Will Dyno My GT35/40 in 2 weeks. Wanna take a stab at what numbers to expect?

#77

Mad Man

Originally Posted by pluto

if I remembered correctly, David's boost guage reading is tied to the UIM (those two nipples) where the rest of the senstitive conponents (boost control, map sensor, and fuel pressure) is tied by the factory OEM map pickup location. This could explain why his gauge shows oscillation while the map and boost reference for ECU and boost controller is fine.

For those that have a hard time understanding feedback and control systems, you should look at the manufactures manual under *tech* link and Greddy profec B spec II in Greddy's website.

It is very straight forward on how to install it.

If you want to learn more on how control and feedback systems work, you can also get this book in here.

http://www.amazon.com/exec/obidos/AS...358966-0548066

This is the same author/book I studied when I was in college but is an updated version. Eventhough most of the concept applies to electrical in this book, the principle and concept remains the same in both electrical and mechanical. After you read it, I'm not expecting you to understand the math behind it since most feedback system's are calculated in laplace transform (diff eq) but the literature explains a great detail on what and how feedback system works. you'll grasp higher understanding on overshoot and undershoot charteristics in control systems and how to eliminate it along with filtration for frequency resonances in a feedback system.

hope that helps for those who are curious why things were done in a certain way

For those that have a hard time understanding feedback and control systems, you should look at the manufactures manual under *tech* link and Greddy profec B spec II in Greddy's website.

It is very straight forward on how to install it.

If you want to learn more on how control and feedback systems work, you can also get this book in here.

http://www.amazon.com/exec/obidos/AS...358966-0548066

This is the same author/book I studied when I was in college but is an updated version. Eventhough most of the concept applies to electrical in this book, the principle and concept remains the same in both electrical and mechanical. After you read it, I'm not expecting you to understand the math behind it since most feedback system's are calculated in laplace transform (diff eq) but the literature explains a great detail on what and how feedback system works. you'll grasp higher understanding on overshoot and undershoot charteristics in control systems and how to eliminate it along with filtration for frequency resonances in a feedback system.

hope that helps for those who are curious why things were done in a certain way

Perhaps you can enlighten us as to why you think measuring pressure at the compressor is better than at the UIM. If you know the answer, why refer us to a text book, instead of simply explaining what you are thinking? I suppose if a particular boost controller does a poor job of avoiding overshoot, then reading at the compressor is safer than the actual pressure that the engine is seeing, but it would seem that buying a better boost controller might be in order, assuming that the boost control issue cannot be solved.

I am not attacking you, nor do I claim to have equal knowledge when it comes to tuning. I am simply making an observation, and asking a question.

Anyone have the FD3S diagram Greddy mentions on their site? The only reason to measure at the compressor, is to give the device more time to react. Wher do MOTEC, Haltech, AEM, and Microtech want you to read pressure for purposes of engine control systems? Nuff said... Carl

#78

Rotary Freak

Join Date: Feb 2001

Location: fort worth, tx, usa

Posts: 1,926

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by Carl Byck

Arrogance is not a trait to be proud of, and put on public display. When I questioned you on another thread about reading off the compressor, you said that generally you did not, and that the UIM was the best place. I can find the quote if you like. Nobody is having trouble understanding anything other than why Davids car behaved the way that it did.

Being Arrongant? Hardly, but for some reason you still questioned something I already answered you previously. Instead of answering the same questions again, I simply linked you to the proper page so that you can read it yourself. Feedback system is not something that can be explained in a couple sentence so who else has more credential to explain feedback system than a professor who wrote the book about it?

Hereís the reply I made previously from the other post, if you reread it again, youíll see that I never mentioned anything about using the turbo outlet for signal reference.

__________________________________________________ _____________________

Carl,

for an electonic boost control, the boost reading is always read from the intake manifold (the least harmonic point). However, the solenoid lines are tied as close to the turbo as possible to prevent any boost fluctuation. If the boost line and the boost reference line are at the intake manifold (where most people tied to the same reference point as the boost guage), you'll see a noticable boost fluctuation as the port opens and closes. This is the same concept why we have fuel pulsation damper to prevent fuel pressure stability. Generally, Boost reading should be tied as close to the stock map sensor pickup (by the throttle body) and the solenoids pickup point as close to the turbo as possible. If you're running a manual boost control, the pickup line is generally as close to the turbo as possible since it creates the least amount of harmonics in the system.

You have to remember that both the manual boost control and electronic boost control operates differently. Manual controller is a passive device/system where as the electronic boost controller is an active device/system.

manual boost control restricts the air flow (pressure) to the wastegate to allow the boost to come up based on the restriction.

Electronic boost controller reads the boost level at the manifold and then sends the correct duty cycle to the solenoid to restrict the wastegate flow accordingly.

Hope that makes sense?

__________________________________________________ _____________

If youíre still referring to David Preeceís boost problem, All I did was simply band aid the boost problem he has by placing his signal line outside of the throttle body to prevent boost oscillation so that I can continue with the tuning.

