it IS 2015: Gentleman start your turbos

#51

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

Gentleman,

while there is nothing wrong w discussing apex seals, the subject is off topic to this thread which is about new turbos. perhaps a moderator (hello?) will either delete or move and retitle all posts from #39 forward so we can get back to the subject that the people reading this thread have as an interest.

for those people, i am traveling to Hebron, Indiana tomorrow to spend the day w Precision Turbo, especially Dan Barlog, and will report in on my return.

my 9180 fixturing is moving forward and should be on the dyno very soon.

howard

while there is nothing wrong w discussing apex seals, the subject is off topic to this thread which is about new turbos. perhaps a moderator (hello?) will either delete or move and retitle all posts from #39 forward so we can get back to the subject that the people reading this thread have as an interest.

for those people, i am traveling to Hebron, Indiana tomorrow to spend the day w Precision Turbo, especially Dan Barlog, and will report in on my return.

my 9180 fixturing is moving forward and should be on the dyno very soon.

howard

#52

Well I got 45k on some used rotor housings with RA classics on my 91 vert so I'm not experiencing the so called wear issues that some have reported with unbreakable seals. Engine is pre-mix only. I stopped driving this car when a hail storm damaged the top. That was back in 2009. Last year I fire it up for the 1st time in 5 years and she still runs with zero flooding problems. The shitty tephlon coolant seals just went out a couple months ago. I took before images of the housings before the rebuild. Keep in mind, I still resused both housings from when the engine blew with factory seals. Yes there were scuffs but she doesn't seem to care and has NEVER had hard hot starting problems. This same engine also got 26mpg on the highway. Should be intersting to see how they look now.

Edit: Sorry Howard, I know the seal talk is off topic but at least now, where getting some long term results from multiple sources (which is great info) that still relate to single upgrades and mods most will do anyways.

#53

I'm not challenging RA classic seals, never have. Then again, they aren't "unbreakable". The super seals were the discussion between Banzai and I. It's useless, he would be foolish to admit they do what they do. They are great for builders who provide warranties and those willing to accept the trade off. If I was planning to run 20+lbs I would run them, it's not like I'm saying don't buy them. I'm just honest enough to tell people what to expect.

We can carry this on in another thread if anyone cares enough. The data is there, not much really to discuss.

We can carry this on in another thread if anyone cares enough. The data is there, not much really to discuss.

#55

#56

Senior Member

And about the off topic,

It seems we could develop an algorithm that would predict when threads go off topic and deteriorate into some form of "you're wrong, no, you're wrong....." Back and forth, based on how many posts are in the thread.

#57

Gentleman, while there is nothing wrong w discussing apex seals, the subject is off topic to this thread which is about new turbos.

for those people, i am traveling to Hebron, Indiana tomorrow to spend the day w Precision Turbo, especially Dan Barlog, and will report in on my return. my 9180 fixturing is moving forward and should be on the dyno very soon. howard

for those people, i am traveling to Hebron, Indiana tomorrow to spend the day w Precision Turbo, especially Dan Barlog, and will report in on my return. my 9180 fixturing is moving forward and should be on the dyno very soon. howard

#58

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

perhaps i might veer off the current topic of apex seals and swing back over to the 2015 turbo landscape.

i spent much of yesterday with Dan Barlog, Engineering Director at Precision Turbo in Hebron, Indiana. Aaron Hoyt, Sales Rep for the East Coast, was kind enough to put the day together and added lots of additional info.

Dan has been w Precision for over 15 years and is responsible for the design and execution of the company's product.

as previously mentioned, i had never really looked at Precision's turbos as they didn't have compressor maps and i thought they were just warmed over Garretts. given the company was a startup 27 years ago that was probably a partially accurate assessment initially.

the lightbulb illuminated for me at the PRI as i examined the CEA/GEN2 technology and asked Aaron the money question:

are your CEA GEN2 turbos totally engineered and built by you?

"yes."

given my profession of 37 years as financial analyst/investment broker. i greatly appreciate the potential positive leverage of a startup company headed on the proper path. leverage not only in creating shareholder value but leverage in terms of creating unique product.

