Coatings for Manifolds, Down Pipes, and Housings

#51

Place your ad here...

Originally Posted by t-von

saxyman990 Anyway to find out what the prices would be for the coatings without the middle man?

-Rob

#52

Originally Posted by saxyman990

Sigh...

Again, I suppose I was too subtle in my last post. Let me rephrase my response: there is no such thing as "stoich temps"!! That phrase doesn't make any sense. Stoichiometric has absolutely nothing to do with temperatures or flame fronts. It refers to the correct mixture of chemical components in a reaction. The maximum (theoretical) temperature of combustion is usually refered to as "adiabatic flame temperatures." This usually occurs at stoichiometric (chemical reaction) conditions. But the phrase "stoichiometric temperatures" makes absolutely no sense when you're talking about curing temperatures of your coating!

Again, I suppose I was too subtle in my last post. Let me rephrase my response: there is no such thing as "stoich temps"!! That phrase doesn't make any sense. Stoichiometric has absolutely nothing to do with temperatures or flame fronts. It refers to the correct mixture of chemical components in a reaction. The maximum (theoretical) temperature of combustion is usually refered to as "adiabatic flame temperatures." This usually occurs at stoichiometric (chemical reaction) conditions. But the phrase "stoichiometric temperatures" makes absolutely no sense when you're talking about curing temperatures of your coating!

Originally Posted by saxyman990

Speaking of curing temperatures, again you said yours cures at 5000degrees, so you physically cannot heat it to the full curing temp. Again, this is complete BS. ALL KNOWN Ceramic based coatings cure around 500-600deg F (yes, even those found on the spaceshuttle). If you do not fully cure the product, it will not fully adhere to the surface. I would never purchase a product that didn't reach it's curing temperatrue.

Originally Posted by saxyman990

I asked this before, but you didn't answer it, so I'll ask it again. Are you saying that your products can withstand 5000-6000deg F? You do realize that the highest temp coating available (other than what may be available in classified research labs) is a Diamond-Like Carbon (DLC) coating (not ceramic), which has a sustained temp rating of 4000deg? We use DLC coatings on turbine blades of our most advanced jets. And I can tell you right now, even they don't have curing temps of 5kdegF.

Originally Posted by saxyman990

You stated earlier that you do this coating in your shop. So you have a "nasa spec clean room" (whatever that is) in your shop? Interesting... FYI, ANY company that specializes in coatings is extremely careful with product prep. Your particular coating is no different.

That is not what I have seen, we have used almost every automotive brand coating on the market. Most do not last, nor even make munch of a worthwhile diffference. Again that is just my experience.

Originally Posted by saxyman990

Now that I know polydyn is your supplier, I will say something to your benifit: Polydyn has some absolutely great products. Very top of the line, and high-quality. We use them for many things. If that's what you're using, then you definitely will have good results. But nothing exists that is quite to the level that you describe it. Many other companies can equal the quality that polydyn can provide.

I wasn't going to post because I don't see a reason to spend much time on the internet, its just a bunch of people talking, hell I bet maybe 1% of the people on this or reading this will even buy ANY brand coating for any of their stuff. But after I start getting phone calls from customers, I guess I feel the need to come on here and post..

Last edited by Turblown; 11-28-05 at 10:59 AM.

#53

Originally Posted by saxyman990

Update: Just got off the phone with Keith over at polydyn. He informed me of the Gold Ceramic Coating that 1Revvin7 uses on his manifolds and other parts. This is currently the best heat-barrier coating that they have available.

Curing temperature of this ceramic is approximately 550deg F for steels and irons.

Max sustainable temp is approximately 2200-2400deg F.

It's definitely a great looking coating, and probably better than most of the other ceramic coatings on the market. It'll probably outlast the standard jethot coatings. But its not nearly what you were making it out to be. Care to comment?

Keith also mentioned that these particular coatings are currently sprayed on. They are working on a new technique to ensure 100% coverage of the inside of parts. This process involves a dip of some type, but he would not go into much more detail than that (proprietary info). But he did inform me that it uses virtually the same ceramic material as a coating (ie, cure temp of 550, and max temp of 2400).

I asked him about the 5-6000 degrees issue, as well as the phrase "stoichiometric temperatures." Keith mentioned something about "smoking" and "crack," but I didn't pick up on the entire response...

-Rob

Curing temperature of this ceramic is approximately 550deg F for steels and irons.

Max sustainable temp is approximately 2200-2400deg F.

