What is the 2023 consensus on rotor reconditioning?

#1

What is the 2023 consensus on rotor reconditioning?

Hi all,

I have a collection of very crusty rotors that I really should clean up to put into engines that will run or pass on to someone who will actually use them. I've left them disgusting due to some old beliefs regarding how they need to be cleaned in order to not damage anything. I'd like to see if the thinking has changed since and potentially compile the wisdom in a single thread.

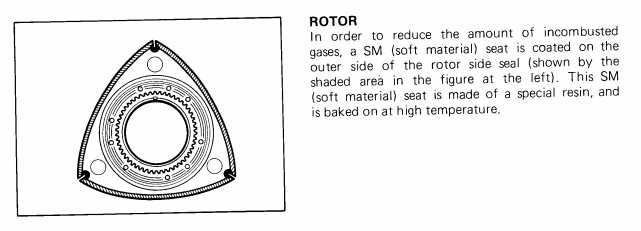

From recollection, the rotors need to be absolutely sterile of old carbon baked on all the surfaces. I was under the assumption that in order to prevent any damage to the coatings on the rotor, you had to sit through the arduous process of tickling the carbon off with soft nylon brushes and simple green or similar non-aggressive detergents. On the other hand, I'm looking at an old rebuild video about engine rebuilding from KMR/Mazdatrix where they suggest scrubbing off the carbon using scotch-brite and a metal bristled brush. Doing some searching, it sounds like there are 2 types of coatings the rotors receive: an anti-corrosion coating just like bolts do (is there a definitive answer on if this is Cadmium based or a yellow zinc?) and some sort of coating on the side faces made of a soft bearing-like material to prevent side housing damage in case it rubs against it. For the anti-corrosion coating, it sounds like most posters do not care to preserve it, so long as something like a coat of oil is used to prevent flash rusting once the coating is scrubbed off. However, for the soft side coating, I don't have as good of answers. Was this something Mazda always did, or was it implemented for certain years/generations? Do the coatings hold up in high mileage engines? Does preserving what's left or restoring the coating really matter to the home rebuild? For higher end performance builds, is something like side clearancing preferred?

From what I can tell, these rotors are made of cast iron - so does the cleaning solution matter? I've heard all sorts of suggestions from simple green to carb cleaner. I can't think of a reason cast iron would care about the cleaning solution, but maybe the coating mentioned above does. I also saw one poster mentioned a strong degreaser like purple power shouldn't be used if you're re-using the bearings. Are there any other cleaning solutions to avoid if you decide to reuse the bearings?

On the subject of, I've read in the past that replacing rotor bearings wasn't advised due to it being more likely that you'd wind up with a spun bearing than if you were to just keep the old bearing. Is this still the case? Is there something you can check for, some sort of assembly procedure that improves your chances if you're forced to replace a rotor bearing? And as for gauging if the bearing is OK to reuse, is it purely down to oil clearance, or does the babbitt have to be intact? Looking at all of the rotors I've accumulated, they all seem to have it worn out at the interlocking seam (for the bearings that weren't spun lol)

For cleaning the apex and side seal slots, it seems like the consensus on just using a broken seal or similar to scrape out carbon hasn't really changed. I know you can buy specific size files to really ensure the apex seal slots are cleaned out and remedy a pinched slot. Is there something you could do if the side seal slots are tight?

I've never heard of anything regarding the teeth being of concern provided they were still there and didn't look chewed up, but I'd like to hear it if there's anything I should be aware of.

I know a good chunk of these engines wind up being rebuilds post-coolant seal failure and some rust pitting is expected. Is there a rule of thumb to gauge if it's too much to be reusable? Can face clearancing clean up a rotor that's otherwise unusable? I think I was told years ago that any pitting can potentially become hot spots where carbon accumulates, so it wouldn't be advisable reuse on a high horsepower rebuild. On the other hand, I have these rotors sitting in front of me covered in carbon everywhere. Between that and the as-cast bathtubs of S4 and earlier rotors not being machined, I can't reconcile why pitting would be the bigger issue. How about other surface defects, like scratches or dents?

Lastly, do people still care about the lower compression ratio of S4 T2 rotors, or has that kind of gone to the wayside with modern EFI?

Appreciate you all for reading through all the questions

I have a collection of very crusty rotors that I really should clean up to put into engines that will run or pass on to someone who will actually use them. I've left them disgusting due to some old beliefs regarding how they need to be cleaned in order to not damage anything. I'd like to see if the thinking has changed since and potentially compile the wisdom in a single thread.

