How best to run my fuel system

#1

The wankel way!!

Thread Starter

Join Date: May 2008

Location: New Zealand

Posts: 462

Likes: 0

Received 0 Likes

on

0 Posts

How best to run my fuel system

Hi guys, I have had a look through a number of old posts around this but havn't found anything all that recent.

Currently I have a single FD with standard fuel rails and injectors and an Airtex intank Fuel pump running through the standard lines. Its al prety much stock apart from the breather line is not connected.

I have a KGParts secondary rail and 1680 injectors and plan to run the standard secondary 850s as the primaries in the standard primary rail.

Im now looking at getting all the lines and fitting together to install the new rail.

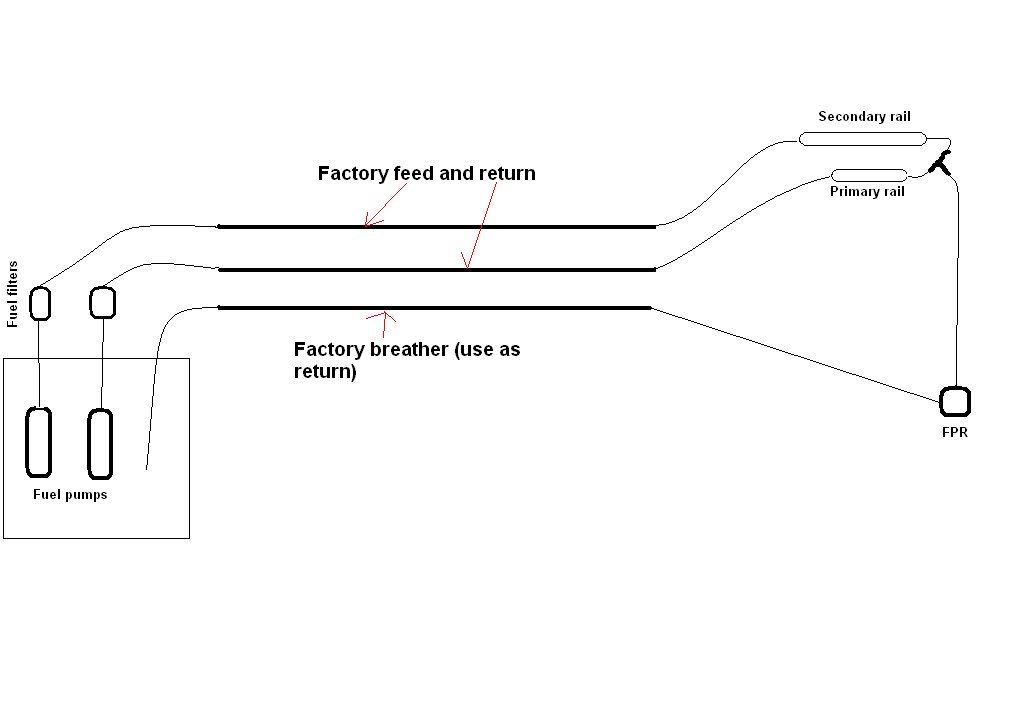

Im planing on using a second intank pump, using the standard feed and return as feed lines and the breather as the return as many have done and a FPR.

Is is best to run the two rails in series or paralell?

If I run them in series then I can just buy the banjo adapter from KGparts and the install will be easy. Running them in parallel will be a little harder but not a problem really.

What is the best way to go?

Currently I have a single FD with standard fuel rails and injectors and an Airtex intank Fuel pump running through the standard lines. Its al prety much stock apart from the breather line is not connected.

I have a KGParts secondary rail and 1680 injectors and plan to run the standard secondary 850s as the primaries in the standard primary rail.

Im now looking at getting all the lines and fitting together to install the new rail.

Im planing on using a second intank pump, using the standard feed and return as feed lines and the breather as the return as many have done and a FPR.

Is is best to run the two rails in series or paralell?

If I run them in series then I can just buy the banjo adapter from KGparts and the install will be easy. Running them in parallel will be a little harder but not a problem really.

