2nd Gear Peak Boost - T04E

#1

2nd Gear Peak Boost - T04E

So my FD has 4.77 gears and I autox it. I have a used single turbo kit (modified HKS single kit) as follows:

HKS/Garrett TO4E

* 0.84 Turbine A/R

* 0.60 Compressor A/R

* Divided Turbine Housing

* Upgraded 360* Journal Bearing

HKS External Wastegate (8 lbs spring)

HKS Downpipe w/ O2 Bung

HKS Exhaust Manifold w/ Divided Turbine Inlet

The previous owner says it's was a TO4E 57 trim from the HKS turbo kit and now it's a TO4E 60 trim with the upgraded compressor.

My experience is that the turbo can spool up in higher gear to the 17-18 psi or 1.2kg/cm^2, however, I need the power in 2nd gear for autox. The load is dramatically lower in 2nd due to the gearing and as a result, even with the wastegate completely disconnected, 2nd gear will only spool to 1.01 kg/cm^2.

I think this is a mechanical limit to the turbo itself (assuming a free flowing exhaust and intake). What would need to be change mechanically with the turbo to create higher 2nd gear boost (and as a bonus also increase low end response)? Or is it possible the turbo is damaged. I don't know what other people are able to peak in second with similar turbos.

HKS/Garrett TO4E

* 0.84 Turbine A/R

* 0.60 Compressor A/R

* Divided Turbine Housing

* Upgraded 360* Journal Bearing

HKS External Wastegate (8 lbs spring)

HKS Downpipe w/ O2 Bung

HKS Exhaust Manifold w/ Divided Turbine Inlet

The previous owner says it's was a TO4E 57 trim from the HKS turbo kit and now it's a TO4E 60 trim with the upgraded compressor.

My experience is that the turbo can spool up in higher gear to the 17-18 psi or 1.2kg/cm^2, however, I need the power in 2nd gear for autox. The load is dramatically lower in 2nd due to the gearing and as a result, even with the wastegate completely disconnected, 2nd gear will only spool to 1.01 kg/cm^2.

I think this is a mechanical limit to the turbo itself (assuming a free flowing exhaust and intake). What would need to be change mechanically with the turbo to create higher 2nd gear boost (and as a bonus also increase low end response)? Or is it possible the turbo is damaged. I don't know what other people are able to peak in second with similar turbos.

#2

Checking for exhaust restrictions

Verify engine health ie 100+ psi compression

Checking for boost leaks

Checking wastegate does not leak

Checking for exhaust leaks between engine and turbine housing

Testing with a stronger wastegate spring

Changine turbine housing to 0.7A/R

Refresh turbo

Replace compressor wheel with a wheel actually suited to the rotary engines airflow requirements (flow @ low boost not flow @ high boost).

Verify engine health ie 100+ psi compression

Checking for boost leaks

Checking wastegate does not leak

Checking for exhaust leaks between engine and turbine housing

Testing with a stronger wastegate spring

Changine turbine housing to 0.7A/R

Refresh turbo

Replace compressor wheel with a wheel actually suited to the rotary engines airflow requirements (flow @ low boost not flow @ high boost).

#4

I would check everything else before blaming the turbo. I doubt the the T04E wheel will make it spool slower. I don't like them because they have larger wheels than T04B wheels for the same flow. To me it looks like all changes are for low rpm high boost low flow engines (pist-on).

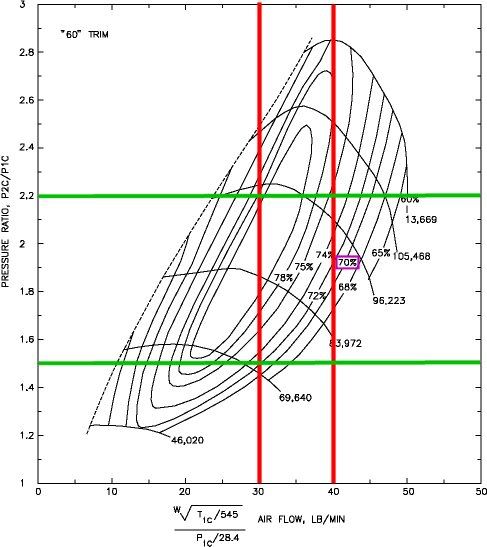

Btw the 60-trim isn't too bad regarding flow at low boost, I just checked the maps, and it stands to reason because it has a 60-trim wheel. Have a read of this, and remember you want response go as small as possible.

