Power FC PFC wasgate/Precontrol

#1

Senior Member

Thread Starter

Join Date: Feb 2006

Location: mooresville

Posts: 454

Likes: 0

Received 0 Likes

on

0 Posts

Hello,

I have been dealing with poor part throttle turbo transition...anyways I went back through some logs and found something strange.... It appears that the PFC keeps both the WG and PC open until boost is achieved at which time the waste gate is closed???? the result is that when I part throttle accelerate through the transition as soon as the PC opens it causes a drop in boost(normal)...but if the boost drops just into vacuum the PFC opens the waste gate thus dumping all boost momentarily until you pedal it enough to respool both turbo's(not normal). this also makes initial spool slower than it should be.

Has anyone noticed this or have any idea why this is?

thanks for any input.

Tyler

I have been dealing with poor part throttle turbo transition...anyways I went back through some logs and found something strange.... It appears that the PFC keeps both the WG and PC open until boost is achieved at which time the waste gate is closed???? the result is that when I part throttle accelerate through the transition as soon as the PC opens it causes a drop in boost(normal)...but if the boost drops just into vacuum the PFC opens the waste gate thus dumping all boost momentarily until you pedal it enough to respool both turbo's(not normal). this also makes initial spool slower than it should be.

Has anyone noticed this or have any idea why this is?

thanks for any input.

Tyler

#3

Senior Member

Thread Starter

Join Date: Feb 2006

Location: mooresville

Posts: 454

Likes: 0

Received 0 Likes

on

0 Posts

Thanks Chuck..I was afraid that most were non seq...I however am still trying to beat a dead horse and am now really starting to regret the PFC...For a fully programmable ECU it has way to many weird nuances such as non adjustable parameters and or very rough adjustments especially on the drivability side of things. This one really has me on the brink of ditching it and going with a better ECU...It's as plain as day in the logs when you compare WG%/PC% vs boost....As soon as the ecu/map sensor detects vac it opens both.

#5

on second thought, you may have a mechanical issue with your sequential system. I was tuning a friend's sequential FD with FMIC, 550/1300 and other supporting mods and I just set boost to .95 on the primary/PC and .90 on secondary/WG. never had any hesitations, boost dropping too far, anything.

#6

Eye In The Sky

iTrader: (2)

Join Date: Feb 2001

Location: In A Disfunctional World

Posts: 7,892

Likes: 0

Received 114 Likes

on

66 Posts

An don't forget that the stock seq twins system also sucks when it comes to reliability.

#7

Senior Member

Thread Starter

Join Date: Feb 2006

Location: mooresville

Posts: 454

Likes: 0

Received 0 Likes

on

0 Posts

Thanks for the input, I do have datalogit(shudder at the thought of not having it) however while there are a decent amount of knowledgeable individuals tunning with it there are still some pretty annoying unknown and or unadjustable parameters which lead to compromises in everyday drivability....such as rather poor eccel enrichment table, no target lambda table, rough IAT table unadjustable areas of the base map...etc and then the current issue.

No its not a mechanical issue, the ecu determines the wg/pc duty cycle and for some reason APEXi has written into they're strategy to open both when Map is in vac. I'm tempted to install a MBC and see how much of an affect this has.

Yes I agree the stock seq, ecu strategy sucked...this is part of the reason I went with the PFC...in hopes of more tunability which it has to some extent but defiantly not to the point that I wish it were. Granted some of this is due to the oem mechanicals

No its not a mechanical issue, the ecu determines the wg/pc duty cycle and for some reason APEXi has written into they're strategy to open both when Map is in vac. I'm tempted to install a MBC and see how much of an affect this has.

Yes I agree the stock seq, ecu strategy sucked...this is part of the reason I went with the PFC...in hopes of more tunability which it has to some extent but defiantly not to the point that I wish it were. Granted some of this is due to the oem mechanicals

Trending Topics

#8

http://www.autosportracetech.com/RX-...erOverview.htm it may differ slightly on a PFC but that's the idea.

I just don't get why you seem to be the only one talking about this kind of problem. I don't say this as a personal attack. I agree that the PFC can be frustrating for some of its little quirks, but I'm genuinely puzzled by your description of the problem with your sequential system.

