Megasquirt Upgrading Firmware

#1

RX-7 Alumni

Thread Starter

Upgrading Firmware

Thought it would be a good idea to have a discussion area for those needing help with the firmware upgrade, me being the first. Hopefully this discussion will reduce some of the problem traffic that we would normally see.

FYI: The best instructions I've found thus far are located here: http://megasquirt.sourceforge.net/extra/setup.html

Right now I have my Megatune successfully upgraded from version b514 to b717 working with the 024S12 firmware.

I've copied the 026i_mod msns-extra.ini file to my new project area. I haven't loaded the firmware yet--as I think it's best to get MT working completely first. When I open Megatune with my latest msq file, I get the alot of warnings. Here's the warnings I get from the audit.log file:

*********Start of audit.log warnings **********

C:/Program Files/MegaSquirt/RX7_b717_026i/megasquirt200512261807.msq:Open

WARNING(01): Signatures don't match.

Found in msq "MSnS-extra format 024s *********"

Expected from ini "MSnS-extra format 026_mod ******"

WARNING(03): Value from option list "AccelMapASE" = "Normal" not found.

WARNING(04): Constant "IgAdvDeg" units mismatch, "°F" in msq, expected "F" from ini.

WARNING(04): Constant "IgAdvTemp" units mismatch, "°F" in msq, expected "F" from ini.

WARNING(04): Constant "IgRetDeg" units mismatch, "°F" in msq, expected "F" from ini.

WARNING(04): Constant "IgRetTemp" units mismatch, "°F" in msq, expected "F" from ini.

WARNING(04): Constant "idle_dc_lo" units mismatch, "dc%" in msq, expected "Freq" from ini.

WARNING(04): Constant "idledashdc" units mismatch, "dc%" in msq, expected "Freq" from ini.

WARNING(04): Constant "idlekickdc" units mismatch, "dc%" in msq, expected "Freq" from ini.

WARNING(04): Constant "idlemindc" units mismatch, "dc%" in msq, expected "Freq" from ini.

WARNING(04): Constant "idleperiod" units mismatch, "ticks" in msq, expected "Ignition Events" from ini.

WARNING(06): Constant named "AFMUse" remains unaltered.

WARNING(06): Constant named "AirCorAFM" remains unaltered.

WARNING(06): Constant named "ConsBarCor" remains unaltered.

WARNING(06): Constant named "ExFuelCrank" remains unaltered.

WARNING(06): Constant named "ExtraFMult" remains unaltered.

WARNING(06): Constant named "IATCTemp1" remains unaltered.

WARNING(06): Constant named "IATCTemp2" remains unaltered.

WARNING(06): Constant named "IATCTemp3" remains unaltered.

WARNING(06): Constant named "IATCTemp4" remains unaltered.

WARNING(06): Constant named "IATCTemp5" remains unaltered.

WARNING(06): Constant named "IATCTemp6" remains unaltered.

WARNING(06): Constant named "IATCTemp7" remains unaltered.

WARNING(06): Constant named "IATCor" remains unaltered.

WARNING(06): Constant named "IATCor1" remains unaltered.

WARNING(06): Constant named "IATCor2" remains unaltered.

WARNING(06): Constant named "IATCor3" remains unaltered.

WARNING(06): Constant named "IATCor4" remains unaltered.

WARNING(06): Constant named "IATCor5" remains unaltered.

WARNING(06): Constant named "IATCor6" remains unaltered.

WARNING(06): Constant named "IATCor7" remains unaltered.

WARNING(06): Constant named "IATCorTy" remains unaltered.

WARNING(06): Constant named "IdleAdv" remains unaltered.

WARNING(06): Constant named "IdleAdvCLT" remains unaltered.

WARNING(06): Constant named "IdleAdvRPM" remains unaltered.

WARNING(06): Constant named "IdleAdvTPS" remains unaltered.

WARNING(06): Constant named "IdleDelayTime" remains unaltered.

WARNING(06): Constant named "LC_f_limangle" remains unaltered.

WARNING(06): Constant named "LC_f_slim" remains unaltered.

WARNING(06): Constant named "LC_flatlim" remains unaltered.

WARNING(06): Constant named "LC_flatsel" remains unaltered.

WARNING(06): Constant named "N2Odel_flat" remains unaltered.

WARNING(06): Constant named "N2Odel_launch" remains unaltered.

WARNING(06): Constant named "N2Oholdon" remains unaltered.

WARNING(06): Constant named "Nos2Angle" remains unaltered.

WARNING(06): Constant named "Nos2PWHi" remains unaltered.

WARNING(06): Constant named "Nos2PWLo" remains unaltered.

WARNING(06): Constant named "Nos2Rpm" remains unaltered.

WARNING(06): Constant named "Nos2RpmMax" remains unaltered.

WARNING(06): Constant named "Nos2delay" remains unaltered.

WARNING(06): Constant named "RPMAE1" remains unaltered.

WARNING(06): Constant named "RPMAE2" remains unaltered.

WARNING(06): Constant named "RPMAE3" remains unaltered.

WARNING(06): Constant named "RPMAE4" remains unaltered.

WARNING(06): Constant named "RPMBAsedAE" remains unaltered.

WARNING(06): Constant named "RPMRedHi" remains unaltered.

WARNING(06): Constant named "RPMRedLo" remains unaltered.

WARNING(06): Constant named "RPMmS1" remains unaltered.

