Fundamental Understanding of Turbos Question

#1

Fundamental Understanding of Turbos Question

For this question, assume gases are ideal and environments are controlled. Intake air temps are identical between the two cases.

Is it correct to say that if temperature was corrected to some temperature (let's say 23* C) and density of air adjusted for such, given the same intake and exhaust tracts except for the differences between two turbos, different turbos at the same psi will flow the same instantaneous amount of air, corrected for temperature differences?

For example, a snail vs. a truck turbo blowing at 16 psi, the snail will be blowing tons of hot air, the truck turbo might be in it's efficient zone. If we were to calculate how much air would actually be flowing if the snail turbo air was at the same temperature as the truck turbo air (and consequently, the mass of the the snail turbo air increases), would we see very close, if not identical instantaneous flow numbers?

Is it correct to say that if temperature was corrected to some temperature (let's say 23* C) and density of air adjusted for such, given the same intake and exhaust tracts except for the differences between two turbos, different turbos at the same psi will flow the same instantaneous amount of air, corrected for temperature differences?

For example, a snail vs. a truck turbo blowing at 16 psi, the snail will be blowing tons of hot air, the truck turbo might be in it's efficient zone. If we were to calculate how much air would actually be flowing if the snail turbo air was at the same temperature as the truck turbo air (and consequently, the mass of the the snail turbo air increases), would we see very close, if not identical instantaneous flow numbers?

#4

Wastegate John

iTrader: (13)

Join Date: Feb 2008

Location: Long Island NY 11746

Posts: 2,979

Likes: 0

Received 9 Likes

on

9 Posts

^ If the velocity ( outlet air velocity) is the same (with the same pipe diameter) then you controlled all of the variables so the flow would be the same.

With your above example the only variable would be the velocity due to the increased flow of the different compressor wheels. The mass air flow would be increased.

I don't understand what you are trying to get at with this thought experiment though .

.

With your above example the only variable would be the velocity due to the increased flow of the different compressor wheels. The mass air flow would be increased.

I don't understand what you are trying to get at with this thought experiment though

.

.

#5

One of the problems with the example is that pressure is effected by restriction. The tiny compressor, on a 500ci engine, may not even be able to move enough air to build 16 psi of pressure.

Let's say you put a 1" restrictor on the end of your 3/4" garden hose. It ain't making no pressure in the hose. Now put the same restrictor on the end of a fire hose hooked to the water main. You have enough volume potential in the fire hose to create pressure.

Let's say you put a 1" restrictor on the end of your 3/4" garden hose. It ain't making no pressure in the hose. Now put the same restrictor on the end of a fire hose hooked to the water main. You have enough volume potential in the fire hose to create pressure.

#6

^ If the velocity ( outlet air velocity) is the same (with the same pipe diameter) then you controlled all of the variables so the flow would be the same.

With your above example the only variable would be the velocity due to the increased flow of the different compressor wheels. The mass air flow would be increased.

I don't understand what you are trying to get at with this thought experiment though .

.

With your above example the only variable would be the velocity due to the increased flow of the different compressor wheels. The mass air flow would be increased.

I don't understand what you are trying to get at with this thought experiment though

.

.