I was just helping out a friend of mine on stock sequential turbos (using PFC to control boost, no vac line reduction whatsoever) tune his car the other night (he has no datalogit). I'm not an expert but I've at least read the forums and I have Chuck Westbrook's tuning notes which I have read thoroughly. We got the boost running 14-10-14, which isn't perfect but it wasn't bad, and all the injector setup worked out (he has 550/1300). I noticed 0 hesitation when driving it after the injectors and accel tables were taken care of. Now I didn't comb through a bunch of logs to the extent that you did, but from a driver's perspectives I had no problem.

but I will ask again: have you experimented with the part throttle turbo transition settings? what did you do and what were your results?

I just don't get why you seem to be the only one talking about this kind of problem. I don't say this as a personal attack. I agree that the PFC can be frustrating for some of its little quirks, but I'm genuinely puzzled by your description of the problem with your sequential system.

I was just helping out a friend of mine on stock sequential turbos (using PFC to control boost, no vac line reduction whatsoever) tune his car the other night (he has no datalogit). I'm not an expert but I've at least read the forums and I have Chuck Westbrook's tuning notes which I have read thoroughly. We got the boost running 14-10-14, which isn't perfect but it wasn't bad, and all the injector setup worked out (he has 550/1300). I noticed 0 hesitation when driving it after the injectors and accel tables were taken care of. Now I didn't comb through a bunch of logs to the extent that you did, but from a driver's perspectives I had no problem.

but I will ask again: have you experimented with the part throttle turbo transition settings? what did you do and what were your results?

Last edited by arghx; 12-09-07 at 02:33 AM.

#9

Senior Member

Thread Starter

Join Date: Feb 2006

Location: mooresville

Posts: 454

Likes: 0

Received 0 Likes

on

0 Posts

No offense taken... Hopefully you feel the same.

Yes I do fully understand the seq. turbo set-up and the ECU's strategy for controlling it, As for lack of complaints on this. Perhaps my expectations of what can be achieved in the transition are more picky than most also It seems that most of the knowledgeable members here no longer use the PFC boost control or have just given up and gone single or non seq.

I have moved the PC(low rpm#) both directions as well as the high rpm and have managed to improve the masking of the problem simply by speeding up transition point however it is still noticeable at light throttle while moving through the transition. As soon as the PC opens at the Low rpm setting if I'm not fully boosting I'll notice increase in exhaust volume and drop off what little boost I had...which I originally attributed to PC being open however with looking at WG% have now concluded that it is the WG being open...??? at nearly or full boost it is not noticeable since boost is constantly maintained through the transition.

Yes I do fully understand the seq. turbo set-up and the ECU's strategy for controlling it, As for lack of complaints on this. Perhaps my expectations of what can be achieved in the transition are more picky than most also It seems that most of the knowledgeable members here no longer use the PFC boost control or have just given up and gone single or non seq.

I have moved the PC(low rpm#) both directions as well as the high rpm and have managed to improve the masking of the problem simply by speeding up transition point however it is still noticeable at light throttle while moving through the transition. As soon as the PC opens at the Low rpm setting if I'm not fully boosting I'll notice increase in exhaust volume and drop off what little boost I had...which I originally attributed to PC being open however with looking at WG% have now concluded that it is the WG being open...??? at nearly or full boost it is not noticeable since boost is constantly maintained through the transition.

#10

Eye In The Sky

iTrader: (2)

Join Date: Feb 2001

Location: In A Disfunctional World

Posts: 7,892

Likes: 0

Received 114 Likes

on

66 Posts

" sereneseven statements"

s1: rather poor eccel enrichment table

R1: Do you know about/what it does - INJ vs Accel TPS1? This is the real table that affects/applies the first table.

S2: no target lambda table

A2: how many ecu systems have an auto AFR/lamba tuning feature for $1000?

S3: rough IAT table

A3: I agree the spread between points is large, but if you move the AIT sensor to the throttle body elbow or FMIC outlet, the sensor works a lot better and you can then change the AIR Temp vs INJ table for correct seasonal chnages. I did this over 5 years ago.

S4: unadjustable areas of the base map

A4: if you are talking about idle area timing, there is a way to control it but you have to give up the ISC auto idle control.

It appears you lack full knowledge of what the system can do. You can either buy my most comprehensive PFC/DL notes or get rid of the PFC and leave this forum.

s1: rather poor eccel enrichment table

R1: Do you know about/what it does - INJ vs Accel TPS1? This is the real table that affects/applies the first table.

