Strange fuel pressure issue E85

#76

I had little over 400hp, single bosch pump, stock hard lines under the car.

What was your whp and did it max out at that point?

I know -8 is over kill for my setup but what ever does the job at this point.

Your right I never pulled it out because I tried the Walbro 485 pump and filter earlier and had the same results. It's been checked a few time and kept it's original shape it's metal haha

What was your whp and did it max out at that point?

I know -8 is over kill for my setup but what ever does the job at this point.

Your right I never pulled it out because I tried the Walbro 485 pump and filter earlier and had the same results. It's been checked a few time and kept it's original shape it's metal haha

Well what happened with me is on the dyno that day we tuned on pump fuel due to injector change. Flipped the switch to also run a E85 tune. We tuned on E85 and turned up the boost, my wastegate was not holding higher boost so we had to shut it down that day. When we did the car had dynoed 409 I believe but that was almost 2 years ago.

I took care of the wastegate issue and then the storm hit and my house flooded ( my car was stored somewhere else at the time anyhow ) .

I never got back to the dyno since then. The car sat from october- July. Last year a few weeks before rotorfest I put a big brake setup on the car. I only drove it 2-3 times if that. Its been stored since October or so again and a month ago I moved it and we have been restoring the suspension/subframe, new fuel and hard brake lines and other stuff.

Next time I get back on the dyno I will have my new fuel lines in place.

#78

Racing Rotary Since 1983

iTrader: (6)

FWIW, was reading on a fuel pump site and they mentioned that in higher peformance apps a dash 6 (or larger) fuel vent is necessary... any possibility you have an occluded fuel vent?

#80

The fuel line was replaced with a -8 hose and that seemed to fix the issue. I'm waiting on the log file to confirm for myself and will post, it must have been a restriction in the -6 SS line and not that it needed a larger line.

Thank you all for your help.

-Jonathan

Thank you all for your help.

-Jonathan

#82

I believe it was the line with to many bends probably cavitating the fuel. I had a shop make me a SS -6 line that had the same bends and curves as the stock line instead of a straighter line.

Still working on it will post more information when it's completely put back together.

Still working on it will post more information when it's completely put back together.

#83

On another note I'm not sure If I posted this before I found a 10 micron SS E85 rated inline fuel filter instead of Fuelabs fiberglass 6 micron really large inline filter.

F-10 Inline Modular Fuel Filter

I plan to run a fuel pressure sensor on this inline filter since I heard some horror stories from foreinnovations about E85 fuel being delivered dirty and causing issues on brand new GTR's. From what he said the government is not as strict on the filtering process on E85 as they are with regular fuel..

F-10 Inline Modular Fuel Filter

I plan to run a fuel pressure sensor on this inline filter since I heard some horror stories from foreinnovations about E85 fuel being delivered dirty and causing issues on brand new GTR's. From what he said the government is not as strict on the filtering process on E85 as they are with regular fuel..

#90

Sorry if I missed it ^ but have you checked your filter?Pump Socks? I'm going to be keeping a really close eye on mine...but Also want to get the stainless steel level socks just to prevent corrosion.....or I guess not corrosion but fuel from eating away at the filter element

#91

Yes I did it was replaced with a Walbro 485 and sock. I then re-installed the Fuelab SS sock and Bosch 044 after it didn't fix the issue.

I also went to a 10 micron SS inline filter with -8 lines, flow tested the injectors, replaced FPR, re routed fuel lines the stock way and replaced fuel pressure sensor and nothing has fixed my issue.

The only thing I have not replaced is the pickup assembly and fuel rails.

-J

I also went to a 10 micron SS inline filter with -8 lines, flow tested the injectors, replaced FPR, re routed fuel lines the stock way and replaced fuel pressure sensor and nothing has fixed my issue.

The only thing I have not replaced is the pickup assembly and fuel rails.

-J

#92

#93

Rotary Enthusiast

iTrader: (19)

Join Date: Apr 2002

Location: Colorado Springs, CO

Posts: 1,169

Likes: 0

Received 11 Likes

on

10 Posts

I have a couple of questions. Just curious on why you are tuning E85 to an AFR of 11 or so?