From recollection, the rotors need to be absolutely sterile of old carbon baked on all the surfaces. I was under the assumption that in order to prevent any damage to the coatings on the rotor, you had to sit through the arduous process of tickling the carbon off with soft nylon brushes and simple green or similar non-aggressive detergents. On the other hand, I'm looking at an old rebuild video about engine rebuilding from KMR/Mazdatrix where they suggest scrubbing off the carbon using scotch-brite and a metal bristled brush. Doing some searching, it sounds like there are 2 types of coatings the rotors receive: an anti-corrosion coating just like bolts do (is there a definitive answer on if this is Cadmium based or a yellow zinc?) and some sort of coating on the side faces made of a soft bearing-like material to prevent side housing damage in case it rubs against it. For the anti-corrosion coating, it sounds like most posters do not care to preserve it, so long as something like a coat of oil is used to prevent flash rusting once the coating is scrubbed off. However, for the soft side coating, I don't have as good of answers. Was this something Mazda always did, or was it implemented for certain years/generations? Do the coatings hold up in high mileage engines? Does preserving what's left or restoring the coating really matter to the home rebuild? For higher end performance builds, is something like side clearancing preferred?

From what I can tell, these rotors are made of cast iron - so does the cleaning solution matter? I've heard all sorts of suggestions from simple green to carb cleaner. I can't think of a reason cast iron would care about the cleaning solution, but maybe the coating mentioned above does. I also saw one poster mentioned a strong degreaser like purple power shouldn't be used if you're re-using the bearings. Are there any other cleaning solutions to avoid if you decide to reuse the bearings?

On the subject of, I've read in the past that replacing rotor bearings wasn't advised due to it being more likely that you'd wind up with a spun bearing than if you were to just keep the old bearing. Is this still the case? Is there something you can check for, some sort of assembly procedure that improves your chances if you're forced to replace a rotor bearing? And as for gauging if the bearing is OK to reuse, is it purely down to oil clearance, or does the babbitt have to be intact? Looking at all of the rotors I've accumulated, they all seem to have it worn out at the interlocking seam (for the bearings that weren't spun lol)

For cleaning the apex and side seal slots, it seems like the consensus on just using a broken seal or similar to scrape out carbon hasn't really changed. I know you can buy specific size files to really ensure the apex seal slots are cleaned out and remedy a pinched slot. Is there something you could do if the side seal slots are tight?

I've never heard of anything regarding the teeth being of concern provided they were still there and didn't look chewed up, but I'd like to hear it if there's anything I should be aware of.

I know a good chunk of these engines wind up being rebuilds post-coolant seal failure and some rust pitting is expected. Is there a rule of thumb to gauge if it's too much to be reusable? Can face clearancing clean up a rotor that's otherwise unusable? I think I was told years ago that any pitting can potentially become hot spots where carbon accumulates, so it wouldn't be advisable reuse on a high horsepower rebuild. On the other hand, I have these rotors sitting in front of me covered in carbon everywhere. Between that and the as-cast bathtubs of S4 and earlier rotors not being machined, I can't reconcile why pitting would be the bigger issue. How about other surface defects, like scratches or dents?

Lastly, do people still care about the lower compression ratio of S4 T2 rotors, or has that kind of gone to the wayside with modern EFI?

Appreciate you all for reading through all the questions

Last edited by pzr2; 11-01-23 at 03:59 PM.

The following users liked this post:

diabolical1 (11-01-23)

#2

Old [Sch|F]ool

If seal slots are tight, narrow the seal, tight slots are basically unicorns.

S4 T2 rotors are still good IMO, they can make more power than anything else, turbo or non turbo.

S4 T2 rotors are still good IMO, they can make more power than anything else, turbo or non turbo.

#3

i don't know what they did before the REW, if anything, but i remember seeing a photo of the gear side of a rotor in the Gen 3 Rx-7 brochure. it looked sort of like a color somewhere between gold and copper. if memory serves, i think they said it was molybdenum and it had something to do with helping the engine oil. presumably, like you said, it had to do with protecting the side housings. unlike, so many of my Rx-7 stuff, i think i actually know exactly where that brochure is, so the next time i go to my parents' house (if i remember, and if i actually find it), i'll take a look and post what it says.

what i've found with rotors, is it really depends on how carboned up they (the faces) are. sometimes you get lucky and they will come clean with the right solvent. when i first started, i used to use either diesel or kerosene and brass brush or scotch brite pad, and they worked until i came across my first REALLY carboned up rotor, then i actually had to go with medium (220 or 320) wet/dry sandpaper on the thick carbon areas. i got introduced to Simple Green some time ago, so now i only use the kerosene or diesel whenever i have the time to actually soak the rotor in it. otherwise, i now use Simple Green and Dawn mostly.

