Strange fuel pressure issue E85

#1

I just recently put a new E85 setup on my car and since I've changed over I'm having a fuel pressure issue under load. I would appreciate your help on this matter.

Fuel System:

Bosh 044 pump inline -6 line welded on to stock pickup 70 micron SS sock ( changed to Walbro 485 same thing) (real Bosch 044 confirmed)

Large bulk heads on pickup 10 gauge wire to chassis ground and wired to Haltech PS1K relay. I've also tried wiring to battery directly no change

-6 SS 90 fittings welded on to stock pickup for feed and return line

1/4 Mocal vent (tested ventilation by unscrewing cap and doing a log no change)

Feed line -6 Teflon coated line to inline -10 micron SS filter brand new to SS hard lines in factory location (changed inline to larger filter no change)

-6 Teflon line to Earl's fuel Y block this is where my SS fuel pressure sensor in mounted (changed fpr sensor no change)

-6 line Teflon coated to feed primary KD rail and secondary KD rail anodized, EV14 1000/2200cc (Teflon lines replaced same thing) (injectors have been re flow tested and cleaned same thing)

Aeromotive FPR new diaphragm a1000 -6 (changed FPR no change)

Return line -6 Teflon coated to hard line -6

Alternator rebuilt high amp with new regulator constant 13.6 Volts under load no change. Tested voltage while under load at relay reads 13.0 volts.

I'm all out of idea's and options...

I had a shop flow test since I know it's a volume /restriction issue and it passed in the rear and middle but not in the engine bay. I had him replace the Teflon lines in the front thinking it was a kink in the line. He also found a fitting that was reduced from hard line to Teflon line in engine bay changed that no change.