WARNING(06): Constant named "RPMmS2" remains unaltered.

WARNING(06): Constant named "RPMmS3" remains unaltered.

WARNING(06): Constant named "RPMmS4" remains unaltered.

WARNING(06): Constant named "StgCycles" remains unaltered.

WARNING(06): Constant named "delay2rpm" remains unaltered.

WARNING(06): Constant named "hrd_disable" remains unaltered.

WARNING(06): Constant named "idlePeriod2" remains unaltered.

WARNING(06): Constant named "idle_dc_hi" remains unaltered.

WARNING(06): Constant named "idleclosed" remains unaltered.

WARNING(06): Constant named "idlefreq" remains unaltered.

WARNING(06): Constant named "idlekpaval1" remains unaltered.

WARNING(06): Constant named "idlekpaval2" remains unaltered.

WARNING(06): Constant named "ikpamin1" remains unaltered.

WARNING(06): Constant named "ikpamin2" remains unaltered.

WARNING(06): Constant named "irestorerpm" remains unaltered.

WARNING(06): Constant named "n2ostage2" remains unaltered.

WARNING(06): Constant named "oddfire" remains unaltered.

WARNING(06): Constant named "outaoffs" remains unaltered.

WARNING(06): Constant named "outaoffv" remains unaltered.

WARNING(06): Constant named "outboffs" remains unaltered.

WARNING(06): Constant named "outboffv" remains unaltered.

WARNING(06): Constant named "outcoffs" remains unaltered.

WARNING(06): Constant named "outcoffv" remains unaltered.

WARNING(06): Constant named "outdoffs" remains unaltered.

WARNING(06): Constant named "outdoffv" remains unaltered.

WARNING(06): Constant named "rotaryFDign" remains unaltered.

WARNING(06): Constant named "tachconf" remains unaltered.

WARNING(06): Constant named "tachconfdiv" remains unaltered.

WARNING(06): Constant named "wheel_old" remains unaltered.

Warning Details

---------------

WARNING(01) means that the file you read was not written from the

configuration that you are currently using. If the

two configurations were similar, you should see few

warnings and most settings will carry over successfully.

If they were quite different, you may have lots of

problems getting things to work, but you need to make

the judgement call on this by examining the other

warnings above.

WARNING(03) means that the value expressed in the file for the

constant was not found one of the options listed in the

current configuration. The constant was not altered, so

you probably want to look more closely at this one and

see what caused the mismatch.

WARNING(04) means that you have different units set in the msq and

your current configuration. This almost always means

that the value of the constant is incorrect and you must

manually correct the situation. The easiest way might

be to reset your configuration's settings, say from

Celsius to Fahrenheit, then re-reading the msq.

WARNING(06) means that the constant found in the current configuration

was not found in the file, and thus has not been altered by

the file read. Make sure that the value of the constant

makes sense in the context of the other changes.

*********End of audit.log warnings **********

I'm thinking I can go into the msq file (since it's xml based) and fix most of these warnings. I understand using b717 with the older 026 based firmware is a bit of a leap, but the MT b717 has alot of good improvements that are desired. Once we get thru these little issues it will be great. I'll be sure to post any solution when I find one.

Scott

FYI: The best instructions I've found thus far are located here: http://megasquirt.sourceforge.net/extra/setup.html

Right now I have my Megatune successfully upgraded from version b514 to b717 working with the 024S12 firmware.

I've copied the 026i_mod msns-extra.ini file to my new project area. I haven't loaded the firmware yet--as I think it's best to get MT working completely first. When I open Megatune with my latest msq file, I get the alot of warnings. Here's the warnings I get from the audit.log file:

*********Start of audit.log warnings **********

C:/Program Files/MegaSquirt/RX7_b717_026i/megasquirt200512261807.msq:Open

WARNING(01): Signatures don't match.

Found in msq "MSnS-extra format 024s *********"

Expected from ini "MSnS-extra format 026_mod ******"

WARNING(03): Value from option list "AccelMapASE" = "Normal" not found.

WARNING(04): Constant "IgAdvDeg" units mismatch, "°F" in msq, expected "F" from ini.

WARNING(04): Constant "IgAdvTemp" units mismatch, "°F" in msq, expected "F" from ini.

WARNING(04): Constant "IgRetDeg" units mismatch, "°F" in msq, expected "F" from ini.

WARNING(04): Constant "IgRetTemp" units mismatch, "°F" in msq, expected "F" from ini.

WARNING(04): Constant "idle_dc_lo" units mismatch, "dc%" in msq, expected "Freq" from ini.

WARNING(04): Constant "idledashdc" units mismatch, "dc%" in msq, expected "Freq" from ini.

WARNING(04): Constant "idlekickdc" units mismatch, "dc%" in msq, expected "Freq" from ini.

WARNING(04): Constant "idlemindc" units mismatch, "dc%" in msq, expected "Freq" from ini.

WARNING(04): Constant "idleperiod" units mismatch, "ticks" in msq, expected "Ignition Events" from ini.

WARNING(06): Constant named "AFMUse" remains unaltered.

WARNING(06): Constant named "AirCorAFM" remains unaltered.

WARNING(06): Constant named "ConsBarCor" remains unaltered.

WARNING(06): Constant named "ExFuelCrank" remains unaltered.

WARNING(06): Constant named "ExtraFMult" remains unaltered.

WARNING(06): Constant named "IATCTemp1" remains unaltered.

