Turbo into turbo set up?

#51

Banned. I got OWNED!!!

Join Date: Dec 2007

Location: paradise Florida

Posts: 946

Likes: 0

Received 0 Likes

on

0 Posts

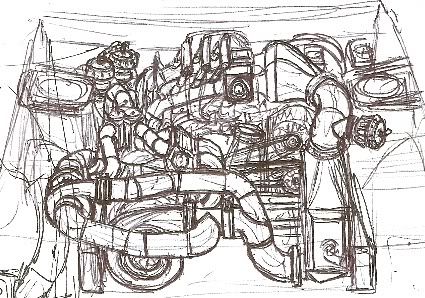

I have had a few ideas before on compound/sequential turbo systems, which have all made it to my sketchpad.. maybe this is the right place to share it. The idea is to see where my single s475 will lead me, and if i could go for some more response i'll be upgrading to one of the below.

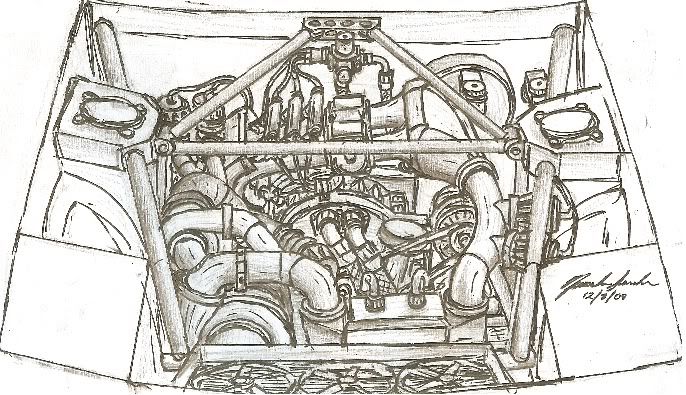

this is the compound turbo setup. everybody here already knows how it works if they read through the thread.

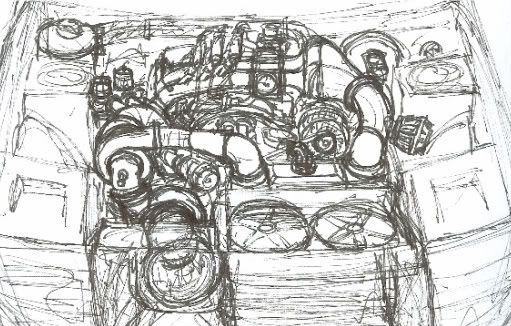

this is the sequential turbo setup. it has a small, maybe gt25 or something, turbo added on. There is a set of valves that separates the two turbos, with an electric motor powering its opening and closing. There are two valves directly stacked on top of each other, allowing the setup to stay dual scroll for both turbos. the exhaust of the small turbo enters back into the runners going into the big turbo, allowing the big turbo to get spinning as the small one is in boost. On the compressor side of things, there is a valve just to the right of where the small turbos inlet enters the big turbos outlet. this also would help the big turbo get spinning, and keep a single point of air entry (the big turbo.)

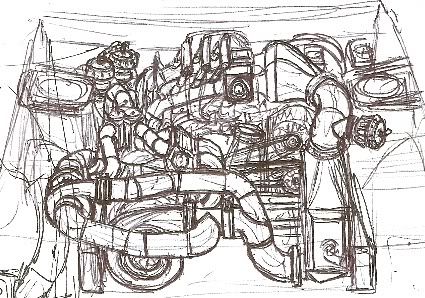

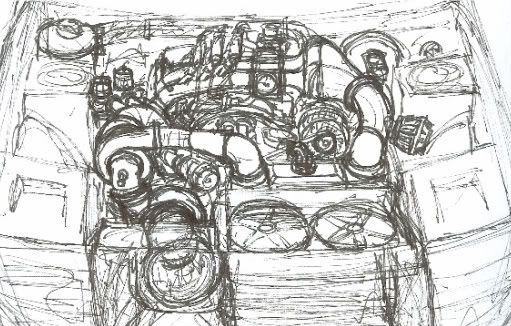

both of them are of course drawn along with my 13bpp that i'm building.. hopefully this will give you guys some ideas.