Precision competes against Garrett, which is now owned by Honeywell, and Borg Warner.

9/30/2014 quarterly revs

HON 10.1 Billion $

BWA 2.0 Billion $

all 3 companies are SERIOUSLY interested in turbos. two companies of the 3 are interested in turbos for the OE market.

2 of the 3 use racing/motorsports as a means of funding R&D for future OE products.

one of the 3 uses racing/motorsports as the FINAL OBJECTIVE.

one of the three companies has limited resources and can fail if it doesn't WIN.

none of this is meant to be a negative w re to BW or Garrett but rather to set a context for my visit.

i was hoping to see a highly efficient, highly design-oriented, highly motivated and fast moving entrepreneurial company focused on WINNING ontrack.

that's what i found.

PT is a succession of buildings, each larger and more modern tucked away in a small Indiana town running two shifts and adding additional robotics to replace the workers they can't find for a third shift.

the facilities are hospital clean, highly organised and ultra modern down to geothermal heating. Dan, Aaron and i toured the facilities and at each stop Dan picked up a component and explained how it differed from both BW and Garrett but also from previous PT designs. literally every component is scratch designed and built by PT.

i will say that a bit of it passed over my head and of course it is possible that some of what i heard was fluff or possibly inconsequential but for most of the subject matter i did get and liked what i heard.

i could quickly see that my initial going in hopes seemed to be being realized.

PT offers two turbo lines....

MFS (Machined From Solid) "entry level"

CEA (Competition Engineered Aerodynamics) with the latest iteration of CEA being GEN2

at the entry level i found it interesting that the company is pretty much not doing much w cast comp wheels as at this point it is either as cheap or cheaper to make billet comp wheels which deliver advantages V cast.

the CEA comp wheels are an entirely different breed.

the wheels are made from a "closed die" and as such the grain of the material better aligns w the shape of the vanes. as such the vanes can be made thinner and w a significantly more efficient profile...

more expensive

more efficient

more power

the CEA comp wheel has less hub area so it has more working area at a given inducer diameter. this is primarily, as i understand, due to the material being stronger because of the way it is formed. the more stout structure allows for a better aero configuration but also requires significantly more production cycle time/cost.

Dan showed me a competitor's wheel and a PT MFS wheel and they both are made similarly. the CEA wheel was markedly different.

bearings were worth 30 minutes of discussion... larger, ceramic, of a different material than most... living at 8 bar of boost! there was as much emphasis on the cage as the bearing itself as well as the lubrication delivery design. (Patent here)

next to the compressors were a bunch of shiny beautifully machined items i didn't initially recognise. Dan pulled one out and i realised it was the PT version of the stamped steel bucket (i am sure there is a better name for it) that fits around the turbine wheel. the reason i didn't recognise it was it was a machined piece... something about the stamped pieces getting hot and bulging...

Quality Control occupies a great deal of floor space and seems nailed down from every aspect. each hotside wheel is optically inspected and numbered. if PT needs to know the specifics on an individual wheel they can call up the dimensions to 5 decimal places.

of course the big question is how does all this net out.

PT keeps score by customer wins...

from mega dollar diesel stuff at the highest levels where the boost and power levels are crazy to the hottest class in drag racing, Pro Mod, to areas where we would be more conversant PT is well represented on the podiums.

after i finish w my BW EFR 9180 i will be planning to see for myself.

turbos in the PT lineup that interest me and might interest you:

GEN2 6266SP

800 hp piston (615 rotary)

comp 62.23 X 86.61

this is the NEW 62 CEA wheel and it has interesting aspects...

while the inducer (62.23) size is very close to the GT35, S300 62 the exducer is a large 86.61. the GT35 and GTX35 have smaller exducers at 82. the S300 is 83, the S300 FMW is 83.4 as is the S300 SXE 62.

the compressor has a 6.91 average area V around 6.3-6.5 for the others. further, w the GEN2 construction the hub is significantly smaller yielding more working (vane) area. if we use PT's power number we conclude that this is an 80 pound per minute wheel!

the 62.2/86.6 relationship yields a favorable for spool Tirm of 52 V the GT35 at 57 Trim.

