gauging cost on build

#26

Old [Sch|F]ool

One topic I haven't brought up yet,how can I get a bp quiet enough for street use without restricting too much? How much are cats gonna cost me that will put up with turbo and a pretty viscious anti lag?

Heck, I had a stock port in good running condition that I purchased from someone who removed the catalyst train. I installed a $40 Catco POS (back when they were $40) and when I removed it 40 miles later, I found half of the substrate was plugged up. But it passed and I put the cat on the shelf for the next test in two years.

I witnessed an FC with a half bridge engine and a big ol' Precision turbo that made, he said, something like 450hp at a nice low boost, running through a Racing Beat catback exhaust. It was quiet. It was quieter than my car. It had severe traction problems, too...

It's not really a race car, it's my car and I compete with it sometimes. The problem with bushings is they hurt articulation (my secret weapon - the drive wheels are always able to give thrust) because the link is mounted so high up relative to the Watts center, and anyway that is something I'd have to fabricate instead of just spending $50 for new rod ends every so often. I value my time more than that.

It probably doesn't help any that the third link mounts inside the cabin, and I never bothered to cover up the hole in the floor except for a chunk of mudflap that I bungeed over the hole.

#27

Full Member

Thread Starter

Join Date: Apr 2014

Location: Brainerd area Minnesota

Posts: 88

Likes: 0

Received 0 Likes

on

0 Posts

Well my issue is not that I care about the environments, it's in Minnesota we don't have the 2 year tests,if a cop pulls me over and is mad and wants to hit me with everything he can,he can put a sensor to my pipe and make me illegal. So I don't know where to go with that.

#30

Old [Sch|F]ool

Oh hell no. There's nothing remotely emissions legal about a bridge or peripheral engine. When they are running, if they aren't under heavy throttle, literally half of the fuel goes straight out of the exhaust unburnt. That is why they get such crappy low-load fuel economy.

My car, for instance, uses half as much fuel at idle as it does going 65mph. My injector duty cycle is around 15% at highway cruise and around 7% at idle. I think my fuel economy is around 2mpg city 25mpg highway.

I don't like the emissions, and I tend to use fuel odorants to make it less unpleasant (the vanilla scents are the nicest) but I can't effectively put together a piston engine that is as reliable and has a powerband as broad without spending a LOT of money.

My car, for instance, uses half as much fuel at idle as it does going 65mph. My injector duty cycle is around 15% at highway cruise and around 7% at idle. I think my fuel economy is around 2mpg city 25mpg highway.

I don't like the emissions, and I tend to use fuel odorants to make it less unpleasant (the vanilla scents are the nicest) but I can't effectively put together a piston engine that is as reliable and has a powerband as broad without spending a LOT of money.

#31

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,763

Received 2,556 Likes

on

1,819 Posts

#32

Full Member

Thread Starter

Join Date: Apr 2014

Location: Brainerd area Minnesota

Posts: 88

Likes: 0

Received 0 Likes

on

0 Posts

So is it possible to get the airflow required for the 500hp range with a large street port and possibly some drilled ports instead of the larger bridge combined with high psi to reduce overlap?

#33

Old [Sch|F]ool

Drilled ports aren't for power, they are for the misfire.

What you want, if you want to have a happy cat, is no misfires. Which means mild streetport at best. Basically, if it has a lumpy idle, you can't use it.

What you want, if you want to have a happy cat, is no misfires. Which means mild streetport at best. Basically, if it has a lumpy idle, you can't use it.

#34

2. once the intake port is open on one of these engine, your overlap begins. you can't reduce overlap. the only thing you can do at that point is alter flow - for better or worse. if you want reduced overlap, you keep it stock or close-to-stock.

#35

Full Member

Thread Starter

Join Date: Apr 2014

Location: Brainerd area Minnesota

Posts: 88

Likes: 0

Received 0 Likes

on

0 Posts

So drilling is only gonna get me a braap sound? And likely nasty emissions and hot exhaust?

I do plan on going with upgraded housings like pineapple or something, that is one thing I'm pretty sure I will do.

I do plan on going with upgraded housings like pineapple or something, that is one thing I'm pretty sure I will do.

#36

it's either emissions or a race-type port, you can't have both.

follow this thread and see for yourself where it goes with drilled ports.

https://www.rx7club.com/naturally-as...build-1052902/

what upgraded Pineapple housings?

follow this thread and see for yourself where it goes with drilled ports.

https://www.rx7club.com/naturally-as...build-1052902/

what upgraded Pineapple housings?

#37

Full Member

Thread Starter

Join Date: Apr 2014

Location: Brainerd area Minnesota

Posts: 88

Likes: 0

Received 0 Likes

on

0 Posts

Well I was earlier linked to a housing that was like $860 and I thought it was pineapple racing but can't find the link to prove one way or another. But I was planning on upgrading housings,seals,and tranny if I can afford it right away,and everything else as it breaks or I can afford it.