this is the compound turbo setup. everybody here already knows how it works if they read through the thread.

this is the sequential turbo setup. it has a small, maybe gt25 or something, turbo added on. There is a set of valves that separates the two turbos, with an electric motor powering its opening and closing. There are two valves directly stacked on top of each other, allowing the setup to stay dual scroll for both turbos. the exhaust of the small turbo enters back into the runners going into the big turbo, allowing the big turbo to get spinning as the small one is in boost. On the compressor side of things, there is a valve just to the right of where the small turbos inlet enters the big turbos outlet. this also would help the big turbo get spinning, and keep a single point of air entry (the big turbo.)

both of them are of course drawn along with my 13bpp that i'm building.. hopefully this will give you guys some ideas.

#52

Rotary Enthusiast

HEY!! Chaotic,, that is interesting setup, like the stepper motors to operate the gates,

couple weeks back i talked with boost logic about steppers.

most probs they had was with gates and springs, gettin set to work together at the right time, 2 controllers.

one thing they are thinkin about is 3 gates, with 2 controllers??

anyway, it will take some R&D to get this kind of technology runnin properly! IMO

but think about the FUN you will have do in it,, and cant even think about the knowledge learned.

couple weeks back i talked with boost logic about steppers.

most probs they had was with gates and springs, gettin set to work together at the right time, 2 controllers.

one thing they are thinkin about is 3 gates, with 2 controllers??

anyway, it will take some R&D to get this kind of technology runnin properly! IMO

but think about the FUN you will have do in it,, and cant even think about the knowledge learned.

#53

Rotary Enthusiast

and then Garrett has a new tech turbo, 2 compressor wheels on one turbine shaft, says its better than two turbs in series, supposed to quick boost and big air on top.

its going on the 2011 Ford diesel trucks,DBB, variable vane,

course engine is only 6.7 L, most turbs we use could easily huff an 18 wheeler, like 78s

its going on the 2011 Ford diesel trucks,DBB, variable vane,

course engine is only 6.7 L, most turbs we use could easily huff an 18 wheeler, like 78s

#54

Banned. I got OWNED!!!

Join Date: Dec 2007

Location: paradise Florida

Posts: 946

Likes: 0

Received 0 Likes

on

0 Posts

thanks man, i appreciate it.

i would love to try out that new garrett turbo, but i dont think that the variable vanes are capable of the exhaust heat a rotary puts out, and will seize. i could be wrong though.

i would love to try out that new garrett turbo, but i dont think that the variable vanes are capable of the exhaust heat a rotary puts out, and will seize. i could be wrong though.

#55

Personally I think simple is the way to go. No sense over complicating things with flappers, doors and solenoids. That's one of the main advantages of ditching the twins is for simplicity. A compound turbo setup with the first internally gated, the second can be internal or external doesn't matter. Use one boost controller on the second turbo and just set the first turbo wastegate to say 10- 15 psi. It's simple enough, the boost wouldn't have any strange transitions and it should be easy to design and fit. Response would be good and power would be unreal.

#56

Rotary Enthusiast

iTrader: (3)

Join Date: Jan 2007

Location: st. louis

Posts: 1,000

Likes: 0

Received 0 Likes

on

0 Posts

Personally I think simple is the way to go. No sense over complicating things with flappers, doors and solenoids. That's one of the main advantages of ditching the twins is for simplicity. A compound turbo setup with the first internally gated, the second can be internal or external doesn't matter. Use one boost controller on the second turbo and just set the first turbo wastegate to say 10- 15 psi. It's simple enough, the boost wouldn't have any strange transitions and it should be easy to design and fit. Response would be good and power would be unreal.

#57

You need to have a BIG gate on the first, smaller, turbo on a petrol compound setup or it will overboost like mad. Ideally two.

Diesel setups are no issue as they use the compounding to make big boost, but on a petrol its purely for spoolup, and even if you was running 3bar and the smallest turbo was a small T3 you generally need two gates to bypass the first one enough that it dont creep past what you want it to hold.