hot 66.0 X 74.17

i could see lots of excitement coming my way when Dan discussed the CEA turbine wheel. while it is made in inconel, PT experimented w something similar to BW's titanium aluminide. hats off the BW for coming up w it and making it work. PT found they couldn't cast it properly unless they made configuration concessions and they picked flow over weight loss.

as in all GEN2s a very impressive PT engineered ceramic ball bearing assembly gets it done. lots of thermal engineering as to heat flow paths on the CHRA which is clean sheet of paper design.

retail $1780 w a divided T4 1.0

GEN2 6466

900 hp (692 rotary)

comp 64.39 X 86.61 turbo differs only at the inducer V the 6266...

7.11 average compressor area Trim is 55.

same hotside

retail $1995 w a 1.0 divided T4

GEN2 6870

1100 hp (846 rotary)

comp 68.02 X 92.46

8.01 average compressor area 54 Trim

retail price is $2430.

my GT4094r has a 8.175 sq inch compressor and will make 800 piston 615 rotary. if in fact the GEN2 6870 produces as advertised, PT and Dan Barlog have something special.

i will shortly evaluate my new generation BW EFR 9180 which has a 7.97 sq inch compressor.

there are of course many other factors re compressors than average area but the metric gets us in the neighborhood. so i will explore the neighborhood.

job one for me is the March 27 Texas Mile and the 9180 will be evaluated first and if i have time a GEN2 will be next up.

to some on the board PT isn't news.

to the other 95%, i see an interesting 2015 story developing.

howard

i spent much of yesterday with Dan Barlog, Engineering Director at Precision Turbo in Hebron, Indiana. Aaron Hoyt, Sales Rep for the East Coast, was kind enough to put the day together and added lots of additional info.

Dan has been w Precision for over 15 years and is responsible for the design and execution of the company's product.

as previously mentioned, i had never really looked at Precision's turbos as they didn't have compressor maps and i thought they were just warmed over Garretts. given the company was a startup 27 years ago that was probably a partially accurate assessment initially.

the lightbulb illuminated for me at the PRI as i examined the CEA/GEN2 technology and asked Aaron the money question:

are your CEA GEN2 turbos totally engineered and built by you?

"yes."

given my profession of 37 years as financial analyst/investment broker. i greatly appreciate the potential positive leverage of a startup company headed on the proper path. leverage not only in creating shareholder value but leverage in terms of creating unique product.

Precision competes against Garrett, which is now owned by Honeywell, and Borg Warner.

9/30/2014 quarterly revs

HON 10.1 Billion $

BWA 2.0 Billion $

all 3 companies are SERIOUSLY interested in turbos. two companies of the 3 are interested in turbos for the OE market.

2 of the 3 use racing/motorsports as a means of funding R&D for future OE products.

one of the 3 uses racing/motorsports as the FINAL OBJECTIVE.

one of the three companies has limited resources and can fail if it doesn't WIN.

none of this is meant to be a negative w re to BW or Garrett but rather to set a context for my visit.

i was hoping to see a highly efficient, highly design-oriented, highly motivated and fast moving entrepreneurial company focused on WINNING ontrack.

that's what i found.

PT is a succession of buildings, each larger and more modern tucked away in a small Indiana town running two shifts and adding additional robotics to replace the workers they can't find for a third shift.

the facilities are hospital clean, highly organised and ultra modern down to geothermal heating. Dan, Aaron and i toured the facilities and at each stop Dan picked up a component and explained how it differed from both BW and Garrett but also from previous PT designs. literally every component is scratch designed and built by PT.

i will say that a bit of it passed over my head and of course it is possible that some of what i heard was fluff or possibly inconsequential but for most of the subject matter i did get and liked what i heard.

i could quickly see that my initial going in hopes seemed to be being realized.

PT offers two turbo lines....