What is the best way to go?

#4

The wankel way!!

Thread Starter

Join Date: May 2008

Location: New Zealand

Posts: 462

Likes: 0

Received 0 Likes

on

0 Posts

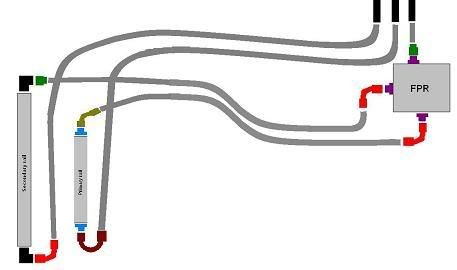

Also I have just brougt a second fuel pump and want to know the best way to utilize the factory hard lines to the firewall.

Was thinking of the following:

Is this the best way to utilize these?

Was thinking of the following:

Is this the best way to utilize these?

#5

Will work for horsepower

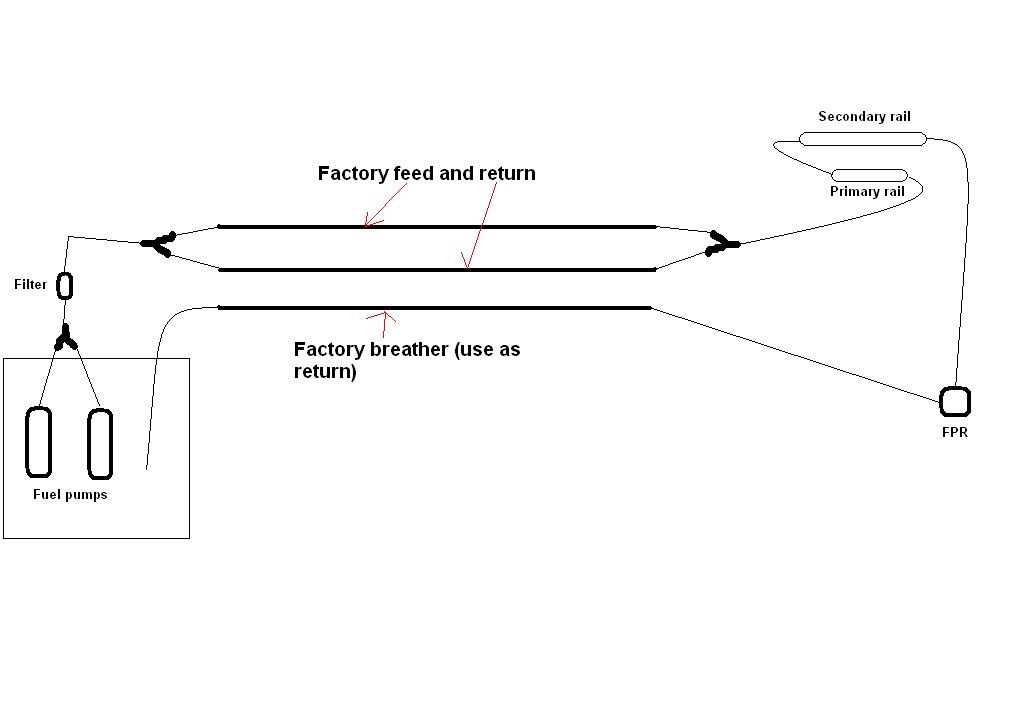

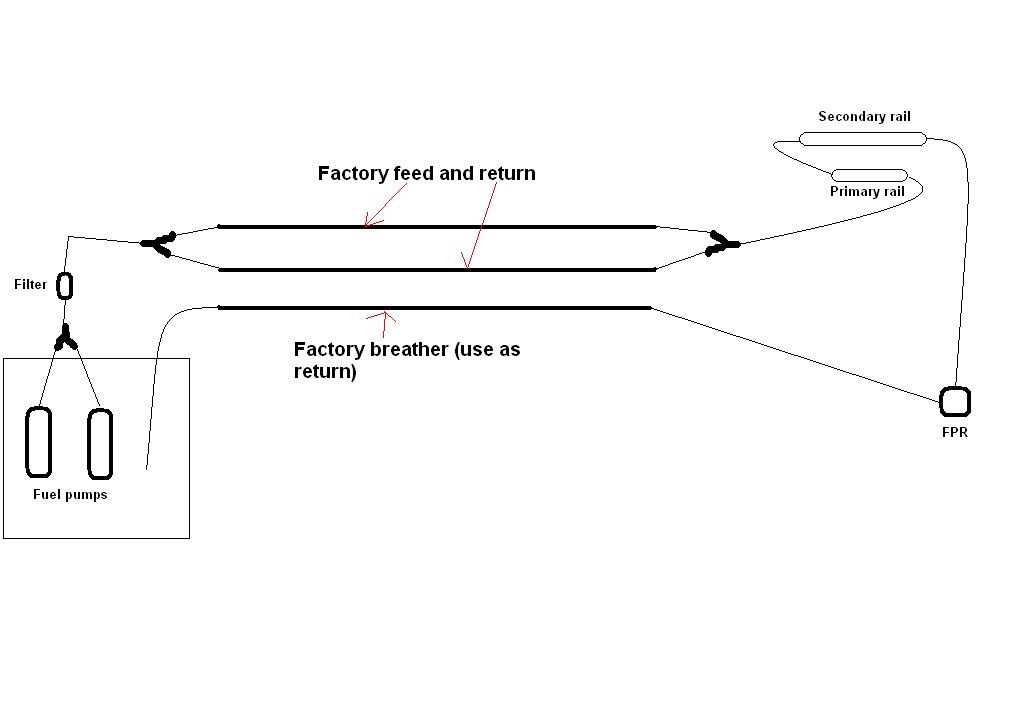

Thats what i have except i ran one pump per fuel rail and tied them at the fpr.

Dont forget fuel filter. I removed the pump assembley and drilled a hole for the return line and brazied it from the inside were its very clean[no gas fumes].

3/8s break line works good for return.

Dont forget fuel filter. I removed the pump assembley and drilled a hole for the return line and brazied it from the inside were its very clean[no gas fumes].

3/8s break line works good for return.

#6

The wankel way!!

Thread Starter

Join Date: May 2008

Location: New Zealand

Posts: 462

Likes: 0

Received 0 Likes

on

0 Posts

So something like this would work well? or would you run both returns to the FPR instead of the T piece? Will this still keep presures in both rails even?

Do you have the factory primary rail?

Do you have the factory primary rail?

#7

Will work for horsepower

Thats pretty much how mine is run but the fuel pressure regulator has two in's and one return on it.

