EFI 26B 4 Rotor Engine Project (Here we GO!)

#102

excellent build.....Love all the detailed pictures! After seeing so many V8 FD's recently it's nice to see the good stuff  Just out of curiosity, how long can a PP engine last? I haven't really found any info about reliability compared to side ports.

Just out of curiosity, how long can a PP engine last? I haven't really found any info about reliability compared to side ports.

You're using a heavy *** 20b water pump? Any reason why you don't want to use an electric water pump....seems to be the common theme among four rotors.

-Dan

Just out of curiosity, how long can a PP engine last? I haven't really found any info about reliability compared to side ports.

Just out of curiosity, how long can a PP engine last? I haven't really found any info about reliability compared to side ports.You're using a heavy *** 20b water pump? Any reason why you don't want to use an electric water pump....seems to be the common theme among four rotors.

-Dan

#104

Injected with a Poison

Thread Starter

iTrader: (1)

Join Date: Jul 2003

Location: Miami, FL

Posts: 795

Likes: 0

Received 0 Likes

on

0 Posts

i have not recieved the E-shaft as of yet. I did speak to Alec Bell last night and he should have a ship date for me by June 22 2009. as for right now, The past 2 nights i have been working on the exaust ports and finishing the timming sequence as per Carlos Lopez. I should have these finished and will be taking the housings to him tomorow for re-inspection. i will post some pics up then.

#105

Ok, thanks. jantore used carb jets. I think if the 4 rotor I'm working on winds up being p-ported, the carb jets would work fine. Otherwise if its side ported (hey, what a concept!) it will need stock squirters so it'll maintain pressure at the lower idle speeds side ports can do.

#107

My concern is there are four rotor bearings and four stationary bearings using up available oil pressure and volume instead of just the two and two of a 2 rotor. We plan on using an FD front plate with the FD oil pump as we believe it is the highest volume stock pump. Think it would work with 2mm carb jets if doubled the amount?

#108

Rotary Enthusiast

My concern is there are four rotor bearings and four stationary bearings using up available oil pressure and volume instead of just the two and two of a 2 rotor. We plan on using an FD front plate with the FD oil pump as we believe it is the highest volume stock pump. Think it would work with 2mm carb jets if doubled the amount?

JT

#109

My concern is there are four rotor bearings and four stationary bearings using up available oil pressure and volume instead of just the two and two of a 2 rotor. We plan on using an FD front plate with the FD oil pump as we believe it is the highest volume stock pump. Think it would work with 2mm carb jets if doubled the amount?

#110

Injected with a Poison

Thread Starter

iTrader: (1)

Join Date: Jul 2003

Location: Miami, FL

Posts: 795

Likes: 0

Received 0 Likes

on

0 Posts

If your building a 4 Rotor engine and a "$3000.00 Mazda Motorsport Oil Pump" cannot meet your budget........Id say oil jets in your e-shaft are going to be the least of your problems. And yes i know that the Mad Mike FD looks to be running on an OEM Oil Pump but, 1 he uses the car for drift events which consist of a few if maybe 3 laps around a track and 2nd i would like to see what kind of engine ware that 4 rotor may have whenever it is dissasembled. Just my .10 cents worth. Dont cut corners where you need them most.

#111

Rotary Enthusiast

If your building a 4 Rotor engine and a "$3000.00 Mazda Motorsport Oil Pump" cannot meet your budget........Id say oil jets in your e-shaft are going to be the least of your problems. And yes i know that the Mad Mike FD looks to be running on an OEM Oil Pump but, 1 he uses the car for drift events which consist of a few if maybe 3 laps around a track and 2nd i would like to see what kind of engine ware that 4 rotor may have whenever it is dissasembled. Just my .10 cents worth. Dont cut corners where you need them most.

And yes madmike is running a 20b front plate, with a ported oil tunnel ports in the front casting for more oil flow. This will work for him during the drifting, but nothing else. The extra flow you get from the dry sump is critical, and -10 lines to the oil coolers will not flow enough oil to feed the engine.

Im running -12 and -16 on the scavenge line from the dry sump. As i have -10 lines on my oil coolers, they are on the return, and run in paralell insted of in series for it to flow enough oil trough the oil coolers.