MFS (Machined From Solid) "entry level"

CEA (Competition Engineered Aerodynamics) with the latest iteration of CEA being GEN2

at the entry level i found it interesting that the company is pretty much not doing much w cast comp wheels as at this point it is either as cheap or cheaper to make billet comp wheels which deliver advantages V cast.

the CEA comp wheels are an entirely different breed.

the wheels are made from a "closed die" and as such the grain of the material better aligns w the shape of the vanes. as such the vanes can be made thinner and w a significantly more efficient profile...

more expensive

more efficient

more power

the CEA comp wheel has less hub area so it has more working area at a given inducer diameter. this is primarily, as i understand, due to the material being stronger because of the way it is formed. the more stout structure allows for a better aero configuration but also requires significantly more production cycle time/cost.

Dan showed me a competitor's wheel and a PT MFS wheel and they both are made similarly. the CEA wheel was markedly different.

bearings were worth 30 minutes of discussion... larger, ceramic, of a different material than most... living at 8 bar of boost! there was as much emphasis on the cage as the bearing itself as well as the lubrication delivery design. (Patent here)

next to the compressors were a bunch of shiny beautifully machined items i didn't initially recognise. Dan pulled one out and i realised it was the PT version of the stamped steel bucket (i am sure there is a better name for it) that fits around the turbine wheel. the reason i didn't recognise it was it was a machined piece... something about the stamped pieces getting hot and bulging...

Quality Control occupies a great deal of floor space and seems nailed down from every aspect. each hotside wheel is optically inspected and numbered. if PT needs to know the specifics on an individual wheel they can call up the dimensions to 5 decimal places.

of course the big question is how does all this net out.

PT keeps score by customer wins...

from mega dollar diesel stuff at the highest levels where the boost and power levels are crazy to the hottest class in drag racing, Pro Mod, to areas where we would be more conversant PT is well represented on the podiums.

after i finish w my BW EFR 9180 i will be planning to see for myself.

turbos in the PT lineup that interest me and might interest you:

GEN2 6266SP

800 hp piston (615 rotary)

comp 62.23 X 86.61

this is the NEW 62 CEA wheel and it has interesting aspects...

while the inducer (62.23) size is very close to the GT35, S300 62 the exducer is a large 86.61. the GT35 and GTX35 have smaller exducers at 82. the S300 is 83, the S300 FMW is 83.4 as is the S300 SXE 62.

the compressor has a 6.91 average area V around 6.3-6.5 for the others. further, w the GEN2 construction the hub is significantly smaller yielding more working (vane) area. if we use PT's power number we conclude that this is an 80 pound per minute wheel!

the 62.2/86.6 relationship yields a favorable for spool Tirm of 52 V the GT35 at 57 Trim.

hot 66.0 X 74.17

i could see lots of excitement coming my way when Dan discussed the CEA turbine wheel. while it is made in inconel, PT experimented w something similar to BW's titanium aluminide. hats off the BW for coming up w it and making it work. PT found they couldn't cast it properly unless they made configuration concessions and they picked flow over weight loss.

as in all GEN2s a very impressive PT engineered ceramic ball bearing assembly gets it done. lots of thermal engineering as to heat flow paths on the CHRA which is clean sheet of paper design.

retail $1780 w a divided T4 1.0

GEN2 6466

900 hp (692 rotary)

comp 64.39 X 86.61 turbo differs only at the inducer V the 6266...

7.11 average compressor area Trim is 55.

same hotside

retail $1995 w a 1.0 divided T4

GEN2 6870

1100 hp (846 rotary)

comp 68.02 X 92.46

8.01 average compressor area 54 Trim

retail price is $2430.

my GT4094r has a 8.175 sq inch compressor and will make 800 piston 615 rotary. if in fact the GEN2 6870 produces as advertised, PT and Dan Barlog have something special.

i will shortly evaluate my new generation BW EFR 9180 which has a 7.97 sq inch compressor.

there are of course many other factors re compressors than average area but the metric gets us in the neighborhood. so i will explore the neighborhood.

job one for me is the March 27 Texas Mile and the 9180 will be evaluated first and if i have time a GEN2 will be next up.

to some on the board PT isn't news.

to the other 95%, i see an interesting 2015 story developing.

howard

#60

Full Member

iTrader: (3)

Join Date: May 2009

Location: Montreal

Posts: 192

Likes: 0

Received 0 Likes

on

0 Posts

Very small question but never covered anywhere by you Howard Coleman, you always compare HP Pistons to HP rotary and it would seem that the rotary has a loss of about 24% efficiency, but what happens when your displacement in this rotary application gets bigger? What if you are working with a 3 rotor or a 4 rotor engine? Does your 900 HP piston turbo will still have that 24% loss? Or will the end power will be the same except that you have more HP and torque sooner?

