Borg Warner S300 SXE 62

#1

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

Borg Warner S300 SXE 62

finally able to do some initial road tuning w my SXE62 (91 back end). i have a 1.0 which i will swap in once i get all the data i need from the 91.

i am primarily interested in comparing SXE62 spool to the EFR 8374,

rolling into the throttle around 3400 and not matting it i find 19 psi by 3600 rpm. i am pretty sure i can better that since i was around 60 TPS and i could have started earlier . i really didn't want the car sideways.

at 19 psi boost my exhaust back pressure was 13 psi!

the boost/backpressure relationship is due to my turbo manifold design. the value of efficient/low back pressure cannot be overstated.

lower EGTs

lower internal engine temps promoting happy apex seals

more energy delivered to the driven (turbine) wheel

i will post some graphs when i figure out why my logs are all of a sudden not appearing on my laptop screen. i am hugely impressed w my SXE 62.

the SXE line truly is the working man's weapon avail in 5 sizes from 573 to 738 rotary rwhp SAE.

combine this w change back from your thousand dollar bill and OE build quality

lots more data to follow

i am primarily interested in comparing SXE62 spool to the EFR 8374,

rolling into the throttle around 3400 and not matting it i find 19 psi by 3600 rpm. i am pretty sure i can better that since i was around 60 TPS and i could have started earlier . i really didn't want the car sideways.

at 19 psi boost my exhaust back pressure was 13 psi!

the boost/backpressure relationship is due to my turbo manifold design. the value of efficient/low back pressure cannot be overstated.

lower EGTs

lower internal engine temps promoting happy apex seals

more energy delivered to the driven (turbine) wheel

i will post some graphs when i figure out why my logs are all of a sudden not appearing on my laptop screen. i am hugely impressed w my SXE 62.

the SXE line truly is the working man's weapon avail in 5 sizes from 573 to 738 rotary rwhp SAE.

combine this w change back from your thousand dollar bill and OE build quality

lots more data to follow

Last edited by Howard Coleman; 11-05-17 at 07:01 PM.

#3

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

sure... pls PM me your email and i will send you a 6 page tech piece on it.

BTW, i run a 3 inch DP and the WG is plumbed really nicely into the DP. 93 octane pump gas and 100% meth AI.

BTW, i run a 3 inch DP and the WG is plumbed really nicely into the DP. 93 octane pump gas and 100% meth AI.

Last edited by Howard Coleman; 11-17-17 at 11:07 AM.

The following users liked this post:

Bradfc3srx7turbo (11-11-23)

#4

Rotary Enthusiast

Hi Howard,

I'm very confused by all the config options available for these turbos.

Can you please post the exact model you are suggesting

SXE62 (91 back end).

What do you est. the WHP would be for this setup?

I'm very confused by all the config options available for these turbos.

Can you please post the exact model you are suggesting

SXE62 (91 back end).

What do you est. the WHP would be for this setup?

#5

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

"Can you please post the exact model you are suggesting"

i am not suggesting any particular model as we all have individual objectives when choosing a turbo. i will say i am continually amazed at the lack of proper fit re turbo selection and owner objectives.

further, there has been an explosion of turbo options in the last 5 years as 21st Century tech impacts the space.

there are FIVE SXE options based on compressor size.

all five are exactly similar as to outer dimensions. which means you can switch all five as bolt ins.

3 of the five can be bought with two different sized turbine wheels.

5 of the five can be bought with different hotside turbine housings

decision one is compressor size, or how much power do you want. from 573 to 738

decision 2 is turbine wheel size. there are two options for the first 3

decision 3 is hotside housing size on all five turbos. .

it is my opinion that the smallest of the 5, the "62" may have the broadest appeal as it spools immediately and is a legitimate 550+ hp turbo.

i personally own a SXE 62 w a .91 and a 1.0 housing, a SXE 66/1.0 and an EFR 9180, along w my trusty older school GT4094r.

the 62 is on my car as i am evaluating it. i am very interested in comparing the .91 and 1.0 hotside housings and i have the instrumentation to do it.

once complete i will move on to my SXE 66.

the P/N of the current turbo on my car is: BW 13009097056. this is a "SuperCore" and doesn't include the hotside housing.

hotside housings for this turbo are 177207 .91 & 177209 1.0

interested parties on any of the 5 are invited to inquire V PM re which turbo they should consider, availability and pricing. it is my opinion based on performance, wide options and price that the SXE line will become the most popular rotary option.

i am not suggesting any particular model as we all have individual objectives when choosing a turbo. i will say i am continually amazed at the lack of proper fit re turbo selection and owner objectives.

further, there has been an explosion of turbo options in the last 5 years as 21st Century tech impacts the space.

there are FIVE SXE options based on compressor size.

all five are exactly similar as to outer dimensions. which means you can switch all five as bolt ins.

3 of the five can be bought with two different sized turbine wheels.

5 of the five can be bought with different hotside turbine housings

decision one is compressor size, or how much power do you want. from 573 to 738

decision 2 is turbine wheel size. there are two options for the first 3

decision 3 is hotside housing size on all five turbos. .

it is my opinion that the smallest of the 5, the "62" may have the broadest appeal as it spools immediately and is a legitimate 550+ hp turbo.

i personally own a SXE 62 w a .91 and a 1.0 housing, a SXE 66/1.0 and an EFR 9180, along w my trusty older school GT4094r.

the 62 is on my car as i am evaluating it. i am very interested in comparing the .91 and 1.0 hotside housings and i have the instrumentation to do it.

once complete i will move on to my SXE 66.

the P/N of the current turbo on my car is: BW 13009097056. this is a "SuperCore" and doesn't include the hotside housing.

hotside housings for this turbo are 177207 .91 & 177209 1.0

interested parties on any of the 5 are invited to inquire V PM re which turbo they should consider, availability and pricing. it is my opinion based on performance, wide options and price that the SXE line will become the most popular rotary option.

#6

I'd like to see you do testing in 3rd gear from a 2500 roll going WOT and on flat surface. Ill gladly do the same in my stock ported 8374 setup and we can compare. I'm not logging right now but can buy a tablet to hook to the Haltech so we can compare. I havent researched the SXE line so if you dont mind please inform me on the major advantages over their standard S line.

#7

Full Member

interested in the topic cant seem to find the subscribe button

running the 63 SXE atm with the 67/76 wheel but a .88 A/R 11PSI was 330HP at 6800 if anyone was curious.

running the 63 SXE atm with the 67/76 wheel but a .88 A/R 11PSI was 330HP at 6800 if anyone was curious.

