Zero Clearance Side Seals?

#52

"Elusive, not deceptive!”

Thread Starter

#53

F'n Newbie...

iTrader: (6)

#54

Junior Member

iTrader: (2)

Join Date: Aug 2009

Location: Denver

Posts: 32

Likes: 0

Received 0 Likes

on

0 Posts

I'm gonna bump this instead of making a new thread.

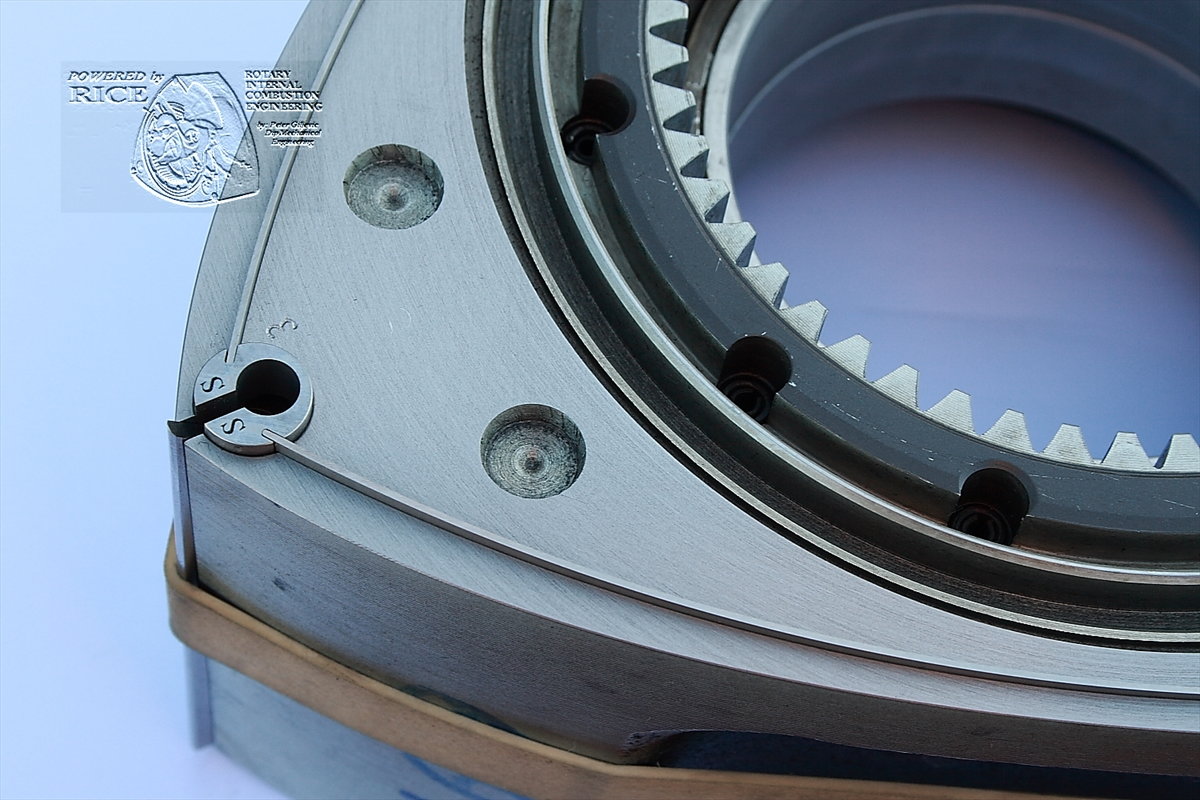

Why is a corner seal design like this.....

...not used by Mazda? I'm not usually the 'OEM always does it best' type, but this *seems* like a no-brainer that Mazda had to have tried and obviously rejected. Is it a better design that just cost too much to mass produce, does it have some inherent fatal flaw, or are the benefits just too small for the machining involved?

In short, would this be a worthwhile mod?

Why is a corner seal design like this.....

...not used by Mazda? I'm not usually the 'OEM always does it best' type, but this *seems* like a no-brainer that Mazda had to have tried and obviously rejected. Is it a better design that just cost too much to mass produce, does it have some inherent fatal flaw, or are the benefits just too small for the machining involved?

