Critical Damping for an FC?

#1

Critical Damping for an FC?

Howdy.

Has anyone done the math for FC critical damping? I have DA konis, just gotta find a good starting place.

Car is ~2900 with driver, 50/50 distro.

550F 450R springs (most likely)

ST front bar, no rear

Wheel/tire combo is ~45-50lbs each

255/275 direzzas for track, 285/315 V710's for autox

I'm sure the EP and ITS guys have it down to a science, but my car is a bit heavier with more tire and a lot more power.

So whaddya think?

Has anyone done the math for FC critical damping? I have DA konis, just gotta find a good starting place.

Car is ~2900 with driver, 50/50 distro.

550F 450R springs (most likely)

ST front bar, no rear

Wheel/tire combo is ~45-50lbs each

255/275 direzzas for track, 285/315 V710's for autox

I'm sure the EP and ITS guys have it down to a science, but my car is a bit heavier with more tire and a lot more power.

So whaddya think?

#2

Rough estimate using your numbers would be in the 70 lb/in/S in the front and 55 lb/in/S rear. There is way more info needed to get numbers that you can really use as a base but if you want to start somewhere and you have dyno graphs for your shocks, there you go.

Critical damping isn't where the car will work the best anyway. Your looking for about 65-70% Crit. At this point there are too many variables to get a useful number.

You will have more than enough adjustment with the Koni's so the best way to tune for a track is to start out full soft in compression and rebound. Adjust the compression(bump) stiffer until the car feels unsettled,is upset easily or just feels harsh. Then back off a click or two.

Once you get compression set go after the rebound. You can usually make pretty big adjustments at first. If you have 13 clicks, go up 4 each adjustment. When the car feels skittish back off a couple clicks.

You're getting into a black art and a lot of people won't share secrets too freely. Shocks are really about getting that last .5sec a lap. You'd be suprised how fast you can go with a less than ideal set up.

Critical damping isn't where the car will work the best anyway. Your looking for about 65-70% Crit. At this point there are too many variables to get a useful number.

You will have more than enough adjustment with the Koni's so the best way to tune for a track is to start out full soft in compression and rebound. Adjust the compression(bump) stiffer until the car feels unsettled,is upset easily or just feels harsh. Then back off a click or two.

Once you get compression set go after the rebound. You can usually make pretty big adjustments at first. If you have 13 clicks, go up 4 each adjustment. When the car feels skittish back off a couple clicks.

You're getting into a black art and a lot of people won't share secrets too freely. Shocks are really about getting that last .5sec a lap. You'd be suprised how fast you can go with a less than ideal set up.

#5

ya i know about the recommended 65% with a knee around 3in/s. i just figured critical would be an easier # to come up with from raw data.

other questions.. what about compression? i generally see a lot less compression than rebound. is ideal compression calculated from a different set of parameters than rebound?