JT

JT

#112

Injected with a Poison

Thread Starter

iTrader: (1)

Join Date: Jul 2003

Location: Miami, FL

Posts: 795

Likes: 0

Received 0 Likes

on

0 Posts

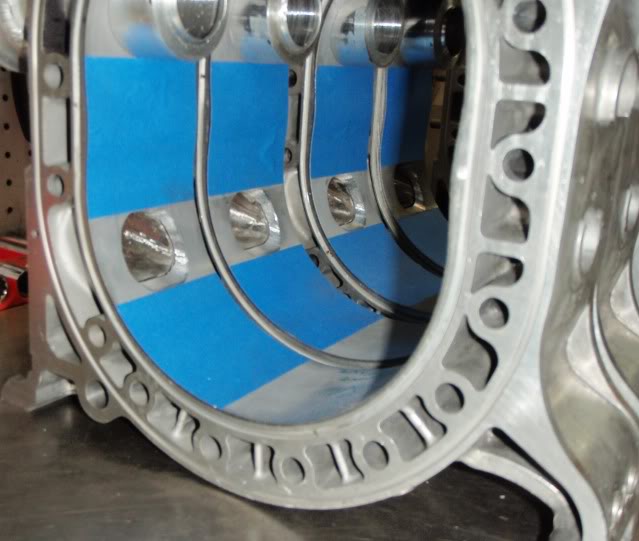

Still no e-shaft from New Zeland but "allegedly" it has shipped. as for progress here, we have been hard at work preparing the rotor housings for both my engine and Big Als 3 rotor. There are alot of steps to getting these Housings to CLR Specs. Big Thanks to Carlos Lopez for helping us throught this Journey. LOL anyways, now to the good stuff. PICS!