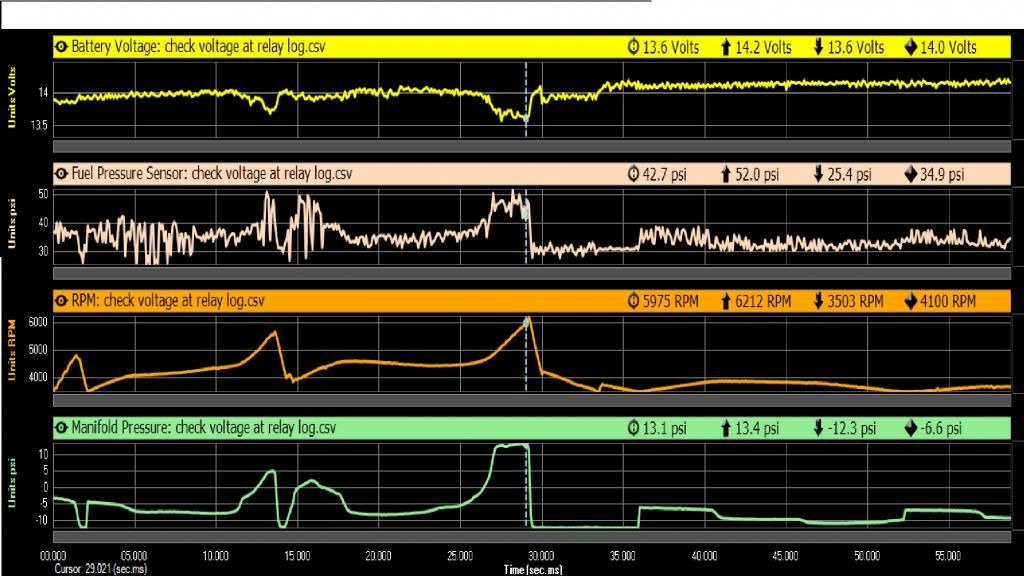

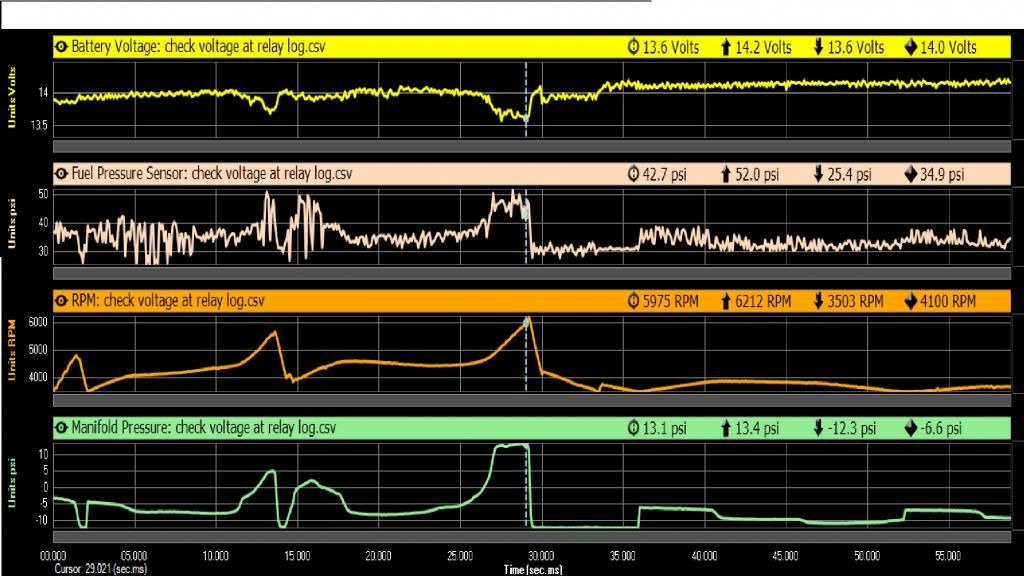

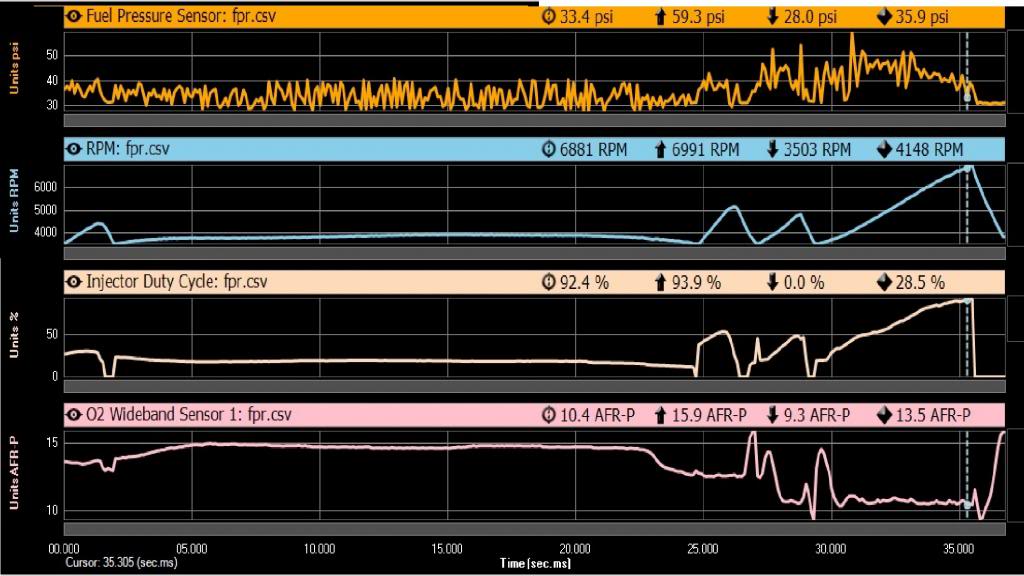

Here is a picture of the log middle of the map is under load. Fuel pressure drops to 42psi from 52psi the lowest point at 5,900rpm, 13.6 volts and 13psi manifold pressure. Fuel pressure starts dropping at 5,200 rpm you can also see under normal driving the fuel pressure is erratic.