WARNING(06): Constant named "IATCTemp2" remains unaltered.

WARNING(06): Constant named "IATCTemp3" remains unaltered.

WARNING(06): Constant named "IATCTemp4" remains unaltered.

WARNING(06): Constant named "IATCTemp5" remains unaltered.

WARNING(06): Constant named "IATCTemp6" remains unaltered.

WARNING(06): Constant named "IATCTemp7" remains unaltered.

WARNING(06): Constant named "IATCor" remains unaltered.

WARNING(06): Constant named "IATCor1" remains unaltered.

WARNING(06): Constant named "IATCor2" remains unaltered.

WARNING(06): Constant named "IATCor3" remains unaltered.

WARNING(06): Constant named "IATCor4" remains unaltered.

WARNING(06): Constant named "IATCor5" remains unaltered.

WARNING(06): Constant named "IATCor6" remains unaltered.

WARNING(06): Constant named "IATCor7" remains unaltered.

WARNING(06): Constant named "IATCorTy" remains unaltered.

WARNING(06): Constant named "IdleAdv" remains unaltered.

WARNING(06): Constant named "IdleAdvCLT" remains unaltered.

WARNING(06): Constant named "IdleAdvRPM" remains unaltered.

WARNING(06): Constant named "IdleAdvTPS" remains unaltered.

WARNING(06): Constant named "IdleDelayTime" remains unaltered.

WARNING(06): Constant named "LC_f_limangle" remains unaltered.

WARNING(06): Constant named "LC_f_slim" remains unaltered.

WARNING(06): Constant named "LC_flatlim" remains unaltered.

WARNING(06): Constant named "LC_flatsel" remains unaltered.

WARNING(06): Constant named "N2Odel_flat" remains unaltered.

WARNING(06): Constant named "N2Odel_launch" remains unaltered.

WARNING(06): Constant named "N2Oholdon" remains unaltered.

WARNING(06): Constant named "Nos2Angle" remains unaltered.

WARNING(06): Constant named "Nos2PWHi" remains unaltered.

WARNING(06): Constant named "Nos2PWLo" remains unaltered.

WARNING(06): Constant named "Nos2Rpm" remains unaltered.

WARNING(06): Constant named "Nos2RpmMax" remains unaltered.

WARNING(06): Constant named "Nos2delay" remains unaltered.

WARNING(06): Constant named "RPMAE1" remains unaltered.

WARNING(06): Constant named "RPMAE2" remains unaltered.

WARNING(06): Constant named "RPMAE3" remains unaltered.

WARNING(06): Constant named "RPMAE4" remains unaltered.

WARNING(06): Constant named "RPMBAsedAE" remains unaltered.

WARNING(06): Constant named "RPMRedHi" remains unaltered.

WARNING(06): Constant named "RPMRedLo" remains unaltered.

WARNING(06): Constant named "RPMmS1" remains unaltered.

WARNING(06): Constant named "RPMmS2" remains unaltered.

WARNING(06): Constant named "RPMmS3" remains unaltered.

WARNING(06): Constant named "RPMmS4" remains unaltered.

WARNING(06): Constant named "StgCycles" remains unaltered.

WARNING(06): Constant named "delay2rpm" remains unaltered.

WARNING(06): Constant named "hrd_disable" remains unaltered.

WARNING(06): Constant named "idlePeriod2" remains unaltered.

WARNING(06): Constant named "idle_dc_hi" remains unaltered.

WARNING(06): Constant named "idleclosed" remains unaltered.

WARNING(06): Constant named "idlefreq" remains unaltered.

WARNING(06): Constant named "idlekpaval1" remains unaltered.

WARNING(06): Constant named "idlekpaval2" remains unaltered.

WARNING(06): Constant named "ikpamin1" remains unaltered.

WARNING(06): Constant named "ikpamin2" remains unaltered.

WARNING(06): Constant named "irestorerpm" remains unaltered.

WARNING(06): Constant named "n2ostage2" remains unaltered.

WARNING(06): Constant named "oddfire" remains unaltered.

WARNING(06): Constant named "outaoffs" remains unaltered.

WARNING(06): Constant named "outaoffv" remains unaltered.

WARNING(06): Constant named "outboffs" remains unaltered.

WARNING(06): Constant named "outboffv" remains unaltered.

WARNING(06): Constant named "outcoffs" remains unaltered.

WARNING(06): Constant named "outcoffv" remains unaltered.

WARNING(06): Constant named "outdoffs" remains unaltered.

WARNING(06): Constant named "outdoffv" remains unaltered.

WARNING(06): Constant named "rotaryFDign" remains unaltered.

WARNING(06): Constant named "tachconf" remains unaltered.

WARNING(06): Constant named "tachconfdiv" remains unaltered.

WARNING(06): Constant named "wheel_old" remains unaltered.

Warning Details

---------------

WARNING(01) means that the file you read was not written from the

configuration that you are currently using. If the

two configurations were similar, you should see few

warnings and most settings will carry over successfully.

If they were quite different, you may have lots of

problems getting things to work, but you need to make

the judgement call on this by examining the other

warnings above.

WARNING(03) means that the value expressed in the file for the

constant was not found one of the options listed in the

current configuration. The constant was not altered, so

you probably want to look more closely at this one and

see what caused the mismatch.

WARNING(04) means that you have different units set in the msq and

your current configuration. This almost always means

that the value of the constant is incorrect and you must

manually correct the situation. The easiest way might

be to reset your configuration's settings, say from

Celsius to Fahrenheit, then re-reading the msq.

