A little project I like to call Gloria (GL+RE+EA)

#1

its supposed to do that

Thread Starter

A little project I like to call Gloria (GL+RE+EA)

Having come to a point in my life where i have more motors than project cars, I have decided to move forward with a little something I have been dreaming up for ages. Gloria is an 83 Subaru Leone coupe, with GL trim, and an EA series drivetrain. As you can imagine, the whole thing is begging for a rotary engine (RE).

Glorious 80s digidash.

Everybody likes mouse crap

All Leone coupes came as fwd, but being no stranger to old subes, I had planned to swap it to 4wd, and use a kennedy engineering adapter plate I have acquired to run the rotary through the subaru trans. As time progressed and parts collected dust, I decided that 4wd wasn't going to cut it and I wanted another small lightweight RWD rotary.

As luck would have it an entire 1st gen legacy rear suspension showed up on craigslist for a paltry $20. Money exchanged hands and soon I had a plan, but where was I going to get an rx7 drivetrain? In hindsight I should have played the lottery that week, because I acquired a free '83 gsl in running condition that had been in a front end collision. I will be using the engine and tranny from the gsl for now, and upgrading in the future (bridgeport 12a )

)

Out with the old

In with the new

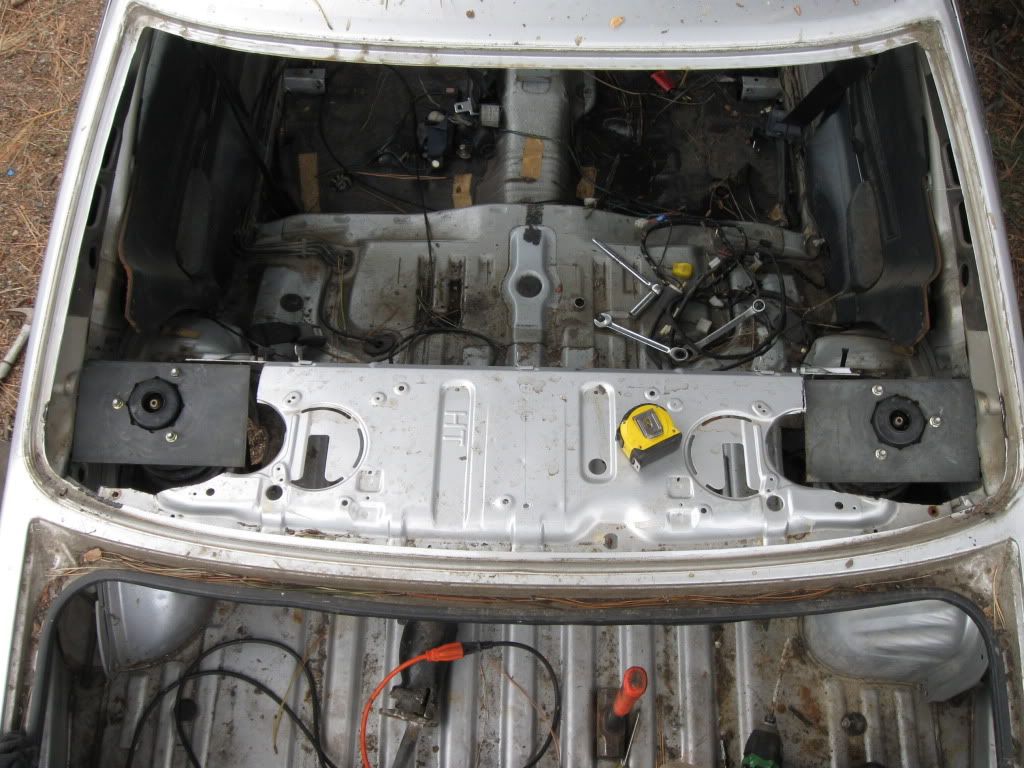

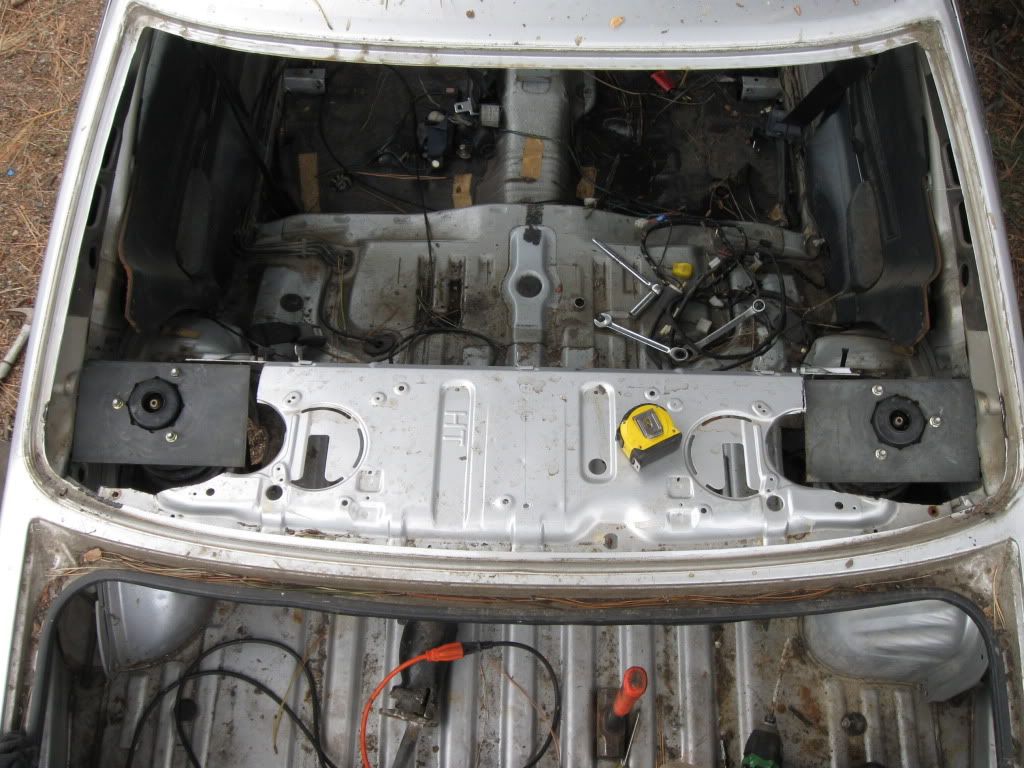