The following users liked this post:

FwkUiWN (12-10-17)

Trending Topics

#8

Banned. I got OWNED!!!

Compressor Specifications

- Compressor Type: Forged-Milled Wheel (FMW) Extended Tip

- Compressor Wheel OD (exducer): 83.47mm

- Compressor Wheel Inducer: 61.44mm

- Max Flow Rate: 78 lb/min

- Max Recommended Turbo Shaft Speed: 128136 RPM

- Compressor Housing Connections:

- Inlet: 4.0″ Hose Coupler

- Outlet: 2.5″ Hose Coupler

- Turbine Type: Inconel S300SX Turbine Wheel

- Turbine Wheel OD: 76mm

- Housing Material: D5S sandcast

- Housing Size and A/R ratio: S300SXE 8376 is available in three (3) different turbine housing configurations:

- 0.88 A/R T4 Single Scroll

- 0.91 A/R T4 Twin Scroll

- 1.00 A/R T4 Twin Scroll

What else do you need?

Last edited by RGHTBrainDesign; 11-09-17 at 11:09 PM.

#10

Rotary Enthusiast

Compressor Specifications

- Compressor Type: Forged-Milled Wheel (FMW) Extended Tip

- Compressor Wheel OD (exducer): 83.47mm

- Compressor Wheel Inducer: 61.44mm

- Max Flow Rate: 78 lb/min

- Max Recommended Turbo Shaft Speed: 128136 RPM

- Compressor Housing Connections:

- Inlet: 4.0″ Hose Coupler

- Outlet: 2.5″ Hose Coupler

- Turbine Type: Inconel S300SX Turbine Wheel

- Turbine Wheel OD: 76mm

- Housing Material: D5S sandcast

- Housing Size and A/R ratio: S300SXE 8376 is available in three (3) different turbine housing configurations:

- 0.88 A/R T4 Single Scroll

- 0.91 A/R T4 Twin Scroll

- 1.00 A/R T4 Twin Scroll

What else do you need?

I finally decided to learn how to read the compressor map and calculate the CFM flow based on desired boost level.

i made a excel spread sheet to do this based on information i found.

i could be completely off on this but based on this compressor map.

target boost 20psi, 2.36 pressure ratio, 8500rpm, we are looking at 57.38lb/min compressor flow.

which is in the efficiency island, but that's an est. 500whp on a 13b engine (assuming a decent street port)

am i calculating this correctly?

Based on my target WHP of 575whp, i think i'll need a bigger turbo then.

#11

If your target is 575whp, I'd consider going to the 80mm turbine wheel anyways. The general rule of thumb is that a rotary require 0.13#/hr flow per whp. So, 575whp is roughly 75#/hr.

To know your pressure requirements for a given engine, you basically have to know what the engine would make naturally aspirated. For a street ported engine, 200whp is a good round number.

For instance, it's not uncommon for a street port engine to make 400whp at ~14.5psi, or 2:1 pressure ratio. and close to 600whp at 29psi (3:1 PR) if everything in the system is up to it. IE, the turbine isn't maxed out, the exhaust isn't a bottleneck.

For a street port engine and 575whp, you're probably going to need 2.9:1 pressure ratio at 75#/hr comp flow. The 362 SX-E isn't even capable of those flow rates at that pressure ratio.

The S369 SX-E or the EFR 9180 would be a good fit and have mid-70s efficiency at those flows and pressures. It could be done with something smaller like the S364 SX-E, but you're going to be in the low 60s compressor efficiency. This means more wheel RPM and more drive pressure which also hurt power. If you can afford the EFR, that is absolutely the way to go, there's no real downside.

To know your pressure requirements for a given engine, you basically have to know what the engine would make naturally aspirated. For a street ported engine, 200whp is a good round number.

For instance, it's not uncommon for a street port engine to make 400whp at ~14.5psi, or 2:1 pressure ratio. and close to 600whp at 29psi (3:1 PR) if everything in the system is up to it. IE, the turbine isn't maxed out, the exhaust isn't a bottleneck.

For a street port engine and 575whp, you're probably going to need 2.9:1 pressure ratio at 75#/hr comp flow. The 362 SX-E isn't even capable of those flow rates at that pressure ratio.

The S369 SX-E or the EFR 9180 would be a good fit and have mid-70s efficiency at those flows and pressures. It could be done with something smaller like the S364 SX-E, but you're going to be in the low 60s compressor efficiency. This means more wheel RPM and more drive pressure which also hurt power. If you can afford the EFR, that is absolutely the way to go, there's no real downside.

#12

If your target is 575whp, I'd consider going to the 80mm turbine wheel anyways. The general rule of thumb is that a rotary require 0.13#/hr flow per whp. So, 575whp is roughly 75#/hr.

To know your pressure requirements for a given engine, you basically have to know what the engine would make naturally aspirated. For a street ported engine, 200whp is a good round number.

For instance, it's not uncommon for a street port engine to make 400whp at ~14.5psi, or 2:1 pressure ratio. and close to 600whp at 29psi (3:1 PR) if everything in the system is up to it. IE, the turbine isn't maxed out, the exhaust isn't a bottleneck.

For a street port engine and 575whp, you're probably going to need 2.9:1 pressure ratio at 75#/hr comp flow. The 362 SX-E isn't even capable of those flow rates at that pressure ratio.

The S369 SX-E or the EFR 9180 would be a good fit and have mid-70s efficiency at those flows and pressures. It could be done with something smaller like the S364 SX-E, but you're going to be in the low 60s compressor efficiency. This means more wheel RPM and more drive pressure which also hurt power. If you can afford the EFR, that is absolutely the way to go, there's no real downside.

To know your pressure requirements for a given engine, you basically have to know what the engine would make naturally aspirated. For a street ported engine, 200whp is a good round number.

For instance, it's not uncommon for a street port engine to make 400whp at ~14.5psi, or 2:1 pressure ratio. and close to 600whp at 29psi (3:1 PR) if everything in the system is up to it. IE, the turbine isn't maxed out, the exhaust isn't a bottleneck.

For a street port engine and 575whp, you're probably going to need 2.9:1 pressure ratio at 75#/hr comp flow. The 362 SX-E isn't even capable of those flow rates at that pressure ratio.

The S369 SX-E or the EFR 9180 would be a good fit and have mid-70s efficiency at those flows and pressures. It could be done with something smaller like the S364 SX-E, but you're going to be in the low 60s compressor efficiency. This means more wheel RPM and more drive pressure which also hurt power. If you can afford the EFR, that is absolutely the way to go, there's no real downside.