It's definitely a great looking coating, and probably better than most of the other ceramic coatings on the market. It'll probably outlast the standard jethot coatings. But its not nearly what you were making it out to be. Care to comment?

Keith also mentioned that these particular coatings are currently sprayed on. They are working on a new technique to ensure 100% coverage of the inside of parts. This process involves a dip of some type, but he would not go into much more detail than that (proprietary info). But he did inform me that it uses virtually the same ceramic material as a coating (ie, cure temp of 550, and max temp of 2400).

I asked him about the 5-6000 degrees issue, as well as the phrase "stoichiometric temperatures." Keith mentioned something about "smoking" and "crack," but I didn't pick up on the entire response...

-Rob

Again the information you have recieved is not the same I have here.

The techniques and temperatures are lot different that what you have been told.

It appears this information is not public, so I'm not going to post it until I ok it with them.

#54

Originally Posted by t-von

saxyman990 Anyway to find out what the prices would be for the coatings without the middle man?

Last edited by Turblown; 11-28-05 at 11:12 AM.

#55

Originally Posted by Kevin T. Wyum

Who mentioned coating the inside of the rotor housings? Maybe my memory is failing me in my old age but I seem to recall the "chrome" surface having micro pores/channels for oil to assist in lubrication of the seals. Maybe Saxy knows this but can you think of any application that uses a coating like these (the ceramic coatings being discussed) on a frictional surface? Maybe you can machine this stuff smooth enough for other internal parts not needing the lubrication.

Kevin T. Wyum

Kevin T. Wyum

Kevin,

I sent Polydyn a few complete rotary engines to be coated. Several new prototype coatings where done on the side plates, and the rotor housings. These coatings are a combination of heat rejection and oil attraction/retention. There is a motor I built running around on the street with over 5K miles on it, that recieved all of those coatings, plus the rotors, beaings, pump etc etc. I thought the factory rotor housing coating was just for breakin and wore off within that time frame.

Speaking of having the seals done, I just finished ultrasonic cleaning several motors, inprepation to be coated, and I planned on doing the corner and side seals. Again I don't know if its true or not, but I saw on a supposed factory race prep manual that they do the same.

Last edited by Turblown; 11-28-05 at 11:17 AM.

#56

Round&Round not Up&Down

Thread Starter

Join Date: Aug 2001

Location: West Bloomfield, MI

Posts: 2,805

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by KNONFS

Same thing happened on the FC3S forum thread, go figure

Anyways, where did you sent yours, I will do the same to the manifold, DP, and intake manifold!

Anyways, where did you sent yours, I will do the same to the manifold, DP, and intake manifold!

I talked to a local company extensively through email about the coatings for my parts. They gave me a not-so-detailed procedure of what will be done and mentioned they did not want to disclose their procedure. I respect their privacy, and if I don't like the coating, I'll get it removed and try someone else. At a cost of $50 plus shipping, I might as well try. I figured I'd try the manifold first, then if I like it, I'll get the rest of the parts done by them. Their prices are great, I'm hoping that does not reflect their quality. They have done rotary parts before and I spoke with the 7 owner. He couldn't say enough good things about them, so I sent them my manifold.

#57

Round&Round not Up&Down

Thread Starter

Join Date: Aug 2001

Location: West Bloomfield, MI

Posts: 2,805

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by Mills

Did they say why?

#58

Round&Round not Up&Down

Thread Starter

Join Date: Aug 2001

Location: West Bloomfield, MI

Posts: 2,805

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by ROTARYFDTT

DId you send it out to QC Coatings? I was planning on dropping off my manifold there sometime within the next week.

Yes, QC coatings is the company. They have a website, google it and it'll come up. I spoke with Bill Walker. I'll let everyone know what this thing turns out like when I get it back.

#59

Place your ad here...

Wow. I'm actually really impressed that you actually responded Elliot. I was afraid for a little while that we may have scared you away.

Basically, we are arguing semantics. Which is exactly my point. You don't even know the definitions of the words you're spewing forth. It seems from my end that you're just spouting off $10 words in an effort to sound smart, yet you really have no clue what you're talking about.

Whoa now.... hold the phone! You're telling me that you're hyping the sales of a product (your own personal sales, I might add) by stating facts and figures from a SECONDARY SOURCE??!! You mean to tell me that not all of the info you have comes direct from your supplier (polydyn)? But instead it's hearsay from some other person? That's like a ferrari dealer saying "Well you should buy this Enzo because Jimmy-Joe-Bob told me that it will do 3000mph"

I'm sorry, but if you're selling a product, I personally think that you need to know what it is you're selling. If you don't have all the details or knowledge, then don't pretend you do in order to keep your sales up. Research it, and find the correct information that people are asking for.