And thanks for the link,saddening but informative. All of this heartbreaking reality is forcing me to consider the option of making this a track only car and driving the Buick around everywhere for my dd

Also after a thorough craigslist scouring I found no 4 door 323 in my entire state let alone a glc. And to my dismay all I found were fwd 323's. But if this does become a track only car I can go back to rx7 but I sorta don't like how it looks out of place on the drag strip. Any other fairly simple rotary conversions out there besides the 323 and other rx models?

Lastly,this is a really noob question,I've tried looking it up before but couldn't understand anything I found,I don't understand the 4 port and 6 port deal, what's it even have to do with? only pics I could find were too close up to be able to tell their purpose or where they were located.

And thanks for the link,saddening but informative. All of this heartbreaking reality is forcing me to consider the option of making this a track only car and driving the Buick around everywhere for my dd

Also after a thorough craigslist scouring I found no 4 door 323 in my entire state let alone a glc. And to my dismay all I found were fwd 323's. But if this does become a track only car I can go back to rx7 but I sorta don't like how it looks out of place on the drag strip. Any other fairly simple rotary conversions out there besides the 323 and other rx models?

Lastly,this is a really noob question,I've tried looking it up before but couldn't understand anything I found,I don't understand the 4 port and 6 port deal, what's it even have to do with? only pics I could find were too close up to be able to tell their purpose or where they were located.

#39

Full Member

Thread Starter

Join Date: Apr 2014

Location: Brainerd area Minnesota

Posts: 88

Likes: 0

Received 0 Likes

on

0 Posts

Yeah,the main reason I'm going rotary is to have a cheaper powerful car,it's just way too expensive to modify a piston engine to handle any boost. Gonna have a hard time finding it financially reasonable to stray from rotary in my track car.

#40

Rotary Enthusiast

Erm, what?

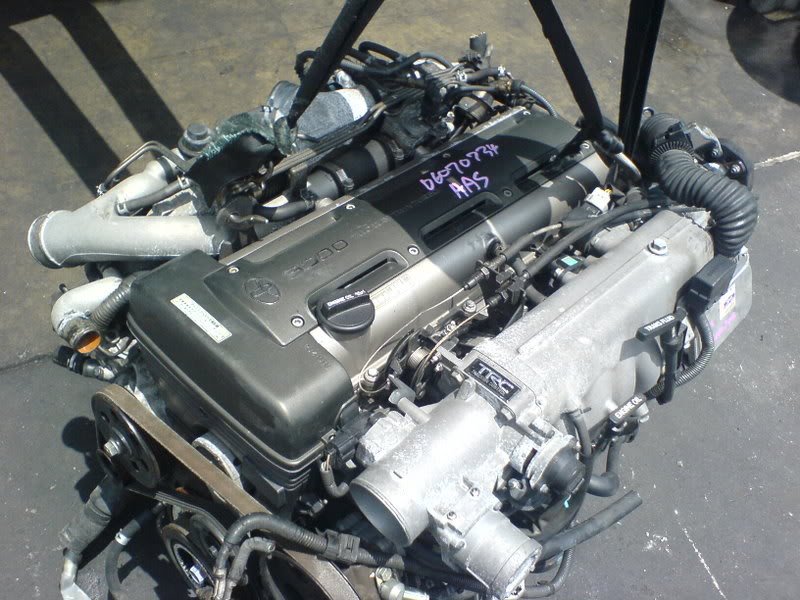

It's far, far, far cheaper to start with a factory turbocharged engine like the above pictured Toyota 2JZ-GTE. These make a smidge over 300HP to the wheels 100% stock and cost around $2000 used with a trans.

The engine itself can handle 800hp (this has been achieved and documented) WITHOUT having to even modify the bottom end.

You have it totally backwards. Rotaries are different not a good value. Look, I'm not here to promote this engine in particular. But, when you look at the cold hard facts of horsepower per dollar there are tons of options that get you far more power for less money than rotaries.

Consider looking into:

GM LS 5.3

Toyota 2JZ-GTE

Nissan RB25DET (NEO, if you've got the *****)

Toyota 1UZ-FE

Nissan VH Series

Any of these engines represent a great value for your dollar will put you so much farther ahead as a starting point and get so much more in the long run especially with the goal of the car being streetable. Do some more research and you'll be pleasantly suprised what you can do.

I have nothing against Rotaries, just in this instance they don't make much sense for your goals.

#41

Full Member

Thread Starter

Join Date: Apr 2014

Location: Brainerd area Minnesota

Posts: 88

Likes: 0

Received 0 Likes

on

0 Posts

Can you show me where I can find these engines for less than several grand? I've searched for 2jz before and found nothing less than 5 grand for engine only.