http://fc3spro.com/TECH/TURBO/compmap.html

Btw the 60-trim isn't too bad regarding flow at low boost, I just checked the maps, and it stands to reason because it has a 60-trim wheel. Have a read of this, and remember you want response go as small as possible.

http://fc3spro.com/TECH/TURBO/compmap.html

#6

I don't think it has a boost leak considering it made 377 whp at 1.19 kg/cm^2 in 4th gear on the dyno. This was at 75% wastegate duty PFC setting controlling a MAC 3 way solenoid valve.

The fact is, there is a high-flow metallic substrate cat, that is a serious bottle neck. But due to sound restrictions with SCCA now, I can't have the car back firing or I will get dsq'ed. The fact that the turbo hits the target boost fine in 4th gear, but short in 2nd leads me to think it is a load issue.

How do you test to see if the wastegate is bypassing exhaust without a triggered opening (ie leaking exhaust past the turbine)?

The fact is, there is a high-flow metallic substrate cat, that is a serious bottle neck. But due to sound restrictions with SCCA now, I can't have the car back firing or I will get dsq'ed. The fact that the turbo hits the target boost fine in 4th gear, but short in 2nd leads me to think it is a load issue.

How do you test to see if the wastegate is bypassing exhaust without a triggered opening (ie leaking exhaust past the turbine)?

#7

You have a weak wastegate spring. I wonder if the exhaust backpressure is pushing it open.

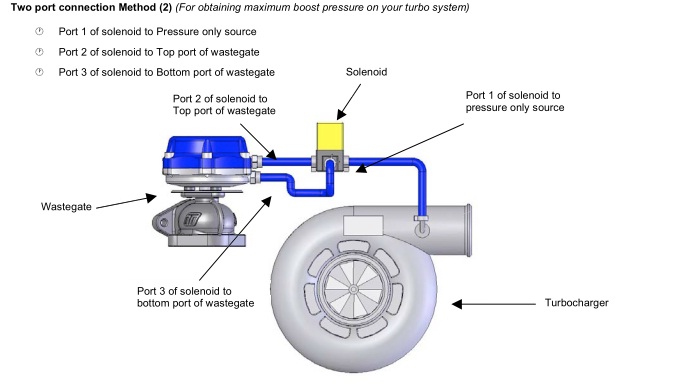

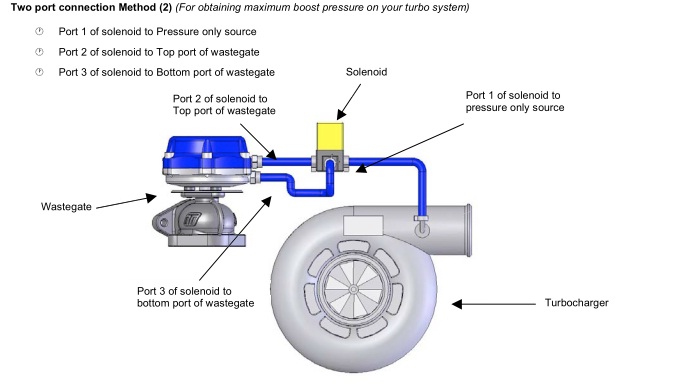

Run a line from the compressor housing to the top port only. ONLY to the top port, leave the side port open and do not install any form of boost controller. Be VERY CAREFUL when you do this as it could dramatically increase boost. The pressure supplied from the compressor housing will push on the diaphragm in the wastegate in order to help fight exhaust backpressure which may be forcing the valve open. This is a test to determine whether your spring is too weak.

Never under normal circumstances should you run an uninterrupted pressure source to the top of an external wastegate. This is only a test.