I don't consider myself a master of anything, specially not turbos; but I grew up with the mentality of running larger turbine wheels on rotary engines. I honestly have no idea if 80mm turbine wheel will affect spool up/transition boost compared to the 76mm, but I would go with the 80mm even if it was a SXE 62mm turbo!

#13

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

back from San Diego and had a brief opportunity to do a run today. it is 33 degrees and the road surface doesn't have much traction so i did it in 4th.

i am in the process of switching back to gas w meth AI so my map is not finished in the upper boost levels but i do want to see what my SE 62 can do as far as spool.

the log shows a roll into the throttle:

i started at 22% throttle (TP) at 3240 and upped it to 47 to 50% at 3314. i was at peak boost (17.6 psi) at 3965 at 49.6% TP.

at peak boost of 17.6 my exhaust back pressure was 12.4 psi. back pressure crossover with the .91 hotside was at 5592. my previous data w a 1.0 places crossover with my manifold at 6100.

i find that at 27 psi w my GT4094r (around 580) my back pressure is +24% to boost or 33 psi.

note duty cycle on the Wastegate... 100% til 3746, 75% at 3821 and 17% after 4013.

so this isn't a ***** out run and the data can improve a bit.

a few comments re prior posts... while the SXE 62 can/should make 570, i of course wouldn't recommend it to someone who wanted to run that number. as has been stated it is always good to run things a bit off their max. the only turbo in the 5 turbo line i don't particularly like is the 63. it makes about 10 more hp but needs a 7.06 sq inch comp wheel V the 62's 6.54 wheel. i talked to BW about it and it is probably going away. likewise, the 80 mm turbine wheel on the 62 may fade out of the picture as it isn't a match. turbine wheels are HEAVY and you don't want too large a wheel.

the 62 has a 6.54 average sq inch area compressor

the 76 turbine wheel is 6.34 or 97%. anything near 1 to 1 is awesome and larger is not awesome.

by comparison the GTX3584r is 5.17 (teeny).

the 80 is 7.15... way too big for a 6.54 comp wheel.

i like the SXE 66 for around 600 without working too hard or at too high a boost. it has a 7.74 inch compressor and 7.15 turbine (80). 600 at 29/30 psi which works fine on a proper build.

.

i am in the process of switching back to gas w meth AI so my map is not finished in the upper boost levels but i do want to see what my SE 62 can do as far as spool.

the log shows a roll into the throttle:

i started at 22% throttle (TP) at 3240 and upped it to 47 to 50% at 3314. i was at peak boost (17.6 psi) at 3965 at 49.6% TP.

at peak boost of 17.6 my exhaust back pressure was 12.4 psi. back pressure crossover with the .91 hotside was at 5592. my previous data w a 1.0 places crossover with my manifold at 6100.

i find that at 27 psi w my GT4094r (around 580) my back pressure is +24% to boost or 33 psi.

note duty cycle on the Wastegate... 100% til 3746, 75% at 3821 and 17% after 4013.

so this isn't a ***** out run and the data can improve a bit.

a few comments re prior posts... while the SXE 62 can/should make 570, i of course wouldn't recommend it to someone who wanted to run that number. as has been stated it is always good to run things a bit off their max. the only turbo in the 5 turbo line i don't particularly like is the 63. it makes about 10 more hp but needs a 7.06 sq inch comp wheel V the 62's 6.54 wheel. i talked to BW about it and it is probably going away. likewise, the 80 mm turbine wheel on the 62 may fade out of the picture as it isn't a match. turbine wheels are HEAVY and you don't want too large a wheel.

the 62 has a 6.54 average sq inch area compressor

the 76 turbine wheel is 6.34 or 97%. anything near 1 to 1 is awesome and larger is not awesome.

by comparison the GTX3584r is 5.17 (teeny).

the 80 is 7.15... way too big for a 6.54 comp wheel.

i like the SXE 66 for around 600 without working too hard or at too high a boost. it has a 7.74 inch compressor and 7.15 turbine (80). 600 at 29/30 psi which works fine on a proper build.

.

#14

a few comments re prior posts... while the SXE 62 can/should make 570, i of course wouldn't recommend it to someone who wanted to run that number. as has been stated it is always good to run things a bit off their max. the only turbo in the 5 turbo line i don't particularly like is the 63. it makes about 10 more hp but needs a 7.06 sq inch comp wheel V the 62's 6.54 wheel. i talked to BW about it and it is probably going away. likewise, the 80 mm turbine wheel on the 62 may fade out of the picture as it isn't a match. turbine wheels are HEAVY and you don't want too large a wheel.

the 62 has a 6.54 average sq inch area compressor

the 76 turbine wheel is 6.34 or 97%. anything near 1 to 1 is awesome and larger is not awesome.

.

the 62 has a 6.54 average sq inch area compressor

the 76 turbine wheel is 6.34 or 97%. anything near 1 to 1 is awesome and larger is not awesome.

.

#15

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

"...would benefit from larger turbine wheels"

when picking a turbo size to fit your app the first item should be the flow from the compressor. match the flow to your power objective.

also near the top of the list should be the turbine size in relation to the compressor. if you reference my sticky "Turbo Comparisons" thread you will see 110 turbos and the area of their cold and hot side wheels along w the % relationship.

while of course there are other important factors such as wheel efficiency the cold/hot relationship is important, especially w rotaries as they need to flow around 30% more air than a piston engine to make similar power. they also run a few hundred degrees more EGT. the primary factor as to lag is the WEIGHT of the turbine wheel. inconel is heavy and we are wanting to spin it over 100,000 RPM. (this weight factor is the primary reason the EFR does have a transient response advantage over the SXE).

one interesting sidebar as to the EFR titanium/aluminide material is that according to Dan Barlog, Chief Engineer at Precision, the material did not have the structural properties to allow them to mold/machine it into an optimum flow configuration. i remember his direct comment... "we picked flow over weight." so there may be an offset. or there may be marketing going on. i suspect a bit of both.

getting back to the 62 and the turbine wheel options:

the 62 w the 76 hotside is 97% cold 6.54 hot 6.34

the 62 w an 80 hotside is at 109% cold 6.54 hot 7.15

if you reference my Turbo Comparisons thread you will see that 109% is miles from almost everyone of the turbos and 97% is near the top so the 76 should get high marks for the rotary as it is a LARGE hotside for the 62 compressor.

comp/turbo wheel relationships can also work detrimentally on the other side... remember that compressor maps are not generated by a turbine wheel. the comp wheel is spun by an electric motor. a good example is the GTX3582. a really nice compressor map... beautiful. however who knows what happens when this killer comp wheel is hitched to a 5.17 inch turbine. the turbine might not be able to drive the comp wheel to the nicer areas of the map.

i think there is a very narrow window on cold/hot area relationships.