Also I seldom see any talk about the Turbonetics line up. They have their GTK - xxx HPC series (the xxx stand for different sizes ie 600, 850, 1050). This new (3 years old) turbo is basically their their GTK series but with a billet wheel. They also have their proprietary design for the bearings. The product seems to be well built. I am guessing the reason why there is not much talk about them is because they are very expensive and they don't post any data (not even how much air it would flow) on their turbos (which I have tried many times to get to offer them to the club) or because their design is dated?

Thank you!

Andrew

Also I seldom see any talk about the Turbonetics line up. They have their GTK - xxx HPC series (the xxx stand for different sizes ie 600, 850, 1050). This new (3 years old) turbo is basically their their GTK series but with a billet wheel. They also have their proprietary design for the bearings. The product seems to be well built. I am guessing the reason why there is not much talk about them is because they are very expensive and they don't post any data (not even how much air it would flow) on their turbos (which I have tried many times to get to offer them to the club) or because their design is dated?

Thank you!

Andrew

#61

Senior Member

The reason for the approximately 24% difference in power output has to do with the geometry of the rotary engine. While being a very good pump, the rotary doesn't do well converting that to mechanical force. And that inefficiency remains regardless of how many rotors you stack together.

Typically a piston engine can yield about 10hp/lb of airflow, but the rotary is closer to 7,6hp/lb.

So a 60lb turbo is about 600hp on a piston engine, and 456hp on a rotary.

These values give a good comparison, but are also subject to other variables such as volumetric efficiency, etc...

Typically a piston engine can yield about 10hp/lb of airflow, but the rotary is closer to 7,6hp/lb.

So a 60lb turbo is about 600hp on a piston engine, and 456hp on a rotary.

These values give a good comparison, but are also subject to other variables such as volumetric efficiency, etc...