I have nothing against you personally, or your coatings for that matter. But your actions remind me of a sleazy used-car dealer.

I'm not exactly Johnny-Q-Public. And these numbers you speak of, they are the ones from a "secondhand source?"

You apparently have a very limited experience base. Ceramic Coating is nothing new, and good quality coatings hold up just fine. My father has had a set of ceramic headers on his ~600rwhp Charger for the last ~15 years. They still look brand new.

Interesting, I've done some searches on this forum and the only post where you mentioned polydyn has absolutely nothing to do with coating (something about a car show). So did you delete these posts like you apparently did with the posts over at nopistons (I don't frequent over there so I don't know)? What kind of heat were you getting about these posts?

Again, second hand information? wow... unbelieveable.

I'm not saying that you're not allowed to make mistakes. You're completely right, we are all only human and make mistakes quite often (myself included). Maybe I'm making a mistake right here, but it sure seems to me (and many others in this thread, I might add), that you're being vague because you don't know what you're talking about, but you're trying desperately to make it look like you do.

So your customers are starting to call you because they are concerned about the idea that they might not get exactly what you promised them? I don't blame them...

So let me get this straight: You're going to charge the same price as polydyn would charge, but you'll also add in a little buffer to account for the shipping charges. That makes sense, you wouldn't want to loose money on shipping. But explain to us what the advantage is to going through you, instead of cutting out the middle man and going straight to Polydyn (or any other equally qualified coater)?

I look forward to your posts about these "top secret" coatings and processes when you finally get a chance to talk with polydyn about it. Hopefully, you'll post back here with some more information when that time comes (and hopefully it won't be based on second-hand misinformation).

-Rob

Originally Posted by 1Revvin7

I think you are reading to far into what I have said...

Originally Posted by 1Revvin7

Thats not the impression I am under, but then again I HAD been getting a lot of the information from a second hand source.

I'm sorry, but if you're selling a product, I personally think that you need to know what it is you're selling. If you don't have all the details or knowledge, then don't pretend you do in order to keep your sales up. Research it, and find the correct information that people are asking for.

I have nothing against you personally, or your coatings for that matter. But your actions remind me of a sleazy used-car dealer.

Originally Posted by 1Revvin7

Well it appears that this information is not given to the public, so I'll have to find out what I should or should not be saying. The numbers I have here are extremly high compared to most other automotive companies.

Originally Posted by 1Revvin7

I never said my shop. I said in the shop.

That is not what I have seen, we have used almost every automotive brand coating on the market. Most do not last, nor even make munch of a worthwhile diffference. Again that is just my experience.

That is not what I have seen, we have used almost every automotive brand coating on the market. Most do not last, nor even make munch of a worthwhile diffference. Again that is just my experience.

Originally Posted by 1Revvin7

Yes Poldyn is my supplier, I have mentioned this many times in the past, especially when I first started making Rx-7 manifolds. From the internet crowd I was getting a lot of heat mentioning details about the coatings, and polydyn's history.

Originally Posted by 1Revvin7

Just like on here, there is a reason I have been vaque with a lot of questions, sure some of my answers are not correct, I am only human, I do make mistakes, and not all the information I had been getting from a second hand source was correct.

I'm not saying that you're not allowed to make mistakes. You're completely right, we are all only human and make mistakes quite often (myself included). Maybe I'm making a mistake right here, but it sure seems to me (and many others in this thread, I might add), that you're being vague because you don't know what you're talking about, but you're trying desperately to make it look like you do.

Originally Posted by 1Revvin7

But after I start getting phone calls from customers, I guess I feel the need to come on here and post..

Originally Posted by 1Revvin7

I advertise everything available to the public at MSRP, but again I have to add shipping to and from Polydyn. After I get back from my flight this week to meet with Carl, I will lay it out pretty well in a website.

I look forward to your posts about these "top secret" coatings and processes when you finally get a chance to talk with polydyn about it. Hopefully, you'll post back here with some more information when that time comes (and hopefully it won't be based on second-hand misinformation).

-Rob

Last edited by saxyman990; 11-28-05 at 01:43 PM.