BTW, while i post a lot on the SXE line i like the EFRs also. as mentioned i have an EFR9180. i sell EFRs. i will say the one thing i don't like on the 8374 and 9180 is the internal wastegate. i also am of the opinion that many turbo manifolds are junk and manifolds are the least appreciated item in the power chain.

exhaust back pressure is the marker for manifold efficiency.

it is not uncommon to see 40 psi of back pressure at 20 psi boost. i am at 25 at 8950 RPM.

i raced for many years in the NA world and appreciate flow benches etc. turbos breed sloppy engineering as it is easy to just bolt on a bigger hammer/turbo. nothing wrong w big hammers but they work better when the rest of the system is properly engineered for flow.

things like carving a 2.5 inch hole in the intercooler to elbow tube for a BOV when it should be located on the flat surface of the IC endtank... i could go on

here's my setup w the SXE62:

when picking a turbo size to fit your app the first item should be the flow from the compressor. match the flow to your power objective.

also near the top of the list should be the turbine size in relation to the compressor. if you reference my sticky "Turbo Comparisons" thread you will see 110 turbos and the area of their cold and hot side wheels along w the % relationship.

while of course there are other important factors such as wheel efficiency the cold/hot relationship is important, especially w rotaries as they need to flow around 30% more air than a piston engine to make similar power. they also run a few hundred degrees more EGT. the primary factor as to lag is the WEIGHT of the turbine wheel. inconel is heavy and we are wanting to spin it over 100,000 RPM. (this weight factor is the primary reason the EFR does have a transient response advantage over the SXE).

one interesting sidebar as to the EFR titanium/aluminide material is that according to Dan Barlog, Chief Engineer at Precision, the material did not have the structural properties to allow them to mold/machine it into an optimum flow configuration. i remember his direct comment... "we picked flow over weight." so there may be an offset. or there may be marketing going on. i suspect a bit of both.

getting back to the 62 and the turbine wheel options:

the 62 w the 76 hotside is 97% cold 6.54 hot 6.34

the 62 w an 80 hotside is at 109% cold 6.54 hot 7.15

if you reference my Turbo Comparisons thread you will see that 109% is miles from almost everyone of the turbos and 97% is near the top so the 76 should get high marks for the rotary as it is a LARGE hotside for the 62 compressor.

comp/turbo wheel relationships can also work detrimentally on the other side... remember that compressor maps are not generated by a turbine wheel. the comp wheel is spun by an electric motor. a good example is the GTX3582. a really nice compressor map... beautiful. however who knows what happens when this killer comp wheel is hitched to a 5.17 inch turbine. the turbine might not be able to drive the comp wheel to the nicer areas of the map.

i think there is a very narrow window on cold/hot area relationships.

BTW, while i post a lot on the SXE line i like the EFRs also. as mentioned i have an EFR9180. i sell EFRs. i will say the one thing i don't like on the 8374 and 9180 is the internal wastegate. i also am of the opinion that many turbo manifolds are junk and manifolds are the least appreciated item in the power chain.

exhaust back pressure is the marker for manifold efficiency.

it is not uncommon to see 40 psi of back pressure at 20 psi boost. i am at 25 at 8950 RPM.

i raced for many years in the NA world and appreciate flow benches etc. turbos breed sloppy engineering as it is easy to just bolt on a bigger hammer/turbo. nothing wrong w big hammers but they work better when the rest of the system is properly engineered for flow.

things like carving a 2.5 inch hole in the intercooler to elbow tube for a BOV when it should be located on the flat surface of the IC endtank... i could go on

here's my setup w the SXE62:

Last edited by Howard Coleman; 11-18-17 at 09:49 AM.

The following users liked this post:

KNONFS (11-18-17)

#18

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

re Precision:

there are interesting dynamics at play.

Precision, today, is a very successful company that was started approx 30 years ago by a real racer using modest capital initially modding Garrett turbos in a small town in Indiana. as in any startup venture they had their share of successes and failures as they grew. spotty durability here and there along the way but always w a different flavor than Garrett or Borg Warner.

Borg Warner and Garrett, being OE type companies are constrained by significant safety and durability considerations. BW engineers (plural) have told me they fantasize about being able to create product free from some of these constraints.

Precision is free from these self imposed guidelines and as such designs product today closer to the edge.

make no mistake about Precision today... if you travel to Hebron, Indiana you will see a succession of buildings, each larger than the next housing a succession of cutting edge equipment. it is no accident that amongst the highest dollar racing circles race teams routinely pay $25,000 for one of their turbos. i spent more than half a day w Dan Barlog inspecting everything they do in the building process and it was clear that today (there's that word again) literally every piece of their CEA Gen 2 and beyond turbos is a clean sheet of paper Precision design.

while i have yet to own and test any of their turbos it is my opinion that their top shelf offerings are probably tops as to performance. i did have a lengthy discussion w Dan re the BW lighterweight turbine wheels. there is no BW patent on the material and Precision, IMO, did fully evaluate it. we did discuss the specifics re the turbine fins and my firm view of Dan is he is totally obsessed w cutting edge engineering as any real racer is and may not even know how to spell marketing.

Turbos, which are magic for the rotary, are in such a growth spurt today... lots of tech being applied. Precision has an oil-less air cooled ceramic bearing for example. the ceramic material is different than others and is proprietary. BW has the light turbine wheel, Garrett has a new President after being bought by Honeywell. the new Pres, Dan Sussna, was a Honeywell jet engine engineer and now has 2000 Honeywell engineers he can use to move forward. and move forward he will.

i will be at the Performance Racing Industry trade show in 2 weeks and have a chance to find out what magic is featured for 2018.

there are interesting dynamics at play.

Precision, today, is a very successful company that was started approx 30 years ago by a real racer using modest capital initially modding Garrett turbos in a small town in Indiana. as in any startup venture they had their share of successes and failures as they grew. spotty durability here and there along the way but always w a different flavor than Garrett or Borg Warner.