#7

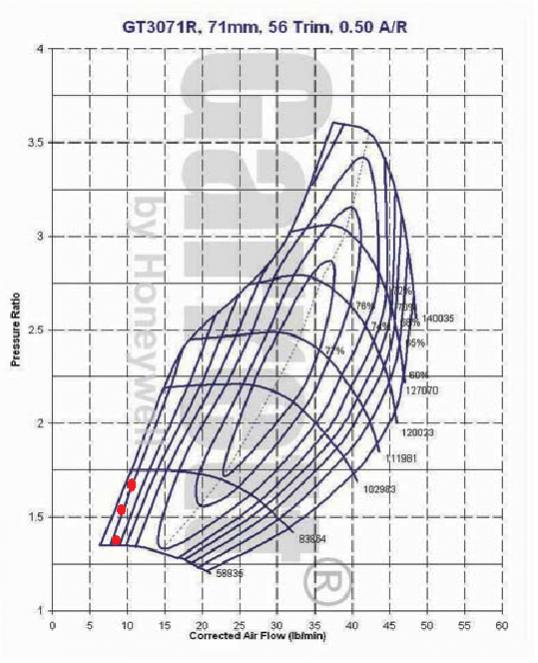

No, it sounds like you are putting too much importance on pressure. When you say "amount of air" just do yourself a favor and stop thinking of pressure and start thinking in terms of flow, cfm, volume, ect. Look up some compressor maps, check out the difference from a 2876r at a pressure ratio of 2.0 and a gt4094r at the same 2.0 pressure ratio, very different!

Trending Topics

#8

No, it sounds like you are putting too much importance on pressure. When you say "amount of air" just do yourself a favor and stop thinking of pressure and start thinking in terms of flow, cfm, volume, ect. Look up some compressor maps, check out the difference from a 2876r at a pressure ratio of 2.0 and a gt4094r at the same 2.0 pressure ratio, very different!

In practice, cfm means more than psi, but that's what happens in the real world and muddies the mechanics of what's actually happening to get to that result. For most people, they don't care what's actually happening, just how it makes their car faster and that's fine for them, but that's not what I'm asking.

Compressor maps show islands of efficiency. My question is, given that two turbos do not have the same efficiency, so the one is pushing out air at a different temperature than another, if we standardize both air temps coming out of the compressor and make adjustments to the mass of air (i.e if the compressor's output temp is higher than the standardized temp, we increase the mass of air appropriately according to fluid dynamics and vice versa if the output temp is lower than the standardized temp) coming out of each compressor, will both compressors flow the same temp-corrected air at the same psi regardless of size or are there still differences between compressors?

#9

Compressor maps show islands of efficiency. My question is, given that two turbos do not have the same efficiency, so the one is pushing out air at a different temperature than another, if we standardize both air temps coming out of the compressor and make adjustments to the mass of air (i.e if the compressor's output temp is higher than the standardized temp, we increase the mass of air appropriately according to fluid dynamics and vice versa if the output temp is lower than the standardized temp) coming out of each compressor, will both compressors flow the same temp-corrected air at the same psi regardless of size or are there still differences between compressors?

If someone else doesn't go into more detail first, I will when I have more time.

#10

i dont think temp has much to do with it, its more about air flow restriction caused by the hot side in order to create the pressure on the compressor side. a smaller turbo will restrict flow in the turbine in order to create a given pressure by the compressor, but a larger turbo will flow more at the same intake pressure

#12

Is it correct to say that if temperature was corrected to some temperature (let's say 23* C) and density of air adjusted for such, given the same intake and exhaust tracts except for the differences between two turbos, different turbos at the same psi will flow the same instantaneous amount of air, corrected for temperature differences?

For example, a snail vs. a truck turbo blowing at 16 psi, the snail will be blowing tons of hot air, the truck turbo might be in it's efficient zone. If we were to calculate how much air would actually be flowing if the snail turbo air was at the same temperature as the truck turbo air (and consequently, the mass of the the snail turbo air increases), would we see very close, if not identical instantaneous flow numbers?

One of the neat things about using an engine dyno to size turbos is that you can separate the various causes and effects happening in the turbo. You have temperature and pressure sensors in both scrolls (assuming single twin scroll turbo), temperature and pressure at the inlet and outlet of the turbo, at the intercooler, etc. You also have mass flow meters for the fuel and sometimes the air. In a situation where the engine is a scavenging/high overlap phase, the wideband O2 is inaccurate. So you use a gas analyzer to back calculate in-cylinder AFR based on the exhaust gas constituents. It's a big science experiment.

So let's assume either a 2 rotor or a 4 cylinder engine with single twin scroll turbo. The condition is a fixed 2000rpm. Actually, let's call it a 4 cylinder DI engine with dual cam phasers, like the current Hyundai turbo engine. The turbo has an internal wastegate that is electrically controlled. The throttle is also electrically controlled. So you can adjust both valve's positions however you want them to, and you can dial in however much overlap you want for scavenging.

