thermal efficiency in the rotary

#1

Senior Member

Thread Starter

Join Date: Jul 2007

Location: fl

Posts: 306

Likes: 0

Received 0 Likes

on

0 Posts

thermal efficiency in the rotary

*disclaimer: this is all just a theory of mine that i disclosed to a close friend of mine which gave me the idea to post it here also. so please correct me if i am wrong about anything. im still a bit of a noob.

well i've been thinking the rotary is thermally inefficient which gives the engine one of the biggest disadvantages imo. the combustion chamber is too long and so lots of energy is dissipated really fast as heat energy. the plus to that is the internal combustion temperature is lower than in a piston giving the rotary the ability to run low quality low octane fuel even at a high compression. anyways my question here is: is it possible to safely coat the inner wall of the rotor housings with some type of very high heat resistance substance to improve power and fuel economy? i know honda coated the inside of their h22s with something to improve cylinder wall strength so they can operate safely with relatively thinner walls than most other piston engines. the idea came to me when i bought some one part epoxy from home depot. it intrigued me that it was only one part and didnt require any mixing but just some exposure to air or rubbing to get it started so i went to google to researched epoxy since i didnt really know much about it. i found out that epoxy is extremely amazing. its incredibly strong has high insulating properties and a high chemical resistance. i think ill use it from now on as a wire insulator when i splice them together, its much faster and easier than soldering. anyways the bad thing is that most can only last up to 400degress Fahrenheit. combustion chamber temps easily exceed that. so that might mean my idea wont get off the ground but if only i could find another substance that can withstand those temps. of course i realized that will mean it wont be long before i have to jump up to the next grade in octane but i think it will be worth it.

well i've been thinking the rotary is thermally inefficient which gives the engine one of the biggest disadvantages imo. the combustion chamber is too long and so lots of energy is dissipated really fast as heat energy. the plus to that is the internal combustion temperature is lower than in a piston giving the rotary the ability to run low quality low octane fuel even at a high compression. anyways my question here is: is it possible to safely coat the inner wall of the rotor housings with some type of very high heat resistance substance to improve power and fuel economy? i know honda coated the inside of their h22s with something to improve cylinder wall strength so they can operate safely with relatively thinner walls than most other piston engines. the idea came to me when i bought some one part epoxy from home depot. it intrigued me that it was only one part and didnt require any mixing but just some exposure to air or rubbing to get it started so i went to google to researched epoxy since i didnt really know much about it. i found out that epoxy is extremely amazing. its incredibly strong has high insulating properties and a high chemical resistance. i think ill use it from now on as a wire insulator when i splice them together, its much faster and easier than soldering. anyways the bad thing is that most can only last up to 400degress Fahrenheit. combustion chamber temps easily exceed that. so that might mean my idea wont get off the ground but if only i could find another substance that can withstand those temps. of course i realized that will mean it wont be long before i have to jump up to the next grade in octane but i think it will be worth it.

#2

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,805

Received 2,577 Likes

on

1,831 Posts

epoxy in some form is fine on wiring, or actually hot glue is better, because if you need to remove it, you can.

i dunno about coating the rotor housing, but if you contact eliot at turblown, he will gladly coat everything else in the engine. the rotor faces, exhaust ports, bearings, side housings...

the bearing coating = less friction = lower oil temps

rotor face coating = less heat going into the rotor = lower oil temps

i dunno about coating the rotor housing, but if you contact eliot at turblown, he will gladly coat everything else in the engine. the rotor faces, exhaust ports, bearings, side housings...

the bearing coating = less friction = lower oil temps

rotor face coating = less heat going into the rotor = lower oil temps

#3

Lives on the Forum

ANY I.C.E. - Internal Combustion Engine is "inefficient".

I think the max efficiency is still only in the 30% range?

The rotary engine is no exception.

Yes, the problem with epoxies is HEAT.

-Ted

I think the max efficiency is still only in the 30% range?

The rotary engine is no exception.

Yes, the problem with epoxies is HEAT.

-Ted

#5

I've thought about this too

There is an add in Grassroots Motorsports for a company called Swain Tech Coatings. They coat pistons with a heat resistant substance. I don't know if they would do a rotor, but it seems a rotor would get the same benefits as a piston.