#60

Round&Round not Up&Down

Thread Starter

Join Date: Aug 2001

Location: West Bloomfield, MI

Posts: 2,805

Likes: 0

Received 0 Likes

on

0 Posts

revvin,

Deleting posts in your thread on nopistons isn't cool if you're trying to sell yourself as a good businessman. If someone comes to you and questions your business and you get upset with the questions are you going to turn around and pretend they are not there?

What's the difference if a customer sends his parts to you instead of directly to Polydyne? Besides the customer saving some $$. Are they doing something special to the parts that you send to them that don't do to regular Joe Schmoe's parts?

Deleting posts in your thread on nopistons isn't cool if you're trying to sell yourself as a good businessman. If someone comes to you and questions your business and you get upset with the questions are you going to turn around and pretend they are not there?

What's the difference if a customer sends his parts to you instead of directly to Polydyne? Besides the customer saving some $$. Are they doing something special to the parts that you send to them that don't do to regular Joe Schmoe's parts?

Last edited by jimmyv13; 11-28-05 at 04:07 PM.

#61

Old School

Join Date: Mar 2001

Location: Baldwin City, KS

Posts: 473

Likes: 0

Received 0 Likes

on

0 Posts

Here's a ceramic supplier that sells to the public...

http://www.techlinecoatings.com/

They even have a cermet coating. Anyone tried these products? Are prices in line with buying through a place like Polydyn? Any other comments?

http://www.techlinecoatings.com/

They even have a cermet coating. Anyone tried these products? Are prices in line with buying through a place like Polydyn? Any other comments?

#62

So my motor was recently rebuilt and coated by Elliot....

I'm pretty sure that's my engine he's talking about. He finished work on it in early october. I want to say that i have experienced nothing but satisfaction with the engine and his work. The Polydyn coatings, particularly on the headers, as well as every other part in that engine are very attractive as well as beneficial. I do have a noticable drop in underhood temperatures, at least with the "hey that didn't burn my hand off" thermometer. I just want it to be known that I'm a satisfied customer.

As for the other stuff, there's not much else I can say because i'm not involved, but I am happy with his work.

Originally Posted by 1Revvin7

There is a motor I built running around on the street with over 5K miles on it, that recieved all of those coatings, plus the rotors, beaings, pump etc etc.

As for the other stuff, there's not much else I can say because i'm not involved, but I am happy with his work.

#63

Originally Posted by '89Vert

I'm pretty sure that's my engine he's talking about. He finished work on it in early october. I want to say that i have experienced nothing but satisfaction with the engine and his work. The Polydyn coatings, particularly on the headers, as well as every other part in that engine are very attractive as well as beneficial. I do have a noticable drop in underhood temperatures, at least with the "hey that didn't burn my hand off" thermometer. I just want it to be known that I'm a satisfied customer.

As for the other stuff, there's not much else I can say because i'm not involved, but I am happy with his work.

As for the other stuff, there's not much else I can say because i'm not involved, but I am happy with his work.

That's basically how this whole thing started.

That's basically how this whole thing started.

#64

What Subscription?

Join Date: Apr 2001

Location: Aiken SC USA

Posts: 5,926

Likes: 0

Received 0 Likes

on

0 Posts

STILL: No one has provided Emperical evidence supporting these claims on a Rotary Engine. Just a buch of butt-dyno responses. No temps/no thermography/no nothing.

Now, before you jump on my response: I am one of those types who is willing to experiment. I have cryo'd/cryo-remmed/rem polished quite a few pieces, but I have not conducted any data collection as yet. I still have to assemble my Engine Dyno to document my personal findings. When I get results I will post my observations backed by DATA, not a butt-dyno

Now, before you jump on my response: I am one of those types who is willing to experiment. I have cryo'd/cryo-remmed/rem polished quite a few pieces, but I have not conducted any data collection as yet. I still have to assemble my Engine Dyno to document my personal findings. When I get results I will post my observations backed by DATA, not a butt-dyno

#65

Banned. I got OWNED!!!

we are waiting Bazai, this is the real way of proving theory, data backed up research. That's what its all about as long as its unbiased. Thanx

#66

Senior Member

Coating Comparision

Thanks saxyman990 for the prep info.

I was wondering what performance differences these different brands (Techline, Polydyn, others????) of coatings have. Or even the difference between professional applied coatings verses DIY.

I do have access to DAQ equitment including a thermal imaging camera. I was thinking of...