I have aftermarket rails on both with top feed inj. 500 h/p for over ayear no problems. 850's-1680"s inj. holdes steady pressure with a base of 42 psi.

Good luck.

I have aftermarket rails on both with top feed inj. 500 h/p for over ayear no problems. 850's-1680"s inj. holdes steady pressure with a base of 42 psi.

Good luck.

Trending Topics

#9

The wankel way!!

Thread Starter

Join Date: May 2008

Location: New Zealand

Posts: 462

Likes: 0

Received 0 Likes

on

0 Posts

Ill give this design a go. The reason Im a little concerned about the fuel presure is because the two fuel pumps are not the same. They will be the same rating but different brands because I cant get another one the same as what i have.

#11

Will work for horsepower

I belive extruded alum 5051. Some are cast.

The difference in fuel pumps if there is any will balance volume and pressure at the regulator before returning pressure to the tank.

The difference in fuel pumps if there is any will balance volume and pressure at the regulator before returning pressure to the tank.

#12

The wankel way!!

Thread Starter

Join Date: May 2008

Location: New Zealand

Posts: 462

Likes: 0

Received 0 Likes

on

0 Posts

Thanks Busted, The last question I have is, is there any point running one way valves/check valves in the lines in case one pump fails, or is it not possible for fuel to flow that direction through a non running pump? The valves are expencive so Id rather not run them if theres no point but will if they will add safty to the system.