Ive seen one where the guy was running 45psi and wanted the smaller turbo to be limited to 25psi, but even at such high boost it creeped till he added a 2nd wastegate.

Diesel setups are no issue as they use the compounding to make big boost, but on a petrol its purely for spoolup, and even if you was running 3bar and the smallest turbo was a small T3 you generally need two gates to bypass the first one enough that it dont creep past what you want it to hold.

Ive seen one where the guy was running 45psi and wanted the smaller turbo to be limited to 25psi, but even at such high boost it creeped till he added a 2nd wastegate.

#58

Another concern is all the back pressure, not only created by 2 turbos, but especially by the first smaller turbo. All that back pressure is going to increase heat, and reduce the power made at a given pressure level. Just like any exhaust restriction. If you could find a small compressor with a large housing for the first turbo, you could still have faster spool but not have so much back pressure as with a small exhaust housing.

#59

Senior Member

iTrader: (3)

You need to have a BIG gate on the first, smaller, turbo on a petrol compound setup or it will overboost like mad. Ideally two.

Diesel setups are no issue as they use the compounding to make big boost, but on a petrol its purely for spoolup, and even if you was running 3bar and the smallest turbo was a small T3 you generally need two gates to bypass the first one enough that it dont creep past what you want it to hold.

Ive seen one where the guy was running 45psi and wanted the smaller turbo to be limited to 25psi, but even at such high boost it creeped till he added a 2nd wastegate.

Diesel setups are no issue as they use the compounding to make big boost, but on a petrol its purely for spoolup, and even if you was running 3bar and the smallest turbo was a small T3 you generally need two gates to bypass the first one enough that it dont creep past what you want it to hold.

Ive seen one where the guy was running 45psi and wanted the smaller turbo to be limited to 25psi, but even at such high boost it creeped till he added a 2nd wastegate.

I have no idea. I'm not sure how well those internal gates work on the aftermarket turbos. I know most factory wastgates are very small, but I would imagine that the aftermarket turbos have a wide range of wastgate configurations. I also have no idea how you would know if the first turbo was creeping, or if it was just boost from the second turbo.

Another concern is all the back pressure, not only created by 2 turbos, but especially by the first smaller turbo. All that back pressure is going to increase heat, and reduce the power made at a given pressure level. Just like any exhaust restriction. If you could find a small compressor with a large housing for the first turbo, you could still have faster spool but not have so much back pressure as with a small exhaust housing.

Another concern is all the back pressure, not only created by 2 turbos, but especially by the first smaller turbo. All that back pressure is going to increase heat, and reduce the power made at a given pressure level. Just like any exhaust restriction. If you could find a small compressor with a large housing for the first turbo, you could still have faster spool but not have so much back pressure as with a small exhaust housing.

#60

Banned. I got OWNED!!!

Join Date: Dec 2007

Location: paradise Florida

Posts: 946

Likes: 0

Received 0 Likes

on

0 Posts

The primary issue with the small turbo wouldnt only be overboosting, but overspeeding. The larger turbo would be feeding enough air to eventually cause the smaller turbo to overspeed, hence another need for a wastegate.

An internal gate wouldnt be anywhere near enough. Backpressure would be dealt with by a wastegate before the smaller turbo.

An internal gate wouldnt be anywhere near enough. Backpressure would be dealt with by a wastegate before the smaller turbo.

thats why i like having a valve on the exhaust runners, and a valve on the intake runners. There would be no worries of overspooling, and once the small turbo has kicked in enough, it gets shut off completely. You could even use a single motor for both valves operation. On top of that because the exhaust doesn't have a sharp 90* turn to travel through, like in a wastegate, it would be more ideal.

it really shouldn't be too difficult to tune, it would just require a bit of dyno time to get used to the speed the turbos come in, and get the valves to open and close accordingly.

Thread

Thread Starter

Forum

Replies

Last Post

trickster

2nd Generation Specific (1986-1992)

25

07-01-23 04:40 PM

13b, 60mm, air, compound, cummins, diagram, flow, helicopter, large, primary, restriction, set, setup, small, terminolgoy, turbo, turbocharger, wastegate