S2: no target lambda table

A2: how many ecu systems have an auto AFR/lamba tuning feature for $1000?

S3: rough IAT table

A3: I agree the spread between points is large, but if you move the AIT sensor to the throttle body elbow or FMIC outlet, the sensor works a lot better and you can then change the AIR Temp vs INJ table for correct seasonal chnages. I did this over 5 years ago.

S4: unadjustable areas of the base map

A4: if you are talking about idle area timing, there is a way to control it but you have to give up the ISC auto idle control.

It appears you lack full knowledge of what the system can do. You can either buy my most comprehensive PFC/DL notes or get rid of the PFC and leave this forum.

#11

Senior Member

Thread Starter

Join Date: Feb 2006

Location: mooresville

Posts: 454

Likes: 0

Received 0 Likes

on

0 Posts

" sereneseven statements"

s1: rather poor eccel enrichment table

R1: Do you know about/what it does - INJ vs Accel TPS1? This is the real table that affects/applies the first table.

S2: no target lambda table

A2: how many ecu systems have an auto AFR/lamba tuning feature for $1000?

S3: rough IAT table

A3: I agree the spread between points is large, but if you move the AIT sensor to the throttle body elbow or FMIC outlet, the sensor works a lot better and you can then change the AIR Temp vs INJ table for correct seasonal chnages. I did this over 5 years ago.

S4: unadjustable areas of the base map

A4: if you are talking about idle area timing, there is a way to control it but you have to give up the ISC auto idle control.

It appears you lack full knowledge of what the system can do. You can either buy my most comprehensive PFC/DL notes or get rid of the PFC and leave this forum.

s1: rather poor eccel enrichment table

R1: Do you know about/what it does - INJ vs Accel TPS1? This is the real table that affects/applies the first table.

S2: no target lambda table

A2: how many ecu systems have an auto AFR/lamba tuning feature for $1000?

S3: rough IAT table

A3: I agree the spread between points is large, but if you move the AIT sensor to the throttle body elbow or FMIC outlet, the sensor works a lot better and you can then change the AIR Temp vs INJ table for correct seasonal chnages. I did this over 5 years ago.

S4: unadjustable areas of the base map

A4: if you are talking about idle area timing, there is a way to control it but you have to give up the ISC auto idle control.

It appears you lack full knowledge of what the system can do. You can either buy my most comprehensive PFC/DL notes or get rid of the PFC and leave this forum.

Yes I believe the enrichment table is poor...Yes I do realize that Inj vs tps1 is the the table in which the amount of fuel is added vs vs throttle% change however I feel it is poor due to there only being three points of adjustment and there doesn't seem to be a definitive answer as to what the #s actually mean (Input=throttle input vs time?)

You are correct for the price I Know of no other ECU with a Target Lambda table.

Yes I agree the IAT sensor/location is a major problem....but this brings up another PFC short coming which is non configurable sensor inputs which means you have to either find a sensor which matches OE specs (magneti marelli) or setup a formula outside of the ECU to calibrate it.

Unadjustable areas of the base fuel map...very low off idle p row fuel changes seem to have no affect on actual fueling...the only way I can get these areas to lean out is with - lag adjustment (stock injectors). As well as the idle timing compromise you mentioned.

#12

Eye In The Sky

iTrader: (2)

Join Date: Feb 2001

Location: In A Disfunctional World

Posts: 7,892

Likes: 0

Received 114 Likes

on

66 Posts

Yes I believe the enrichment table is poor...Yes I do realize that Inj vs tps1 is the the table in which the amount of fuel is added vs vs throttle% change however I feel it is poor due to there only being three points of adjustment and there doesn't seem to be a definitive answer as to what the #s actually mean (Input=throttle input vs time?)

R1: the manual only gives an estimate of how the water temp correction table works, but I never had any real problems with using the "Inj vs tps1" table as most tip in problems are just of idle unless AFR tuning is bad above that.

Yes I agree the IAT sensor/location is a major problem....but this brings up another PFC short coming which is non configurable sensor inputs which means you have to either find a sensor which matches OE specs (magneti marelli) or setup a formula outside of the ECU to calibrate it.

R2: I am waiting for Steve (DL forum) to answer my question about if the temp

side of the "air temp vs inj" table is fixed or can it be overrided with a DL software upgrade.