#62

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

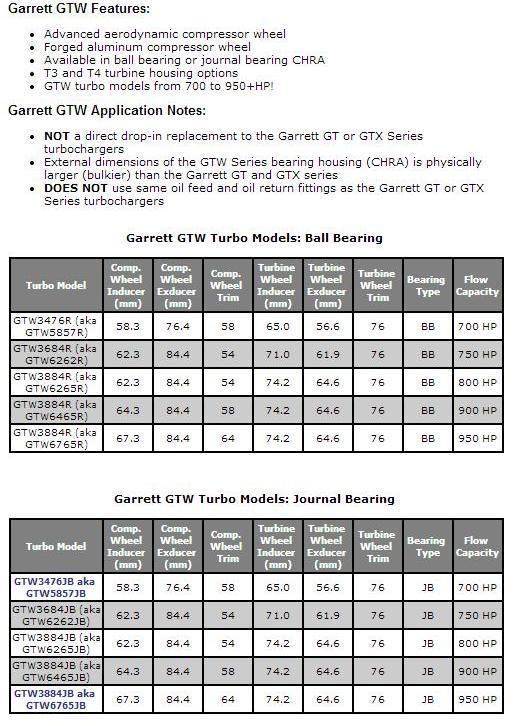

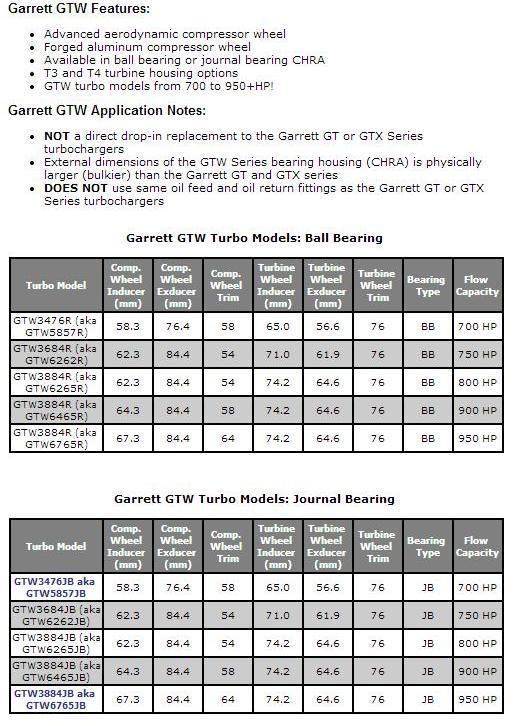

as mentioned in post one of the thread Garrett introduced a new (and they really are new) line of turbos at the PRI. they are tagged as

GTW...

the sales rep (as in maybe knows the story) told me the W was for Wide as in the compressor map. wide is good. and apparently given the hp tags on the turbos, they do put out more air.

here are the details on the five models as per ATP's site.

you'll note some initial confusion as to labels

three of the sizes share the same GTW3884r tag yet are all different so we have an AKA designation.

maybe we should just call them GTW-AKAs.

while some confusion as to names exists it does appear that these turbos are highly consequential for Garrett.... note new bearing assemblies and little interchange-ability as to the package.

also higher than usual power levels for each.

the 62 is rated at 750 piston, around 575 rotary. this is fairly similar to the GTX3582r. the bigger news might be, finally, a different turbine wheel.

while the GT3582r and GTX3582r shared the same hotside 62.2 X 68 wheel (5.1 sq inches) the GTW62 is offered in two configs.... differing as to hotside.

the AKA 6262 has a 61.9 X 71 wheel which, though not much different from sizing, is probably more advanced aerowise. a big step at Garrett. 5.38 sq inches.

the AKA 6265 employs a 64.6 X 74.2 turbine (5.88 sq inches) the turbine sizing adds 50 hp according to Garrett. 800 piston, 615 rotary.

the next step up is the GTW6465

a 64.3 X 84.4 comp wheel (6.84 av sq inches) with a fairly high trim at 58.

mated to the same hotside as the larger 62... (5.88)

900 hp or 692 rotary

finally we have the GTW6765

comp 67.3 X 84.4 or 7.09

same hotside as the 6265 and 6465 at 5.88

950 piston 730 rotary.

no prices or availability as yet that i am aware of.

taking a step back and looking at the Turbo landscape in early 2015 and of course w the caveat that most of the following turbos have yet to be evaluated:

Borg Warner (alphabetical order )

)

a significantly uprated new line of SXE turbos that based on comparative compressor maps look materially advanced as to output and probably friendly priced due to being journal bearing and carrying forward the S300 general architecture.

the further proving out of the advanced higher priced EFR line

Garrett

totally new line of 5 new turbos w uprated mechanicals to the point they are not bolt on swaps. avail in both BB and journal bearings. if the output is similar to the most recently released comp map (GTX4088r) the turbos should be excellent.

Precision Turbo

now offering (CEA GEN2) completely engineered from scratch turbos 3 of which (62, 64, 68) fit our dual purpose rotaries. Precision is singularly focused on winning at every level of motorsports and it shows upon examination of their product.

it is clear that there is a major uptick as to 2015 turbo output and it is also exciting that pretty much all of the actual results remain just in front of us at this moment.

welcome to the party Garrett.

howard

GTW...

the sales rep (as in maybe knows the story) told me the W was for Wide as in the compressor map. wide is good. and apparently given the hp tags on the turbos, they do put out more air.

here are the details on the five models as per ATP's site.

you'll note some initial confusion as to labels

three of the sizes share the same GTW3884r tag yet are all different so we have an AKA designation.

maybe we should just call them GTW-AKAs.

while some confusion as to names exists it does appear that these turbos are highly consequential for Garrett.... note new bearing assemblies and little interchange-ability as to the package.

also higher than usual power levels for each.

the 62 is rated at 750 piston, around 575 rotary. this is fairly similar to the GTX3582r. the bigger news might be, finally, a different turbine wheel.