Machining identical test plates (i.e. 2"x2"x1/8") from alum. Then coating one side with the different brands and or methods (of course leaving one uncoated for a control). Then expose the coated side to a consistant heat source like a flame from a propane torch. Watch the other side with the thermal imaging camera or datalog a thermocouple. Compare these responses, a slow transient response would mean a good coating.

Any input? What other brands would be good canidates? Would anyone offering a coating or coating service want to participate?

Justin

I was wondering what performance differences these different brands (Techline, Polydyn, others????) of coatings have. Or even the difference between professional applied coatings verses DIY.

I do have access to DAQ equitment including a thermal imaging camera. I was thinking of...

Machining identical test plates (i.e. 2"x2"x1/8") from alum. Then coating one side with the different brands and or methods (of course leaving one uncoated for a control). Then expose the coated side to a consistant heat source like a flame from a propane torch. Watch the other side with the thermal imaging camera or datalog a thermocouple. Compare these responses, a slow transient response would mean a good coating.

Any input? What other brands would be good canidates? Would anyone offering a coating or coating service want to participate?

Justin

#67

What's your point ?

Join Date: Feb 2001

Location: Gainesville, Fla.

Posts: 3,573

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by saxyman990

I honestly don't have any first-hand knowledge of Tech Line coatings, although I have a few friends that are using them on their V8 headers (and like you, they seem to be holding up fine). What I will say is that do-it-yourself coatings can be great if you take the time to do them properly, or they can fail miserably if you don't use the utmost care. Any professional coating shop will take the time to properly prep the material (as 1Revvin7 correctly pointed out). This usually involves a thermal degreaser or various chemical solutions (something the average DIYer doesn't usually have access to). Take what you will from that.

As an FYI, I had a professional coating company do all of my parts, and I'm extremely happy with the results.

-Rob

As an FYI, I had a professional coating company do all of my parts, and I'm extremely happy with the results.

-Rob

#70

Place your ad here...

Originally Posted by CantGoStraight

bump waiting on reply from saxyman990

The company I usually use is Aesthetic Finishers in Piqua, OH (www.afipowder.com). Their shop is about a 15 minute drive from my house. Phone number is: 937-778-8777, ask for Greg. He's extremely knowledgeable and will help you with just about any question you may have.

Parts do not need to be sand-blasted for powder or ceramic coating to adhere, but they do need to be prepped in someway. AFI does NOT use silica sand-blasting, nor do they recommend it (silica and silicone based products can cause increased out-gassing during the cure phase). Rather, they use a thermal stripper, alkaline washing, flash rust sealer and a few other treatments. They do coat both the inside and the outside of the parts (unless you specifically request them not to). There are mixed schools of thought on coating the outside/inside/both. IMO, there is no reason to only coat the inside. In addition to adding protection and durability to the metal, coating the exterior will also help in decreasing heat radiation into the engine bay.

I personally use AFI because they are local to me, and I know they do good work. But keep in mind that any reputable coating company should be able to produce good results. Just to give you a few examples of some of my parts:

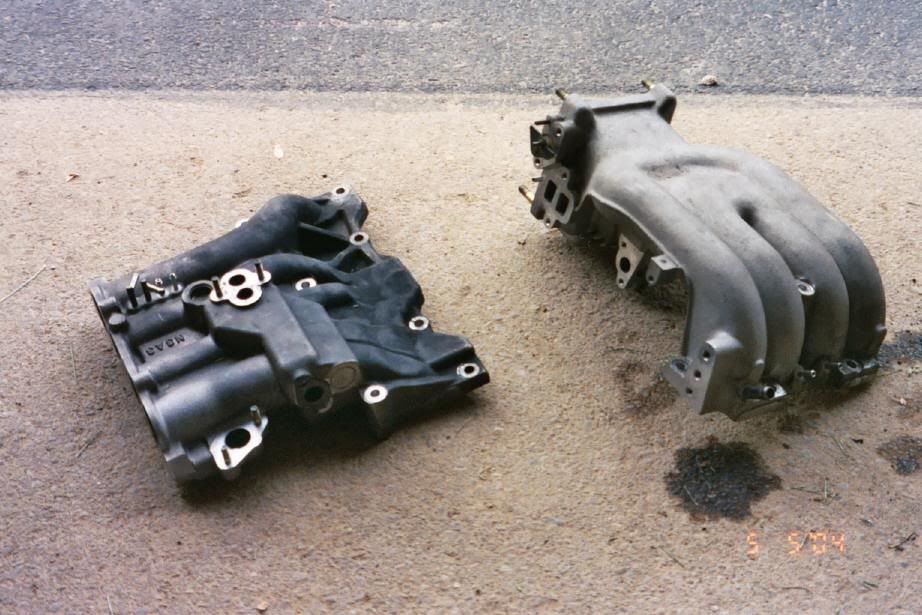

Here is a picture of my nasty-*** manifolds after I pulled the engine (55k miles)