Originally Posted by Carl Byck

Search Steve Kan, you will see that an inordinate number of eople have "boost control issues" during your sessions. You are without a doubt a competent tuner, that said, I would think you would want answers as to why so many cars you tune have this problem, while few others ever mention it when refering to their tuning sessions. Are you particularly tuned in to this problem, and everyone else is missing it?

Originally Posted by Carl Byck

I looked at greddy's site, there is a generic diagram, showing that the pressure source to the solenoid S/B On the charge pipe. It also shows a hose going from the UIM to the head unit. Is this how the unit was set up? I think it is worth noting that it is common place for such diagrams to be both generic, and a compromise, in the intrest of simplicity. Blindly following manufacturers recomendations when you consistently have the same issue seems short sighted for a tuner of your reputation. Greddy is notorious for providing mis-information, and terrible customer service, I would use common sense if I encountered a problem with one of their products.

Originally Posted by Carl Byck

Perhaps you can enlighten us as to why you think measuring pressure at the compressor is better than at the UIM. If you know the answer, why refer us to a text book, instead of simply explaining what you are thinking?

Both feed and reference point tied to UIM.

Pressure oscillation due to intake stroke opening/closing. Oscillation read from the boost reference point, boost controller tries to adjust the duty cycle appropriately to offset the oscillation, input feed gets oscillation caused by abnormal input, the input gets oscillated along with constant duty cycle change. Thereíre points where the duty cycle and input feed get cancel or superposition causing the wastegate to oscillate more and less. (most likely 2-4psi fluctuation)

As you can see, there are two problems in this example, one from the feed and the other from the reference. Both trying to work with and against each other. Now, lets try another example.

Feed ties to the compressor output and reference point ties to the UIM.

Pressure oscillation due to intake stroke opening/closing. Oscillation read from the boost reference point, boost controller tries to adjust the duty cycle appropriately to offset the oscillation, input feed gets positive constant pressure from the compressor output, the input stays clean with constant duty cycle change due to reference point being oscillated. Boost controller may react fast enough to offset most of the oscillation (most likely 1-2 psi fluctuation).

Now, you can see that only one variable to deal with instead of two.

Letís try another one. Boost reference by the throttle body and input feed to the turbo.

Pressure oscillation due to intake stroke opening/closing. Reference point was damper from the pleunum reading less oscillation. Boost controller reads it and adjust appropriately and sets the duty cycle for the boost level that was set for. The only difference this time is that the boost controller has less to deal with to set the proper duty cycle within the system. (most likely .5-1psi fluctuation)

Originally Posted by Carl Byck

I suppose if a particular boost controller does a poor job of avoiding overshoot, then reading at the compressor is safer than the actual pressure that the engine is seeing, but it would seem that buying a better boost controller might be in order, assuming that the boost control issue cannot be solved.

Originally Posted by Carl Byck

I am not attacking you, nor do I claim to have equal knowledge when it comes to tuning. I am simply making an observation, and asking a question.

Anyone have the FD3S diagram Greddy mentions on their site? The only reason to measure at the compressor, is to give the device more time to react. Wher do MOTEC, Haltech, AEM, and Microtech want you to read pressure for purposes of engine control systems? Nuff said... Carl

Anyone have the FD3S diagram Greddy mentions on their site? The only reason to measure at the compressor, is to give the device more time to react. Wher do MOTEC, Haltech, AEM, and Microtech want you to read pressure for purposes of engine control systems? Nuff said... Carl

#79

great post Steve, that is the info I like to read.

>>Arrogance is not a trait to be proud of, and put on public display.

Carl, I spent a good amount of time with Steve when he came to MN a few years back for the Midwest Rotary Rally and to tune a few cars. He crashed at my place one of the nights and we also drove together on the 5-6 hour trip from here to Road America where MRR was held. Steve is not an arrogant guy. I'm not a cocky guy and I am WAY more arrogant than steve. ;-) I think you read into his comments wrong carl, thats all.

>>Arrogance is not a trait to be proud of, and put on public display.

Carl, I spent a good amount of time with Steve when he came to MN a few years back for the Midwest Rotary Rally and to tune a few cars. He crashed at my place one of the nights and we also drove together on the 5-6 hour trip from here to Road America where MRR was held. Steve is not an arrogant guy. I'm not a cocky guy and I am WAY more arrogant than steve. ;-) I think you read into his comments wrong carl, thats all.

#80

Mad Man

First, let me say, that when you comment "for those that have a hard time understanding" , that strikes me as arrogant. Perhaps I am over sensitive, sorry for that.

I certainly appreciate the time that you (Steve ) have taken to explain why you are setting the car up this way. What you say make sense. That said, I do not think that it works consistently in practice, further, David Preece's car was built, and set up by you. In addition it his his second time around(blown motor built, and being tuned by you the first time it blew), correct me if I am mistaken.