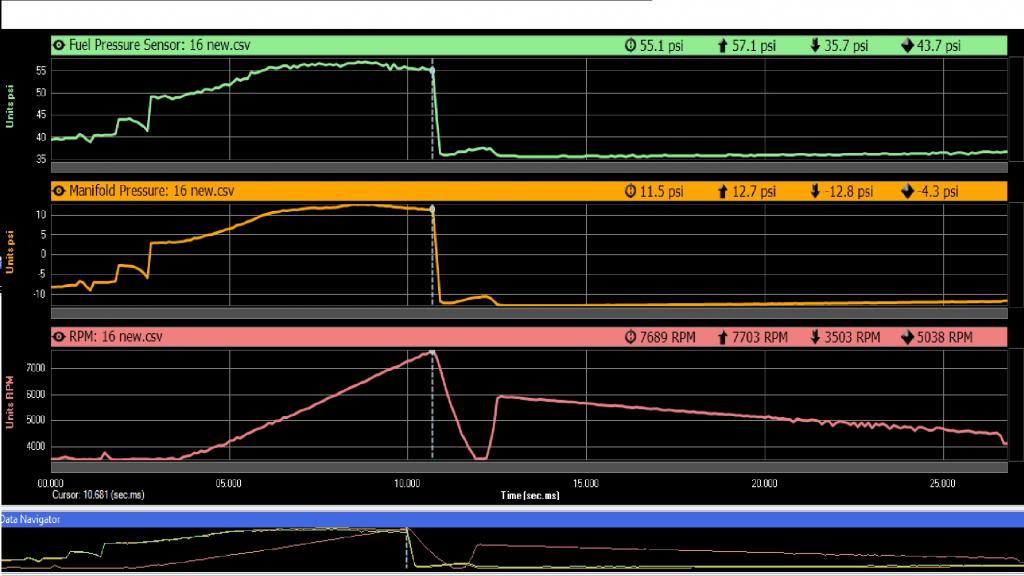

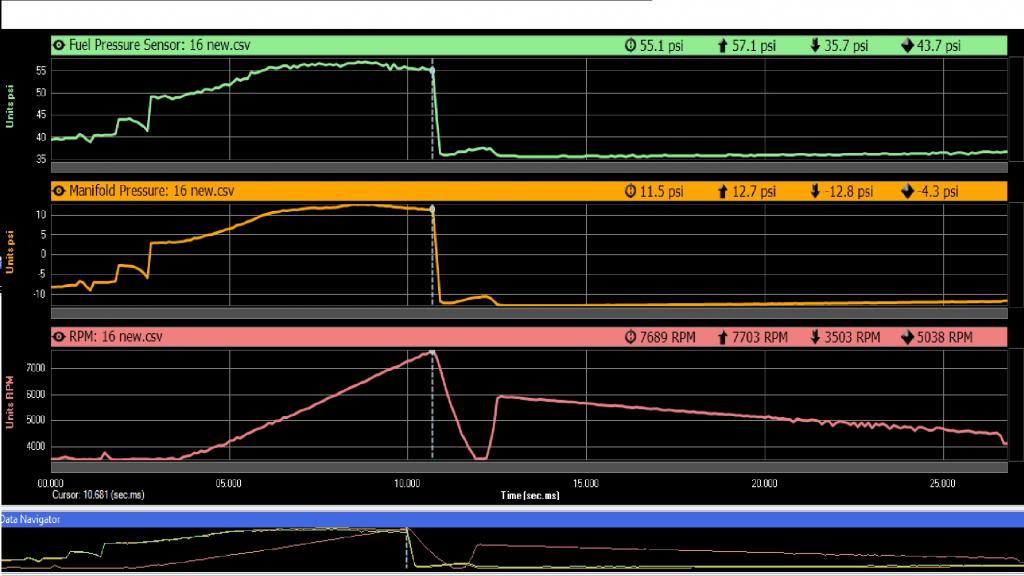

Not my car but normal fuel pressure on dyno:

Thank you in advance

-Jonathan

Fuel System:

Bosh 044 pump inline -6 line welded on to stock pickup 70 micron SS sock ( changed to Walbro 485 same thing) (real Bosch 044 confirmed)

Large bulk heads on pickup 10 gauge wire to chassis ground and wired to Haltech PS1K relay. I've also tried wiring to battery directly no change

-6 SS 90 fittings welded on to stock pickup for feed and return line

1/4 Mocal vent (tested ventilation by unscrewing cap and doing a log no change)

Feed line -6 Teflon coated line to inline -10 micron SS filter brand new to SS hard lines in factory location (changed inline to larger filter no change)

-6 Teflon line to Earl's fuel Y block this is where my SS fuel pressure sensor in mounted (changed fpr sensor no change)

-6 line Teflon coated to feed primary KD rail and secondary KD rail anodized, EV14 1000/2200cc (Teflon lines replaced same thing) (injectors have been re flow tested and cleaned same thing)

Aeromotive FPR new diaphragm a1000 -6 (changed FPR no change)

Return line -6 Teflon coated to hard line -6

Alternator rebuilt high amp with new regulator constant 13.6 Volts under load no change. Tested voltage while under load at relay reads 13.0 volts.

I'm all out of idea's and options...

I had a shop flow test since I know it's a volume /restriction issue and it passed in the rear and middle but not in the engine bay. I had him replace the Teflon lines in the front thinking it was a kink in the line. He also found a fitting that was reduced from hard line to Teflon line in engine bay changed that no change.