Anyways,aside from the pistons topic... With the information I have right now I am still going for rotary as it seems that eventually I can work my way up to a high psi pp pushing 1000. Until I get more info on those engines I'm gonna keep trying to learn more on rotary.

Anyways,aside from the pistons topic... With the information I have right now I am still going for rotary as it seems that eventually I can work my way up to a high psi pp pushing 1000. Until I get more info on those engines I'm gonna keep trying to learn more on rotary.

#42

Old [Sch|F]ool

I'll be blunt. If you think $5k for an engine is a hardship then you need to stop thinking about high horsepower. Because, in addition to the initial expenses of engine + turbo + fuel pumps (plural) + ancillaries + clutch + transmission + rearend + driveshaft + axles + rollcage + + + +... at higher levels of power, you will encounter often depressing levels of breakage. I see it every day. Putting other peoples' broken toys back together is what pays my bills a lot of the time.

$30k to put a car together is not a one time expense. That gets you running. Then things start breaking or wearing out. If you are engineering things on the fly, then things will be breaking and wearing out much more quickly.

I already own my car, already built it and engineered it, and I figure it runs $5-6k per year to keep going, what with maintenance and breakage. I run my car a bit hard but I also am nowhere near the horsepower levels you're talking about, either.

$30k to put a car together is not a one time expense. That gets you running. Then things start breaking or wearing out. If you are engineering things on the fly, then things will be breaking and wearing out much more quickly.

I already own my car, already built it and engineered it, and I figure it runs $5-6k per year to keep going, what with maintenance and breakage. I run my car a bit hard but I also am nowhere near the horsepower levels you're talking about, either.

#44

Rotary Enthusiast

Can you show me where I can find these engines for less than several grand? I've searched for 2jz before and found nothing less than 5 grand for engine only.

Anyways,aside from the pistons topic... With the information I have right now I am still going for rotary as it seems that eventually I can work my way up to a high psi pp pushing 1000. Until I get more info on those engines I'm gonna keep trying to learn more on rotary.

Anyways,aside from the pistons topic... With the information I have right now I am still going for rotary as it seems that eventually I can work my way up to a high psi pp pushing 1000. Until I get more info on those engines I'm gonna keep trying to learn more on rotary.

I hope you're understanding that a 1000hp rotary engine is a $40,000 investment.

I also hope you're understanding that a peripheral port 13B puts down around 300hp. And as a price comparison, Mazdatrix charges $12000 for that engine which DOES NOT include your intake setup, water pump, accessories, engine control etc.

You cannot "work your way up to a PP". Rotaries have no valvetrain, no camshafts, no piston rods and no crank. Once the engine is ported and assembled, Intake duration is FIXED. Displacement is FIXED. Port timing is FIXED. If you set up a rotary to be a "high horsepower" non-turbo peripheral port, many of those parts cannot be re-used for a turbocharged application. Non turbo applications use high compression, lightweight rotors. Turbo applications cannot use these. Turbo applications also work best with different port timings and durations. This means of course once you grind and port irons for your "non turbo stepping stone" they cannot be used again when you go turbo.

You can't do it in steps with a rotary, it has to be set up for your ultimate goal when the engine is assembled.

And the final nail in the coffin, most of the cars that I'm aware of that are into the 1000HP range are NOT peripheral port 13B's, they are bridge ported 20B's which of course means spending $5000-$6000 to get ahold of a good one before you even start to modify it.

#45

Full Member

Thread Starter

Join Date: Apr 2014

Location: Brainerd area Minnesota

Posts: 88

Likes: 0

Received 0 Likes

on

0 Posts

Yeah,20b is never gonna happen for me. Also,I realize the charge on a pp to be made for me is super high,but if you think I'm gonna send my motor to a shop when I have mills and lathes available to me you're crazy. I know what you mean i can't work up on the engine,but what I meant is everything but as when I'm in that power the engine is the.cheap part,good clutch,tranny,axles etc is the expensive part.

Thank you for telling me about jdm Ottawa,haven't heard of them,that's the kind of info I need,I'll admit I didn't look up 2jz today.but I've searched eBay and Google several times.before and have gotten nothing under 5k.

Thank you for telling me about jdm Ottawa,haven't heard of them,that's the kind of info I need,I'll admit I didn't look up 2jz today.but I've searched eBay and Google several times.before and have gotten nothing under 5k.