while the GT3582r and GTX3582r shared the same hotside 62.2 X 68 wheel (5.1 sq inches) the GTW62 is offered in two configs.... differing as to hotside.

the AKA 6262 has a 61.9 X 71 wheel which, though not much different from sizing, is probably more advanced aerowise. a big step at Garrett. 5.38 sq inches.

the AKA 6265 employs a 64.6 X 74.2 turbine (5.88 sq inches) the turbine sizing adds 50 hp according to Garrett. 800 piston, 615 rotary.

the next step up is the GTW6465

a 64.3 X 84.4 comp wheel (6.84 av sq inches) with a fairly high trim at 58.

mated to the same hotside as the larger 62... (5.88)

900 hp or 692 rotary

finally we have the GTW6765

comp 67.3 X 84.4 or 7.09

same hotside as the 6265 and 6465 at 5.88

950 piston 730 rotary.

no prices or availability as yet that i am aware of.

taking a step back and looking at the Turbo landscape in early 2015 and of course w the caveat that most of the following turbos have yet to be evaluated:

Borg Warner (alphabetical order

)

)a significantly uprated new line of SXE turbos that based on comparative compressor maps look materially advanced as to output and probably friendly priced due to being journal bearing and carrying forward the S300 general architecture.

the further proving out of the advanced higher priced EFR line

Garrett

totally new line of 5 new turbos w uprated mechanicals to the point they are not bolt on swaps. avail in both BB and journal bearings. if the output is similar to the most recently released comp map (GTX4088r) the turbos should be excellent.

Precision Turbo

now offering (CEA GEN2) completely engineered from scratch turbos 3 of which (62, 64, 68) fit our dual purpose rotaries. Precision is singularly focused on winning at every level of motorsports and it shows upon examination of their product.

it is clear that there is a major uptick as to 2015 turbo output and it is also exciting that pretty much all of the actual results remain just in front of us at this moment.

welcome to the party Garrett.

howard

#64

Full Member

iTrader: (3)

Join Date: May 2009

Location: Montreal

Posts: 192

Likes: 0

Received 0 Likes

on

0 Posts

So these proposed turbos by HC will yield the same HP in either a 2 rotor or a 3 rotor? So 600 piston hp will yield 456 HP in a 2 and 3 rotor? I would think another variable comes into play that would increase HP with displacement increase

On a different note has anyone had a good experience with customer service with either proposed turbo? Or does it depend on the reseller you purchase it from?

On a different note has anyone had a good experience with customer service with either proposed turbo? Or does it depend on the reseller you purchase it from?

#65

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

"So 600 piston hp will yield 456 HP in a 2 and 3 rotor?"

that's a good question.

since the power numbers for the turbos are derived from MAX FLOW it would make no difference if the driver was a 2 or 3 rotor motor. at that point the turbo acts as a restrictor plate in that it is incapable of passing any more air whether being driven by either motor.

before the turbo reaches max output the larger displacement 3 rotor would drive the turbo harder so the hp under the curve would be superior.

of course a 3 rotor would be capable of driving a larger turbo than a 2 rotor and at that point would produce more max power...

howard

that's a good question.

since the power numbers for the turbos are derived from MAX FLOW it would make no difference if the driver was a 2 or 3 rotor motor. at that point the turbo acts as a restrictor plate in that it is incapable of passing any more air whether being driven by either motor.

before the turbo reaches max output the larger displacement 3 rotor would drive the turbo harder so the hp under the curve would be superior.

of course a 3 rotor would be capable of driving a larger turbo than a 2 rotor and at that point would produce more max power...

howard

#67

Senior Member

Join Date: Jun 2010

Location: U.K - Instagram - copyninja_fd

Posts: 308

Received 142 Likes

on

82 Posts

I will have a back to back dyno with the EFR IWG 8374 vs the brand new EFR 9180 IWG this spring. I expect to see 35 psi by 4000rpms, and 600+rwhp. Maybe even 650rwhp if we are lucky. I will test with a 3" and 3.5" inch downpipe the lowest boost possible with the medium actuator.

Thread

Thread Starter

Forum

Replies

Last Post