Unadjustable areas of the base fuel map...very low off idle p row fuel changes seem to have no affect on actual fueling...the only way I can get these areas to lean out is with - lag adjustment (stock injectors). As well as the idle timing compromise you mentioned.[/QUOTE]

R3: if the O2 FB switch is on, it makes it hard to adjust this. When off, the only problem is the PFC minimum allowed injector times which only seems to affect it when running large primaries suck as 850s+. Then lag is the only answer.

850s are not needed for street cars unless you want too much streetable power, but there are ways around it. 550 + 1660 or 550 + 2 sets of larger than 850.

The FJO driver makes this easy.

Using are heads to figure around problems is our advantage over other animals.

R1: the manual only gives an estimate of how the water temp correction table works, but I never had any real problems with using the "Inj vs tps1" table as most tip in problems are just of idle unless AFR tuning is bad above that.

Yes I agree the IAT sensor/location is a major problem....but this brings up another PFC short coming which is non configurable sensor inputs which means you have to either find a sensor which matches OE specs (magneti marelli) or setup a formula outside of the ECU to calibrate it.

R2: I am waiting for Steve (DL forum) to answer my question about if the temp

side of the "air temp vs inj" table is fixed or can it be overrided with a DL software upgrade.

Unadjustable areas of the base fuel map...very low off idle p row fuel changes seem to have no affect on actual fueling...the only way I can get these areas to lean out is with - lag adjustment (stock injectors). As well as the idle timing compromise you mentioned.[/QUOTE]

R3: if the O2 FB switch is on, it makes it hard to adjust this. When off, the only problem is the PFC minimum allowed injector times which only seems to affect it when running large primaries suck as 850s+. Then lag is the only answer.

850s are not needed for street cars unless you want too much streetable power, but there are ways around it. 550 + 1660 or 550 + 2 sets of larger than 850.

The FJO driver makes this easy.

Using are heads to figure around problems is our advantage over other animals.

#13

Yes I do fully understand the seq. turbo set-up and the ECU's strategy for controlling it, As for lack of complaints on this. Perhaps my expectations of what can be achieved in the transition are more picky than most also It seems that most of the knowledgeable members here no longer use the PFC boost control or have just given up and gone single or non seq.

I spent a lot of time trying to get a decent transition and now have an acceptable-but-not-spectacular 13-9-14 pattern with a 0.4 second transition. I have two Hallman manual boost controllers with in-cabin controllers. Try as I might, I can not get a shorter transition or smaller dip using the MBCs or the PFC's transition settings. (I have exhaustively tested all my solenoids, actuators, check valves, etc.) I have no idea if this is due to the limitations of the PFC, the stock solenoids or actuators, or of my understanding of how transition works (and I suspect the latter).

It is not at all clear what the PFC high and low transition settings mean in terms of how it controls the six relevant solenoids (precontrol, wastegate [both of which are irrelevant with dual MBCs], turbo control (2), and charge control and charge relief). I have noticed that the best transition occurs at full throttle, at least on my car; part throttle transition can be very bad (0.6 seconds with a 11-6/7-12 pattern, for example). The stock PFC's 0.8/0.7 and 0.9/0.8kg/cm2 boost presets suggest that Apexi may not have been able to get a spectacular transition either.

#16

Eye In The Sky

iTrader: (2)

Join Date: Feb 2001

Location: In A Disfunctional World

Posts: 7,892

Likes: 0

Received 114 Likes

on

66 Posts

I went non-seq+ and never looked back. Being a gear jammer from way back, I use the transmission to optimise power instead of having the ECU try to due what I can do better.

1963 Triumph TR3 2.2L "over bore kit"

1954 VW, 35HP

1968 Alfa Romeo GT1300Jr

1967 Alfa Romeo GT1300JR race prepared street car

1979 Maza GLC

1983 RX-7 FB ralley port 12A

1993 RX-7 FD over 350WHP, GT35R now

Never an auto tranny or V8!

