Stainles Braid Tial WG Lines

#3

Rotary Enthusiast

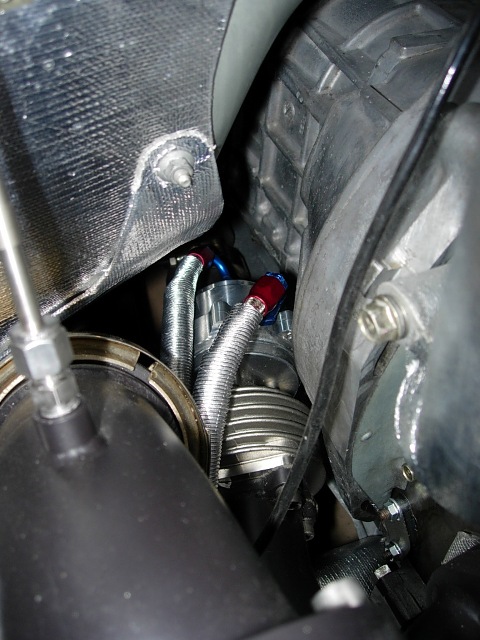

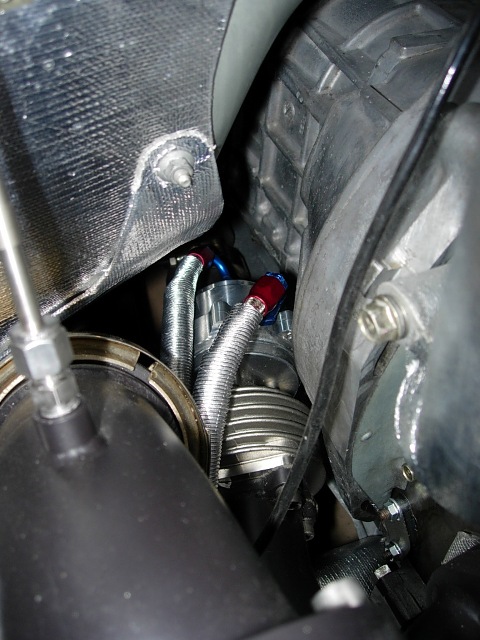

Here's some pics using earls fittngs with ss braided lines. I also used a heat shield tubing as the lines a few inches from the exhaust manifold:

I think it's good insurance.

I think it's good insurance.

#6

I used SS lines on my HKS GT 60mm wastegate. Make sure you use swivel fittings so the hose can rotate even when tightened or it can loosen up easily from the weight of the hose/vibration.

I later added a Hallman Pro manual boost controller and fit it up for -AN lines as well. That was a bit of a pain as the lower nipple is also the valve seat for the ball and the side nipple has the bleed hole.- worked out very well in the end.

I later added a Hallman Pro manual boost controller and fit it up for -AN lines as well. That was a bit of a pain as the lower nipple is also the valve seat for the ball and the side nipple has the bleed hole.- worked out very well in the end.

#7

Full Member

Join Date: Oct 2002

Location: Danville, Califonia

Posts: 158

Likes: 0

Received 0 Likes

on

0 Posts

it is a very good idea to do this for high boost applications. on my car awhile back i had regular rubber hose with a zip tie. one night on 100 octane i was really pushing the car hard (tuned for 27psi) and the line to the wastegate blew off. ended up at 38psi for a few seconds.

stainless lines w/ nice fittings ftw!

stainless lines w/ nice fittings ftw!

Trending Topics

#15

Originally Posted by CMonakar

What size lines are you guys using?

rotarypower101 -3AN?

blue TII -4AN?

rotarypower101 -3AN?

blue TII -4AN?

Therefore the smaller the internal volume the quicker the response time and reaction to the desired position.

But for all intensive purposes, almost any reasonable size is probably be fine.

#20

IRS 4 Life

iTrader: (12)

Join Date: Feb 2001

Location: Sicklerville, South Jersey!!

Posts: 2,634

Likes: 0

Received 2 Likes

on

2 Posts

IIRC most of the -3 is steel stuff, let me see if I can find one

heres steel just in case

http://secure.mycart.net/catalogs/ca...showprevnext=1

heres steel just in case

http://secure.mycart.net/catalogs/ca...showprevnext=1

#22

Mine is big -6an stuff since that is what I had left over from my fuel system.

I haven't had a problem w/ the nylon zip ties melting, but once I repositioned the line wrong after I put in the manual boost controller and the fire hose ended up against the turbo housing.

It smelled bad and discolored a bit- that is how I found out. Hose was still pliable.

Even w/ the manual boost controller (ceramic ball Hallman Pro) it does not spike. Data logs show boost hits a psi or so below max holds there and then settles to max a few tenths of a second later with roll on or downshift boosting.

Wastegates size, boost controller bleed hole size and a bunch of other factors affect this though of course.

I haven't had a problem w/ the nylon zip ties melting, but once I repositioned the line wrong after I put in the manual boost controller and the fire hose ended up against the turbo housing.

It smelled bad and discolored a bit- that is how I found out. Hose was still pliable.

Even w/ the manual boost controller (ceramic ball Hallman Pro) it does not spike. Data logs show boost hits a psi or so below max holds there and then settles to max a few tenths of a second later with roll on or downshift boosting.

Wastegates size, boost controller bleed hole size and a bunch of other factors affect this though of course.

#24

I finally got that WG set-up to work for me without boost creep by porting the manifold and turbo exhaust housing very large up to the WG runners.

Fixed boost creep, but hurt boost response a bit since the stock velocity stacks in the manifold are ported to almost none. I still hits max boost at same rpms (15psi 3,300rpm in 5th), but boost below 3,000rpm boost is lower/slower than it was.

My next stock hybrid will circumvent this problem by putting the WG runners in the manifold right before the velocity stacks and angled so flow wants to exit the WG.

I think that if I put the WG runners in the right spot the turbulence at the far edge of the WG runners will just act as part of the velcocity stack and so not be detrimental to flow.

I am thinking two little Tial WGs to keep it divided instead of one large one with a divider. That WG divider pictured broke again even though it was 1/8" thick SS with a floating design for expansion.

I am thinking of using the BB T04B (T04S) center section and HiFi housing as well.

Anyways, the turbo/WG is working great now. Most of the time Auto-X ing I am having to short shift it keeping it out of the powerband to keep the RA-1s from spinning- but having the power to burn out there on the streets sure is nice. :P

Fixed boost creep, but hurt boost response a bit since the stock velocity stacks in the manifold are ported to almost none. I still hits max boost at same rpms (15psi 3,300rpm in 5th), but boost below 3,000rpm boost is lower/slower than it was.

My next stock hybrid will circumvent this problem by putting the WG runners in the manifold right before the velocity stacks and angled so flow wants to exit the WG.

I think that if I put the WG runners in the right spot the turbulence at the far edge of the WG runners will just act as part of the velcocity stack and so not be detrimental to flow.

I am thinking two little Tial WGs to keep it divided instead of one large one with a divider. That WG divider pictured broke again even though it was 1/8" thick SS with a floating design for expansion.

I am thinking of using the BB T04B (T04S) center section and HiFi housing as well.

Anyways, the turbo/WG is working great now. Most of the time Auto-X ing I am having to short shift it keeping it out of the powerband to keep the RA-1s from spinning- but having the power to burn out there on the streets sure is nice. :P

#25

Originally Posted by rotarypower101

I have all these pics I have to put them somewhere right

.JPG)

.JPG)

I like the boost solenoid instead of the EGR.... neat..... will set up mine there

Any heat issues?

Sorry for hijacking this.... but its worth an ask !