Borg Warner and Garrett, being OE type companies are constrained by significant safety and durability considerations. BW engineers (plural) have told me they fantasize about being able to create product free from some of these constraints.

Precision is free from these self imposed guidelines and as such designs product today closer to the edge.

make no mistake about Precision today... if you travel to Hebron, Indiana you will see a succession of buildings, each larger than the next housing a succession of cutting edge equipment. it is no accident that amongst the highest dollar racing circles race teams routinely pay $25,000 for one of their turbos. i spent more than half a day w Dan Barlog inspecting everything they do in the building process and it was clear that today (there's that word again) literally every piece of their CEA Gen 2 and beyond turbos is a clean sheet of paper Precision design.

while i have yet to own and test any of their turbos it is my opinion that their top shelf offerings are probably tops as to performance. i did have a lengthy discussion w Dan re the BW lighterweight turbine wheels. there is no BW patent on the material and Precision, IMO, did fully evaluate it. we did discuss the specifics re the turbine fins and my firm view of Dan is he is totally obsessed w cutting edge engineering as any real racer is and may not even know how to spell marketing.

Turbos, which are magic for the rotary, are in such a growth spurt today... lots of tech being applied. Precision has an oil-less air cooled ceramic bearing for example. the ceramic material is different than others and is proprietary. BW has the light turbine wheel, Garrett has a new President after being bought by Honeywell. the new Pres, Dan Sussna, was a Honeywell jet engine engineer and now has 2000 Honeywell engineers he can use to move forward. and move forward he will.

i will be at the Performance Racing Industry trade show in 2 weeks and have a chance to find out what magic is featured for 2018.

Last edited by Howard Coleman; 11-18-17 at 09:53 AM.

#19

"...would benefit from larger turbine wheels"

when picking a turbo size to fit your app the first item should be the flow from the compressor. match the flow to your power objective.

also near the top of the list should be the turbine size in relation to the compressor. if you reference my sticky "Turbo Comparisons" thread you will see 110 turbos and the area of their cold and hot side wheels along w the % relationship.

while of course there are other important factors such as wheel efficiency the cold/hot relationship is important, especially w rotaries as they need to flow around 30% more air than a piston engine to make similar power. they also run a few hundred degrees more EGT. the primary factor as to lag is the WEIGHT of the turbine wheel. inconel is heavy and we are wanting to spin it over 100,000 RPM. (this weight factor is the primary reason the EFR does have a transient response advantage over the SXE).

one interesting sidebar as to the EFR titanium/aluminide material is that according to Dan Barlog, Chief Engineer at Precision, the material did not have the structural properties to allow them to mold/machine it into an optimum flow configuration. i remember his direct comment... "we picked flow over weight." so there may be an offset. or there may be marketing going on. i suspect a bit of both.

getting back to the 62 and the turbine wheel options:

the 62 w the 76 hotside is 97% cold 6.54 hot 6.34

the 62 w an 80 hotside is at 109% cold 6.54 hot 7.15

if you reference my Turbo Comparisons thread you will see that 109 is miles from almost everyone of the turbos and 97% is near the top so the 76 should get high marks for the rotary as it is a LARGE hotside for the 62 compressor.

comp/turbo wheel relationships can also work detrimentally on the other side... remember that compressor maps are not generated by a turbine wheel. the comp wheel is spun by an electric motor. a good example is the GTX3582. a really nice compressor map... beautiful. however who knows what happens when this killer comp wheel is hitched to a 5.17 inch turbine. the turbine might not be able to drive the comp wheel to the nicer areas of the map.

i think there is a very narrow window on cold/hot area relationships.

BTW, while i post a lot on the SXE line i like the EFRs also. as mentioned i have an EFR9180. i sell EFRs. i will say the one thing i don't like on the 8374 and 9180 is the internal wastegate. i also am of the opinion that many turbo manifolds are junk and manifolds are the least appreciated item in the power chain.

exhaust back pressure is the marker for manifold efficiency.

it is not uncommon to see 40 psi of back pressure at 20 psi boost. i am at 25 at 8950 RPM.

i raced for many years in the NA world and appreciate flow benches etc. turbos breed sloppy engineering as it is easy to just bolt on a bigger hammer/turbo. nothing wrong w big hammers but they work better when the rest of the system is properly engineered for flow.

things like carving a 2.5 inch hole in the intercooler to elbow tube for a BOV when it should be located on the flat surface of the IC endtank... i could go on

here's my setup w the SXE62:

when picking a turbo size to fit your app the first item should be the flow from the compressor. match the flow to your power objective.

also near the top of the list should be the turbine size in relation to the compressor. if you reference my sticky "Turbo Comparisons" thread you will see 110 turbos and the area of their cold and hot side wheels along w the % relationship.

while of course there are other important factors such as wheel efficiency the cold/hot relationship is important, especially w rotaries as they need to flow around 30% more air than a piston engine to make similar power. they also run a few hundred degrees more EGT. the primary factor as to lag is the WEIGHT of the turbine wheel. inconel is heavy and we are wanting to spin it over 100,000 RPM. (this weight factor is the primary reason the EFR does have a transient response advantage over the SXE).

one interesting sidebar as to the EFR titanium/aluminide material is that according to Dan Barlog, Chief Engineer at Precision, the material did not have the structural properties to allow them to mold/machine it into an optimum flow configuration. i remember his direct comment... "we picked flow over weight." so there may be an offset. or there may be marketing going on. i suspect a bit of both.

getting back to the 62 and the turbine wheel options:

the 62 w the 76 hotside is 97% cold 6.54 hot 6.34

the 62 w an 80 hotside is at 109% cold 6.54 hot 7.15

if you reference my Turbo Comparisons thread you will see that 109 is miles from almost everyone of the turbos and 97% is near the top so the 76 should get high marks for the rotary as it is a LARGE hotside for the 62 compressor.

comp/turbo wheel relationships can also work detrimentally on the other side... remember that compressor maps are not generated by a turbine wheel. the comp wheel is spun by an electric motor. a good example is the GTX3582. a really nice compressor map... beautiful. however who knows what happens when this killer comp wheel is hitched to a 5.17 inch turbine. the turbine might not be able to drive the comp wheel to the nicer areas of the map.

i think there is a very narrow window on cold/hot area relationships.