In short, would this be a worthwhile mod?

Last edited by Hiko; 06-19-16 at 12:53 AM.

#55

Old [Sch|F]ool

Logically speaking:

The apex seals and corner seals are all in the same place relative to each other. If they weren't, corner seals would bind against apex seals. Side seal lengths vary in length, and the only reason why this could be so is if the side seal grooves are not precisely laid out with respect to the corner seal holes. Therefore if you were to try this, you probably would have to either have selective fit corner seals depending on where the side seal fits in, or the slot in the corner seal would have to be so much of a loose fit that the net gain for all of that trouble is zero.

The apex seals and corner seals are all in the same place relative to each other. If they weren't, corner seals would bind against apex seals. Side seal lengths vary in length, and the only reason why this could be so is if the side seal grooves are not precisely laid out with respect to the corner seal holes. Therefore if you were to try this, you probably would have to either have selective fit corner seals depending on where the side seal fits in, or the slot in the corner seal would have to be so much of a loose fit that the net gain for all of that trouble is zero.

#56

In short, would this be a worthwhile mod?

This is a very good modification not for side seal sealing, but because it allows you to port the intake for earlier opening.

The earliest stock production porting (besides hand ported Cosmo Sport and 13B-MSP) is 32 degrees after top dead center.

With hand porting you can get to ~24 degrees after top dead center (like the Cosmo Sport) and still keep the side seals happy.

This mod extends the sides seal length so that you can move the opening line closer to the 0 degrees after top dead center so you aren't sucking up exhaust and no intake air in the early stage of intake stroke

#57

"Elusive, not deceptive!”

Thread Starter

It is commonly thought that "imitation was the sincerest form of flattery" so I like the design.

l but that aside I see a couple of problems with Peter's design.

The redundant relief hole in the center of the corner seal requires a rubber seal or the pressure under the apex seal leaks to

the "crankcase" losing compression and causing a serious amount of blow-by. This would definitely require a very large crankcase

vent system.

But the rubber seal would only work with stock ports or they would be eaten in a very short time.

I believe it is also redundant using the second side-seal slot because it increases the possibility of locking the corner/apex interface.

Why add an unneeded manufacturing process that can only cause problems...

#58

The redundant relief hole in the center of the corner seal requires a rubber seal or the pressure under the apex seal leaks to

the "crankcase" losing compression and causing a serious amount of blow-by. This would definitely require a very large crankcase

vent system.

I personally haven't found this to be the case.

I now always use the later corner seals without the rubber plug since I have found they crack less easily than the early solid ones. This is because the large round hole in the middle eliminates the stress riser of the apex seal groove corners and allows the corner seal to flex a tiny bit.

I don't use the rubber plugs, because as you say they would fall in/get chopped up by my early opening ports when they shrink with heat enough to move in the corner seal.

For sump venting-

I have one 3/8" line off of the middle iron by the oil fill tube and one 3/8" line off the front of the oil fill tube straight to an open vented container at the top of the firewall.

I have no visible or felt crancase blow-by on the dyno and very very little oil buildup in the catch can when driving, autocrossing, kart track and hillclimb.

This was on a tiny turbo at 26psi boost (so almost constant boost).

Is it possible the side seal makes a pretty good seal against the side housing trapping the combustion gasses behind the apex seal or at worst leaking out between the side seal and apex seal and venting out to the working chambers instead of back behind the corner seal into the sump?

I believe the corner seal rubber plug system was mainly for starting the engine where you don't have the combustion gasses behind the seals helping them seal, so you need a sealing matrix that works without the combustion pressure to keep the compression pressure from leaking down so fast.

Otherwise I am at a loss as to why my engine had such remarkably low sump pressure/venting.

I was really surprised on this high boost set-up to only get about 1/4 teaspoon of oil out of the catch can after 20 gallons race fuel on the dyno, 2 days of auto-x, a 300 mile road trip and then 2 days of practice on the kart track all at 26psi boost.

the "crankcase" losing compression and causing a serious amount of blow-by. This would definitely require a very large crankcase

vent system.