So the rpm is fixed. The wastegate is open and the throttle is closed. Then we go WOT with the wastegate open--naturally aspirated. With electronic throttle and wastegate you can do that. Now we start moving on the compressor map. In this case, let's say we're flowing 60 grams/second or about 8 lb/min at WOT and turbo pressure ratio very close to 1.0 .

The red dots show the engine walking along the compressor surge line as engine load increases from closing the wastegate. The engine is fixed at 2000rpm. As the wastegate closes, we move up and to the right along the map. Eventually though you will collide with the surge line and the compressor will literally stop spinning. That's called hard compressor surge. Various things makes this surge issue worse, especially altitude and intake restriction.

With a different compressor wheel, the map is shifted to the left and you avoid surging. So in this case, we actually can make more engine torque with the smaller turbo because it doesn't surge. Now, if you can improve the volumetric efficiency of the engine at 2000rpm you could move farther to the right on the compressor map and keep the bigger compressor wheel out of surge. Then the bigger wheel might be better choice if it's more efficient at that pressure ratio. The way you improve the volumetric efficiency in our example is by dialing in overlap with the cam phasers.

When you put different turbos on a vehicle and then drive it around or put it on a chassis dyno, there are so many complicating factors that you can't break down the analysis into all these little things.

#13

The system has to be pretty damn choked up for the smaller turbo to make considerably less power.

The intercooler does the density recovery which basically means all you are left with is additional EMAP (exhaust manifold pressure). It might cost you 200rpm and 50mS additional rise time for each psi of EMAP you reduce (by upsizing the turbine housing or increasing the size of the turbine wheel. That single psi of EMAP might only let you make 3HP extra at peak load but cost you on average over the whole Power vs RPM made by on average 5+HP

Very quickly you find that the smaller turbo is faster in all bar conditions of sustained full throttle for more than about 10 seconds, by which time you are travelling 100+mph and you know the stock FD can overheat GOOD road tyres on a race track after less than 5 laps (4-6 minutes running time), and about the same time for the biggest standard brakes to be fading quite badly.

The intercooler does the density recovery which basically means all you are left with is additional EMAP (exhaust manifold pressure). It might cost you 200rpm and 50mS additional rise time for each psi of EMAP you reduce (by upsizing the turbine housing or increasing the size of the turbine wheel. That single psi of EMAP might only let you make 3HP extra at peak load but cost you on average over the whole Power vs RPM made by on average 5+HP

Very quickly you find that the smaller turbo is faster in all bar conditions of sustained full throttle for more than about 10 seconds, by which time you are travelling 100+mph and you know the stock FD can overheat GOOD road tyres on a race track after less than 5 laps (4-6 minutes running time), and about the same time for the biggest standard brakes to be fading quite badly.

#14

The system has to be pretty damn choked up for the smaller turbo to make considerably less power.

The intercooler does the density recovery which basically means all you are left with is additional EMAP (exhaust manifold pressure). It might cost you 200rpm and 50mS additional rise time for each psi of EMAP you reduce (by upsizing the turbine housing or increasing the size of the turbine wheel. That single psi of EMAP might only let you make 3HP extra at peak load but cost you on average over the whole Power vs RPM made by on average 5+HP

The intercooler does the density recovery which basically means all you are left with is additional EMAP (exhaust manifold pressure). It might cost you 200rpm and 50mS additional rise time for each psi of EMAP you reduce (by upsizing the turbine housing or increasing the size of the turbine wheel. That single psi of EMAP might only let you make 3HP extra at peak load but cost you on average over the whole Power vs RPM made by on average 5+HP

So there are a few factors here. Two can be determined in steady-state testing (remember my engine dyno example, 2000rpm with varying load). The other is transient and you will notice it in a vehicle.

There has to be enough power generated by the turbine wheel to build the boost you want. The sizing of the wheel and housing have a big effect on that. The mass flow through the engine and the temperature of the exhaust play a big role in this. If you are running with throttle open, wastegate closed at a steady 2000rpm, whatever boost you get is limited by your turbine power. Re-sizing the exhaust side of the turbo will help, or increasing EGT or running more mass flow.