BTW, while i post a lot on the SXE line i like the EFRs also. as mentioned i have an EFR9180. i sell EFRs. i will say the one thing i don't like on the 8374 and 9180 is the internal wastegate. i also am of the opinion that many turbo manifolds are junk and manifolds are the least appreciated item in the power chain.

exhaust back pressure is the marker for manifold efficiency.

it is not uncommon to see 40 psi of back pressure at 20 psi boost. i am at 25 at 8950 RPM.

i raced for many years in the NA world and appreciate flow benches etc. turbos breed sloppy engineering as it is easy to just bolt on a bigger hammer/turbo. nothing wrong w big hammers but they work better when the rest of the system is properly engineered for flow.

things like carving a 2.5 inch hole in the intercooler to elbow tube for a BOV when it should be located on the flat surface of the IC endtank... i could go on

here's my setup w the SXE62:

Thanks, for the explanation. Would love to know the weight difference between the 76mm and the 80mm, not that it changes the 1 to 1 ratio that you are talking about, just wondering how much heavier one is over the other. I am guessing is a situation like this grams MATTERS!

PS - Quick question, how are you determining the average sq inch area compressor? I've been trying to reverse calculate the numbers, and I am missing something...

Last edited by KNONFS; 11-18-17 at 01:37 PM.

#20

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

"how are you determining the average sq inch area compressor?"

if you read the beginning of my sticky thread "Turbo Comparisons" it is laid out...

solve for the area of the inducer, add the area of the exducer, divide by two gives average area.

for instance take the SXE 62compressor...

61.44 inducer, 83.47 exducer

61.44 is 2.42 inches diameter which is 4.59 sq inches

83.47 exducer, 3.29 diameter which is 8.5 sq inches

4.59 + 8.5 = 13.09 / 2 = 6.54 average area

once you know the two areas you can also solve for the Trim which is another important consideration...

4.59/8.5 = .54 or generally stated as 54 Trim

higher trim numbers towards 60 favor top end. lower trim numbers around 52 or 54 favor spool and midrange

these numbers are available for 110 turbos in the Turbo Comparison thread.

area absolute numbers and hot/cold relationships are not the final word but sizes do correlate very well to flow and can provide an initial guide.

if you read the beginning of my sticky thread "Turbo Comparisons" it is laid out...

solve for the area of the inducer, add the area of the exducer, divide by two gives average area.

for instance take the SXE 62compressor...

61.44 inducer, 83.47 exducer

61.44 is 2.42 inches diameter which is 4.59 sq inches

83.47 exducer, 3.29 diameter which is 8.5 sq inches

4.59 + 8.5 = 13.09 / 2 = 6.54 average area

once you know the two areas you can also solve for the Trim which is another important consideration...

4.59/8.5 = .54 or generally stated as 54 Trim

higher trim numbers towards 60 favor top end. lower trim numbers around 52 or 54 favor spool and midrange

these numbers are available for 110 turbos in the Turbo Comparison thread.

area absolute numbers and hot/cold relationships are not the final word but sizes do correlate very well to flow and can provide an initial guide.

#21

Rotary Enthusiast

reading about turbo sizing some more, I realized we really need to look at the surgline at peaktorque (say 4500rpm) as well.

the popular EFR 9180 seem to go past surgeline at 4500rpm, with 20psi+ boost

now I can see why howard recommends the 13009097056, it has plenty of margin at this rpm level.

for someone that wants to boost 23psi on a large streetport 13b, what about 13009097008 or 13009097055? would these 2 be a better choice at this boost level?

which one would you pick?

the popular EFR 9180 seem to go past surgeline at 4500rpm, with 20psi+ boost

now I can see why howard recommends the 13009097056, it has plenty of margin at this rpm level.

for someone that wants to boost 23psi on a large streetport 13b, what about 13009097008 or 13009097055? would these 2 be a better choice at this boost level?

which one would you pick?

#22

Rotary Enthusiast

using howard's formula I think I just answered my own question

13009097055 seem to be perfect for this scenario of 23psi, 13b large streetport.

and it seem to be much better choice than EFR 9180, 8374

please correct me if i'm wrong

13009097055 seem to be perfect for this scenario of 23psi, 13b large streetport.

and it seem to be much better choice than EFR 9180, 8374

please correct me if i'm wrong

#23

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

Alpine:

power target 575

desired boost pressure 20/23

575 rw rotary SAE is 76 pounds per minute

Edit:

adjust to use 160 cubic inch displacement

since the rotary is 160 cu inches 575 is 3.6 hp per cubic inch or 4.2 flywheel hp per cubic inch.

or the equivalent of a...

1763 hp Corvette LS7 427 motor.

anyone running in this vicinity better have a healthy respect for the razor thin margin for error.

others are thinking their setup is really conservative... at 400 hp.

that'd be a 1226 hp LS7.

it is all about massive CCP. combustion chamber pressure. so fuel, heat and ignition are front page considerations.

but i digress (purposely)

as to the 575 turbo choice, 80 pounds per minute minimum. my older school GT4094r fits perfectly.

being old school, the less efficient compressor is 8.175 area.

newer turbos, such as the SXE (64.5) 7008/7055 do 80 pounds w a 7.17 area compressor, or the SXE 66 over 85 w a 7.74 comp or the SXE69 w a 7.99 wheel close to 100 at 60% efficiency..

Trim is important as to where spool is... Trim is the relationship between the area of the smaller diameter (inducer) and the larger diameter (exducer) of the compressor. Trim range is generally between 50 and 60.

SXE 62 is 54 favoring low to mid range

SXE 64.5 Trim is 54.5, ditto the 62

SXE66 is 52 which really peps up mid range yet the wheel puts out big top end flow, a really nice combo

SXE 69 is 57 making it a top end favorite ( i have one on a Bonneville Lakester)