WARNING(06) means that the constant found in the current configuration

was not found in the file, and thus has not been altered by

the file read. Make sure that the value of the constant

makes sense in the context of the other changes.

*********End of audit.log warnings **********

I'm thinking I can go into the msq file (since it's xml based) and fix most of these warnings. I understand using b717 with the older 026 based firmware is a bit of a leap, but the MT b717 has alot of good improvements that are desired. Once we get thru these little issues it will be great. I'll be sure to post any solution when I find one.

Scott

#2

MegaSquirt Mod

Most likely, all you need to do is save a new xml using the new msns-extra.ini, and you'll be all set.... it's not necessary to "fix" anything. Just make sure your settings are all correct and that's all you have to do. It's not at all a big deal. It'll only become a big deal when upgrading to 028 and higher, as in 028, almost the entire flash was rearranged if I understand it correctly. That's where having your settings saved using the xml format becomes a really big benefit, as there are no longer any assumptions from the config file about the exact locations of various settings in the flash... the msns-extra.ini along with the xml format take care of that for you.

I'd recommend just giving it a go, saving a backup copy of your settings before you do it. Load the new firmware, load all your old settings, and then go through the settings one menu and one option at a time making sure they're all OK. It takes me about 10 minutes to go through and check everything after that kind of upgrade. The new megatune with the xml format will just make it significantly easier to do without any chance of corruption.

EDIT: This was my 1000th post

I'd recommend just giving it a go, saving a backup copy of your settings before you do it. Load the new firmware, load all your old settings, and then go through the settings one menu and one option at a time making sure they're all OK. It takes me about 10 minutes to go through and check everything after that kind of upgrade. The new megatune with the xml format will just make it significantly easier to do without any chance of corruption.

EDIT: This was my 1000th post

#3

RX-7 Alumni

Thread Starter

Originally Posted by muythaibxr

Most likely, all you need to do is save a new xml using the new msns-extra.ini, and you'll be all set....

#4

MegaSquirt Mod

I mean the one from whichever firmware you're upgrading to, so in this case, 026i_mod

It really shouldn't make a big difference what megatune you're using... as all it does is read the msns-extra.ini file, and use that to determine the format of what it needs to send to the MS.

Also, supposedly (I haven't confirmed yet) James (The guy who wrote and maintains the msns-extra firmware) said that he fixed some of the wheel decoder issues I was having with 027+, so once I've confirmed it for sure on my bench and in the car, I'll post here.

Last, tofuball and I tested the transition code, and it worked beautifully, but you still have to set the transition point to somewhere that there will be a decent amount of airflow over the secondaries... It gets rid of the problem altogether at higher engine load though (on an NA this means above 50-60 kPa). This proves to me that adding the secondary transition point with the and/or logic will finish fixing this problem. But yeah, the transition code definitely smooths out the transition above 50-60 kPa...

It really shouldn't make a big difference what megatune you're using... as all it does is read the msns-extra.ini file, and use that to determine the format of what it needs to send to the MS.

Also, supposedly (I haven't confirmed yet) James (The guy who wrote and maintains the msns-extra firmware) said that he fixed some of the wheel decoder issues I was having with 027+, so once I've confirmed it for sure on my bench and in the car, I'll post here.

Last, tofuball and I tested the transition code, and it worked beautifully, but you still have to set the transition point to somewhere that there will be a decent amount of airflow over the secondaries... It gets rid of the problem altogether at higher engine load though (on an NA this means above 50-60 kPa). This proves to me that adding the secondary transition point with the and/or logic will finish fixing this problem. But yeah, the transition code definitely smooths out the transition above 50-60 kPa...

#5

RX-7 Alumni

Thread Starter

Originally Posted by muythaibxr

I mean the one from whichever firmware you're upgrading to, so in this case, 026i_mod

It really shouldn't make a big difference what megatune you're using... as all it does is read the msns-extra.ini file, and use that to determine the format of what it needs to send to the MS.

Also, supposedly (I haven't confirmed yet) James (The guy who wrote and maintains the msns-extra firmware) said that he fixed some of the wheel decoder issues I was having with 027+, so once I've confirmed it for sure on my bench and in the car, I'll post here.

Last, tofuball and I tested the transition code, and it worked beautifully, but you still have to set the transition point to somewhere that there will be a decent amount of airflow over the secondaries... It gets rid of the problem altogether at higher engine load though (on an NA this means above 50-60 kPa). This proves to me that adding the secondary transition point with the and/or logic will finish fixing this problem. But yeah, the transition code definitely smooths out the transition above 50-60 kPa...

It really shouldn't make a big difference what megatune you're using... as all it does is read the msns-extra.ini file, and use that to determine the format of what it needs to send to the MS.

Also, supposedly (I haven't confirmed yet) James (The guy who wrote and maintains the msns-extra firmware) said that he fixed some of the wheel decoder issues I was having with 027+, so once I've confirmed it for sure on my bench and in the car, I'll post here.

Last, tofuball and I tested the transition code, and it worked beautifully, but you still have to set the transition point to somewhere that there will be a decent amount of airflow over the secondaries... It gets rid of the problem altogether at higher engine load though (on an NA this means above 50-60 kPa). This proves to me that adding the secondary transition point with the and/or logic will finish fixing this problem. But yeah, the transition code definitely smooths out the transition above 50-60 kPa...