Here is a picture of the log middle of the map is under load. Fuel pressure drops to 42psi from 52psi the lowest point at 5,900rpm, 13.6 volts and 13psi manifold pressure. Fuel pressure starts dropping at 5,200 rpm you can also see under normal driving the fuel pressure is erratic.

Not my car but normal fuel pressure on dyno:

Thank you in advance

-Jonathan

#2

Which sensor are you using for the fuel pressure? How does your fuel pressure looks while the car is at idle?

I am having similar problems with the fuel pressure readings, and oil pressure readings; both readings are taken from AEM brass sensors to a haltech PS1000.

In my case, a mechanical gauge shows steady pressure!

I am having similar problems with the fuel pressure readings, and oil pressure readings; both readings are taken from AEM brass sensors to a haltech PS1000.

In my case, a mechanical gauge shows steady pressure!

#4

the closer the sensor is to the rails the more likely you are going to pick up on the harmonics of the injectors opening/closing. if the sensor can be moved to the middle of the car or closer to the pump it might not be so erratic, or a filter could be installed inline before the sensor(an orifice, a restrictor to muffle the signal. cheap sensors have no filtering and the readings will be jibberish).

that said once you muffle the signal i'm sure you will find you're just hunting a witch. once you smooth it out if it then still doesn't follow your map lines then you can look at why. the sensor should still be after the filter so a restrictor or different sensor would be a better choice.

that said once you muffle the signal i'm sure you will find you're just hunting a witch. once you smooth it out if it then still doesn't follow your map lines then you can look at why. the sensor should still be after the filter so a restrictor or different sensor would be a better choice.

Last edited by RotaryEvolution; 03-12-14 at 04:25 PM.

#7

I created the same post in another thread here is another post to my issue.

Awesome man.. one of the shops pulled the element out and did a test looking at the digital gauge no log he said it went pig rich so they thought they found the issue too small of a inline filter replaced the inline filter to a larger assembly but it was the same thing.

The weird thing the filter JEGS Billet 40 micron was dirty and looked to be strained as you mentioned. I ran the same filter on my Evo X, E85, 400whp no issues but it's not a rotary.

I had the EXACT issue.

My fuel system is way overkill with a SX fuel pump good for 1300 hp -10 line from tank to injectors.

I had a 100 micron pre pump and 20 micron post pump.

I removed the element from my 20 mic post filter and there was a noticeable increase in pump noise(back to normal)

and it resolved the fuel starvation issue.

For some reason the E85 has a film that develops in the fuel system and clogs the fuel filters.

I cleaned the filters with methanol and noticed some weird stuff settle at the bottom of the container.

Now I'm just running the pre filter and I'll just keep an eye on the injector filters every once in a while.

So even with a pump that runs about 130 Gallons/hr it could not pump the volume through a 20 mic filter.

So for a smaller pump and a 10 mic filter it could be impossible for the pump to do it's job.

As an added note, my filter started to rip holes in the stainless steel element, proving to me that

the pressure between the pump and the filter was extremely high.

I do want to give Johnny at J-Tran Studios props for discovering the issue based on expertise.

My advice, temporally ditch the inline filter completely and let me know if it resolves your issue. It did for me.

Cheers,

Joe

My fuel system is way overkill with a SX fuel pump good for 1300 hp -10 line from tank to injectors.

I had a 100 micron pre pump and 20 micron post pump.

I removed the element from my 20 mic post filter and there was a noticeable increase in pump noise(back to normal)

and it resolved the fuel starvation issue.

For some reason the E85 has a film that develops in the fuel system and clogs the fuel filters.

I cleaned the filters with methanol and noticed some weird stuff settle at the bottom of the container.

Now I'm just running the pre filter and I'll just keep an eye on the injector filters every once in a while.

So even with a pump that runs about 130 Gallons/hr it could not pump the volume through a 20 mic filter.

So for a smaller pump and a 10 mic filter it could be impossible for the pump to do it's job.

As an added note, my filter started to rip holes in the stainless steel element, proving to me that

the pressure between the pump and the filter was extremely high.

I do want to give Johnny at J-Tran Studios props for discovering the issue based on expertise.

My advice, temporally ditch the inline filter completely and let me know if it resolves your issue. It did for me.

Cheers,

Joe

The weird thing the filter JEGS Billet 40 micron was dirty and looked to be strained as you mentioned. I ran the same filter on my Evo X, E85, 400whp no issues but it's not a rotary.