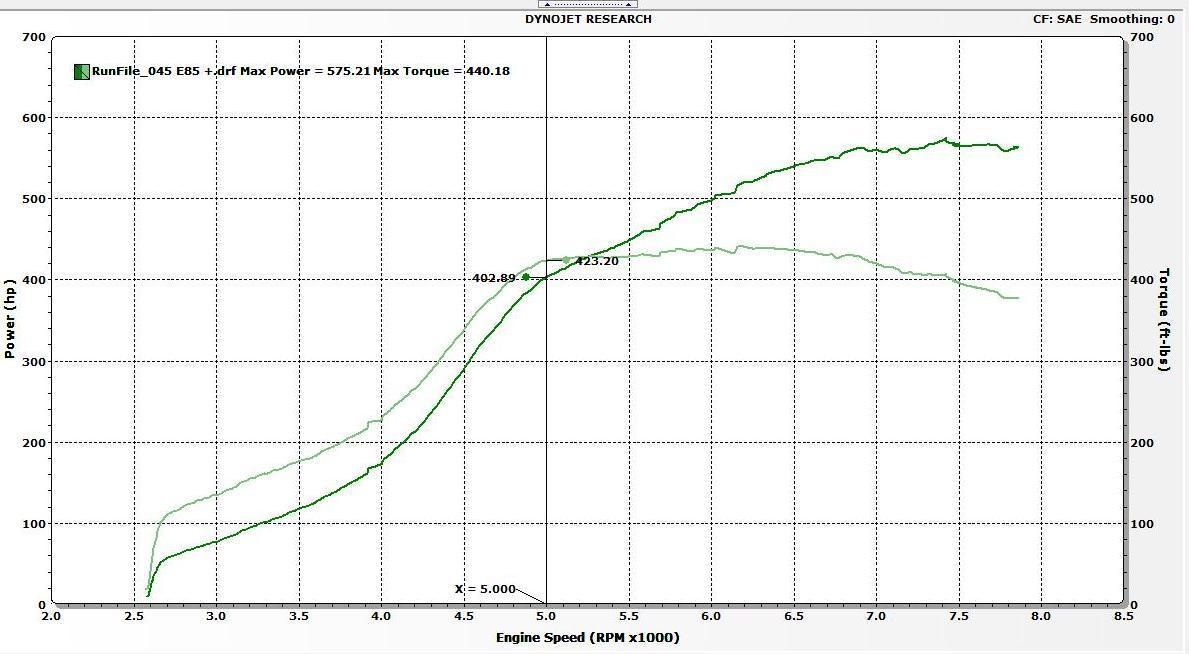

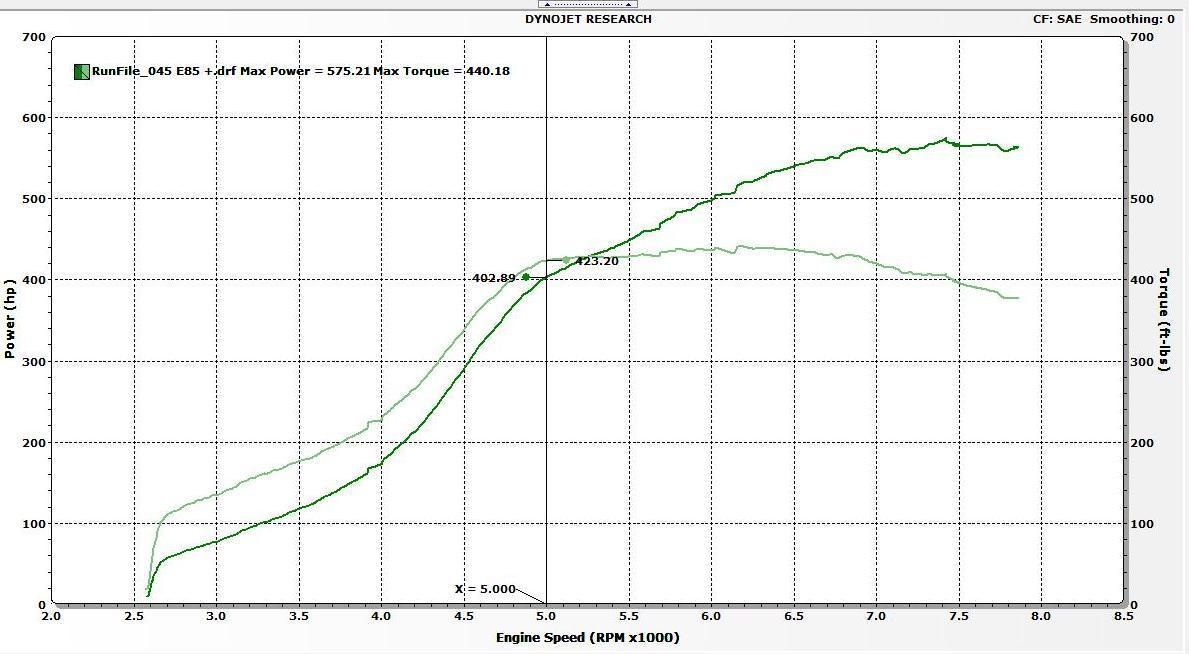

Trim is important. here is a dyno sheet from my car set up for the Texas Mile w the old school GT4094r. you would think that the 8.175 compressor would have been laggy especially being driven by a 6.42 hotside wheel (78% of cold area) but not really. the 52 Trim helped it make 403 SAE/413 STD at 5000 and 448 SAE/459 STD at 550. this is a large 630SAE/646 STD hp turbo and the 52 Trim helps it greatly.

continuing on in my cautionary mode:

i think 500 SAE rwhp is a sweet spot for max power objective for many. sure 575 is larger than 500 but i suggest two considerations.

drive or ride in a real 500 hp FD w the pedal to the metal. if you haven't you have no idea how fast the car is.

above 500 things do not progress linearly as to cost and drive-ability.

for instance, the clutch package. the problem w the clutch is the rotary is a small engine with a 13 X 13 X 13 inch block.

small engines have small flywheels which have small frictional area. there is no magic w re to clutches. frictional area, coefficient of friction for materials versus driving force.

clamp is the adhesive. the more clamp needed the less you will drive your car on the street and the less feather on take-up. not fun having an in or out clutch.

you can double the frictional area by going to a double disc. i run a Mcleod RST. it is perfect, easy take up and holds XXX hp. cost close to $3000. previous to swapping in a T56 i ran an Exedy double which is streetable... they are close to $2000. if you run a single (ACT) you will need the stiffer pressure plate. relatively inexpensive but not fun to drive. around 500 hp you can get by w a friendlier clutch.

this racheting up applies to just about everything on your 575 FD.

that's why the SXE62 is currently on my car... it is an awesome turbo for not much money and is perfect for many who are looking for 500 max and maybe less. no doubt the majority of FD owners. so i want to fully evaluate it.

as to your 575..

i recommend the 7008 (64.5) w the 76 hotside wheel and 1.0 housing.

it will do 573 at 20 psi at 60% efficiency, has a 7.17 compressor (not too large) is capable of 82 pounds at 60% efficiency. really good spool and the appropriate amount of power.

power target 575

desired boost pressure 20/23

575 rw rotary SAE is 76 pounds per minute

Edit:

adjust to use 160 cubic inch displacement

since the rotary is 160 cu inches 575 is 3.6 hp per cubic inch or 4.2 flywheel hp per cubic inch.

or the equivalent of a...