Here is a picture after they were ceramic coated. The exhaust/dp is coated with AFI's black 2000deg coating, and the intakes are coated with the "chrome" 1300. I did not polish any of these parts prior to prep (but they were prepped using the techniques mentioned above). The intakes are still a little bumpy from the original casting. If I had polished them, they would be smooth as glass right now. But, I didn't really want that look. Also note that the intakes still have some of the residue from the coating process (white chalky stuff). That was wiped/polished off later. Even after many miles, the parts still look like they were just done.

Manifolds bolted to the engine:

Engine in the car:

Hope that helps a little bit.

-Rob

#71

That looks good.

I try and tell anyone who asks Can you coat just the outside of my exh. In ceramic its a waste of your time and $$. Ceramic was designed as a thermal barrier. Looks was just a 2nd part of it. If you only do the outside your still gonna get condensation on the inside and rust from the inside out. Same as if you don't vibratory polish it. You get the DIY guys who want to do the ceramic but have no way to polish the inside of the pipes. The ceramic beads used to polish the parts also burnish the surface and "seal" the ceramic.

As for how to prep em. There are tons of diff ways. I use Alum oxide on most parts that get ceramic coated. You do need a good bite for the ceramic to adhere to.

Also Pre-bake the parts at a higher temp than you cure them at. This is the best way to out gas stuff. Pull it out of the oven and let it come down to a good temp before you shoot the parts. In the 6years Ive been coating I haven't had anything come back yet. (knock on wood)

I try and tell anyone who asks Can you coat just the outside of my exh. In ceramic its a waste of your time and $$. Ceramic was designed as a thermal barrier. Looks was just a 2nd part of it. If you only do the outside your still gonna get condensation on the inside and rust from the inside out. Same as if you don't vibratory polish it. You get the DIY guys who want to do the ceramic but have no way to polish the inside of the pipes. The ceramic beads used to polish the parts also burnish the surface and "seal" the ceramic.

As for how to prep em. There are tons of diff ways. I use Alum oxide on most parts that get ceramic coated. You do need a good bite for the ceramic to adhere to.

Also Pre-bake the parts at a higher temp than you cure them at. This is the best way to out gas stuff. Pull it out of the oven and let it come down to a good temp before you shoot the parts. In the 6years Ive been coating I haven't had anything come back yet. (knock on wood)

#72

Place your ad here...

1revvin7: it's been a few weeks since your scheduled meeting with polydyn, and you promised that you would give some details on what transpired. So what's the skinny?

-Rob

-Rob

#73

Originally Posted by saxyman990

1revvin7: it's been a few weeks since your scheduled meeting with polydyn, and you promised that you would give some details on what transpired. So what's the skinny?

-Rob

-Rob

Why should I bother posting moot techincal information?

Anyone who is serious doesn't care about that, that information just concerns keyboard chasers.

#74

~!@#$%^&*()_+

Join Date: Oct 2001

Location: Mpls, MN

Posts: 461

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by 1Revvin7

Gosh you sure do like putting words into my mouth.

Why should I bother posting moot techincal information?

Anyone who is serious doesn't care about that, that information just concerns keyboard chasers.

Why should I bother posting moot techincal information?

Anyone who is serious doesn't care about that, that information just concerns keyboard chasers.

#75

Place your ad here...

Originally Posted by 1Revvin7

Gosh you sure do like putting words into my mouth.

Why should I bother posting moot techincal information?

Anyone who is serious doesn't care about that, that information just concerns keyboard chasers.

Why should I bother posting moot techincal information?

Anyone who is serious doesn't care about that, that information just concerns keyboard chasers.

Page 4 of this thread:

After I get back from my flight this week to meet with Carl, I will lay it out pretty well in a website.

I am going to clear up a lot of this, this coming tuesday when I fly out to meet with Polydyn.

Interesting that you say anyone who is serious doesn't care about technical information. My experience shows just the opposite. Those who are interested in a product have a desire (and a right) to know what they're purchasing.

-Rob