I personally haven't found this to be the case.

I now always use the later corner seals without the rubber plug since I have found they crack less easily than the early solid ones. This is because the large round hole in the middle eliminates the stress riser of the apex seal groove corners and allows the corner seal to flex a tiny bit.

I don't use the rubber plugs, because as you say they would fall in/get chopped up by my early opening ports when they shrink with heat enough to move in the corner seal.

For sump venting-

I have one 3/8" line off of the middle iron by the oil fill tube and one 3/8" line off the front of the oil fill tube straight to an open vented container at the top of the firewall.

I have no visible or felt crancase blow-by on the dyno and very very little oil buildup in the catch can when driving, autocrossing, kart track and hillclimb.

This was on a tiny turbo at 26psi boost (so almost constant boost).

Is it possible the side seal makes a pretty good seal against the side housing trapping the combustion gasses behind the apex seal or at worst leaking out between the side seal and apex seal and venting out to the working chambers instead of back behind the corner seal into the sump?

I believe the corner seal rubber plug system was mainly for starting the engine where you don't have the combustion gasses behind the seals helping them seal, so you need a sealing matrix that works without the combustion pressure to keep the compression pressure from leaking down so fast.

Otherwise I am at a loss as to why my engine had such remarkably low sump pressure/venting.

I was really surprised on this high boost set-up to only get about 1/4 teaspoon of oil out of the catch can after 20 gallons race fuel on the dyno, 2 days of auto-x, a 300 mile road trip and then 2 days of practice on the kart track all at 26psi boost.

#59

I immediately thought of you when I saw Peter's corner seal design.

I learned how to make side seals survive early opening ports reading your posts and Judge Ito's and now more and more engine builders/shops are catching on.

believe it is also redundant using the second side-seal slot because it increases the possibility of locking the corner/apex interface.

Why add an unneeded manufacturing process that can only cause problems...

I agree with this.

Having the top side seal just makes your port's top outer corner that much more critical again.

Will it be ported enough your top side seal drops into the port as normal?

If not, you are giving up your early opening.

If so, you have to have a sharper corner on the top outer corner of the port again that doesn't flow that well.

Better to leave that top side of the corner seal alone in my opinion as well.

I learned how to make side seals survive early opening ports reading your posts and Judge Ito's and now more and more engine builders/shops are catching on.

believe it is also redundant using the second side-seal slot because it increases the possibility of locking the corner/apex interface.

Why add an unneeded manufacturing process that can only cause problems...

I agree with this.

Having the top side seal just makes your port's top outer corner that much more critical again.

Will it be ported enough your top side seal drops into the port as normal?

If not, you are giving up your early opening.

If so, you have to have a sharper corner on the top outer corner of the port again that doesn't flow that well.

Better to leave that top side of the corner seal alone in my opinion as well.

#60

Old [Sch|F]ool

The redundant relief hole in the center of the corner seal requires a rubber seal or the pressure under the apex seal leaks to

the "crankcase" losing compression and causing a serious amount of blow-by. This would definitely require a very large crankcase

vent system.

More than once people have said on this forum that I pointed out something that was, to me, fairly obvious, but to them it was unlocking a great mystery.

I'm on that side of the fence.

I stopped using those rubber plugs after I found them missing from an engine I built. Even bought new ones for that engine, too... Anyway, now that I think of it, every engine I've done since has had pretty nasty oil dilution problems, which can only happen because of blowby.

Now, I'm going to keep not using them, because the engine where they went missing had a stop opening line and they disappeared anyway. But now I have an answer to why I get so much fuel dilution.

My next engine is probably going to be a supercharged stockport. The bridge port's emissions are just too awful

Maybe I can do a tune where it cuts fuel to every other rotor face so it at least sounds cool?

Maybe I can do a tune where it cuts fuel to every other rotor face so it at least sounds cool?

#63

Old [Sch|F]ool

I've never driven a modified Nikki that worked worth a damn! Sorry.

Besides they would be a huge power limiter for me. I'm thinking I want 250-300hp but under 8000rpm so it will be automatic trans friendly, so a supercharged stockport should do the trick nicely...