I know that when I reference boost, and run the solenoid off the UIM My AVCR registers no oscillation that can be discerned while watching the digital display. This is true in my Supra TT, and in my RX7. I have never experienced the oscillations you refer to, and have rock solid steady boost at what ever I set the controller to. So then, why are there these oscillations, and why is he at 88% duty cycle when he should be at a fraction of that based on his injectors? I know what works, and wonder out loud why David is having a problem. Like you, I am trying to help, please consider that as you read this. I am sure with you intimate knowledge of Davids set up, that you will solve both issues. In looking at Davids set up, it seems that he needs an upgraded ignition, and larger pump wires at a minimum. Also, the Supra pump generally does not last at 12V continous, as it is designed for 9V operation, except at WOT. Anyway, your insight, and expertise is appreciated. Perhaps you could speculate on why a set-up(mine) that should be inferior (by way of your explanation) performs better than what is theoretically optimum. Thanks for your time, Carl

I certainly appreciate the time that you (Steve ) have taken to explain why you are setting the car up this way. What you say make sense. That said, I do not think that it works consistently in practice, further, David Preece's car was built, and set up by you. In addition it his his second time around(blown motor built, and being tuned by you the first time it blew), correct me if I am mistaken.

I know that when I reference boost, and run the solenoid off the UIM My AVCR registers no oscillation that can be discerned while watching the digital display. This is true in my Supra TT, and in my RX7. I have never experienced the oscillations you refer to, and have rock solid steady boost at what ever I set the controller to. So then, why are there these oscillations, and why is he at 88% duty cycle when he should be at a fraction of that based on his injectors? I know what works, and wonder out loud why David is having a problem. Like you, I am trying to help, please consider that as you read this. I am sure with you intimate knowledge of Davids set up, that you will solve both issues. In looking at Davids set up, it seems that he needs an upgraded ignition, and larger pump wires at a minimum. Also, the Supra pump generally does not last at 12V continous, as it is designed for 9V operation, except at WOT. Anyway, your insight, and expertise is appreciated. Perhaps you could speculate on why a set-up(mine) that should be inferior (by way of your explanation) performs better than what is theoretically optimum. Thanks for your time, Carl

#82

Eats, Sleeps, Dreams Rotary

Thread Starter

Have to say this thread definately has matured

Over the past 2 days I have learned ALOT. Thanks guys I know I will get the numbers I want...Just approaching everything with caution and modding wisely.

I know I will get the numbers I want...Just approaching everything with caution and modding wisely.

Over the past 2 days I have learned ALOT. Thanks guys

I know I will get the numbers I want...Just approaching everything with caution and modding wisely.

I know I will get the numbers I want...Just approaching everything with caution and modding wisely.

#83

development

Or

Originally Posted by pluto

Being Arrongant? Hardly, but for some reason you still questioned something I already answered you previously. Instead of answering the same questions again, I simply linked you to the proper page so that you can read it yourself. Feedback system is not something that can be explained in a couple sentence so who else has more credential to explain feedback system than a professor who wrote the book about it?

Hereís the reply I made previously from the other post, if you reread it again, youíll see that I never mentioned anything about using the turbo outlet for signal reference.

__________________________________________________ _____________________

Carl,

for an electonic boost control, the boost reading is always read from the intake manifold (the least harmonic point). However, the solenoid lines are tied as close to the turbo as possible to prevent any boost fluctuation. If the boost line and the boost reference line are at the intake manifold (where most people tied to the same reference point as the boost guage), you'll see a noticable boost fluctuation as the port opens and closes. This is the same concept why we have fuel pulsation damper to prevent fuel pressure stability. Generally, Boost reading should be tied as close to the stock map sensor pickup (by the throttle body) and the solenoids pickup point as close to the turbo as possible. If you're running a manual boost control, the pickup line is generally as close to the turbo as possible since it creates the least amount of harmonics in the system.

You have to remember that both the manual boost control and electronic boost control operates differently. Manual controller is a passive device/system where as the electronic boost controller is an active device/system.

manual boost control restricts the air flow (pressure) to the wastegate to allow the boost to come up based on the restriction.

Electronic boost controller reads the boost level at the manifold and then sends the correct duty cycle to the solenoid to restrict the wastegate flow accordingly.

Hope that makes sense?

__________________________________________________ _____________

If youíre still referring to David Preeceís boost problem, All I did was simply band aid the boost problem he has by placing his signal line outside of the throttle body to prevent boost oscillation so that I can continue with the tuning.

Most of the cars I tuned never see boost prior to tuning. The reason being is that they either have a fresh rebuild engine, new turbo setup, new fuel system and/or newly purchased car. I can only recall maybe 10 cars? That has boost issues during tuning out of approximately 200 cars that I tuned in the past few years. You have to remembered that most cars need tuning because they feel something isnít right with it and/or something is added into their car. They probably never realize that they have fuel deliver system issue, boost problem, ignition problem or even clutch problem. I could have said that your car has problems, I canít tune it and refer you to your local mechanic and move on to the next cars. But instead, I tried to isolate the problem so that the person can either fix it on site or know what needs fix in the future. As for boost problem youíre talking about, some of them, I turn the **** up and nothing happens. It sounds like improper installation to me. Does it mean that I should stop at that boost level and be done with it or try to fix it so that I can tune the car to the boost level that the person want? As for the others that have oscillation issues, I donít usually see it until the boost is higher and more noticeable.