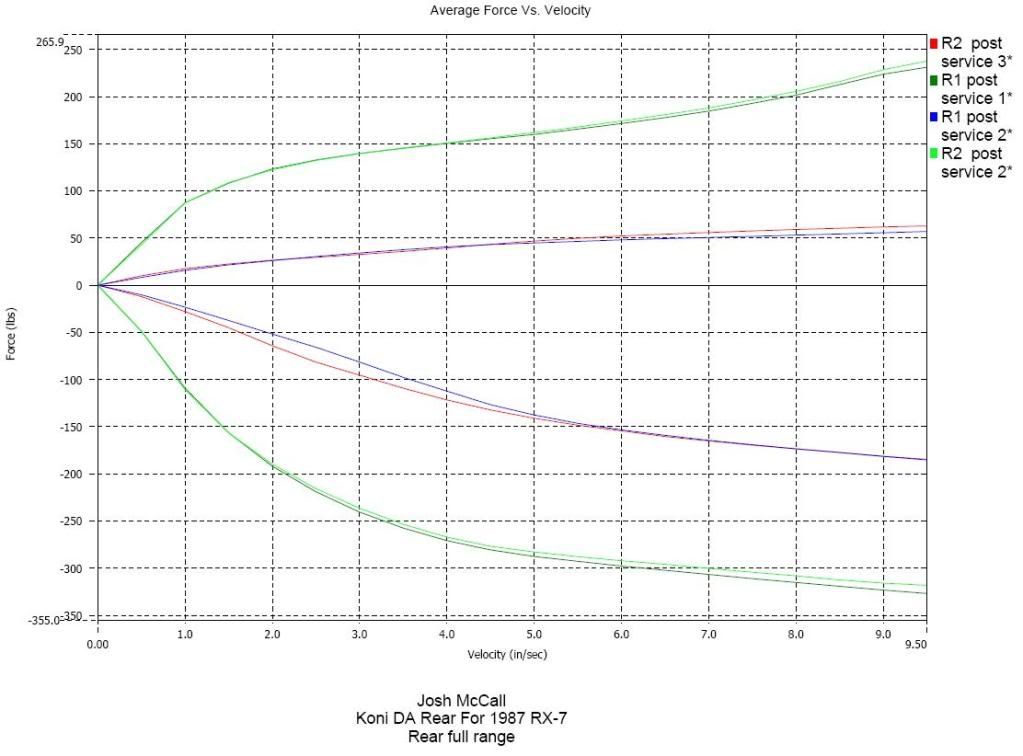

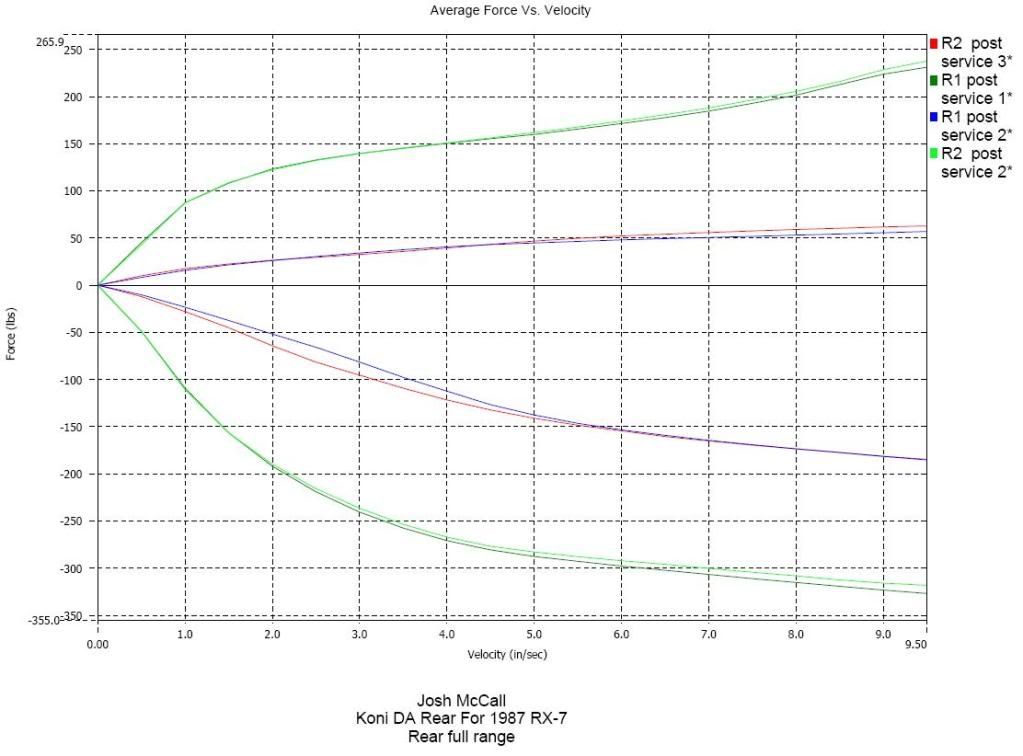

well here are the rear shocks (converted yellows).

no dyno for the front yet (OTS 8611's). i'm gonna do that one of these days...

other questions.. what about compression? i generally see a lot less compression than rebound. is ideal compression calculated from a different set of parameters than rebound?

well here are the rear shocks (converted yellows).

no dyno for the front yet (OTS 8611's). i'm gonna do that one of these days...

Trending Topics

#8

Correct on the rebound #'s

Since you only have double adjustables you just put as much compression as you can until the car jumps around in rough spots. This will change at each track if you're going to get serious about it.

Rebound is where you can change how the car feels in the transitions. Too much rebound and the car jacks down after every bump until it is all over the bumpstops.