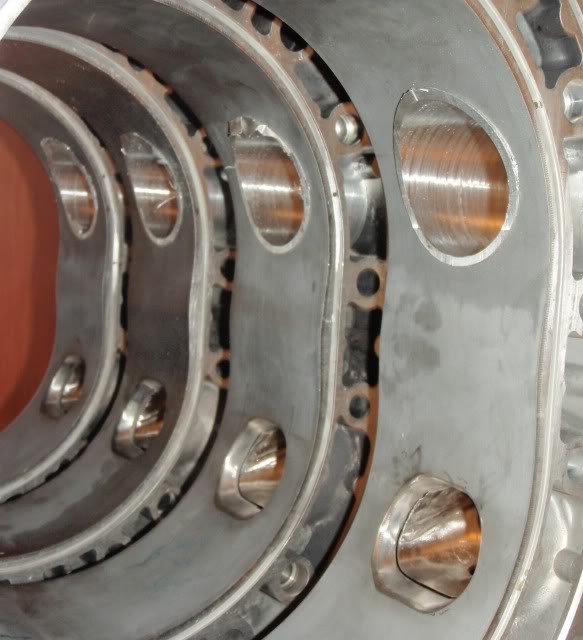

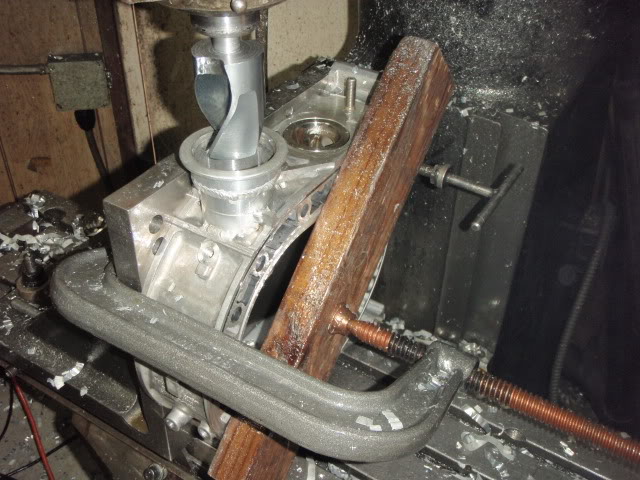

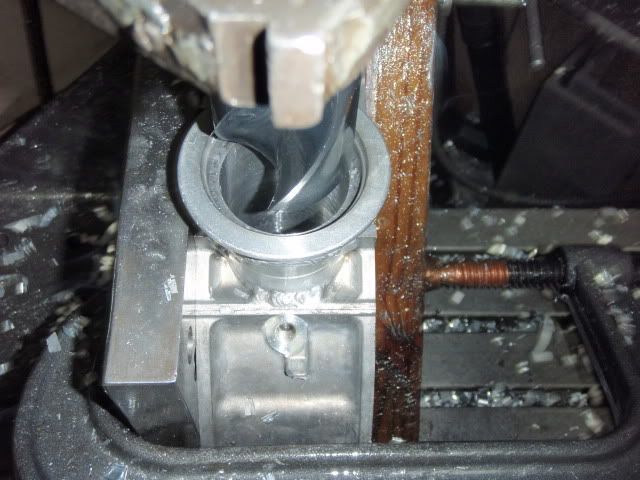

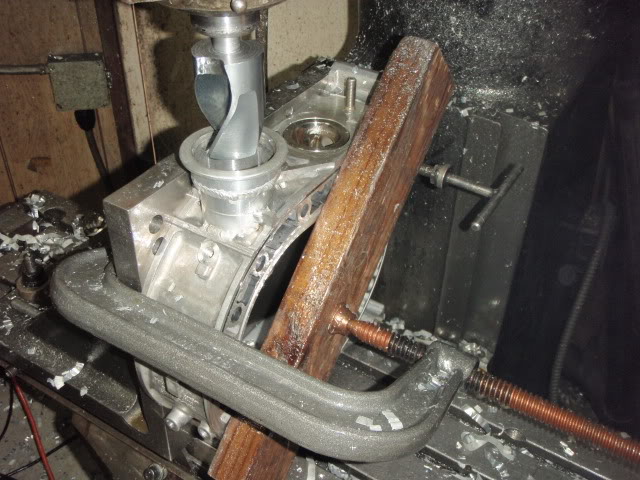

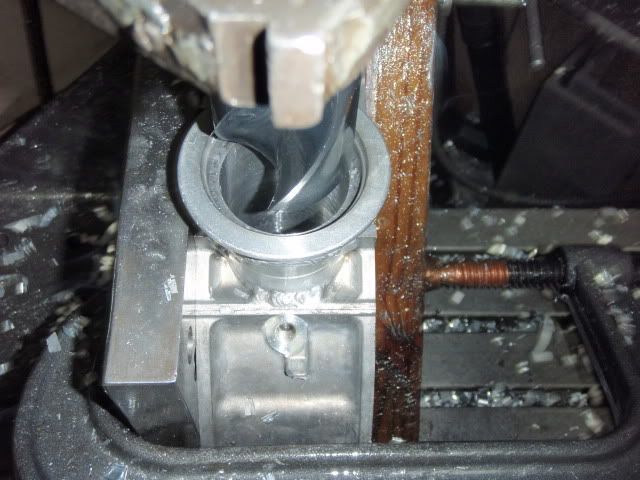

Here is final drilling of the intake sleeve already pressed and welded on the rotor housing

Here is final drilling of the intake sleeve already pressed and welded on the rotor housing

#113

Injected with a Poison

Thread Starter

iTrader: (1)