Hopefully I'll have it running soon.

Thanks again,

Scott

#6

RX-7 Alumni

Thread Starter

Well Ken I'm still getting some errors in pop-up windows--all within the 026i_mod msns-extra.ini file.

I've been able to fix up the file so no errors appear. Here's a summary of the changes:

1) Comment out all 4 occurances of allowAutoTune.

2) Comment out gridOrient

3) For each of the following parameters, add squirrelly brackets {} around the parameter value: Cd, Mass, Crr, Radius, GrTms, DiffRa.

4) Add "#unset TestCode" ahead of the if block using TestCode

So after making those changes to the msns-extra.ini file and saving a new msq file I get no more errors or warnings.

Surely you'll let me know if I really screwed up on those changes.

Now I can try and install the firmware--woohoo!

Scott

I've been able to fix up the file so no errors appear. Here's a summary of the changes:

1) Comment out all 4 occurances of allowAutoTune.

2) Comment out gridOrient

3) For each of the following parameters, add squirrelly brackets {} around the parameter value: Cd, Mass, Crr, Radius, GrTms, DiffRa.

4) Add "#unset TestCode" ahead of the if block using TestCode

So after making those changes to the msns-extra.ini file and saving a new msq file I get no more errors or warnings.

Surely you'll let me know if I really screwed up on those changes.

Now I can try and install the firmware--woohoo!

Scott

#7

MegaSquirt Mod

Those changes all seem harmless... It's interesting that you had to change them but still pretty harmless.

Have fun with that firmware. Hopefully in the next few days I'll have time to add the second parameter for staging. I'm also thinking about hacking around with the closed-loop code so you can turn off closed loop below a certain MAP point as well as above a certain MAP point... I've found that when running lean at low load the engine likes to oscillate a bit when in closed-loop, so I want to get rid of that problem.

Have fun with that firmware. Hopefully in the next few days I'll have time to add the second parameter for staging. I'm also thinking about hacking around with the closed-loop code so you can turn off closed loop below a certain MAP point as well as above a certain MAP point... I've found that when running lean at low load the engine likes to oscillate a bit when in closed-loop, so I want to get rid of that problem.

Trending Topics

#8

RX-7 Alumni

Thread Starter

Upgrade Complete!

OK, I'm good to go with the staged injection. No problems loading the firmware.

First I used the download.bat followed by Easytherm since I'm still sharing sensors with the ECU.

Just for future reference, could I have skipped the download.bat and just gone straight to Easytherm, since it just downloads a new .s19 file?

The hesitation issue has been reduced but it is still shown in the datalogs--but only when gradually increasing the throttle. I think this comes back to the airflow in the secondaries issue. The MAP/RPM based transition point should finish it off I think. The best thing is under acceleration and heavy boost, the lean spike is no longer there.

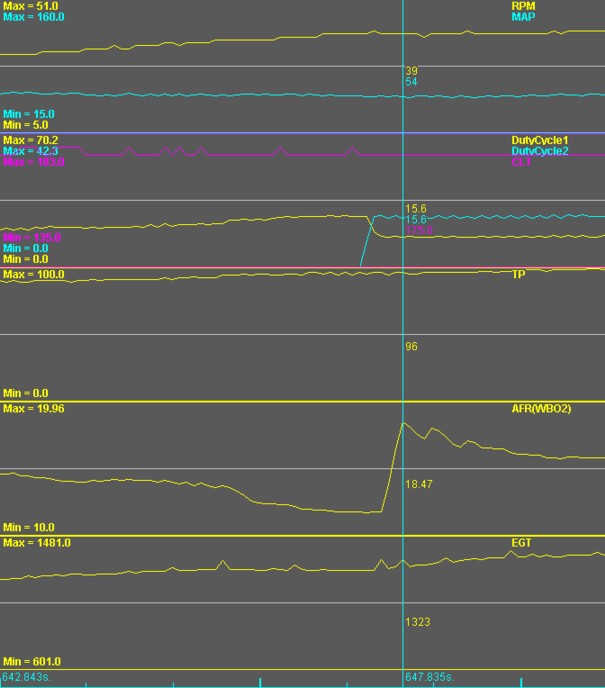

Here's a sample log of the staged transition code working real good under boost--notice there is no big spike in the AFR during transition:

Thanks again Ken for all you've done. Tomorrow I'm going camping so I'll be offline till Sat/Sun.

Scott

p.s. Also noticed lots of other goodies in the build--woohoo!

First I used the download.bat followed by Easytherm since I'm still sharing sensors with the ECU.

Just for future reference, could I have skipped the download.bat and just gone straight to Easytherm, since it just downloads a new .s19 file?

The hesitation issue has been reduced but it is still shown in the datalogs--but only when gradually increasing the throttle. I think this comes back to the airflow in the secondaries issue. The MAP/RPM based transition point should finish it off I think. The best thing is under acceleration and heavy boost, the lean spike is no longer there.

Here's a sample log of the staged transition code working real good under boost--notice there is no big spike in the AFR during transition:

Thanks again Ken for all you've done. Tomorrow I'm going camping so I'll be offline till Sat/Sun.

Scott

p.s. Also noticed lots of other goodies in the build--woohoo!

