave the 13A a thought.

#22

Old [Sch|F]ool

Nobody ever does  Just being a pissant pedant is all, don't mind me.

Just being a pissant pedant is all, don't mind me.

I've never played with one either, but I bet that the bellhousing changeup happened at the same time they eliminated the notch at the top for the topmount starter, which also served as the access hole for the flexplate to torque converter nuts. I know FCs have the notch and FDs don't. From the description of how the starter attaches, the mounting was changed so as to provide access to those nuts once the starter is removed.

Just being a pissant pedant is all, don't mind me.

Just being a pissant pedant is all, don't mind me.I've never played with one either, but I bet that the bellhousing changeup happened at the same time they eliminated the notch at the top for the topmount starter, which also served as the access hole for the flexplate to torque converter nuts. I know FCs have the notch and FDs don't. From the description of how the starter attaches, the mounting was changed so as to provide access to those nuts once the starter is removed.

#23

actually looks like i was incorrect, but i do still somewhat remember one version not having the top driver side mount hole, here is a picture of an REW auto iron and it has the mount hole. it's not like the autos are all that common on anything aside from the MSP engine anyways.

it does have the unused mount hole between that one at the top center.

it does have the unused mount hole between that one at the top center.

Last edited by RotaryEvolution; 09-03-13 at 12:23 PM.

#24

Junior Member

[QUOTE=peejay;11331655]Those gray holes look a little bit like the VWAG dual bolt pattern transaxles built starting in 1988 or so.

Just stumbled upon this thread while looking for the bellhousing bolt pattern. I'm adapting my gearbox to a VW VR5 and the fact that you lads are talking about Audi engines is a bit uncanny seeing as though VW used the same bolt pattern as Audi in many of their early 2000's engines, and as a matter of fact my VR5 that I bought off eBay came with an O1E adaptor plate bolted to it. Anyways thanks for the help

Just stumbled upon this thread while looking for the bellhousing bolt pattern. I'm adapting my gearbox to a VW VR5 and the fact that you lads are talking about Audi engines is a bit uncanny seeing as though VW used the same bolt pattern as Audi in many of their early 2000's engines, and as a matter of fact my VR5 that I bought off eBay came with an O1E adaptor plate bolted to it. Anyways thanks for the help

Thread

Thread Starter

Forum

Replies

Last Post

at least now I know that I can use an 01A until I can get my hands on a 01E (these SOBs are still pretty expensive).

at least now I know that I can use an 01A until I can get my hands on a 01E (these SOBs are still pretty expensive).