If you look at the HKS, apexi, blitz, turboXs website, they all refer the boost control to tied to the same location. Even car manufacture ties to the same location. Look at the 3rd gen sequential system. There were two nipples coming from the turbo outlet. One of which goes to the wastegate control while the other goes to pre-control.

The answer is simple. In order to have a clean output, you must first have a clean input. To give you an example, you can have the top of the line home theater amplifier and tied that to a radio shack receiver. The quality of sound will still not be as clean as a good low noise receiver. Everything in a feedback/feed forward system works the same way. The input gets filter, amplified, compared, and then back to the input/output. When you have a noisy signal that is amplified, the noise associated with it will also get amplified. Your S/N and performance degraded. Turbo feedback system works the same way. In an electronic boost controller, you have a boost reference point to determine the duty cycle of the system, you also have an input feed from the turbo to the wastegate that is limited by the duty cycle. Letís try a few example and see how it really works.

Both feed and reference point tied to UIM.

Pressure oscillation due to intake stroke opening/closing. Oscillation read from the boost reference point, boost controller tries to adjust the duty cycle appropriately to offset the oscillation, input feed gets oscillation caused by abnormal input, the input gets oscillated along with constant duty cycle change. Thereíre points where the duty cycle and input feed get cancel or superposition causing the wastegate to oscillate more and less. (most likely 2-4psi fluctuation)

As you can see, there are two problems in this example, one from the feed and the other from the reference. Both trying to work with and against each other. Now, lets try another example.

Feed ties to the compressor output and reference point ties to the UIM.

Pressure oscillation due to intake stroke opening/closing. Oscillation read from the boost reference point, boost controller tries to adjust the duty cycle appropriately to offset the oscillation, input feed gets positive constant pressure from the compressor output, the input stays clean with constant duty cycle change due to reference point being oscillated. Boost controller may react fast enough to offset most of the oscillation (most likely 1-2 psi fluctuation).

Now, you can see that only one variable to deal with instead of two.

Letís try another one. Boost reference by the throttle body and input feed to the turbo.

Pressure oscillation due to intake stroke opening/closing. Reference point was damper from the pleunum reading less oscillation. Boost controller reads it and adjust appropriately and sets the duty cycle for the boost level that was set for. The only difference this time is that the boost controller has less to deal with to set the proper duty cycle within the system. (most likely .5-1psi fluctuation)

Overshoot is generally caused by a slow response. It could be the boost controller has a slow frequency or it could also be the line to the reference point is too long causing it to react slower. There are other factors the may be associated such as small wastegate, leaky wastegate diaphram or long feedback line from turbo to the wastegate.

Iím not sure why youíre combining map sensor for EMS in here since it is irrelevant? I think you have the feed line and reference line confused. You need to reread what I said previously since I never mentioned placing the reference line to the turbo. I'm not sure why you keep thinking that I said the reference line is in the compressor. If youíre referring to the manual boost controller, it doesnít matter where you put it, it simply restricts/regulate the pressure to the wastegate

Hereís the reply I made previously from the other post, if you reread it again, youíll see that I never mentioned anything about using the turbo outlet for signal reference.

__________________________________________________ _____________________

Carl,

for an electonic boost control, the boost reading is always read from the intake manifold (the least harmonic point). However, the solenoid lines are tied as close to the turbo as possible to prevent any boost fluctuation. If the boost line and the boost reference line are at the intake manifold (where most people tied to the same reference point as the boost guage), you'll see a noticable boost fluctuation as the port opens and closes. This is the same concept why we have fuel pulsation damper to prevent fuel pressure stability. Generally, Boost reading should be tied as close to the stock map sensor pickup (by the throttle body) and the solenoids pickup point as close to the turbo as possible. If you're running a manual boost control, the pickup line is generally as close to the turbo as possible since it creates the least amount of harmonics in the system.

You have to remember that both the manual boost control and electronic boost control operates differently. Manual controller is a passive device/system where as the electronic boost controller is an active device/system.

manual boost control restricts the air flow (pressure) to the wastegate to allow the boost to come up based on the restriction.

Electronic boost controller reads the boost level at the manifold and then sends the correct duty cycle to the solenoid to restrict the wastegate flow accordingly.

Hope that makes sense?

__________________________________________________ _____________

If youíre still referring to David Preeceís boost problem, All I did was simply band aid the boost problem he has by placing his signal line outside of the throttle body to prevent boost oscillation so that I can continue with the tuning.

Most of the cars I tuned never see boost prior to tuning. The reason being is that they either have a fresh rebuild engine, new turbo setup, new fuel system and/or newly purchased car. I can only recall maybe 10 cars? That has boost issues during tuning out of approximately 200 cars that I tuned in the past few years. You have to remembered that most cars need tuning because they feel something isnít right with it and/or something is added into their car. They probably never realize that they have fuel deliver system issue, boost problem, ignition problem or even clutch problem. I could have said that your car has problems, I canít tune it and refer you to your local mechanic and move on to the next cars. But instead, I tried to isolate the problem so that the person can either fix it on site or know what needs fix in the future. As for boost problem youíre talking about, some of them, I turn the **** up and nothing happens. It sounds like improper installation to me. Does it mean that I should stop at that boost level and be done with it or try to fix it so that I can tune the car to the boost level that the person want? As for the others that have oscillation issues, I donít usually see it until the boost is higher and more noticeable.