#9

RX-7 Alumni

Thread Starter

A Bad Transition

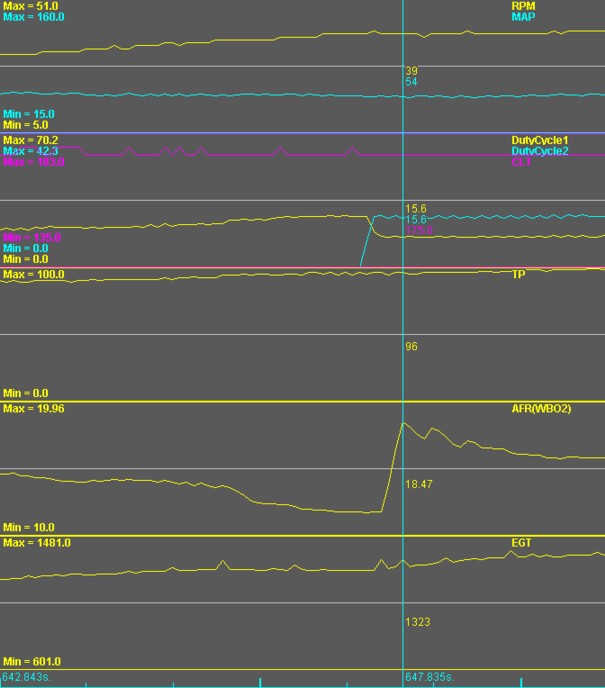

Just for reference, thought it would be good to post a sample of a bad transition. Notice I'm just barely increasing the throttle as the engine goes thru the transition point. In this case, I think the transition is happening way too early (even though it's at the 4k trigger point) and there is not enough airflow in the secondaries to get the fuel into the rotor chambers on-time. The MAP/RPM based transition point should fix this last issue.

#10

MegaSquirt Mod

yeah, I've noticed that you have to be around 60 kPa for the staging to not have a stutter or a lean spot. but that number used to be around 80 without the transition code for me at least... and like you said, it'll really help people when they're on boost to keep them from having some nasty lean spikes. I'll try to get to writing the remainder of the code on thu, as tomorrow is my girlfriend's birthday, so I won't have time for coding.

One thing that'd be useful though is if you graphed pulse-widths instead of duty-cycles...

One thing that'd be useful though is if you graphed pulse-widths instead of duty-cycles...

#11

MegaSquirt Mod

I just finished the 2nd parameter (MAP only at this point) code.

Basically I made it so you can set whether you're using a second parameter or not, whether both the first parameter and second parameter need to be met, or just one of them need to be met... and you can set the MAP and delta....

So if both need to be met, you can box in an area of your map and say that you have to be above both the RPM and KPA values, and if only one needs to be met, you can say either above this KPA, or above this RPM, engage staging...

I still have to test it on the bench before I'll post anything though... at this point I've only made sure it assembles properly, and made sure that the msns-extra.ini that I created is read and used properly by megatune.

EDIT:

I just tested my new code, and it works great. It does exactly what I want it to.

However, 029a (the version of the code I modified) still has the rpm spike problem at 4000 rpms... so I may consider adding this feature to my 026i_mod in the meantime.

Basically I made it so you can set whether you're using a second parameter or not, whether both the first parameter and second parameter need to be met, or just one of them need to be met... and you can set the MAP and delta....

So if both need to be met, you can box in an area of your map and say that you have to be above both the RPM and KPA values, and if only one needs to be met, you can say either above this KPA, or above this RPM, engage staging...

I still have to test it on the bench before I'll post anything though... at this point I've only made sure it assembles properly, and made sure that the msns-extra.ini that I created is read and used properly by megatune.

EDIT:

I just tested my new code, and it works great. It does exactly what I want it to.

However, 029a (the version of the code I modified) still has the rpm spike problem at 4000 rpms... so I may consider adding this feature to my 026i_mod in the meantime.

Last edited by muythaibxr; 01-11-06 at 09:00 PM.

#12

Senior Member

Join Date: Oct 2005

Location: High Point North carolina

Posts: 417

Likes: 0

Received 0 Likes

on

0 Posts

Rex do you still have your MS hooked up piggyback style? Im getting the same errors you had and will try the same fix. Also is your aeromotive fuel reg a rising rate unit? If it is I think its the same as mine. Im also wondering what base fuel pressure your using? Im at 43 psi as of now. When your completely using MS that Rtek ecu will fetch around 150.00 or more on ebay. Thanks and hope you have spark working,Shawn

#13

RX-7 Alumni

Thread Starter

Originally Posted by custom13B

Rex do you still have your MS hooked up piggyback style? Im getting the same errors you had and will try the same fix. Also is your aeromotive fuel reg a rising rate unit? If it is I think its the same as mine. Im also wondering what base fuel pressure your using? Im at 43 psi as of now. When your completely using MS that Rtek ecu will fetch around 150.00 or more on ebay. Thanks and hope you have spark working,Shawn

The FPR is a 1:1 unit, no need for a rising rate--MS can do that part.

I'm using 45 psi to get a little more top end out of the injectors. They are generally rated at 43.5 psi so I saw no harm going up a little.

Maybe some day I'll sell it but the way I'm doing it I could switch back to the Rtek in about 10 minutes. Once I get more time and experience with the MS I'll consider it.

Scott

#14

I wish I was driving!

Originally Posted by custom13B

Also is your aeromotive fuel reg a rising rate unit?

All of their FPR's increase fuel pressure at a 1:1 ratio to boost pressure.

This is not rising rate; all FPR's do this.

Even by definition of the term, rising fuel pressure alone would not dictate rising rate.

