Manifold Porting

The following users liked this post:

Slider84 (12-22-22)

#7

Registered shy guy

iTrader: (1)

Join Date: Jul 2007

Location: tewksbury, ma

Posts: 1,436

Likes: 0

Received 0 Likes

on

0 Posts

hey man this is a od question iam trying to port some thing else a intake for my drag car what tools are you using to get down the big chunks.

the intake iam working on is for a 84 rs turbo capri.

the intake iam working on is for a 84 rs turbo capri.

Trending Topics

#9

If you go in and polish the runners all the way through and pin the manifolds for fitment you should have gains from several affects.

1) The flow gains from actual diameter gained as well as the smaller boundry layer (from smoother walls) creating more effective flow diameter.

2) The smoother port walls accentuate the dynamic effect quite a bit as the acoustic waves lose much less energy traveling from port to port.

Then you could go all crazy on the throttle body. The usual TB port and polish, halfshaft the primary throttle shaft with flat head screws, contour the 2ndary throttle shaft with flat head screws, round out the rear of the leading edge of the throttle plates and contour the rear of the TB for a smooth flow merge between plates.

1) The flow gains from actual diameter gained as well as the smaller boundry layer (from smoother walls) creating more effective flow diameter.

2) The smoother port walls accentuate the dynamic effect quite a bit as the acoustic waves lose much less energy traveling from port to port.

Then you could go all crazy on the throttle body. The usual TB port and polish, halfshaft the primary throttle shaft with flat head screws, contour the 2ndary throttle shaft with flat head screws, round out the rear of the leading edge of the throttle plates and contour the rear of the TB for a smooth flow merge between plates.

#11

Full Member

Thread Starter

Join Date: Sep 2006

Location: Cali

Posts: 182

Likes: 0

Received 0 Likes

on

0 Posts

A CNC machine would be ideal but I dont have one so I start out with a saw to cut as much then use my long bits. For thight corners I use a Dremel.

#12

Full Member

Thread Starter

Join Date: Sep 2006

Location: Cali

Posts: 182

Likes: 0

Received 0 Likes

on

0 Posts

#13

Registered shy guy

iTrader: (1)

Join Date: Jul 2007

Location: tewksbury, ma

Posts: 1,436

Likes: 0

Received 0 Likes

on

0 Posts

dont need to hijack your thread just wanted to see a pic of the bit your useing, port tools are like carb setups on the net; black magic,not every one is willing to help. no ford guys wanna help out at all. i was hopeing you rx7 guys would help me out.(i do own a rx7)

yeah its a 90deg elbow iam gutting. its has 4 runners in a square pattern(inline 4 banger 2.3 ford turbo motor). i all ready put it in a bridgeport mill to remove 90% of the metal. just wanted to see the dermal tools your useing

this is the pic of the part iam working on

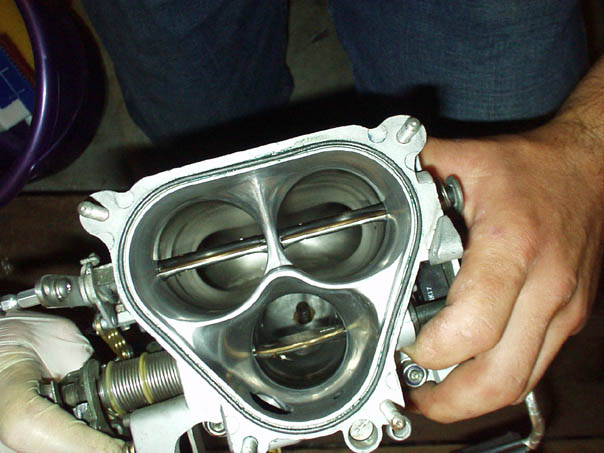

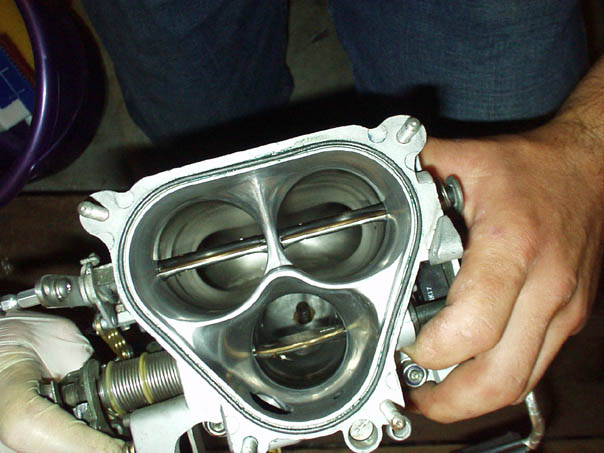

this is whats this inside should look like when iam done

i all ready got the lower manifold to look like this

yeah its a 90deg elbow iam gutting. its has 4 runners in a square pattern(inline 4 banger 2.3 ford turbo motor). i all ready put it in a bridgeport mill to remove 90% of the metal. just wanted to see the dermal tools your useing

this is the pic of the part iam working on

this is whats this inside should look like when iam done

i all ready got the lower manifold to look like this

#15

This is what Rob said:

Small gains from cleaning up the upper are possible. Considering the work necessary, not a great trade off unless you have time and want to play. The t/body is the biggest restriction area. If you have time, start there and the manifold match where it bolts on.

Something to consider, one of the posts mentions a signal bounce. A motor under boost looses the effect, so any reduction in signal strength helps the more the throttle is closed.

On wall finish, the more fuel the area sees the rougher. Helps atomize the fuel before it enters the chamber. Be careful of over polishing, it enbrittles the surface and may cause cracking.

Nice workmanship on both the FD and ford intake. I have done one of the fords, may years ago.

Their best friend is a 1/4" drill blank w/ a slot in the end. You can make it any length. THEY ARE POTENTIALLY VERY DANGEROUS!! If the shank is spun up without being

on a surface it could easily bend. It can bend 90* so a 6" length is now spinning a ONE FOOT dia. circle at the end of the grinder!! This could take off fingers!!

Small gains from cleaning up the upper are possible. Considering the work necessary, not a great trade off unless you have time and want to play. The t/body is the biggest restriction area. If you have time, start there and the manifold match where it bolts on.

Something to consider, one of the posts mentions a signal bounce. A motor under boost looses the effect, so any reduction in signal strength helps the more the throttle is closed.

On wall finish, the more fuel the area sees the rougher. Helps atomize the fuel before it enters the chamber. Be careful of over polishing, it enbrittles the surface and may cause cracking.

Nice workmanship on both the FD and ford intake. I have done one of the fords, may years ago.

Their best friend is a 1/4" drill blank w/ a slot in the end. You can make it any length. THEY ARE POTENTIALLY VERY DANGEROUS!! If the shank is spun up without being

on a surface it could easily bend. It can bend 90* so a 6" length is now spinning a ONE FOOT dia. circle at the end of the grinder!! This could take off fingers!!

#16

Registered shy guy

iTrader: (1)

Join Date: Jul 2007

Location: tewksbury, ma

Posts: 1,436

Likes: 0

Received 0 Likes

on

0 Posts

the picture of the upper is not mine, the picture of the lower intake is what my lower intake looks like. iam kinda confused as to the "drill blank w/ a slot in the end".

with the upper intake i kinds have "steps" where the 90 deg bend is that iam not sure what tool to use ect.

can you guys post pics of the tools to use.

for the lower i just used a rat file to get rid of most of the metal then used these werid dremal disk's i stole from work. they just remove little bit at a time.

didnt mean to high jack your thread i came in to see pics how how you guys did yours cause a friend needs help with his rx.

now i need to find pics of a ported rx7 carb for my self.

with the upper intake i kinds have "steps" where the 90 deg bend is that iam not sure what tool to use ect.

can you guys post pics of the tools to use.

for the lower i just used a rat file to get rid of most of the metal then used these werid dremal disk's i stole from work. they just remove little bit at a time.

didnt mean to high jack your thread i came in to see pics how how you guys did yours cause a friend needs help with his rx.

now i need to find pics of a ported rx7 carb for my self.

#19

Full Member

Thread Starter

Join Date: Sep 2006

Location: Cali

Posts: 182

Likes: 0

Received 0 Likes

on

0 Posts

No problem. None of use where born with this knowled, I'm glad this is informative for others too. Sorry it took a while to show the tools, I was too caught up with my project.

the picture of the upper is not mine, the picture of the lower intake is what my lower intake looks like. iam kinda confused as to the "drill blank w/ a slot in the end".

with the upper intake i kinds have "steps" where the 90 deg bend is that iam not sure what tool to use ect.

can you guys post pics of the tools to use.

for the lower i just used a rat file to get rid of most of the metal then used these werid dremal disk's i stole from work. they just remove little bit at a time.

didnt mean to high jack your thread i came in to see pics how how you guys did yours cause a friend needs help with his rx.

now i need to find pics of a ported rx7 carb for my self.

with the upper intake i kinds have "steps" where the 90 deg bend is that iam not sure what tool to use ect.

can you guys post pics of the tools to use.

for the lower i just used a rat file to get rid of most of the metal then used these werid dremal disk's i stole from work. they just remove little bit at a time.

didnt mean to high jack your thread i came in to see pics how how you guys did yours cause a friend needs help with his rx.

now i need to find pics of a ported rx7 carb for my self.