in addition, within the last 15 years or so, i started using an industrial degreaser that i get at Harbor Freight, it is awesome for an initial cleaning on really bad rotors, but i learned not to leave them soaking in that stuff for more than a few minutes ... TOPS!!! i prefer to clean and rinse it thoroughly right away. afterwards, dry them (compressed air) and oil them up - inside and out. toothbrushes are what i use for all the surfaces.

on the rotor sides, they are usually pretty easy. the toothbrush will get it 90+% clean - no REAL elbow grease. if you find stubborn areas, they are likely to be the land for the side seals (the combustion side) and the machined areas where Mazda balanced the rotor. a light go with the wet/dry paper and it's usually good.

for the apex and side slots, i use old seals. just make sure to protect your fingers and hands. they are unbelievably sharp! for corner slots, i use my dremel and wire brush fitting.

what i've found with rotors, is it really depends on how carboned up they (the faces) are. sometimes you get lucky and they will come clean with the right solvent. when i first started, i used to use either diesel or kerosene and brass brush or scotch brite pad, and they worked until i came across my first REALLY carboned up rotor, then i actually had to go with medium (220 or 320) wet/dry sandpaper on the thick carbon areas. i got introduced to Simple Green some time ago, so now i only use the kerosene or diesel whenever i have the time to actually soak the rotor in it. otherwise, i now use Simple Green and Dawn mostly.

in addition, within the last 15 years or so, i started using an industrial degreaser that i get at Harbor Freight, it is awesome for an initial cleaning on really bad rotors, but i learned not to leave them soaking in that stuff for more than a few minutes ... TOPS!!! i prefer to clean and rinse it thoroughly right away. afterwards, dry them (compressed air) and oil them up - inside and out. toothbrushes are what i use for all the surfaces.

on the rotor sides, they are usually pretty easy. the toothbrush will get it 90+% clean - no REAL elbow grease. if you find stubborn areas, they are likely to be the land for the side seals (the combustion side) and the machined areas where Mazda balanced the rotor. a light go with the wet/dry paper and it's usually good.

for the apex and side slots, i use old seals. just make sure to protect your fingers and hands. they are unbelievably sharp! for corner slots, i use my dremel and wire brush fitting.

The following users liked this post:

pzr2 (11-02-23)

#4

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,826

Received 2,594 Likes

on

1,842 Posts

no definitive answer on the coating, its probably yellow zinc, although in the newer engines they have some kind of carbon resistant coating that is black.

the stuff between the side seal and the rotor face is usually not there enough to really tell what it was, i think it was an attempt to try and have fewer spaces for unburned fuels to hide in.

for the face i usually just start with a razor blade, and scrape off the big chunks. it makes it way easier to clean the rest

for cleaners, the rotor is cast iron, but you need to pick something that is compatible with the bearings, unless you want to change the bearings

the old seals work for cleaning the grooves because they fit nicely, but other than that there isn't anything really special going on.

i do like to do a quick clean and then measure the grooves, no point in spending all the time to clean a rotor that isn't any good

the stuff between the side seal and the rotor face is usually not there enough to really tell what it was, i think it was an attempt to try and have fewer spaces for unburned fuels to hide in.

for the face i usually just start with a razor blade, and scrape off the big chunks. it makes it way easier to clean the rest

for cleaners, the rotor is cast iron, but you need to pick something that is compatible with the bearings, unless you want to change the bearings

the old seals work for cleaning the grooves because they fit nicely, but other than that there isn't anything really special going on.

i do like to do a quick clean and then measure the grooves, no point in spending all the time to clean a rotor that isn't any good

The following users liked this post:

pzr2 (11-02-23)

#5

Racing Rotary Since 1983

iTrader: (6)

brass brush wheels in a half inch drill remove the carbon but do not disturb the rotor surface.

https://www.mcmaster.com/products/br...erial~brass-1/

https://www.mcmaster.com/products/br...erial~brass-1/

#6

Old [Sch|F]ool

FWIW, I soaked a set of rotors in Evaporust for a week and while they got very clean, the side seals were still stuck hard in them and I gave up.

The following 2 users liked this post by pzr2:

diabolical1 (11-22-23),

j9fd3s (11-22-23)

Thread

Thread Starter

Forum

Replies

Last Post