The rate at which fuel is referenced to would have to rise... so, say, an 8 psi fuel rise for every psi of boost.

Ignore what any google search will tell you. Reference to boost at 1:1 is NOT rising rate.

The reason all FPR's do this is to maintain a constant pressure differential between the injectors and the manifold.

If you had 40 psi of fuel pressure, and 40 psi of boost, you would get no fuel into your engine: there would be just as much pressure in the manifold pushing the fuel back into the rails.

At 20 psi of boost, your rail pressures would be 60 psi. Differential of 40 psi.

at 40 psi of boost, rail pressures would be 80 psi. Fuel pressure always goes up at a 1:1 ratio.

That's one of the reasons why a true RRFPR sucks. If you jack up the pressure above this differential, atomization severely suffers. Say, with an 8:1 RRFPR, at 10 psi, you'd be at 120 psi of rail pressure. That's TWICE the intended pressure differential. The fuel would literally coat the intake track rather than atomize. Very bad.

#15

Senior Member

Join Date: Oct 2005

Location: High Point North carolina

Posts: 417

Likes: 0

Received 0 Likes

on

0 Posts

Scott,

Im at 43 psi at the moment with 4-720cc injectors,so I expect it to be a while before I run out of duty cycle. My aeromotive regulator is aslo 1:1 and its a rising rate style. I do have a vacuume/boost line going to it at the moment. I havnt given it much thought since my car has yet to leave the garage. I finally got it running and idling tonight with the new 717 MT and 026i firmware. The spark map seems to be pretty close for a turbo application. I have revved the engine and it revves freely and hit around 5 psi boost with no detonation. I can hit boost without moving with my weird turbo kit. Im just making small VE changes and watching it respond for now. Im still working on a few small issues before I attempt a relaxed drive and datalog. I also have water injection so that may be helping me avoid detonation as well. At 4 psi boost the H20 pump kicks on. I kick it on purposely to help steam clean the plugs on occasion. I was dead in the water for a while with MS issues so I made a new center dash console out of alluminum. I also had to add a electric oil scavenging pump to my turbo because its mounted so low. The oil would not drain back and pooled inside the turbo and seeped past the seals into the intake and exhaust. What a mess that made! A restrictor was also needed to reduce oil flow. Did you have any of these issues? My wideband isnt responding properly and I think its because it got oil soaked from the turbo issue. Im going to attempt to clean it and do a new free air calibration. Cant hurt it isnt working properly anyways. Anyways car looks great almost exactly like mine! Shawn

Im at 43 psi at the moment with 4-720cc injectors,so I expect it to be a while before I run out of duty cycle. My aeromotive regulator is aslo 1:1 and its a rising rate style. I do have a vacuume/boost line going to it at the moment. I havnt given it much thought since my car has yet to leave the garage. I finally got it running and idling tonight with the new 717 MT and 026i firmware. The spark map seems to be pretty close for a turbo application. I have revved the engine and it revves freely and hit around 5 psi boost with no detonation. I can hit boost without moving with my weird turbo kit. Im just making small VE changes and watching it respond for now. Im still working on a few small issues before I attempt a relaxed drive and datalog. I also have water injection so that may be helping me avoid detonation as well. At 4 psi boost the H20 pump kicks on. I kick it on purposely to help steam clean the plugs on occasion. I was dead in the water for a while with MS issues so I made a new center dash console out of alluminum. I also had to add a electric oil scavenging pump to my turbo because its mounted so low. The oil would not drain back and pooled inside the turbo and seeped past the seals into the intake and exhaust. What a mess that made! A restrictor was also needed to reduce oil flow. Did you have any of these issues? My wideband isnt responding properly and I think its because it got oil soaked from the turbo issue. Im going to attempt to clean it and do a new free air calibration. Cant hurt it isnt working properly anyways. Anyways car looks great almost exactly like mine! Shawn

#16

Senior Member

Join Date: Oct 2005

Location: High Point North carolina

Posts: 417

Likes: 0

Received 0 Likes

on

0 Posts

Scathcart,

Nice write up thanks for doing that,easy to understand. I do have a Cartech true rising rate reg but am not using it. I like to be able to adjust the base fuel pressure and watch my fuel pressure guage under boost. Maybe Im paronoid but these engines do not like leaning out one bit. I leaned out a boosted 12a and learned my lesson. Can never know too much,Thanks

Nice write up thanks for doing that,easy to understand. I do have a Cartech true rising rate reg but am not using it. I like to be able to adjust the base fuel pressure and watch my fuel pressure guage under boost. Maybe Im paronoid but these engines do not like leaning out one bit. I leaned out a boosted 12a and learned my lesson. Can never know too much,Thanks

#17

RX-7 Alumni

Thread Starter

Originally Posted by custom13B

I also have water injection so that may be helping me avoid detonation as well. At 4 psi boost the H20 pump kicks on. I kick it on purposely to help steam clean the plugs on occasion. I was dead in the water for a while with MS issues so I made a new center dash console out of alluminum. I also had to add a electric oil scavenging pump to my turbo because its mounted so low. The oil would not drain back and pooled inside the turbo and seeped past the seals into the intake and exhaust. What a mess that made! A restrictor was also needed to reduce oil flow. Did you have any of these issues? My wideband isnt responding properly and I think its because it got oil soaked from the turbo issue. Im going to attempt to clean it and do a new free air calibration. Cant hurt it isnt working properly anyways. Anyways car looks great almost exactly like mine! Shawn

First I'd stay off the water injection till you get everything working right. Honestly I can't see how you would need it if you stay under 10 psi. Then once all is working well add it in.