#46

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,763

Received 2,556 Likes

on

1,819 Posts

You have it totally backwards. Rotaries are different not a good value. Look, I'm not here to promote this engine in particular. But, when you look at the cold hard facts of horsepower per dollar there are tons of options that get you far more power for less money than rotaries.

so between an NA 13B and the Honda B18 engine, they both have about the same reliability, and make roughly the same power (the LS engine is a little less, the type R is a little more).

the cost?

when they need rebuilds the Honda costs much much more. plus there is frequently major damage to the Honda engine, and big used parts like blocks, and heads are more expensive than a 13B housing.

the BMW's are funny, we've never had to do an engine, but everything else breaks. the E30 was in the same cost range as the Honda/Rx7, but the E46 was logarithmically more, and most of the failures we had occurred when it was sitting in the garage between races!

so piston engines might be cheap used, but its been my experience that they are not cheaper to run long term.

#47

Old [Sch|F]ool

I've driven a long ways home on a blown engine, I wouldn't trust trying to drive home on an engine that threw a rod or something, assuming that it even ran.

That is before trying to put together a piston engine that will make a more or less flat torque curve from 3k to 10k, and do it for a minimum of 30,000mi, and not require forced induction to do it.

#48

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,763

Received 2,556 Likes

on

1,819 Posts

...which is why I keep going back to "scrounge up more rotary parts" instead of piston engine swap.

I've driven a long ways home on a blown engine, I wouldn't trust trying to drive home on an engine that threw a rod or something, assuming that it even ran.

That is before trying to put together a piston engine that will make a more or less flat torque curve from 3k to 10k, and do it for a minimum of 30,000mi, and not require forced induction to do it.

I've driven a long ways home on a blown engine, I wouldn't trust trying to drive home on an engine that threw a rod or something, assuming that it even ran.

That is before trying to put together a piston engine that will make a more or less flat torque curve from 3k to 10k, and do it for a minimum of 30,000mi, and not require forced induction to do it.

we've also had catastrophic failures, the Hondas like to drop valves, and as such are intolerant of over revving. dropped valve = broken head, cracked block, etc etc, basically you throw the whole engine out and start over, good thing that motor was a loaner!

our type R engine, with all the fancy AARP studs and accusumps, and trick valve train etc etc, still doesn't rev as high as the junkyard 13B we ran in the Rx7... and it isn't as fast in a straight line as a stock Rx8. Rx8's are commonly referred to a slow, BTW

the K series makes way more power, but reliability goes way down, and thus cost skyrockets. i forget which 25 it was, but we did one, where EVERY K motor blew up, even the FACTORY team blew up, put in the spare engines, and then blew up again. one of the other 25's BMW brought over their 3 series diesel, those died too...

#49

Rotary Enthusiast

Neither I or the OP are talking about throwaway 150hp engines, that kind of data isn't relevant.

Things change when you start making real horsepower. If you're under the impression that rotaries don't suffer catastrophic failures just as often when pushing 25lbs of boost you are delusional.

It seems we keep getting into this chaotic discussion of all sorts of different engines and power ranges and missing the point entirely. Let's get back on topic and summarize the findings that answer the original question:

1: You won't be driving a PP on the street

2: You won't be building a PP on minimum wage

3: You won't get 1000hp for $4000

4: You can't afford to maintain a PP rotary car

5: You don't have the knowledge to build this engine

6: You can't make up your mind what type of Rotary build you're looking for

You're setting yourself up for failure. Start with a reasonable goal, buy an engine and go race. If you insist on not listening to any of us who have built cars we will be more than happy to buy your failed project for 1/4 of what you paid for it when you give up. Don't think it doesn't happen.... it happens often.

Things change when you start making real horsepower. If you're under the impression that rotaries don't suffer catastrophic failures just as often when pushing 25lbs of boost you are delusional.

It seems we keep getting into this chaotic discussion of all sorts of different engines and power ranges and missing the point entirely. Let's get back on topic and summarize the findings that answer the original question:

1: You won't be driving a PP on the street

2: You won't be building a PP on minimum wage

3: You won't get 1000hp for $4000

4: You can't afford to maintain a PP rotary car

5: You don't have the knowledge to build this engine

6: You can't make up your mind what type of Rotary build you're looking for

You're setting yourself up for failure. Start with a reasonable goal, buy an engine and go race. If you insist on not listening to any of us who have built cars we will be more than happy to buy your failed project for 1/4 of what you paid for it when you give up. Don't think it doesn't happen.... it happens often.

#50

Full Member

Thread Starter

Join Date: Apr 2014

Location: Brainerd area Minnesota

Posts: 88

Likes: 0

Received 0 Likes

on

0 Posts

Pretty sure this is the second time I'm saying this,all this info is to help me decide what goal/build to go for.

I am now pretty sure that I will be building this as a track only car now unless after some more research it looks financially smarter to do otherwise. So that means that rx7 is back in the question even though I think it looks odd on the drag strip. So lumpy polluting bridgey might just happen.

I am now pretty sure that I will be building this as a track only car now unless after some more research it looks financially smarter to do otherwise. So that means that rx7 is back in the question even though I think it looks odd on the drag strip. So lumpy polluting bridgey might just happen.