#17

Senior Member

Thread Starter

Join Date: Feb 2006

Location: mooresville

Posts: 454

Likes: 0

Received 0 Likes

on

0 Posts

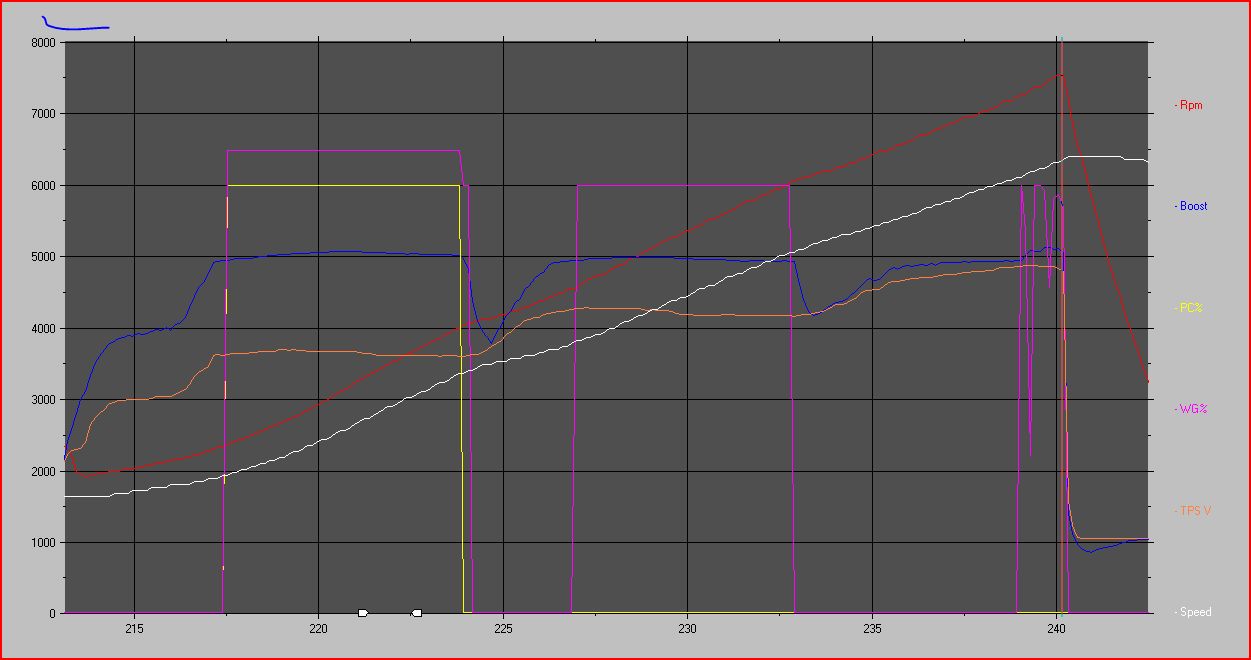

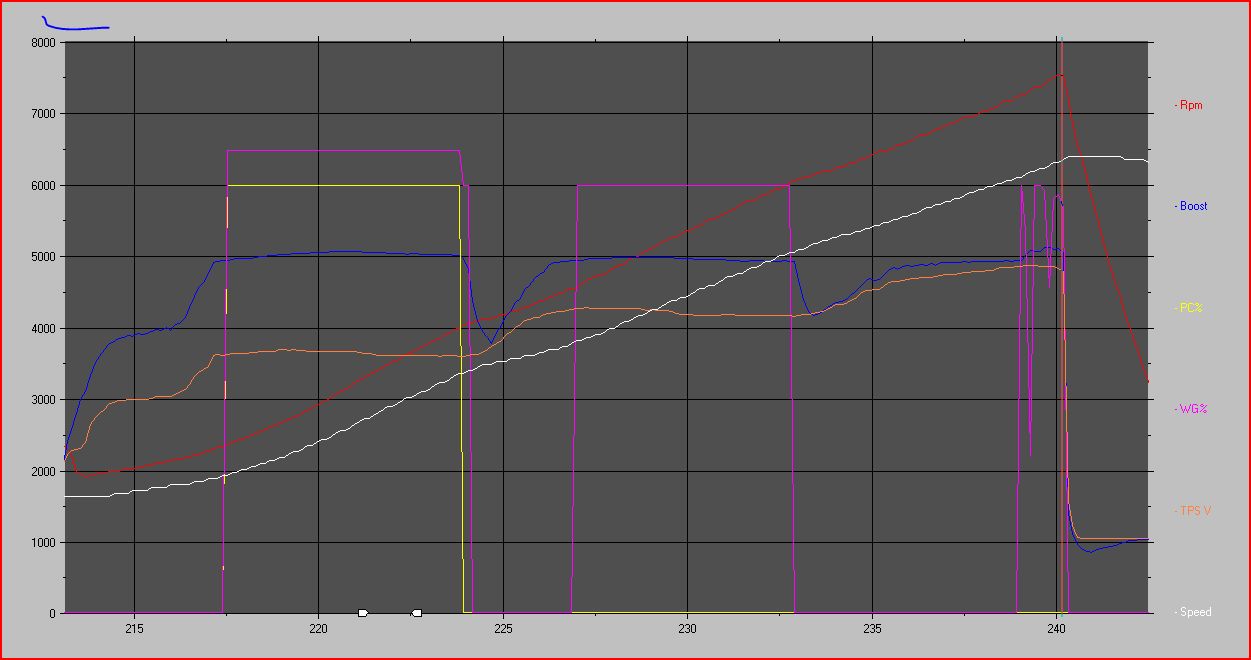

here are some snapshots from logs showing the PC% and WG% the first is light throttle through transition which clearly depicts the WG being opened with the PC and then closing to a set duty% once boost is recovered with more throttle input. the second has moderate throttle though transisition where the WG simply drops down to a lower % when the PC opens...this is what i would expect it to do except if you look as soon as the throttle is lifted (shift) the WG opens again?

#18

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,778

Received 2,563 Likes

on

1,823 Posts

There is very little expertise available on transition tuning be it with a PFC or not. While you will find many threads on the main board about transition problems, I'm convinced that there has never been a single person on this board who really understands the operation of the sequential system on this car.

.

.

if you're statement is true, it is because the people that do know the sequential system do not post. there are people who understand the system.

#19

However, I have not seen a single post on this or any other board or mailing lists that demonstrated that the writer fully understood how these components work in detail - and in particular how they work together. For example, I'd love to know the answers to the following questions:

. How long should transition take in a properly functioning system? 100 milliseconds, 1/2 a second?

. At what rpm is the CRV opened? Is the opening point load dependent? If so, what is the relationship between load and opening point? Is activation instantaneous or is the CRV modulated in some way?

. At what rpm is the CCV opened? Is the opening point load dependent? If so, what is the relationship between load and opening point? Is activation instantaneous or is the CCV modulated in some way?

. At what what rpm does the pre-control actuator start opening. Is the opening point load dependent? If so, what is the relationship between load and opening point? At what rpm is the pre-control actuator fully open?