It really gets fun when you have triples, 4 ways, or gas pressures to play with.

Since you only have double adjustables you just put as much compression as you can until the car jumps around in rough spots. This will change at each track if you're going to get serious about it.

Rebound is where you can change how the car feels in the transitions. Too much rebound and the car jacks down after every bump until it is all over the bumpstops.

It really gets fun when you have triples, 4 ways, or gas pressures to play with.

#9

Since you only have double adjustables you just put as much compression as you can until the car jumps around in rough spots. This will change at each track if you're going to get serious about it.

You may consider running less compression damping than the above recommeded in the rear if you are having trouble getting traction coming off the apexes.

When I changed out my JIC FLT-A2s for softer compression to rebound curve JIC FLT-TARs on the same 7K/5K springs I gained all sorts of traction as the car is able to transfer the weight to the back as it squats when power comes on.

I can now be light on the throttle before the apex and on it past the apex. Before it was no throttle until past the apex when you could countersteer while SLOWLY squeezing the gas.

Other racers comment that I need new shocks (car squats so hard it looks like blown shocks), but the lap times have dropped and the car is easier/safer to drive. Less sketchy in the rear on braking as well.

You may consider running less compression damping than the above recommeded in the rear if you are having trouble getting traction coming off the apexes.

When I changed out my JIC FLT-A2s for softer compression to rebound curve JIC FLT-TARs on the same 7K/5K springs I gained all sorts of traction as the car is able to transfer the weight to the back as it squats when power comes on.

I can now be light on the throttle before the apex and on it past the apex. Before it was no throttle until past the apex when you could countersteer while SLOWLY squeezing the gas.

Other racers comment that I need new shocks (car squats so hard it looks like blown shocks), but the lap times have dropped and the car is easier/safer to drive. Less sketchy in the rear on braking as well.

#10

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,780

Received 2,565 Likes

on

1,824 Posts

we've done a lot of shock tweaking on the current car, we've even gone so far as to put sensors on the wheels and look at the data logs, and its more about driver feel than laptimes, once you're in the ball park

#12

Been here since dirt...

Join Date: Jan 2009

Location: AZ

Posts: 327

Likes: 0

Received 0 Likes

on

0 Posts

Correct on the rebound #'s

Since you only have double adjustables you just put as much compression as you can until the car jumps around in rough spots. This will change at each track if you're going to get serious about it.

Rebound is where you can change how the car feels in the transitions. Too much rebound and the car jacks down after every bump until it is all over the bumpstops.

It really gets fun when you have triples, 4 ways, or gas pressures to play with.

Since you only have double adjustables you just put as much compression as you can until the car jumps around in rough spots. This will change at each track if you're going to get serious about it.

Rebound is where you can change how the car feels in the transitions. Too much rebound and the car jacks down after every bump until it is all over the bumpstops.

It really gets fun when you have triples, 4 ways, or gas pressures to play with.

It is all really good until the playing with gas pressures idea. That is the last idea, but realistically pressure should never be a variable. In my expereince with off-road and on road manufacturers, it is kept at a constant.

gd

#13

What're the available shock options for an FC these days? AWR has the Bilsteins and pretty much everybody else seems to run the KONIs?

#14

Been here since dirt...

Join Date: Jan 2009

Location: AZ

Posts: 327

Likes: 0

Received 0 Likes

on

0 Posts

Have to disagree with you and agree with jgrewe. The difference between 150psi and 125psi or 100psi can be huge. It is a working variable in shocks like the Penske, Ohlins, Moton, or the race Bilsteins.

What're the available shock options for an FC these days? AWR has the Bilsteins and pretty much everybody else seems to run the KONIs?

What're the available shock options for an FC these days? AWR has the Bilsteins and pretty much everybody else seems to run the KONIs?

The gas only has two functions and neither is for damping adjustment.

1) Prevent the fluid from cavitating by compressing the minor gas into solution.

2) To allow the shock some free volume to account for the rod as it enters the shock body. It does displace fluid.