If you look at the HKS, apexi, blitz, turboXs website, they all refer the boost control to tied to the same location. Even car manufacture ties to the same location. Look at the 3rd gen sequential system. There were two nipples coming from the turbo outlet. One of which goes to the wastegate control while the other goes to pre-control.

The answer is simple. In order to have a clean output, you must first have a clean input. To give you an example, you can have the top of the line home theater amplifier and tied that to a radio shack receiver. The quality of sound will still not be as clean as a good low noise receiver. Everything in a feedback/feed forward system works the same way. The input gets filter, amplified, compared, and then back to the input/output. When you have a noisy signal that is amplified, the noise associated with it will also get amplified. Your S/N and performance degraded. Turbo feedback system works the same way. In an electronic boost controller, you have a boost reference point to determine the duty cycle of the system, you also have an input feed from the turbo to the wastegate that is limited by the duty cycle. Letís try a few example and see how it really works.

Both feed and reference point tied to UIM.

Pressure oscillation due to intake stroke opening/closing. Oscillation read from the boost reference point, boost controller tries to adjust the duty cycle appropriately to offset the oscillation, input feed gets oscillation caused by abnormal input, the input gets oscillated along with constant duty cycle change. Thereíre points where the duty cycle and input feed get cancel or superposition causing the wastegate to oscillate more and less. (most likely 2-4psi fluctuation)

As you can see, there are two problems in this example, one from the feed and the other from the reference. Both trying to work with and against each other. Now, lets try another example.

Feed ties to the compressor output and reference point ties to the UIM.

Pressure oscillation due to intake stroke opening/closing. Oscillation read from the boost reference point, boost controller tries to adjust the duty cycle appropriately to offset the oscillation, input feed gets positive constant pressure from the compressor output, the input stays clean with constant duty cycle change due to reference point being oscillated. Boost controller may react fast enough to offset most of the oscillation (most likely 1-2 psi fluctuation).

Now, you can see that only one variable to deal with instead of two.

Letís try another one. Boost reference by the throttle body and input feed to the turbo.

Pressure oscillation due to intake stroke opening/closing. Reference point was damper from the pleunum reading less oscillation. Boost controller reads it and adjust appropriately and sets the duty cycle for the boost level that was set for. The only difference this time is that the boost controller has less to deal with to set the proper duty cycle within the system. (most likely .5-1psi fluctuation)

Overshoot is generally caused by a slow response. It could be the boost controller has a slow frequency or it could also be the line to the reference point is too long causing it to react slower. There are other factors the may be associated such as small wastegate, leaky wastegate diaphram or long feedback line from turbo to the wastegate.

Iím not sure why youíre combining map sensor for EMS in here since it is irrelevant? I think you have the feed line and reference line confused. You need to reread what I said previously since I never mentioned placing the reference line to the turbo. I'm not sure why you keep thinking that I said the reference line is in the compressor. If youíre referring to the manual boost controller, it doesnít matter where you put it, it simply restricts/regulate the pressure to the wastegate

input HIGH, output LOW = WG open later.

sorry had too.

#84

Rotary Freak

Join Date: Feb 2001

Location: fort worth, tx, usa

Posts: 1,926

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by Carl Byck

First, let me say, that when you comment "for those that have a hard time understanding" , that strikes me as arrogant. Perhaps I am over sensitive, sorry for that.

I guess I do that alot and people misinterpret it differently. Maybe I should have said that "for those that wants to learn more on the theory of feedback system and such".

Originally Posted by Carl Byck

I certainly appreciate the time that you (Steve ) have taken to explain why you are setting the car up this way. What you say make sense. That said, I do not think that it works consistently in practice, further, David Preece's car was built, and set up by you. In addition it his his second time around(blown motor built, and being tuned by you the first time it blew), correct me if I am mistaken.

Originally Posted by Carl Byck

I know that when I reference boost, and run the solenoid off the UIM My AVCR registers no oscillation that can be discerned while watching the digital display. This is true in my Supra TT, and in my RX7. I have never experienced the oscillations you refer to, and have rock solid steady boost at what ever I set the controller to. So then, why are there these oscillations,

Did you actually datalog and see if you have oscillation? What the boost gauge and/or boost controller said are irrelvent to what the EMS reads.

Originally Posted by Carl Byck

and why is he at 88% duty cycle when he should be at a fraction of that based on his injectors? I know what works, and wonder out loud why David is having a problem.

I tuned David's car that way because of his previous problem. I didn't want to take a chance until I know everything was sorted out. I know that David was aware of that because he was there when we tuned the car. As for oscillation, I'll have to investgate it further to be able to narrow down the exact cause of the problem. One of the things that I was aware of is that his boost guage always oscillate even before his car came to us. I told him to verifiy it with a different gauge and see if its the gauge that is at fault or it is really oscillating. As for the dyno chart, it could be that it was running rich in certain cells causing it to look like it is oscillating from the a/f ratio that was tuned for.