1763 hp Corvette LS7 427 motor.

anyone running in this vicinity better have a healthy respect for the razor thin margin for error.

others are thinking their setup is really conservative... at 400 hp.

that'd be a 1226 hp LS7.

it is all about massive CCP. combustion chamber pressure. so fuel, heat and ignition are front page considerations.

but i digress (purposely)

as to the 575 turbo choice, 80 pounds per minute minimum. my older school GT4094r fits perfectly.

being old school, the less efficient compressor is 8.175 area.

newer turbos, such as the SXE (64.5) 7008/7055 do 80 pounds w a 7.17 area compressor, or the SXE 66 over 85 w a 7.74 comp or the SXE69 w a 7.99 wheel close to 100 at 60% efficiency..

Trim is important as to where spool is... Trim is the relationship between the area of the smaller diameter (inducer) and the larger diameter (exducer) of the compressor. Trim range is generally between 50 and 60.

SXE 62 is 54 favoring low to mid range

SXE 64.5 Trim is 54.5, ditto the 62

SXE66 is 52 which really peps up mid range yet the wheel puts out big top end flow, a really nice combo

SXE 69 is 57 making it a top end favorite ( i have one on a Bonneville Lakester)

Trim is important. here is a dyno sheet from my car set up for the Texas Mile w the old school GT4094r. you would think that the 8.175 compressor would have been laggy especially being driven by a 6.42 hotside wheel (78% of cold area) but not really. the 52 Trim helped it make 403 SAE/413 STD at 5000 and 448 SAE/459 STD at 550. this is a large 630SAE/646 STD hp turbo and the 52 Trim helps it greatly.

continuing on in my cautionary mode:

i think 500 SAE rwhp is a sweet spot for max power objective for many. sure 575 is larger than 500 but i suggest two considerations.

drive or ride in a real 500 hp FD w the pedal to the metal. if you haven't you have no idea how fast the car is.

above 500 things do not progress linearly as to cost and drive-ability.

for instance, the clutch package. the problem w the clutch is the rotary is a small engine with a 13 X 13 X 13 inch block.

small engines have small flywheels which have small frictional area. there is no magic w re to clutches. frictional area, coefficient of friction for materials versus driving force.

clamp is the adhesive. the more clamp needed the less you will drive your car on the street and the less feather on take-up. not fun having an in or out clutch.

you can double the frictional area by going to a double disc. i run a Mcleod RST. it is perfect, easy take up and holds XXX hp. cost close to $3000. previous to swapping in a T56 i ran an Exedy double which is streetable... they are close to $2000. if you run a single (ACT) you will need the stiffer pressure plate. relatively inexpensive but not fun to drive. around 500 hp you can get by w a friendlier clutch.

this racheting up applies to just about everything on your 575 FD.

that's why the SXE62 is currently on my car... it is an awesome turbo for not much money and is perfect for many who are looking for 500 max and maybe less. no doubt the majority of FD owners. so i want to fully evaluate it.

as to your 575..

i recommend the 7008 (64.5) w the 76 hotside wheel and 1.0 housing.

it will do 573 at 20 psi at 60% efficiency, has a 7.17 compressor (not too large) is capable of 82 pounds at 60% efficiency. really good spool and the appropriate amount of power.

Last edited by Howard Coleman; 03-01-18 at 01:59 PM.

The following 2 users liked this post by Howard Coleman:

RGHTBrainDesign (11-26-17),

swif (06-26-21)

#24

Arrogant Wankeler

Don't need the hyperbole.

13B equivalent 720 degree displacement is 2.6L not 1.3 mazda nomenclature, halve those piston outputs for similar chamber pressure.

I agree for power 2 rotors need a lot of clutch, fewer big torque impulses adding to the mean like a big 4 cylinder rather than a 6 or 8.

13B equivalent 720 degree displacement is 2.6L not 1.3 mazda nomenclature, halve those piston outputs for similar chamber pressure.

I agree for power 2 rotors need a lot of clutch, fewer big torque impulses adding to the mean like a big 4 cylinder rather than a 6 or 8.

Last edited by Slides; 11-27-17 at 07:35 AM.

#25

Rotary Enthusiast

Hi Howard,

Thank you for your response. I like to learn more about why you picked the 13009097008 over the 13009097055.

maybe i'm not understanding some of this correctly.

as i understand it so far, there are 3 things we can calculate to see if the turbo size is in the ball park

1. Wheel Ratio: comp wheel exducer / turbine wheel inducer, with the goal being 1.1-1.2 for best spool.

2. comp wheel avg area / turbine wheel avg area, with the goal being 0.95 - 1.0 being best

This was from your post single turbo comprison, please let me know if i'm not understanding this correctly

https://www.rx7club.com/single-turbo...st-one-869614/

3. comp wheel trim, with 50 - 54 being best for low/mid range

4. turbine wheel trim? is there an relationship of turbine wheel trim to powerband characteristic? What is ideal

Based on the above

1. 13009097008 has

wheel ratio: 1.15

comp avg area / turbine avg area: 0.88

comp wheel trim: 54.45

2. 13009097055

wheel ratio: 1.10

comp avg area / turbine avg area: 0.99

comp wheel trim: 54.45

it seem to me the 13009097055 is more optimal for spool, with the same hp capability (same compressor)

Please let me know your thoughts.

Thank you for your response. I like to learn more about why you picked the 13009097008 over the 13009097055.

maybe i'm not understanding some of this correctly.

as i understand it so far, there are 3 things we can calculate to see if the turbo size is in the ball park

1. Wheel Ratio: comp wheel exducer / turbine wheel inducer, with the goal being 1.1-1.2 for best spool.

2. comp wheel avg area / turbine wheel avg area, with the goal being 0.95 - 1.0 being best

This was from your post single turbo comprison, please let me know if i'm not understanding this correctly

https://www.rx7club.com/single-turbo...st-one-869614/

3. comp wheel trim, with 50 - 54 being best for low/mid range

4. turbine wheel trim? is there an relationship of turbine wheel trim to powerband characteristic? What is ideal

Based on the above

1. 13009097008 has

wheel ratio: 1.15

comp avg area / turbine avg area: 0.88

comp wheel trim: 54.45

2. 13009097055

wheel ratio: 1.10

comp avg area / turbine avg area: 0.99

comp wheel trim: 54.45

it seem to me the 13009097055 is more optimal for spool, with the same hp capability (same compressor)

Please let me know your thoughts.