#13

Will work for horsepower

Theres no need for check valves and if you did loose a pump it will still work all four injectors but the volume and pressure will drop. Thats why you need to moniture the afr's when your driving it hard!

You can install a hobbs safty pressure switch should you loose a pump and shut down the spark! I dont have one but it can cut ing. in an emergency.

You can install a hobbs safty pressure switch should you loose a pump and shut down the spark! I dont have one but it can cut ing. in an emergency.

#14

The wankel way!!

Thread Starter

Join Date: May 2008

Location: New Zealand

Posts: 462

Likes: 0

Received 0 Likes

on

0 Posts

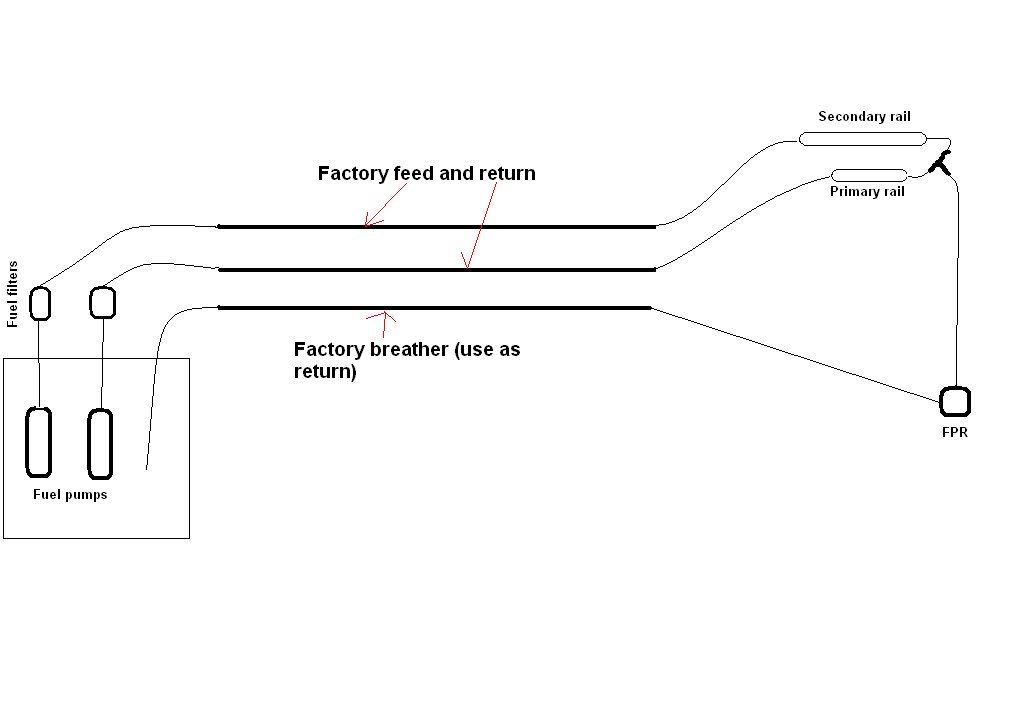

Ok this is the design I have settled on for the Firewall foward:

Only issue I have now is where to put the fuel presure gauge. I have a malpassi fuel reg that only has two inlets and one outlet. I'll probably just buy a new one with a build in gauge.

Thanks for all the help Busted7. Ill post up what I do with the hardlines back to the fuel tank when I have measured it all up.

Only issue I have now is where to put the fuel presure gauge. I have a malpassi fuel reg that only has two inlets and one outlet. I'll probably just buy a new one with a build in gauge.

Thanks for all the help Busted7. Ill post up what I do with the hardlines back to the fuel tank when I have measured it all up.