. At what rpm is the TCA activated. Is it an instantaneous activation or does it occur over an rpm range? If so, what is this range and does it vary with load?

The questions all apply to a stock car with the stock 10-8-10 boost pattern. The interesting questions are then how one varies these parameters when increasing both boost and air flow. The really interesting question is whether the stock solenoids and actuators are actually capable of operating quickly enough to ensure a rapid transition with a lot of extra boost or flow. In particular, is the volume of prespool-generated air flow sufficient to produce enough secondary prespool to ensure a smooth transition in a much higher than stock configuration? In other words, is, say, 18-16-18 possible with the stock solenoids and actuators or would one have to be satisfied with 18-12-18?

if you're statement is true, it is because the people that do know the sequential system do not post.

#20

Eye In The Sky

iTrader: (2)

Join Date: Feb 2001

Location: In A Disfunctional World

Posts: 7,892

Likes: 0

Received 114 Likes

on

66 Posts

On both charts, TPS is not held constant which reflects that throttle movement was unstable. This in turn causes boost fluctuations and changes in all ECU functions. Not good for testing anything as far as I am concerned.

For good tests, the throttle needs to be kept constant at some point.

Adjust the throttle cable or something so that about 1/2 throttle is the most that can be achieve. Then log from 2000 rpm up to 6000 in 4th or 5th with the throttle floored at this 1/2. Do the same for full throttle.

Then chart the logs.

* * * *

The following does not apply to sereneseven, but is an example what a log can tell you and why that may be limited.

I was trying to tune a customers car and the boost was jumping up and down as he drove. This caused much P row jumping which should not happened. Analysis showed that he could not keep the throttle floored and planted solid. He had shaky foot syndrom. I reduced about 3 seconds off his 0-100 times with my initial still safe tune based on this poor log. He not only never came back for more/better tuning, he told me that he put the richer original/slower map back in : to protect the engine from posible being lean".

Speed does scare some people but they still want a "fast" car for image.

For good tests, the throttle needs to be kept constant at some point.