I didn't have any problems with the turbo since I'm using a stock S5 unit. I have heard of those problems you had--that's why custom turbo installs can be difficult.

I'm not sure what to tell you about the probe, but yea it's possible it got contaminated. Check over at the innovate forum and see what they say. I just had to buy a new one, hope it lasts longer than 2 months.

So you have an FB, cool, like to see some pics sometime. Great to hear you got it all running--considering all the difficulty you had--MS is a bigtime diy project alright.

Scott

#18

I wish I was driving!

Originally Posted by custom13B

Scathcart,

Nice write up thanks for doing that,easy to understand. I do have a Cartech true rising rate reg but am not using it. I like to be able to adjust the base fuel pressure and watch my fuel pressure guage under boost. Maybe Im paronoid but these engines do not like leaning out one bit. I leaned out a boosted 12a and learned my lesson. Can never know too much,Thanks

Nice write up thanks for doing that,easy to understand. I do have a Cartech true rising rate reg but am not using it. I like to be able to adjust the base fuel pressure and watch my fuel pressure guage under boost. Maybe Im paronoid but these engines do not like leaning out one bit. I leaned out a boosted 12a and learned my lesson. Can never know too much,Thanks

You're generally going to want to keep your fuel pressures between the 35-45 (static) psi range. Anything outside that pressure range and atomization suffers. Lower pressure and the fuel just dribbles out, higher pressures and the fuel sprays out too fast and hits the intake runner wall.

This is why all car manufacturer's run their EFI systems between this range.

Upping the fuel pressure so high is one of the main reasons why RRFPR's are crappy. FMU's, too.

#19

Senior Member

Join Date: Oct 2005

Location: High Point North carolina

Posts: 417

Likes: 0

Received 0 Likes

on

0 Posts

Good point scathcart,

I remember using this same turbo kit with the stock ECU and it came with a cartech RRFPR which raised the fuel pressure to 100 psi under hard boost. It never worked as well as they claimed and barely drove it in that configuration. I'll keep my pressure at 43 PSI as it seems quite happy there and your knowledge convinced me. I was in B.C. early this summer and didnt see a single 7. I see all you guys on this forum and kept my eyes open because of that. My GF is from Abbotsford and we visited her family there. Long *** flight from central NY and got there at like 3 am B.C. time. Pulling up to her brothers place and going in throught the garage I saw he had a nice new shiny yellow RX-8. He took me for a spirited ride but didnt let me drive,,,wise man! I wouldnt have had it sideways just to see how it handled. Still like the 1st and 3 gens best but it was also new and fun to ride in.

Scott,

MS being a bigtime DIY project is a understatement! Im still fighting some issues. Patience and trial and error have been my friends...lol. I would like to get some pictures posted as well,just keeping this car running has eaten up all my free time for the last like 3 months..lol. Also its dirty and buried in my garage..lots of stuff blocking it in due to the fact its winter and wont be moving far anytime soon. I also am fussy and the engine bay has wires all over in plain sight until I get it running 100%. IMHO it looks sloppy right now. I did clean up the nasty plastic center console by making a new insert out of alluminum. And recently ran a 3" pipe in front of the radiator to the turbo for a cold air intake. Have a K&N air filter there and its protected by the air dam from splashing. The GF is here this weekend so maybe she'll help me get some pics online. Anything in particular you want to see? I was playing kicking on the water injection seeing how the engine responded and if it helped clean the plugs or not. Ttyl,Shawn

I remember using this same turbo kit with the stock ECU and it came with a cartech RRFPR which raised the fuel pressure to 100 psi under hard boost. It never worked as well as they claimed and barely drove it in that configuration. I'll keep my pressure at 43 PSI as it seems quite happy there and your knowledge convinced me. I was in B.C. early this summer and didnt see a single 7. I see all you guys on this forum and kept my eyes open because of that. My GF is from Abbotsford and we visited her family there. Long *** flight from central NY and got there at like 3 am B.C. time. Pulling up to her brothers place and going in throught the garage I saw he had a nice new shiny yellow RX-8. He took me for a spirited ride but didnt let me drive,,,wise man! I wouldnt have had it sideways just to see how it handled. Still like the 1st and 3 gens best but it was also new and fun to ride in.

Scott,

MS being a bigtime DIY project is a understatement! Im still fighting some issues. Patience and trial and error have been my friends...lol. I would like to get some pictures posted as well,just keeping this car running has eaten up all my free time for the last like 3 months..lol. Also its dirty and buried in my garage..lots of stuff blocking it in due to the fact its winter and wont be moving far anytime soon. I also am fussy and the engine bay has wires all over in plain sight until I get it running 100%. IMHO it looks sloppy right now. I did clean up the nasty plastic center console by making a new insert out of alluminum. And recently ran a 3" pipe in front of the radiator to the turbo for a cold air intake. Have a K&N air filter there and its protected by the air dam from splashing. The GF is here this weekend so maybe she'll help me get some pics online. Anything in particular you want to see? I was playing kicking on the water injection seeing how the engine responded and if it helped clean the plugs or not. Ttyl,Shawn

Thread

Thread Starter

Forum

Replies

Last Post

ls1swap

3rd Generation Specific (1993-2002)

12

10-01-15 07:58 PM