#20

If theres no FUEL going through that particular part of the manifold, make it as smooth as you have patience for (READ: POLISHED). Most set ups including stock have NO FUEL running through the throttle body or upper intake, just the lower (secondary runners only). So if theres no fuel going trough it, polish it. If there is fuel going through it (secondary lower intake) leave a slight rough finish. And its NOT to promote any kind of "swirl" for atomization. If to keep fuel from sticking to the runner walls, keeping the fuel "suspended" in the air going into the engine. Even after all this thought and time polishing and roughining doing finishing work (notice, Im talking about finish, not actual porting), you MIGHT be able to measure a differance on a dyno lol.

~Mike.........

~Mike.........

#21

Full Member

Thread Starter

Join Date: Sep 2006

Location: Cali

Posts: 182

Likes: 0

Received 0 Likes

on

0 Posts

Dam....now you just made me realize how much more work I have to do. Good point though.

Thank you

Thank you

If theres no FUEL going through that particular part of the manifold, make it as smooth as you have patience for (READ: POLISHED). Most set ups including stock have NO FUEL running through the throttle body or upper intake, just the lower (secondary runners only). So if theres no fuel going trough it, polish it. If there is fuel going through it (secondary lower intake) leave a slight rough finish. And its NOT to promote any kind of "swirl" for atomization. If to keep fuel from sticking to the runner walls, keeping the fuel "suspended" in the air going into the engine. Even after all this thought and time polishing and roughining doing finishing work (notice, Im talking about finish, not actual porting), you MIGHT be able to measure a differance on a dyno lol.

~Mike.........

~Mike.........

#22

dont need to hijack your thread just wanted to see a pic of the bit your useing, port tools are like carb setups on the net; black magic,not every one is willing to help. no ford guys wanna help out at all. i was hopeing you rx7 guys would help me out.(i do own a rx7)

yeah its a 90deg elbow iam gutting. its has 4 runners in a square pattern(inline 4 banger 2.3 ford turbo motor). i all ready put it in a bridgeport mill to remove 90% of the metal. just wanted to see the dermal tools your useing

this is the pic of the part iam working on

this is whats this inside should look like when iam done

i all ready got the lower manifold to look like this

yeah its a 90deg elbow iam gutting. its has 4 runners in a square pattern(inline 4 banger 2.3 ford turbo motor). i all ready put it in a bridgeport mill to remove 90% of the metal. just wanted to see the dermal tools your useing

this is the pic of the part iam working on

this is whats this inside should look like when iam done

i all ready got the lower manifold to look like this

~Mike............

Last edited by RacerXtreme7; 01-29-08 at 10:56 AM.

#23

Registered shy guy

iTrader: (1)

Join Date: Jul 2007

Location: tewksbury, ma

Posts: 1,436

Likes: 0

Received 0 Likes

on

0 Posts

thanks for the advice. this porting setup is used by alot of the people that are in to 2.3l turbo ford's. stock the 90 deg bend upper goes over the motor, where cutting the upper intake and turning it 90 deg. i under stand what you mean, two of the ports on the lower mani would get air more then the other two. on the way its going to get set up the two ports would get more air forced in.(i worked in havc for a few years and under stand.)

i under stand what you mean about the air/fuel also. me and my buddy(half owner of car) where trying to figure out a way to run 4 ecu's to just control fuel to all ports ect.

i was thinking of bending a sheet of metal and welding in it so its just two big ports on the upper ect.

would you mind pming me and explaining in detail about

"but you should place a plenum on top or some kind of hat that will distribute the air more evenly."?

i under stand what you mean about the air/fuel also. me and my buddy(half owner of car) where trying to figure out a way to run 4 ecu's to just control fuel to all ports ect.

i was thinking of bending a sheet of metal and welding in it so its just two big ports on the upper ect.

would you mind pming me and explaining in detail about

"but you should place a plenum on top or some kind of hat that will distribute the air more evenly."?

Lookin good man holla if you need help with anything. I know that car inside and out.

Lookin good man holla if you need help with anything. I know that car inside and out.