#19

Rotary Enthusiast

I am working on a fuel system too and I left the breather/emissions tube operational(was kinda worried about it causing any problems with vapors in the tank), used the stock fuel line as return and will now route a separate 1/2" tube from the fuel pumps all the way forward to a Y that will then split into two 6an to each fuel rail. I will have one pump run at all times and one will come on with boost via a pressure switch and a relay. It will have 720cc primaries, 1000cc Primary2s and 1680cc Secondaries. The reason for running only one pump is that I am worried the return will not be enough to control pressure when at idle and the fact that having both pumps running all the time will just heat the fuel.

The 1/2" tube isn't that expensive and it might be a viable option for the OP as well in case you don't want to mess with the fuel vapors tube.

What do you guys think?

Chris

The 1/2" tube isn't that expensive and it might be a viable option for the OP as well in case you don't want to mess with the fuel vapors tube.

What do you guys think?

Chris

#20

Will work for horsepower

At 75/80 mph at 14.9/15.1 afr i get 22 mpg.

The 850 inj have no problem ideling!

Thanks.

#21

Will work for horsepower

The kit looks nice.

I went with both pumps running becouse if i see an afr problem caused by a pump quiting i will see it sooner on the afr gauge than wide open throttle maybe.

Ive never had fuel over heat problem even in 98 deg.

Something i forgot to mention running the evap line for a return will require that you vent the fuel tank, i vented the fuel cap with a 3/16 drill bit. No problems with odor or spiting do not drill through the plastic screen in the bottom of the cap.

There are other ways to vent the tank this was just my choice, i was in a hurry at the time and have not found a reason to change it yet. I like simple if it works good.

I went with both pumps running becouse if i see an afr problem caused by a pump quiting i will see it sooner on the afr gauge than wide open throttle maybe.

Ive never had fuel over heat problem even in 98 deg.

Something i forgot to mention running the evap line for a return will require that you vent the fuel tank, i vented the fuel cap with a 3/16 drill bit. No problems with odor or spiting do not drill through the plastic screen in the bottom of the cap.

There are other ways to vent the tank this was just my choice, i was in a hurry at the time and have not found a reason to change it yet. I like simple if it works good.

#22

Rotary Enthusiast

The kit looks nice.

I went with both pumps running becouse if i see an afr problem caused by a pump quiting i will see it sooner on the afr gauge than wide open throttle maybe.

Ive never had fuel over heat problem even in 98 deg.

Something i forgot to mention running the evap line for a return will require that you vent the fuel tank, i vented the fuel cap with a 3/16 drill bit. No problems with odor or spiting do not drill through the plastic screen in the bottom of the cap.

There are other ways to vent the tank this was just my choice, i was in a hurry at the time and have not found a reason to change it yet. I like simple if it works good.

I went with both pumps running becouse if i see an afr problem caused by a pump quiting i will see it sooner on the afr gauge than wide open throttle maybe.

Ive never had fuel over heat problem even in 98 deg.

Something i forgot to mention running the evap line for a return will require that you vent the fuel tank, i vented the fuel cap with a 3/16 drill bit. No problems with odor or spiting do not drill through the plastic screen in the bottom of the cap.

There are other ways to vent the tank this was just my choice, i was in a hurry at the time and have not found a reason to change it yet. I like simple if it works good.

The fuel system was done by me, no kit, although that would've made it easier, it uses Kg parts fuel rails(RX-8) and a lot of thinking on what fittings to get. It should be pretty fool-proof when I am done with it though

Question: When you ran both pumps, where they both Bosch 044-'s returning through the stock fuel line? How did the pressure behave at idle?

Thanks,

Chris

#24

Rotary Enthusiast

ok, I see. that is my worry about having both on all the time...it will be trying to return two Bosch 044 fuel pumps through a 5/16" line....I'm thinking it might cause the pressure to spike when at idle....I guess I'll just have to try it to know.... Thanks for the pointers.

Chris

Chris

#25

The wankel way!!

Thread Starter

Join Date: May 2008

Location: New Zealand

Posts: 462

Likes: 0

Received 0 Likes

on

0 Posts

Hay busted, have you got any pics of how you mounted the two pumps? Did you use one in the factoy location and a bracket to hold to second one next to it?