cold solder

#1

Rotary Enthusiast

Thread Starter

iTrader: (14)

Join Date: Mar 2009

Location: the dalles

Posts: 1,161

Likes: 0

Received 0 Likes

on

0 Posts

cold solder

i know people have repaired these so really what im asking for is some sort of write up or something that will help me fix the cold solder joints in my idiot light cluster.

#4

Listener

Join Date: Sep 2006

Location: Springfield, Missouri

Posts: 163

Likes: 0

Received 0 Likes

on

0 Posts

Here's a good place to start. Google is your friend.

http://www.aaroncake.net/electronics/solder.htm

http://www.aaroncake.net/electronics/solder.htm

#6

I deal with electronics rework and manufacturing engineering procedures for my job.

The following applies to leaded solder only:

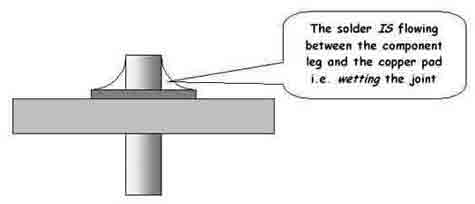

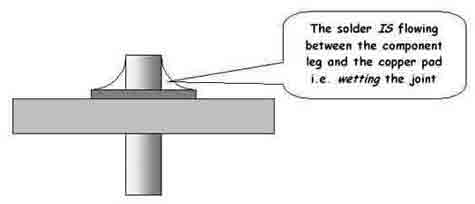

A cold solder joint will appear dull in color. There may also be pitting or improper wetting of the joint.

What has happened, is during soldering, the joint was not sufficiently heated, or there was a mechanical stress on it during cooling. This creates what is called a cold joint. Correctly soldered joints will be shiny silver in color.

This does not apply to lead-free solder. It is very hard to get a shiny joint by hand, without board heaters or a reflow process. The appearance of a dull joint with lead free solder does not indicate a poor connection.

This being said, the rx-7 will have used leaded solder. For rework on these boards, you will achieve best results if you use leaded solder. I would not recommend lead free.

To fix the poor solder joints, clean the soldered area and pad with a high purity Isopropyl alcohol, or electronics flux cleaner. I would then apply a drop of liquid electronics flux (Alpha Chemicals makes some nice stuff). Apply heat to the joint with a good quality electronics soldering iron. For the price, I actually am partial to this guy: http://bernzomatic.com/PRODUCTS/TORC...3/Default.aspx (Walmart carries them for $10).

Reheat the solder joint and apply more solder if necessary. You won't need to add much if any. A good solder joint should look like the picture below with a sort of volcano shape. Blobby solder joints are the result of too much solder.

The following applies to leaded solder only:

A cold solder joint will appear dull in color. There may also be pitting or improper wetting of the joint.

What has happened, is during soldering, the joint was not sufficiently heated, or there was a mechanical stress on it during cooling. This creates what is called a cold joint. Correctly soldered joints will be shiny silver in color.

This does not apply to lead-free solder. It is very hard to get a shiny joint by hand, without board heaters or a reflow process. The appearance of a dull joint with lead free solder does not indicate a poor connection.

This being said, the rx-7 will have used leaded solder. For rework on these boards, you will achieve best results if you use leaded solder. I would not recommend lead free.

To fix the poor solder joints, clean the soldered area and pad with a high purity Isopropyl alcohol, or electronics flux cleaner. I would then apply a drop of liquid electronics flux (Alpha Chemicals makes some nice stuff). Apply heat to the joint with a good quality electronics soldering iron. For the price, I actually am partial to this guy: http://bernzomatic.com/PRODUCTS/TORC...3/Default.aspx (Walmart carries them for $10).

Reheat the solder joint and apply more solder if necessary. You won't need to add much if any. A good solder joint should look like the picture below with a sort of volcano shape. Blobby solder joints are the result of too much solder.

Thread

Thread Starter

Forum

Replies

Last Post

frosty1993

General Rotary Tech Support

3

09-30-15 01:27 PM