So let's say I know I can hit 20psi at 2000rpm in a laboratory, or on a chassis dyno with the rpm fixed at 2000rpm. The main transient factor that plays into this in the real world is the mass of the wheel and its inertia. There is the inertia of the rotating mass, the ball vs journal bearing, etc. A lot of that is where expensive materials come into play.

For example, I could have a ball-bearing turbo with less inertia that is more able to spin up quickly. You can see that between shifts in a vehicle. You can see that on a "load step" test at fixed repm on an engine dyno. However, if there isn't enough turbine power the engine isn't capable of reaching the intended boost no matter how much time it has to spin up the turbo. On an engine dyno, we have unlimited time for spool, so in some ways we can separate steady-state and transient effects.

Very quickly you find that the smaller turbo is faster in all bar conditions of sustained full throttle for more than about 10 seconds, by which time you are travelling 100+mph and you know the stock FD can overheat GOOD road tyres on a race track after less than 5 laps (4-6 minutes running time), and about the same time for the biggest standard brakes to be fading quite badly.

#15

Senior Member

But where does the volumetric efficiency of the engine come into play?

Since VE is mostly fixed (except for the restriction on the exhaust side being different depending on turbine housing/wheel size) it seems that putting a larger turbo on to allow more output can only get you so far.

If the small and large turbos proposed by the OP would in real world both be able to achieve a particular boost level (say 18psi), would the actual difference be in the density of the air that arrives at the throttle due to the differences in efficiency and the resulting heat effects?

At what point does one reach a drop off in the gains where an even larger turbo won't get enough more to make it worthwhile?

Since VE is mostly fixed (except for the restriction on the exhaust side being different depending on turbine housing/wheel size) it seems that putting a larger turbo on to allow more output can only get you so far.

If the small and large turbos proposed by the OP would in real world both be able to achieve a particular boost level (say 18psi), would the actual difference be in the density of the air that arrives at the throttle due to the differences in efficiency and the resulting heat effects?

At what point does one reach a drop off in the gains where an even larger turbo won't get enough more to make it worthwhile?

#16

VE is fixed on a 4 port rotary, but not on an engine with continuously variable valve timing or lift. You can change those parameters in steady state or transients to move horizontally on the compressor map or spool the turbo on tip in.

My example above about surging is an example where a bigger compressor isn't better. You'll lose low end torque if the compressor stalls or the turbine can't make the required boost.

The small and large turbo in OP's example would have different outlet temperatures. The small one would be spinning faster and have less margin for high altitude. The bigger one would have more inertia and spin up slower in transients.

At what point is a turbo too big? When there is too much inertia in the wheel for good transient response, when the turbine side is so big that it needs too much mass flow to spin up.

Hope that helps, posting from my phone

My example above about surging is an example where a bigger compressor isn't better. You'll lose low end torque if the compressor stalls or the turbine can't make the required boost.

The small and large turbo in OP's example would have different outlet temperatures. The small one would be spinning faster and have less margin for high altitude. The bigger one would have more inertia and spin up slower in transients.

At what point is a turbo too big? When there is too much inertia in the wheel for good transient response, when the turbine side is so big that it needs too much mass flow to spin up.

Hope that helps, posting from my phone

#17

In a lab environment, you control the inlet air supply to the turbo. There's a big inflated bag which is like a giant plenum in front of the intake for the turbo. That air is controlled according to temperature and (depending on the test cell capabilities) pressure. You can hook up an air-to-water intercooler to the compressor outlet, and then use the test cell to regulate the water flowing into the cooler. This will control the compressor outlet temperatures. If you can arrange absolutely everything right, you can get the same massflow of air out of two different turbos. But that doesn't mean you'll make the same power, because of all the other factors involved like turbine-side backpressure.

The same massflow of air at the same manifold pressure if the massflow number was compensated for the efficiency differences between two turbos?

Thread

Thread Starter

Forum

Replies

Last Post