With a bit of cutting, welding, and fabrication the legacy rear end just about bolts in Once I mount the strut tops and fab the crossbraces I will be moving on to engine/tranny installation.

Once I mount the strut tops and fab the crossbraces I will be moving on to engine/tranny installation.

Glorious 80s digidash.

Everybody likes mouse crap

All Leone coupes came as fwd, but being no stranger to old subes, I had planned to swap it to 4wd, and use a kennedy engineering adapter plate I have acquired to run the rotary through the subaru trans. As time progressed and parts collected dust, I decided that 4wd wasn't going to cut it and I wanted another small lightweight RWD rotary.

As luck would have it an entire 1st gen legacy rear suspension showed up on craigslist for a paltry $20. Money exchanged hands and soon I had a plan, but where was I going to get an rx7 drivetrain? In hindsight I should have played the lottery that week, because I acquired a free '83 gsl in running condition that had been in a front end collision. I will be using the engine and tranny from the gsl for now, and upgrading in the future (bridgeport 12a

)

)Out with the old

In with the new

With a bit of cutting, welding, and fabrication the legacy rear end just about bolts in

Once I mount the strut tops and fab the crossbraces I will be moving on to engine/tranny installation.

Once I mount the strut tops and fab the crossbraces I will be moving on to engine/tranny installation.