Adjust the throttle cable or something so that about 1/2 throttle is the most that can be achieve. Then log from 2000 rpm up to 6000 in 4th or 5th with the throttle floored at this 1/2. Do the same for full throttle.

Then chart the logs.

* * * *

The following does not apply to sereneseven, but is an example what a log can tell you and why that may be limited.

I was trying to tune a customers car and the boost was jumping up and down as he drove. This caused much P row jumping which should not happened. Analysis showed that he could not keep the throttle floored and planted solid. He had shaky foot syndrom. I reduced about 3 seconds off his 0-100 times with my initial still safe tune based on this poor log. He not only never came back for more/better tuning, he told me that he put the richer original/slower map back in : to protect the engine from posible being lean".

Speed does scare some people but they still want a "fast" car for image.

#21

Senior Member

Thread Starter

Join Date: Feb 2006

Location: mooresville

Posts: 454

Likes: 0

Received 0 Likes

on

0 Posts

Chuck,

these were just a quick example I grabbed from a few random logs... yes the throttle is not constant..They were from some fuel tunning logs where i was trying to build some fuel data during the transition for some of the p rows. I will try to find some constant throttle logs to post....however this is still odd to me even with these logs since there is no reason for the WG to be opened during these conditions all it's doing is dumping potential energy out the pipe instead of spooling the turbo. I have racked my brain for any possible scenario in which this would be beneficial and have not come up with anything other than a possible safety measure to reduce the on time of the solenoids and thus increase they're longevity.

these were just a quick example I grabbed from a few random logs... yes the throttle is not constant..They were from some fuel tunning logs where i was trying to build some fuel data during the transition for some of the p rows. I will try to find some constant throttle logs to post....however this is still odd to me even with these logs since there is no reason for the WG to be opened during these conditions all it's doing is dumping potential energy out the pipe instead of spooling the turbo. I have racked my brain for any possible scenario in which this would be beneficial and have not come up with anything other than a possible safety measure to reduce the on time of the solenoids and thus increase they're longevity.

#22

Back from the dead.

I have been reading up a lot on the stock WG solenoid in order to understand it better, and I think the OP here is misunderstanding how WG duty works. The terminology can be confusing.

The factory WG solenoid is a Normally Closed vent solenoid. By normally closed, it means that applying 12V to the solenoid opens the pathway and allows air to pass. So an "open" air passage is the opposite of an "open circuit" in which current does not flow. That was kind of confusing for me to figure out.

This is actually the same type of solenoid used in an external wastegate. That's why on the Denso solenoid for the Profec etc you switch from "normally open" NO port (internal wastegate) to the "normally closed" NC port (External wastegate). On an external wastegate, the more duty the wastegate solenoid sees, the more air passes through. The more air passes through the solenoid, the more force is exerted on the diaphragm and the higher the boost.

On the factory system, the more WG duty the more air passes through the solenoid--except this controls how much air leaves the WG actuator (more air leaving means more boost), not how much air enters it as on an external wastegate.

A lot of people hate on this setup, but given the early 90s technology (8 bit ECU) it is actually a better design IMO than the inline bleeder solenoid (NC normally closed type) of the series 5 turbo cars, which was a lot dumber than modern electronically controlled internal wastegates and should not be compared to an STi factory EBC.

Anyway, the more duty the factory WG solenoid sees, the higher the boost goes--because it is VENTING pressure from the wastegate flapper! And the flapper needs to see something like 7psi to crack open.

Here the OP complained that the wastegate was opening as soon as he hit boost. Not true at all! The wastegate was being held closed by venting the pressure that would normally push it open! This is exactly what our aftermarket EBC's do on internal wastegates, , except it has the unconventional venting setup.

So to summarize, more WG duty (and max duty is technically 255 if you do a WG % watch) equals more boost. I have noticed that duty cycle shoots up as soon as you hit about .1 kg/cm^2. So as soon as pressure is about to push on the factory internal wastegate, the PFC and WG solenoid vents it away in order to improve response.

It doesn't matter what the WG duty is under vacuum. The WG solenoid is a VENT SOLENOID. The flapper will not crack in vacuum whether the vent is open or closed. It has no effect on spool at all.

I have been reading up a lot on the stock WG solenoid in order to understand it better, and I think the OP here is misunderstanding how WG duty works. The terminology can be confusing.