Originally Posted by Carl Byck

Like you, I am trying to help, please consider that as you read this. I am sure with you intimate knowledge of Davids set up, that you will solve both issues. In looking at Davids set up, it seems that he needs an upgraded ignition, and larger pump wires at a minimum. Also, the Supra pump generally does not last at 12V continous, as it is designed for 9V operation, except at WOT.

I'm sure that david really appreciate for everybody's input in his dyno chart. I have been communicating with him for the past few days on what the possible problem might be regarding to oscillation. However, if you really look at the dyno chart, the oscillation is only 5rwhp difference. I don't think it is ignition breakup or boost flutuation but rather just not a clean pull from being a little rich. I don't think there's any fuel pressure drop for his application since I usually check that when I tune cars.

regarding the pump not lasting long when running at 12V continous. This goes true for any components. Every components have an estimated MTBF (mean time between failure). It is calculated based on the components used within the system. In our case, a fuel pump and parts associated with it. The cacluation is done based on extreme temperature (usually -40C and 85C) and also extreme voltage (1V to 24V). MTBF was then estimated based on MIL calcuation under normal operating condition. Usually, electric fans and pumps have the lowest MTBF because of the load and movement assoicated with it. I know that fans usually have around 60000-80000 operating hrs. Not sure what a pump usually have since I'm not a ME. I used to do statistical analysis in a system level for cellular base station so I know a little on MTBF since I spend months doing it for six sigma design and design for manufacturbility for the product.

I don't really think that operating at 12V will kill the pump dramatically like you mentioned. Maybe in a 8 yrs time frame instead of 15 yrs but nothing worth the extra fuel pressure stability in a $250 part.

Originally Posted by Carl Byck

Anyway, your insight, and expertise is appreciated. Perhaps you could speculate on why a set-up(mine) that should be inferior (by way of your explanation) performs better than what is theoretically optimum. Thanks for your time, Carl

In your case, I think that possibly because you have stock intake port having shorter opening/closing duration of intake stroke for it not be signifiant in oscillation. It could also be that your i/c has a big pressure drop allowing more dampering to the problem. I still think that your i/c has a huge pressure drop causing spool up issue. I guess that the only way to find out is to actually test it. However, I would datalog your map sensor and see if you really have any boost flutuation at WOT. In any case, every car is different and has to look at individually in a system level rather than just a sub-system or component level. Basically from a system level down to a component level.

#85

Eats, Sleeps, Dreams Rotary

Thread Starter

A little chime in for the boost flutter...Prior to my Gotham rebuild I had the boost gauge running off one of the nipples on the UIM and also the boost controler feed line....I have a lot more boost flutter...about 2.5psi bouncing up and down at the top end...

After the boost controler feed line was moved to the compressor housing it is much less. as shown in the videos. Seems to fluctuate only within 1psi...I am just not sure if it's something that i should be really worried about...I will do as steve says and install a manual BC and see what happens with that..

Also, for the spool up time. It's really easy for me to record a small WOT run showing both the boost gauge and RPM in the background since the boost gauge is on the steering column. Should be interesting to see where it's actually building boost. Maybe friday before i can do that but will post it here.

After the boost controler feed line was moved to the compressor housing it is much less. as shown in the videos. Seems to fluctuate only within 1psi...I am just not sure if it's something that i should be really worried about...I will do as steve says and install a manual BC and see what happens with that..

Also, for the spool up time. It's really easy for me to record a small WOT run showing both the boost gauge and RPM in the background since the boost gauge is on the steering column. Should be interesting to see where it's actually building boost. Maybe friday before i can do that but will post it here.

#86

Originally Posted by apneablue

A little chime in for the boost flutter...Prior to my Gotham rebuild I had the boost gauge running off one of the nipples on the UIM and also the boost controler feed line....I have a lot more boost flutter...about 2.5psi bouncing up and down at the top end...

After the boost controler feed line was moved to the compressor housing it is much less. as shown in the videos. Seems to fluctuate only within 1psi...I am just not sure if it's something that i should be really worried about...I will do as steve says and install a manual BC and see what happens with that..

Also, for the spool up time. It's really easy for me to record a small WOT run showing both the boost gauge and RPM in the background since the boost gauge is on the steering column. Should be interesting to see where it's actually building boost. Maybe friday before i can do that but will post it here.

After the boost controler feed line was moved to the compressor housing it is much less. as shown in the videos. Seems to fluctuate only within 1psi...I am just not sure if it's something that i should be really worried about...I will do as steve says and install a manual BC and see what happens with that..

Also, for the spool up time. It's really easy for me to record a small WOT run showing both the boost gauge and RPM in the background since the boost gauge is on the steering column. Should be interesting to see where it's actually building boost. Maybe friday before i can do that but will post it here.

#87

Eats, Sleeps, Dreams Rotary

Thread Starter

Originally Posted by the_glass_man

Did you tap and weld the compressor housing?