#5

its supposed to do that

Thread Starter

Made some progress today

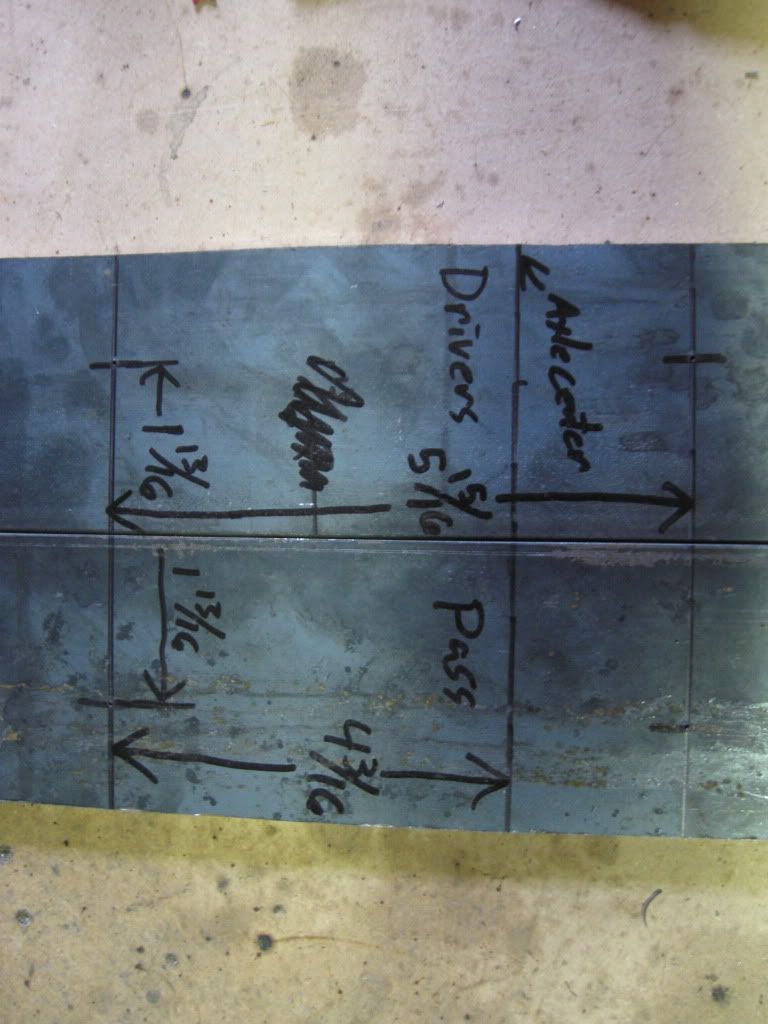

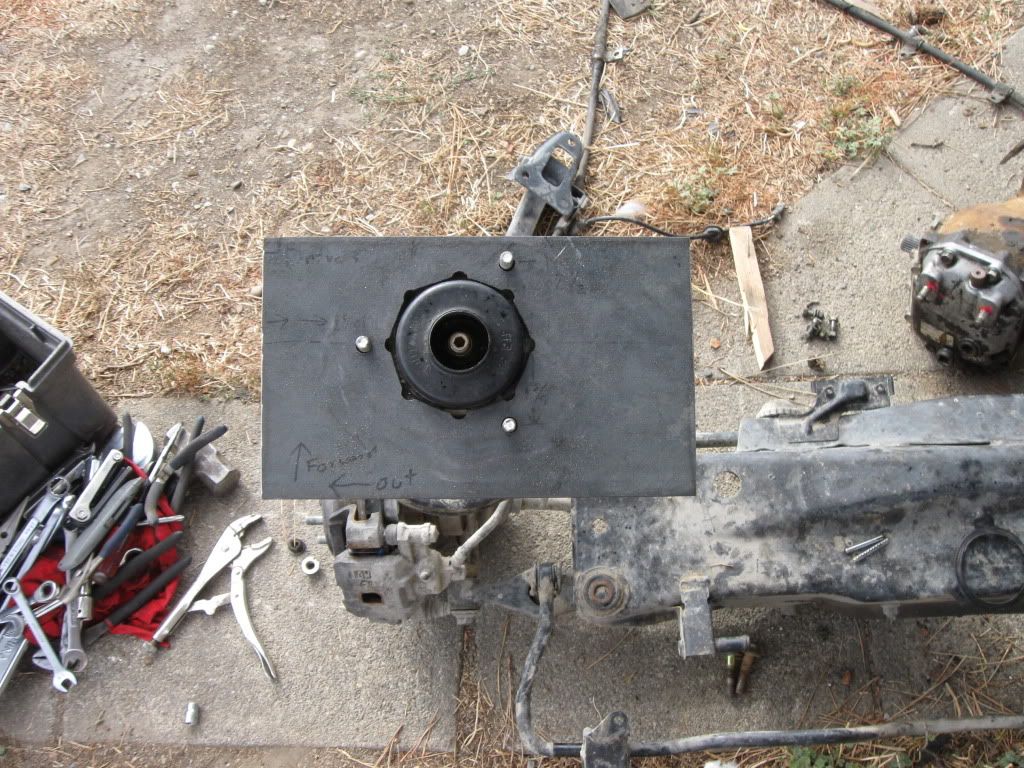

I originally planned to butt the strut top plates against the underside outer corner of the rear deck, because that is where I designed the strut top plates to index from, and then brace accordingly. Since this car is going to spend most of its life really low, and sideways, I decided to cut out part of the rear deck in order to gain an extra inch of vertical rise.

Once I had the struts in I threw a set of stock 15in legacy wheels on it to double check the fit, and my math.