I haven't ever used new oil rings but I do replace the O-rings and I throw away anything that is outside of spec. That only seems to affect oil burning, not fuel dilution.

Besides they would be a huge power limiter for me. I'm thinking I want 250-300hp but under 8000rpm so it will be automatic trans friendly, so a supercharged stockport should do the trick nicely...

I haven't ever used new oil rings but I do replace the O-rings and I throw away anything that is outside of spec. That only seems to affect oil burning, not fuel dilution.

#64

"Elusive, not deceptive!”

Thread Starter

I think what Blue Tll is saying is that if the sideplates are true the corner and side

seals should only release pressure as they cross the side ports. (and add to this list Peejay's oil seals )

)

Also the factory made the "spring type" corner seals to also allow for some side seal to corner seal interference.

The long (almost 7") side seals grow the most with a quick high heat run. Add this to our attempt of setting

them up tight and results can be gouged plates, broken corner seals and stuck side seals.

I found tighter than .004" can cause problems especially if you cut the seals exactly 90 deg with

exact contour of the corner seal (because full contact allows little room for any wear in).

I have done seals for a few people in Texas and Colorado, and even Judge Ito (long story) and have no reports of any problems.

This leads to an ironic problem.... if something works well, you never see results until it is removed for some other maintenance issue years later. But I guess that is a good problem.

seals should only release pressure as they cross the side ports. (and add to this list Peejay's oil seals

)

)

Also the factory made the "spring type" corner seals to also allow for some side seal to corner seal interference.

The long (almost 7") side seals grow the most with a quick high heat run. Add this to our attempt of setting

them up tight and results can be gouged plates, broken corner seals and stuck side seals.

I found tighter than .004" can cause problems especially if you cut the seals exactly 90 deg with

exact contour of the corner seal (because full contact allows little room for any wear in).

I have done seals for a few people in Texas and Colorado, and even Judge Ito (long story) and have no reports of any problems.

This leads to an ironic problem.... if something works well, you never see results until it is removed for some other maintenance issue years later. But I guess that is a good problem.

Last edited by Barry Bordes; 06-29-16 at 10:26 AM.

#65

Banned. I got OWNED!!!

I heard an old racing story from a buddy a few months back...

New kid uses Daddy's money to build an FD race car (my buddy is his racing instructor).

Kid overheats engine continually, and continues to beat on it.

Eventually they just retorque everything, now knowing that it's going to fail soon, and continue to run it. The damn thing starts making more power...

Robert tells me how it's a total pain the *** to start, but it starts every time. Compression is easily past 110.

When it finally comes time to tear it down (another issue popped up), they find the side clearancing to be gone. The car ended up making 20+whp over the original tune before teardown.

Clearance matters.

Barry, did you ever do a compression test on this motor? 1k Mile? 5k Mile? 20k?

New kid uses Daddy's money to build an FD race car (my buddy is his racing instructor).

Kid overheats engine continually, and continues to beat on it.

Eventually they just retorque everything, now knowing that it's going to fail soon, and continue to run it. The damn thing starts making more power...

Robert tells me how it's a total pain the *** to start, but it starts every time. Compression is easily past 110.

When it finally comes time to tear it down (another issue popped up), they find the side clearancing to be gone. The car ended up making 20+whp over the original tune before teardown.

Clearance matters.

Barry, did you ever do a compression test on this motor? 1k Mile? 5k Mile? 20k?

#66

F'n Newbie...

iTrader: (6)

For sump venting-

I have one 3/8" line off of the middle iron by the oil fill tube and one 3/8" line off the front of the oil fill tube straight to an open vented container at the top of the firewall.

I have no visible or felt crancase blow-by on the dyno and very very little oil buildup in the catch can when driving, autocrossing, kart track and hillclimb.

This was on a tiny turbo at 26psi boost (so almost constant boost).

I have one 3/8" line off of the middle iron by the oil fill tube and one 3/8" line off the front of the oil fill tube straight to an open vented container at the top of the firewall.