#88

Eats, Sleeps, Dreams Rotary

Thread Starter

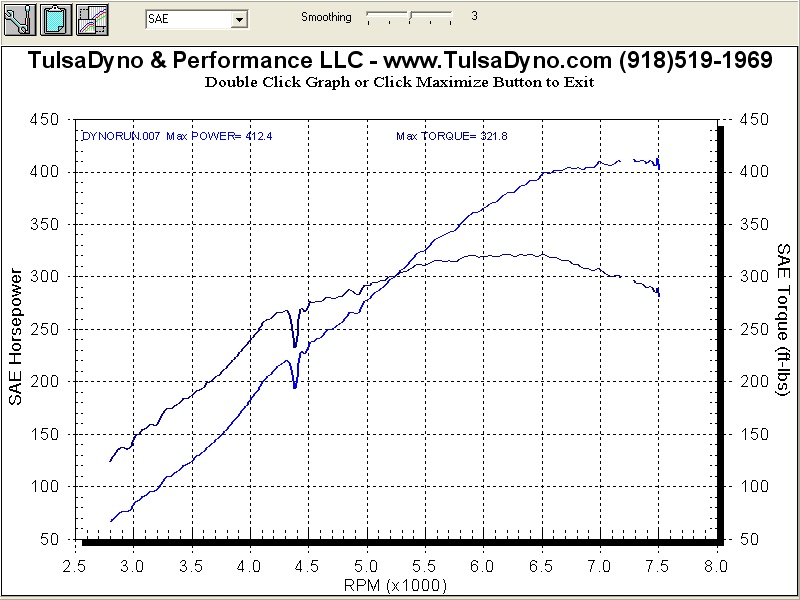

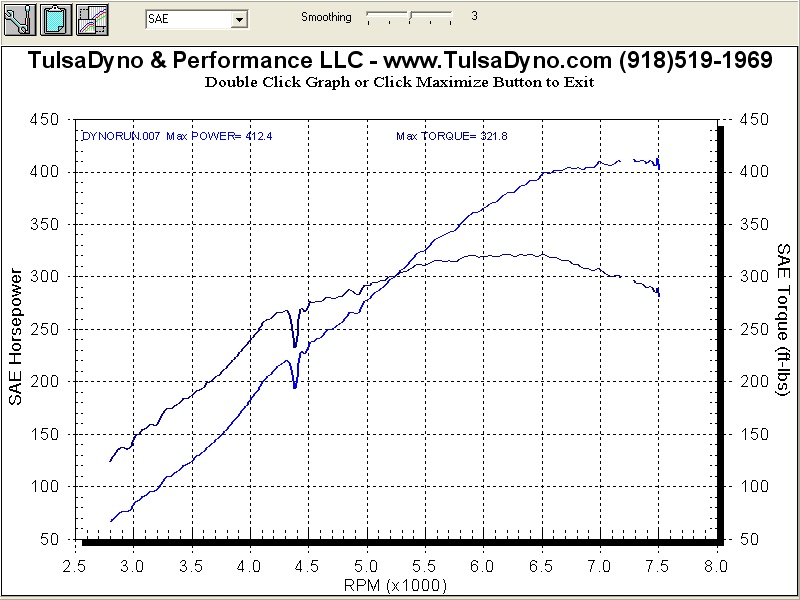

Ok, now the only ingredient I was missing from the last 16psi run was an Ignition Amp...I chose the HKS Twinpower...Mainly because it has been tried and proven over and over...Well, it proved itself once again...I bought and installed the HKS twinpower and went back to the dyno and got 412rwhp...Dyno below.

So get this...Just by installing the HKS Twinpower and dynoing at the same 16psi of boost it did 3 things for me...

1. RWHP Increase of 31rwhp

2. Increased Torque 18 ft/lbs

3. Leaned me out to about 1.2. Going from 10.1 - 10.3:1 to 11.2 - 11.5:1

So buying the HKS twin power was a win win sittuation for me. No more high rpm ignition breakup and idles and accellerates really smooth.