I have worked with Bilstein when they did OEM shocks for GM and they never varied the gas pressure. It's not a tuning tool. Also worked with SACHS, DElphi, Monroe, FOX and Tokico. Nobody varied the gas pressure. The gas had a gas pressure rise on it's own with heat. So lowering it for a softer ride only goes away when it gets hot. or it will ride too soft when cold. It can add more trouble when it goes either direction. Besides, the added pressure only adds minor spring rate not damping changes.

Bilstein used 250 psi. Most all others used 200. These are all mono tube deflecting disc. Twin tube with coined orifice used much less, or a plastic bag with N2.

If you feel the need to alter the gas pressure, then it's time to valve and spring a bit closer.

Hope this helps a bit...

gd

Last edited by gawdodirt; 12-08-09 at 11:03 PM.

#15

If your dealing with OEM stuff, they probably don't vary the pressure, a person on the street would never know the difference. You need about 80-90psi as a minimum to control cavitation.

Changing the gas pressure will have a support effect under braking, acceleration, tire loading at turn in and even in the grip in the middle of the corner when the valves are just along for the ride. Penskes have a range from 150-300 psi to play with and even mention the practice in their set up manual. Its really a good trick in classes that require a stock spring but still has a place in fine tuning even if you can change springs. Gas pressure has a greater effect on one side of the valve than it does on the other when it comes to cavitation, something that can be used to your advantage when you don't even have one adjustment to play with.

Changing the gas pressure will have a support effect under braking, acceleration, tire loading at turn in and even in the grip in the middle of the corner when the valves are just along for the ride. Penskes have a range from 150-300 psi to play with and even mention the practice in their set up manual. Its really a good trick in classes that require a stock spring but still has a place in fine tuning even if you can change springs. Gas pressure has a greater effect on one side of the valve than it does on the other when it comes to cavitation, something that can be used to your advantage when you don't even have one adjustment to play with.

#16

Been here since dirt...

Join Date: Jan 2009

Location: AZ

Posts: 327

Likes: 0

Received 0 Likes

on

0 Posts

If your dealing with OEM stuff, they probably don't vary the pressure, a person on the street would never know the difference. You need about 80-90psi as a minimum to control cavitation.

Changing the gas pressure will have a support effect under braking, acceleration, tire loading at turn in and even in the grip in the middle of the corner when the valves are just along for the ride. Penskes have a range from 150-300 psi to play with and even mention the practice in their set up manual. Its really a good trick in classes that require a stock spring but still has a place in fine tuning even if you can change springs. Gas pressure has a greater effect on one side of the valve than it does on the other when it comes to cavitation, something that can be used to your advantage when you don't even have one adjustment to play with.

Changing the gas pressure will have a support effect under braking, acceleration, tire loading at turn in and even in the grip in the middle of the corner when the valves are just along for the ride. Penskes have a range from 150-300 psi to play with and even mention the practice in their set up manual. Its really a good trick in classes that require a stock spring but still has a place in fine tuning even if you can change springs. Gas pressure has a greater effect on one side of the valve than it does on the other when it comes to cavitation, something that can be used to your advantage when you don't even have one adjustment to play with.

Ya got a lot of topic in one paragraph, so I'll see if I can add anything useful.

Gas pressure: It's not a useful tool for spring rate or valving. The lesser amount increases the lag or hysteresis.

Resevoir: It depends on which side the resevoir is on. FOX and Ohlins have changed it from top to bottom depending on the application. The reason is hysterysis during the transition. You want it on the bottom if you favor critical compression control. On the top for rebound accuracy. The gas is springy.

gd

#17

I guess you and the people that make Penskes will have to disagree on that.

Myself, I'm willing to learn from anybody.

Do you think that not changing the pressure would have to do with production issues? I've drilled the gas chambers and revalved street Bilsteins and with no external adjustment I've found gas pressures effect the feel on the car a lot.

Higher gas pressures will show up in higher shaft pressures as well, to the point that it will effect the ride height. Its not an ideal way but it is a way to get an adjustment when no others are available.

edit: never mentioned in thread that I have a shock dyno

Last edited by jgrewe; 12-09-09 at 06:19 PM.

Thread

Thread Starter

Forum

Replies

Last Post

HalifaxFD

Canadian Forum

126

05-09-16 07:06 PM

Red-Dragon_Akuma

New Member RX-7 Technical

11

09-28-15 06:09 AM

23Racer

Race Car Tech

1

09-21-15 10:48 AM