Doesn't e85 make max power at an AFR of 7-8 AFR?

http://i72.photobucket.com/albums/i1...Conversion.jpg

Stoich for E85 is 9.765 AFR. That is why people see a reduction in MPG.

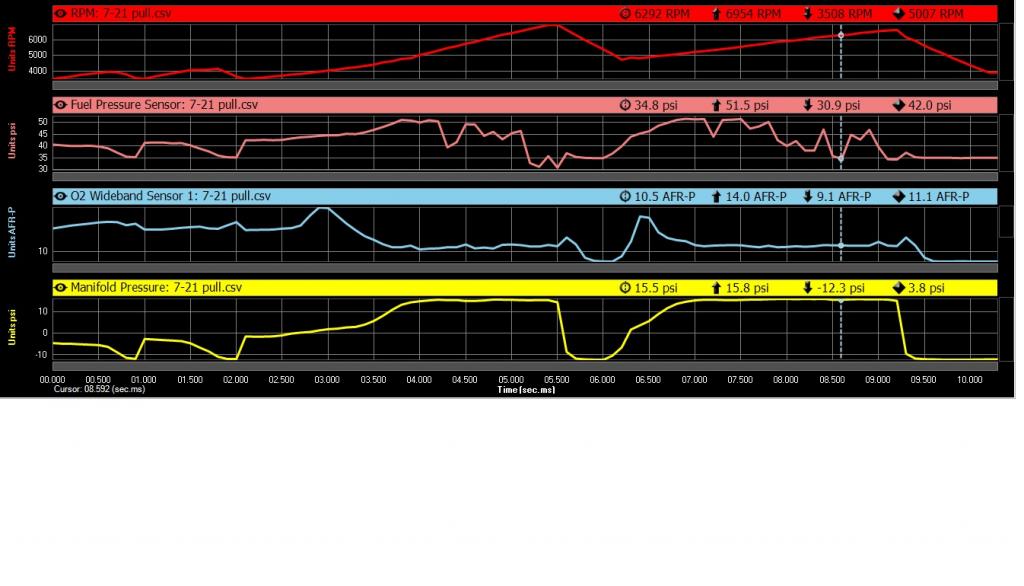

I see the reduction in pressure, but I don't see a reduction in AFR. What does your map look like? Is your base map pretty smooth and what does the curve look like? Does the curve just rocket in the area that the pressure drops are occuring? If not, then perhaps you are chasing a ghost that doesn't exist. Your sensor might not be reading correctly. You can't have a nice steady AFR with a nice smoothed map and have pressure act erratically. Have you tried a lower PSI and see if it still happens? Perhaps make a run at 5PSI, or 8PSI, something lower (especially if you can control it with a boost controller and full peddal it). If the pressure is constant there, or if you get a similar erratic reading but the map and AFR's are nice and smooth.....might be nothing to worry about.

Doesn't e85 make max power at an AFR of 7-8 AFR?

http://i72.photobucket.com/albums/i1...Conversion.jpg

Stoich for E85 is 9.765 AFR. That is why people see a reduction in MPG.

I see the reduction in pressure, but I don't see a reduction in AFR. What does your map look like? Is your base map pretty smooth and what does the curve look like? Does the curve just rocket in the area that the pressure drops are occuring? If not, then perhaps you are chasing a ghost that doesn't exist. Your sensor might not be reading correctly. You can't have a nice steady AFR with a nice smoothed map and have pressure act erratically. Have you tried a lower PSI and see if it still happens? Perhaps make a run at 5PSI, or 8PSI, something lower (especially if you can control it with a boost controller and full peddal it). If the pressure is constant there, or if you get a similar erratic reading but the map and AFR's are nice and smooth.....might be nothing to worry about.

#94

I have a couple of questions. Just curious on why you are tuning E85 to an AFR of 11 or so?