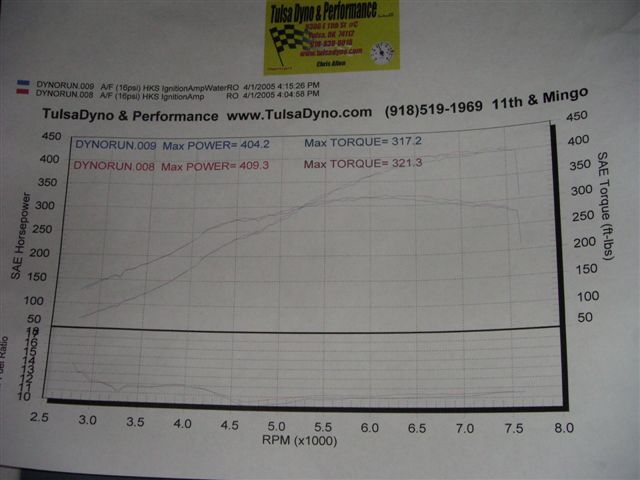

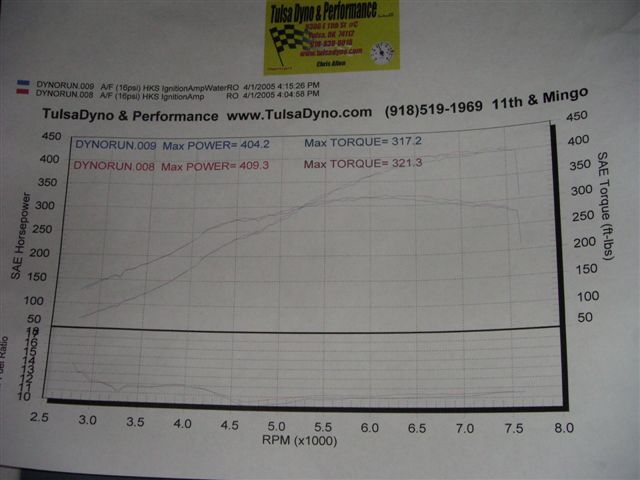

This dyno below was done at the same 16PSI with and without water injection.

The first run was without and I made 409RWHP and then I ran 404rwhp with the water injection....So in terms of RWHP the water injection actually hurt me but what it did was to bring down my AFRs about 0.2 - 0.3 less than the run that I did without it.

Here's the dyno.

So I am a pretty happy camper right now

<!-- / message --><!-- sig -->

So get this...Just by installing the HKS Twinpower and dynoing at the same 16psi of boost it did 3 things for me...

1. RWHP Increase of 31rwhp

2. Increased Torque 18 ft/lbs

3. Leaned me out to about 1.2. Going from 10.1 - 10.3:1 to 11.2 - 11.5:1

So buying the HKS twin power was a win win sittuation for me. No more high rpm ignition breakup and idles and accellerates really smooth.

This dyno below was done at the same 16PSI with and without water injection.

The first run was without and I made 409RWHP and then I ran 404rwhp with the water injection....So in terms of RWHP the water injection actually hurt me but what it did was to bring down my AFRs about 0.2 - 0.3 less than the run that I did without it.

Here's the dyno.

So I am a pretty happy camper right now

<!-- / message --><!-- sig -->

#90

Eats, Sleeps, Dreams Rotary

Thread Starter

Originally Posted by pluto

looks like your car is running strong! congrats. What's that little hickup at 4.4krpm?

So quick question for you since you are here...Since I am running the HKS TP now with the AFRs close to 11.5 (I really didn't expect it to lean out this much from the TP) Do you think I still need to run the Greddy Race Plugs in the leading? Everytime I have cleaned them they are looking almost close to fouled...very sutty (if that's a word)

And I want to come have you tune me to 18 as we had originally set out to do....Maybe later in the summer or early fall....

And yes...the motor sounded really strong....Good Job Boss!

Oh, and injector duty cycle was at 85% this time. I still feel it should be lower with the 850/1600s...don't you think?

#91

Rotary Freak

Join Date: Feb 2001

Location: fort worth, tx, usa

Posts: 1,926

Likes: 0

Received 0 Likes

on

0 Posts

As long as you run the water injection, the a/f ratio is fine. I would richen up just a tad since it's closer to 11.7:1 on the street if you're seeing 11.5:1 on the dyno. Either way, the numbers looked alot closer to our original goal.

You should be able to run 9's with the HKS TP. The only reason why we ran the 10's was because of lack of ignition box.

You should be able to run 9's with the HKS TP. The only reason why we ran the 10's was because of lack of ignition box.

Originally Posted by apneablue

that was my fault...For some reason I looked at the boost gauge and thought i saw a spike but I was just extremely nevous and lifted my foot for a sec....I always say my prayers before I head to the dyno....

So quick question for you since you are here...Since I am running the HKS TP now with the AFRs close to 11.5 (I really didn't expect it to lean out this much from the TP) Do you think I still need to run the Greddy Race Plugs in the leading? Everytime I have cleaned them they are looking almost close to fouled...very sutty (if that's a word)

And I want to come have you tune me to 18 as we had originally set out to do....Maybe later in the summer or early fall....

And yes...the motor sounded really strong....Good Job Boss!

Oh, and injector duty cycle was at 85% this time. I still feel it should be lower with the 850/1600s...don't you think?

So quick question for you since you are here...Since I am running the HKS TP now with the AFRs close to 11.5 (I really didn't expect it to lean out this much from the TP) Do you think I still need to run the Greddy Race Plugs in the leading? Everytime I have cleaned them they are looking almost close to fouled...very sutty (if that's a word)

And I want to come have you tune me to 18 as we had originally set out to do....Maybe later in the summer or early fall....

And yes...the motor sounded really strong....Good Job Boss!

Oh, and injector duty cycle was at 85% this time. I still feel it should be lower with the 850/1600s...don't you think?

Thread

Thread Starter

Forum

Replies

Last Post

Turblown

Group Buy & Product Dev. FD RX-7

7

03-21-18 11:19 AM

HalifaxFD

Canadian Forum

126

05-09-16 07:06 PM

23Racer

Race Car Tech

1

09-21-15 10:48 AM