The factory WG solenoid is a Normally Closed vent solenoid. By normally closed, it means that applying 12V to the solenoid opens the pathway and allows air to pass. So an "open" air passage is the opposite of an "open circuit" in which current does not flow. That was kind of confusing for me to figure out.

This is actually the same type of solenoid used in an external wastegate. That's why on the Denso solenoid for the Profec etc you switch from "normally open" NO port (internal wastegate) to the "normally closed" NC port (External wastegate). On an external wastegate, the more duty the wastegate solenoid sees, the more air passes through. The more air passes through the solenoid, the more force is exerted on the diaphragm and the higher the boost.

On the factory system, the more WG duty the more air passes through the solenoid--except this controls how much air leaves the WG actuator (more air leaving means more boost), not how much air enters it as on an external wastegate.

A lot of people hate on this setup, but given the early 90s technology (8 bit ECU) it is actually a better design IMO than the inline bleeder solenoid (NC normally closed type) of the series 5 turbo cars, which was a lot dumber than modern electronically controlled internal wastegates and should not be compared to an STi factory EBC.

Anyway, the more duty the factory WG solenoid sees, the higher the boost goes--because it is VENTING pressure from the wastegate flapper! And the flapper needs to see something like 7psi to crack open.

Here the OP complained that the wastegate was opening as soon as he hit boost. Not true at all! The wastegate was being held closed by venting the pressure that would normally push it open! This is exactly what our aftermarket EBC's do on internal wastegates, , except it has the unconventional venting setup.

So to summarize, more WG duty (and max duty is technically 255 if you do a WG % watch) equals more boost. I have noticed that duty cycle shoots up as soon as you hit about .1 kg/cm^2. So as soon as pressure is about to push on the factory internal wastegate, the PFC and WG solenoid vents it away in order to improve response.

It doesn't matter what the WG duty is under vacuum. The WG solenoid is a VENT SOLENOID. The flapper will not crack in vacuum whether the vent is open or closed. It has no effect on spool at all.

#24

Here is a log of the factory boost control system working reasonably well. It is a streetported FD with I believe no restrictor pills in the wastegate lines and a bunch of supporting mods. Transition settings are stock, wastegate has been ported. According to the autometer boost gauge the boost pattern is 14-10-14.

Boost control settings:

Primary 1.00 Kg/cm^2 , duty 70

Secondary .90 Kg/cm^2, duty 86

I am still not entirely sure how the "boost" settings work. We know that the boost level helps set a fuel cut , but I still can't be completely sure if it is involved in the actual boost control process. Page 28 of the manual indicates that the duty value will affect boost levels, but it's not completely clear in my mind how much of a role the target boost value plays. According to the uncalibrated stock MAP sensor on this car, boost only reached about .85 Kg/Cm^2, which is weird, because my autometer read 14psi and 14psi is almost exactly the target of 1.00 . "primary" and "secondary" also seem to be strange labels. Shouldn't the Secondary setting be higher than the first one, if it is meant to control duty after transition?

Here's one thing I noticed though. Before transition, WG duty is effectively maxed out, meaning the wastegate flapper is being kept shut. During the primary turbo phase of driving, precontrol duty is logged as "180." 180 divided by 255 (theoretical maximum duty I'm guessing) is 70.5% , which matches the "primary" duty. You can see PC duty increases again there right at the 3800 transition point where the boost looks like it might fall off. Then suddenly PC duty drops like a rock and the wastegate takes over. The wastegate goes from being effectively full open to a number right near the target duty cycle. target duty, "Secondary" duty, is 86%. Logged duty is initially 215/255, or 84%. Boost then starts to oscillate and almost fall off, possibly because the stock twins may be running out of steam. Duty first oscillates and then settles at 225/255, or 88% .

So it seems that, after transition, the PFC wastegate control logic may only have authority to deviate within 2% of the target duty ("secondary" duty). The PC duty also seems to stay within a 2.5% range of the set "primary" duty.

In the OP's screen shot ^^ it appears that his wastegate duty is dropping to zero during transition, whereas this car I am tuning here drops from right near full open WG duty to approximately the target duty value .

#25

Shouldn't the Secondary setting be higher than the first one, if it is meant to control duty after transition?

Here's one thing I noticed though. Before transition, WG duty is effectively maxed out, meaning the wastegate flapper is being kept shut.

...

The wastegate goes from being effectively full open to a number right near the target duty cycle.

...

The wastegate goes from being effectively full open to a number right near the target duty cycle.