I have no visible or felt crancase blow-by on the dyno and very very little oil buildup in the catch can when driving, autocrossing, kart track and hillclimb.

This was on a tiny turbo at 26psi boost (so almost constant boost).

The PFS engine had about 1-2mm of clearance on all side seals, and I'd COMPLETELY fill a mid-sized catch can in less than 100 miles of normal driving on the street.

The home built engine was on the very narrow side of FSM recommended side seal clearance, and I don't think I even had an 8th of my can filled before my engine met an unfortunate end (an oil fitting worked loose, dumped ALL my oil on the highway leaving DGRR) at about 4,000-5,000 miles.

Other than step wear (I started fresh with a new engine, that we tore down and ported/rebuilt) the biggest difference I can think of between the two motors would be clearances, and of course all new seals/rings. The rubber corner seal plugs were used in both builds.

#68

F'n Newbie...

iTrader: (6)

Yeah, it was absolutely DISGUSTING!!!

I was PISSED when I saw that, especially since I had paid over $5k for that "rebuild"... I had to threaten him with substantial legal action to get a refund, but that's a different topic entirely, and not really relevant to the thread.

I was PISSED when I saw that, especially since I had paid over $5k for that "rebuild"... I had to threaten him with substantial legal action to get a refund, but that's a different topic entirely, and not really relevant to the thread.

#69

in theory the channeled side seals into the corner seal is a great idea, in reality i picture those side seals snapping like twigs as soon as the corner seal flinches from even the most minute amount of wear, causing compression to plummet and scarred iron faces/rotors.

#70

Banned. I got OWNED!!!

Development takes sacrifice.

The question I'm asking is besides full teardowns, what methods of data collection are you guys doing for these theories? Bosch has some amazing tools out there these days...

Anyone making it to PRI this year?

The question I'm asking is besides full teardowns, what methods of data collection are you guys doing for these theories? Bosch has some amazing tools out there these days...

Anyone making it to PRI this year?

#71

"Elusive, not deceptive!”

Thread Starter

in theory the channeled side seals into the corner seal is a great idea, in reality i picture those side seals snapping like twigs as soon as the corner seal flinches from even the most minute amount of wear, causing compression to plummet and scarred iron faces/rotors.

This would be very hard to accomplish... snapping off the side seal!

How could that happen? Wouldn't you have to snap of the apex seal also?

Also there is an add advantage when you assemble the engine... the apex seals are

always aligned for insertion with the opposite corner seal.

#72

"Elusive, not deceptive!”

Thread Starter

[QUOTE=SirLaughsALot;12082371

Barry, did you ever do a compression test on this motor? 1k Mile? 5k Mile? 20k? [/QUOTE]

[/QUOTE]

I haven't done conventional compression checks but it has started the same for the last 50k miles.

The engine usually starts within one revolution of the rotor... three of the eccentric shaft.

At idle there is no movement of air from the oil filler tube.

I put a fitting and gauge on the cap for higher rpm/ boost testing but the pressure was nil.

I use the factory PCV system and no catch can but I don't track the car.

The readings from my combustion testing have stayed consistent also.

Barry, did you ever do a compression test on this motor? 1k Mile? 5k Mile? 20k?

[/QUOTE]

[/QUOTE]I haven't done conventional compression checks but it has started the same for the last 50k miles.

The engine usually starts within one revolution of the rotor... three of the eccentric shaft.

At idle there is no movement of air from the oil filler tube.

I put a fitting and gauge on the cap for higher rpm/ boost testing but the pressure was nil.

I use the factory PCV system and no catch can but I don't track the car.

The readings from my combustion testing have stayed consistent also.

#75

Banned. I got OWNED!!!

Thank you Barry! Wow, 50k and still little to no oil consumption. Sounds like you've got it down!

I personally like the simplicity of the wedge design over the notch, seeing as it's self adjusting, but finding exactly how much angle you want can be tricky.

Very impressed with the progress of this thread.

I personally like the simplicity of the wedge design over the notch, seeing as it's self adjusting, but finding exactly how much angle you want can be tricky.

Very impressed with the progress of this thread.