Join Date: Jul 2003

Location: Miami, FL

Posts: 795

Likes: 0

Received 0 Likes

on

0 Posts

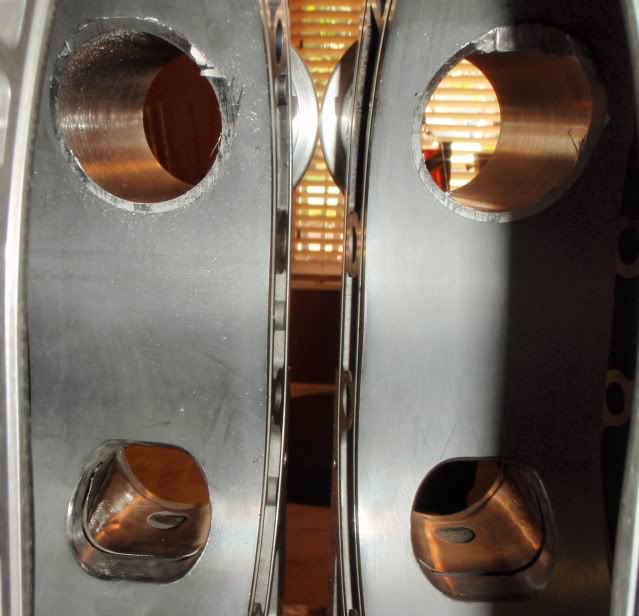

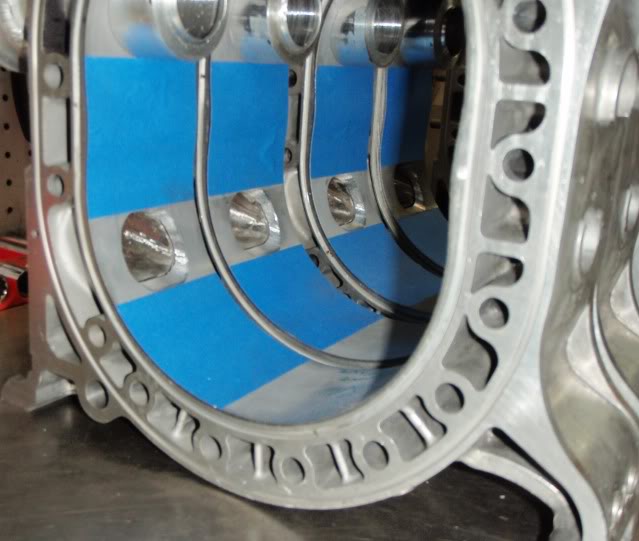

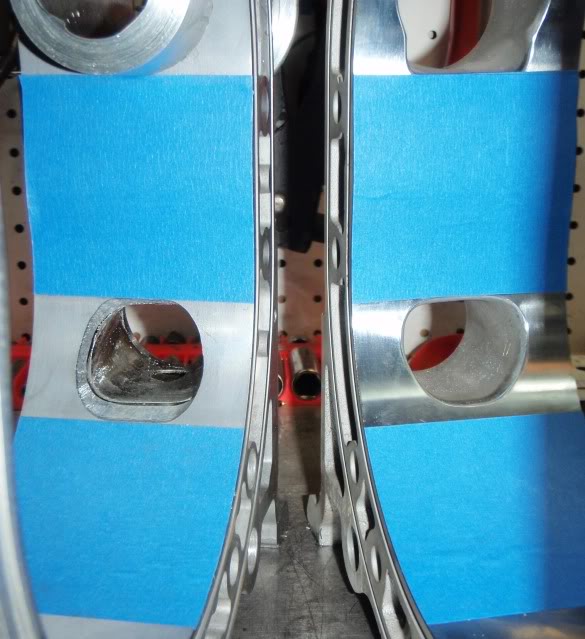

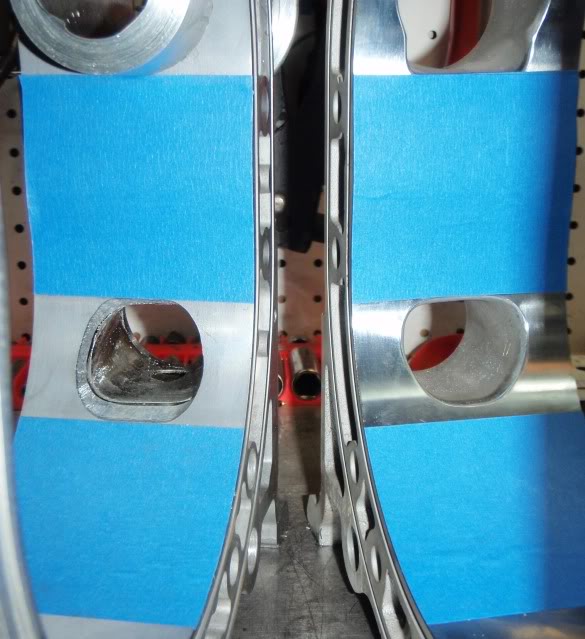

Here are the exaust ports already ported and matched to one of CLR's Mazda Motorsports Housings

The one on the left is mine and the one on the right is a Mazda Race Housing

The one on the left is mine and the one on the right is a Mazda Race Housing

#115

Injected with a Poison

Thread Starter

iTrader: (1)

Join Date: Jul 2003

Location: Miami, FL

Posts: 795

Likes: 0

Received 0 Likes

on

0 Posts

Just picked it up yesterday. Its amazing how so much money went out for so little parts to come back. I took some pics last and will post them this evening when i get home. im going down to CLR to go over the kit and make sure everything is to specs.