Makes the stock 13in xt wheel on the front look pretty small

With a slight fender pull the legacy wheels will be the cats meow

Isaac

I originally planned to butt the strut top plates against the underside outer corner of the rear deck, because that is where I designed the strut top plates to index from, and then brace accordingly. Since this car is going to spend most of its life really low, and sideways, I decided to cut out part of the rear deck in order to gain an extra inch of vertical rise.

Once I had the struts in I threw a set of stock 15in legacy wheels on it to double check the fit, and my math.

Makes the stock 13in xt wheel on the front look pretty small

With a slight fender pull the legacy wheels will be the cats meow

Isaac

#7

its supposed to do that

Thread Starter

Thanks for the thoughts, that is why I'm posting this here

you guys are bound to think of something I haven't factored in.

you guys are bound to think of something I haven't factored in.Isaac

Trending Topics

#9

$ ain't everything, rite?

Join Date: Jun 2009

Location: CT

Posts: 461

Likes: 0

Received 0 Likes

on

0 Posts

Looks great. Nice project and should be a blast to drive. The strut plates look a bit thick for a clean match to the host car structure but if you are good at welding should be fine. Just watch them wheel wells through the complete suspension stroke, you don't want a tire rub after all them mods. Good luck with the build!!!!!!!!!!!!

#10

its supposed to do that

Thread Starter

Looks great. Nice project and should be a blast to drive. The strut plates look a bit thick for a clean match to the host car structure but if you are good at welding should be fine. Just watch them wheel wells through the complete suspension stroke, you don't want a tire rub after all them mods. Good luck with the build!!!!!!!!!!!!

The rear fenders are getting a bit of a pull, just to clear. The legacy rear end does not increase camber as it goes through its stroke, so what clearance I have will be minimal for a smooth look

Isaac

#12

its supposed to do that

Thread Starter

The wife is 7mo pregnant, and the kid has had a sinus infection so this update has taken a bit longer than usual. A lot of progress has been made, and I think I will let the pics do the talking

#15

its supposed to do that

Thread Starter

#18

its supposed to do that

Thread Starter

That is going to have to come out.

Its a shame really, car had AC/PS/Cruise.

Nice empty bay.

New and old, greeting each other in passing.

Isaac

Its a shame really, car had AC/PS/Cruise.

Nice empty bay.

New and old, greeting each other in passing.

Isaac

#19

1) There's a reason everyone uses round tubing. Square tubing is weak and susceptible to certain angles of attack(Anything but orthogonal). Round tubing doesn't care where the force comes from.

2) You should have tied your X bracing into the floor and not the upright side of the angle iron. What is preventing that angle iron from bending over when any lateral force exists? Nothing.

If you don't have the right tools to work with round tubing or don't know how to build a structurally sound cage then let a professional do it.

A for effort.

2) You should have tied your X bracing into the floor and not the upright side of the angle iron. What is preventing that angle iron from bending over when any lateral force exists? Nothing.

If you don't have the right tools to work with round tubing or don't know how to build a structurally sound cage then let a professional do it.

A for effort.

#20

its supposed to do that

Thread Starter

1) round tubing wasn't in the budget  I am into this project a grand total of $100 including the shell.

I am into this project a grand total of $100 including the shell.

2) Lateral forces do not exist in that plane(or do so minimally enough to make it moot), the hubs lateral forces are transferred into the rear lateral links to the rear subframe. The x brace is there to provide extra resistance to lift on the inside face of the strut top plate and/or transfer it to downward force onto the opposing frame rail.

It's not a cage, its a glorified stut tower bar with integrated strut tops.

B is for bracing

I am into this project a grand total of $100 including the shell.

I am into this project a grand total of $100 including the shell.2) Lateral forces do not exist in that plane(or do so minimally enough to make it moot), the hubs lateral forces are transferred into the rear lateral links to the rear subframe. The x brace is there to provide extra resistance to lift on the inside face of the strut top plate and/or transfer it to downward force onto the opposing frame rail.

It's not a cage, its a glorified stut tower bar with integrated strut tops.

B is for bracing

#23

2) Lateral forces do not exist in that plane(or do so minimally enough to make it moot), the hubs lateral forces are transferred into the rear lateral links to the rear subframe. The x brace is there to provide extra resistance to lift on the inside face of the strut top plate and/or transfer it to downward force onto the opposing frame rail.

#25

its supposed to do that

Thread Starter

. For the purpose it serves, I think the whole thing is overkill, but I would rather overkill than under braced.

. For the purpose it serves, I think the whole thing is overkill, but I would rather overkill than under braced.Isaac