Doesn't e85 make max power at an AFR of 7-8 AFR?

http://i72.photobucket.com/albums/i1...Conversion.jpg

Stoich for E85 is 9.765 AFR. That is why people see a reduction in MPG.

Doesn't e85 make max power at an AFR of 7-8 AFR?

http://i72.photobucket.com/albums/i1...Conversion.jpg

Stoich for E85 is 9.765 AFR. That is why people see a reduction in MPG.

This gets into the whole "why you should use Lambda" debate. Rest assured, if his meter is programmed to display gasoline AFR with Lambda of 1 equaling 14.7:1 AFR, when he is running E85 and the meter reads 14.7:1 Lambda is still 1. Lambda 1 of E85, as you stated, is somewhere around 9.8:1 AFR.

Does your head hurt yet? Once you understand you're using a Lambda meter that is calibrated to read AFR for a certain fuel and, if you use a different fuel, the AFR values become irrelevant, you'll understand why he doesn't try to run the engine at 7:1 according to his meter.

#95

Any updates?

I am having the same exact problem (on pump gas). I am too using a bosch 044, and a PS1K ecu. With the engine off, 12v to the fuel pump, the static fuel pressure is rock solid, but when the engine is running, the static pressure oscillate by 5-8 psi.

Pressure sensor has been moved to pre primary rail, post secondary rail, right after the fuel filter; all with the same results. Engine off, static pressure is solid, engine running, pressure oscillates.

There's no fuel damper, and a SX pressure regulator, which in theory acts as a damper. I am thinking of buying a marren damper, or two

I am having the same exact problem (on pump gas). I am too using a bosch 044, and a PS1K ecu. With the engine off, 12v to the fuel pump, the static fuel pressure is rock solid, but when the engine is running, the static pressure oscillate by 5-8 psi.

Pressure sensor has been moved to pre primary rail, post secondary rail, right after the fuel filter; all with the same results. Engine off, static pressure is solid, engine running, pressure oscillates.

There's no fuel damper, and a SX pressure regulator, which in theory acts as a damper. I am thinking of buying a marren damper, or two

#96

Any updates?

I am having the same exact problem (on pump gas). I am too using a bosch 044, and a PS1K ecu. With the engine off, 12v to the fuel pump, the static fuel pressure is rock solid, but when the engine is running, the static pressure oscillate by 5-8 psi.

Pressure sensor has been moved to pre primary rail, post secondary rail, right after the fuel filter; all with the same results. Engine off, static pressure is solid, engine running, pressure oscillates.

There's no fuel damper, and a SX pressure regulator, which in theory acts as a damper. I am thinking of buying a marren damper, or two

I am having the same exact problem (on pump gas). I am too using a bosch 044, and a PS1K ecu. With the engine off, 12v to the fuel pump, the static fuel pressure is rock solid, but when the engine is running, the static pressure oscillate by 5-8 psi.

Pressure sensor has been moved to pre primary rail, post secondary rail, right after the fuel filter; all with the same results. Engine off, static pressure is solid, engine running, pressure oscillates.

There's no fuel damper, and a SX pressure regulator, which in theory acts as a damper. I am thinking of buying a marren damper, or two

#99

where does the return go to in your surge tank?

Seen this?

Fuelab Tech Tips: Return Line Plumbing - YouTube

Seen this?

Fuelab Tech Tips: Return Line Plumbing - YouTube

First time seeing the video, thanks for sharing, and adding that to the list of things to check/test

#100

Senior Member

Looking at the data log, I have to wonder if there may be constant pressure oscillations as the injectors open and close, and due to the sample rate of the data, it shows up as larger dips in pressure.

If the overall flow was too low I'd expect the readings to be smoother.

Do you have access to an oscilloscope to check the raw output from the sensor? You could compare it to the data log. This may be revealing.

Also you can change the sample rate in ECU Manager.

If the overall flow was too low I'd expect the readings to be smoother.

Do you have access to an oscilloscope to check the raw output from the sensor? You could compare it to the data log. This may be revealing.

Also you can change the sample rate in ECU Manager.