#121

How much torque do you apply to the big 48mm nut? I never got an answer from Jeff Bruce.

Make sure your tension bolts are the correct length. Turns out I'll need to trim these here by 10mm or use spacers. Kinda weirded out about that as they are too long for our 12A based engine, but much too short for a 13B based.

Make sure your tension bolts are the correct length. Turns out I'll need to trim these here by 10mm or use spacers. Kinda weirded out about that as they are too long for our 12A based engine, but much too short for a 13B based.

#123

Rotary Enthusiast

How much torque do you apply to the big 48mm nut? I never got an answer from Jeff Bruce.

Make sure your tension bolts are the correct length. Turns out I'll need to trim these here by 10mm or use spacers. Kinda weirded out about that as they are too long for our 12A based engine, but much too short for a 13B based.

Make sure your tension bolts are the correct length. Turns out I'll need to trim these here by 10mm or use spacers. Kinda weirded out about that as they are too long for our 12A based engine, but much too short for a 13B based.

We torqued the flywheel nut with the same torque as the stock one i belive. But we also aplied loctite on it as well.

Im looking forward to getting the engine opend and inspected this winter. And then turn the rpm up to 9500 in the spring. I have been running at max 8200 rpm this summer to run in the ceramic seals before a full out pull. And to see if there is any unbalance in the engine, as we will inspect the bearings when the engine goes apart.

JT

#124

Hmm, maybe Jeff's tension bolt jig is not set right. Someone needs to inform him.

I'd think the rear nut doesn't need as much torque as a stock one due to the splines instead of a taper fit. Locktite sounds like a good idea regardless.

How does the engine feel during accel and idle? I know it's usually difficult to feel an imabalance unless it's at pretty low RPM or really imbalanced, and even then, good luck. The bearings usually show when your flywheel was the wrong series for your rotating assembly, but you already knew that.

I'd think the rear nut doesn't need as much torque as a stock one due to the splines instead of a taper fit. Locktite sounds like a good idea regardless.

How does the engine feel during accel and idle? I know it's usually difficult to feel an imabalance unless it's at pretty low RPM or really imbalanced, and even then, good luck. The bearings usually show when your flywheel was the wrong series for your rotating assembly, but you already knew that.

#125

Rotary Enthusiast

Hmm, maybe Jeff's tension bolt jig is not set right. Someone needs to inform him.

I'd think the rear nut doesn't need as much torque as a stock one due to the splines instead of a taper fit. Locktite sounds like a good idea regardless.

How does the engine feel during accel and idle? I know it's usually difficult to feel an imabalance unless it's at pretty low RPM or really imbalanced, and even then, good luck. The bearings usually show when your flywheel was the wrong series for your rotating assembly, but you already knew that.

I'd think the rear nut doesn't need as much torque as a stock one due to the splines instead of a taper fit. Locktite sounds like a good idea regardless.

How does the engine feel during accel and idle? I know it's usually difficult to feel an imabalance unless it's at pretty low RPM or really imbalanced, and even then, good luck. The bearings usually show when your flywheel was the wrong series for your rotating assembly, but you already knew that.

And im having no water temp problems or oil temp problems

Only thing is the oil pressure is abit low. Max is 90 psi, so will need to check the oil jets and increase the pressrure on the regulator to give it 105-120psi of pressure.

Only thing is the oil pressure is abit low. Max is 90 psi, so will need to check the oil jets and increase the pressrure on the regulator to give it 105-120psi of pressure. But im so sold on NA, will never go back to turbo i think. The power output is so gentel, and you can drive it so much more on the edge without beeing afraid of the power will make you rear wheels spin out, when floring it out of a corner.

The car is going to be so fast next year with slicks tires, 1300 more rpm and 150 more hp

And a driver that is familiar with the car

And a driver that is familiar with the car

JT