Trending Topics

#12

This is what my filter looks like.

Aeromotive 12604 Aeromotive In-Line Fuel Filters - Free Shipping on All Orders @ JEGS

Your filter just might not have enough surface area. That, plus the fact that a fuel pump is very

sensitive on the inlet side of the pump. They work good pumping, not so good sucking.

For example, in the jet, each engine driven fuel pump is good well over 5000+ lbs/hr.

But without the electric boost pumps in the on position, the plane is unable to provide proper fuel pressure over 25000 ft.

The engine driven pumps just have trouble sucking fuel through 50 feet of line, and needs help to get the fuel up to the engines.

Once, not too long ago after switching to E85, a small bit of rubber hose got sucked into the inlet

port of the filter. It was too large to get past the opening of the AN fitting. as the fuel tried to squeeze by

it made erratic noises from the pump and the fuel pressure fluctuated -10 psi.

I wasn't sure if I was going to be able to limp it home, but I did. And lo and behold once removed everything was back to normal.

Joe

OH! How much horsepower are we aiming for? Over 400+ to the wheels I'm guessing??

Aeromotive 12604 Aeromotive In-Line Fuel Filters - Free Shipping on All Orders @ JEGS

Your filter just might not have enough surface area. That, plus the fact that a fuel pump is very

sensitive on the inlet side of the pump. They work good pumping, not so good sucking.

For example, in the jet, each engine driven fuel pump is good well over 5000+ lbs/hr.

But without the electric boost pumps in the on position, the plane is unable to provide proper fuel pressure over 25000 ft.

The engine driven pumps just have trouble sucking fuel through 50 feet of line, and needs help to get the fuel up to the engines.

Once, not too long ago after switching to E85, a small bit of rubber hose got sucked into the inlet

port of the filter. It was too large to get past the opening of the AN fitting. as the fuel tried to squeeze by

it made erratic noises from the pump and the fuel pressure fluctuated -10 psi.

I wasn't sure if I was going to be able to limp it home, but I did. And lo and behold once removed everything was back to normal.

Joe

OH! How much horsepower are we aiming for? Over 400+ to the wheels I'm guessing??

#13

Remember I changed to the larger Aeromotive SS inline filter like picture below and a Walbro 485 pump w/sock the same issue:

I'm on the Bosch with 70 micron SS sock and JEGS Billet 40 micron inline filter again:

Here are the filters I was using the inline I used with stainless element and the sock is stainless 70 micron mounted on bosch 044.

I'm on the Bosch with 70 micron SS sock and JEGS Billet 40 micron inline filter again:

Here are the filters I was using the inline I used with stainless element and the sock is stainless 70 micron mounted on bosch 044.

#14

I plan to pull the inline filter element out and log. I just realized they are both 40 microns which is a lot of filtering, the last shop installed the Aeromotive but they put back in all my old parts when it didn't work.

Here is a 10 micron SS filter

F-10 Inline Modular Fuel Filter

Here is a 10 micron SS filter

F-10 Inline Modular Fuel Filter

#16

talking head

going back to basics.. choose another spot to reference the fuel regulators manifold pressure signal from .. make sure it is not a purge or partial vacuum port

#17

I've also set the fuel pressure at a Static 60 with no manifold pressure plugged in and it was the same. This is why I figure it's a restriction/volume related issue.

This past week all the Teflon lines were pulled off to check for restriction no issues with lines.

My next step besides running the fuel lines like factory is to bypass the lines with a -6 hose.

Thx

-J

#19

talking head

i was thinking you have fuel going up the ref line ( but doesnt explain why it fails same in a static test )

maybe the reg hat has some fuel in it already ?

maybe the reg hat has some fuel in it already ?

Last edited by bumpstart; 03-17-14 at 10:14 PM.

#23

35r 13b first gen

iTrader: (3)

Join Date: Apr 2002

Location: Richland Center WI

Posts: 1,290

Likes: 0

Received 0 Likes

on

0 Posts

A very knowledgable rotary builder/ tuner recommended that I run-8 y into -6 at rails This is for pump. And probably less power than what your looking for... Unless I misread are u running single -6 feed? If so is that large enough for e85?

Has anybody heard of anyone running the fuel lines separately to the fuel rails and both into the FPR and having issues? This is the only thing I ran differently from before.

Has anybody heard of anyone running the fuel lines separately to the fuel rails and both into the FPR and having issues? This is the only thing I ran differently from before.