Run a line from the compressor housing to the top port only. ONLY to the top port, leave the side port open and do not install any form of boost controller. Be VERY CAREFUL when you do this as it could dramatically increase boost. The pressure supplied from the compressor housing will push on the diaphragm in the wastegate in order to help fight exhaust backpressure which may be forcing the valve open. This is a test to determine whether your spring is too weak.

Never under normal circumstances should you run an uninterrupted pressure source to the top of an external wastegate. This is only a test.

Trending Topics

#10

Also, the spring is fully preloaded at the moment.

EDIT: Raymond, what if I run the MAC Valve vent port to the upper portion of the wastegate, and leave the feed routed to the lower portion? Would this do the same as stiffening the wastegate spring?.

EDIT: Raymond, what if I run the MAC Valve vent port to the upper portion of the wastegate, and leave the feed routed to the lower portion? Would this do the same as stiffening the wastegate spring?.

#11

I'm not entirely following what you are suggesting because I don't know exactly which ports on the solenoid you are referring to. But perhaps you meant something like this configuration?

It's definitely worth a shot. That's one of the configurations in the TurboSmart E-boost manual. The Turbosmart uses a similar solenoid. Very little air will be fed to the side port of the gate in that configuration, and the side port is what actually opens the gate up. If that doesn't raise the boost I'd start looking for boost and exhaust leaks next.

It's definitely worth a shot. That's one of the configurations in the TurboSmart E-boost manual. The Turbosmart uses a similar solenoid. Very little air will be fed to the side port of the gate in that configuration, and the side port is what actually opens the gate up. If that doesn't raise the boost I'd start looking for boost and exhaust leaks next.

#15

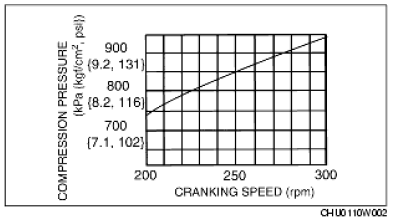

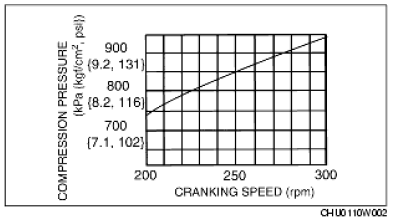

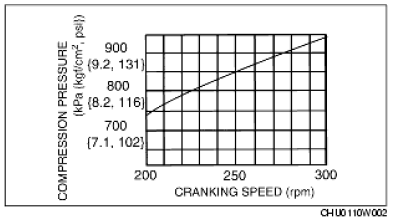

Compression test numbers from Mazda testers are also in kg/cm^2. That's why perfect compression is usually considered to be between 8.2 and 8.5 depending on cranking speed etc.

It's still an oddball Japanese unit though.

#17

As a result, I would anticipate this to build significant more boost at a given wastegate duty, as you mentioned (versus my current setup). The benefit here is that the added pressure of the opposite side of the diaphragm would help resist the exhaust forcing the wastegate open. I certainly would like to try this setup and see if it helps.

Thanks again Raymond.

#18

Canned. I got CORNED!

iTrader: (5)

Join Date: Mar 2007

Location: Appleton, WI

Posts: 1,029

Likes: 0

Received 0 Likes

on

0 Posts

You haven't used Apex'i boost control much then. AVC-R and Power FC use kg/cm^2, where 1.0 kg/cm^2 = 14.22 psi. And there's no way to change the units on these devices. Some oldschool boost gauges also use kg/cm^2.

Compression test numbers from Mazda testers are also in kg/cm^2. That's why perfect compression is usually considered to be between 8.2 and 8.5 depending on cranking speed etc.

It's still an oddball Japanese unit though.

Compression test numbers from Mazda testers are also in kg/cm^2. That's why perfect compression is usually considered to be between 8.2 and 8.5 depending on cranking speed etc.

It's still an oddball Japanese unit though.

Thread

Thread Starter

Forum

Replies

Last Post

rgordon1979

3rd Generation Specific (1993-2002)

40

03-15-22 12:04 PM

Jeff20B

1st Generation Specific (1979-1985)

73

09-16-18 07:16 PM