#6

Senior Member

Thread Starter

Join Date: Jul 2007

Location: fl

Posts: 306

Likes: 0

Received 0 Likes

on

0 Posts

as taken from their page:

"Swain Tech has thermal barrier coatings for pistons, thermal barrier coatings for cylinder heads, thermal barrier coatings for valves, thermal barrier coatings for exhaust parts, and thermal barrier coatings for intake manifolds."

this greatly concerns me bc there might be a good reason for that. perhaps the coating is too efficient that too little energy escapes as heat energy into the coolant system that internal compression temps rise too high and cause glorious amounts of pre-ignition maybe even with an octane like 93. ill email them to see what they think about thermally coating cylinder walls and then from there rotor housings if it looks promising.

Last edited by hhn2002; 09-26-07 at 09:42 AM.

#7

Rotary Freak

Join Date: Dec 2006

Location: New Hampshire

Posts: 1,791

Likes: 0

Received 0 Likes

on

0 Posts

I think its because the coating could get scraped off or that they may not be able to coat the cylinder walls perfectly smooth which may screw up the tolerences.

Search for rotary coatings or something of the sort. There is a company that deal with coating internal rotary parts and I think even the rotor housings but I may be wrong on that. I don't think that coat the side housings for possibly the same reason that company doesn't coat the cylinder walls.

This is very interesting and I never thought about this before.

Search for rotary coatings or something of the sort. There is a company that deal with coating internal rotary parts and I think even the rotor housings but I may be wrong on that. I don't think that coat the side housings for possibly the same reason that company doesn't coat the cylinder walls.

This is very interesting and I never thought about this before.

Trending Topics

#8

#9

Rotary Freak

Join Date: Dec 2006

Location: New Hampshire

Posts: 1,791

Likes: 0

Received 0 Likes

on

0 Posts

Here is a link to RotorSports who also does the same coatings.

http://www.rotorsportsracing.com/per...gine_parts.htm

http://www.rotorsportsracing.com/per...gine_parts.htm

#10

www.jhbperformance.com

they do cermet coated housings. The Cermet has a lower heat transfer coefficient than the chrome surface. This means lower heat transfer of combustion heat into the cooling system.

Cermet is also highly wear resistant. Regarded highly in the cutting tool business for its resistance breakdown due to heat, resistance to wear, and low coefficient of friction over high speed steel, naked carbide, and some coated carbides.

This coating was used in the only Japanese car to win the LeMans - 787B - they coated all housings surfaces.

Their website contains some information on the substance. Or, you can go to this link:

http://en.wikipedia.org/wiki/Cermet

they do cermet coated housings. The Cermet has a lower heat transfer coefficient than the chrome surface. This means lower heat transfer of combustion heat into the cooling system.

Cermet is also highly wear resistant. Regarded highly in the cutting tool business for its resistance breakdown due to heat, resistance to wear, and low coefficient of friction over high speed steel, naked carbide, and some coated carbides.

This coating was used in the only Japanese car to win the LeMans - 787B - they coated all housings surfaces.

Their website contains some information on the substance. Or, you can go to this link:

http://en.wikipedia.org/wiki/Cermet

#11

Thermal Efficiency

Just because the components absorb slightly less heat will not make up for the shape of the combustion chamber.

Yes, JHB does this process and I am running their refurbished housings in my FD. Their main advantage is less friction and enhanced durability. Fuel economy and power are not affected.

Yes, JHB does this process and I am running their refurbished housings in my FD. Their main advantage is less friction and enhanced durability. Fuel economy and power are not affected.

#12

Cotronics has some incredible ceramic based materials. Machinable metal putties and epoxies that top 3000*F. Check them out.

http://www.cotronics.com/vo/cotr/pdf/940series.pdf

http://www.cotronics.com/vo/cotr/pdf/liquidmetals.pdf

http://www.cotronics.com/vo/cotr/pdf/940series.pdf

http://www.cotronics.com/vo/cotr/pdf/liquidmetals.pdf

#13

Periods are your friends.

Q = kA / t * dT or dT = Qt / (kA)

Q = heat transfer

A = area

k = material constant. 200 W/m*K for aluminum, 1 W / m*K for ceramic.

t = THICKNESS

dT = temperature differental across the coating.

A super thin coating cannot insulate. Period. Anyone claiming such is stealing your money. The poor convection in that thin layer of air is a better insulator than that coating. With piston engines that layer of air isn't so thin, hence the better thermal efficiency.

The combustion chamber temperature can get up to ~2000 C. The coolant temperature is about 80C. So dT from the engine to the coolant is huge. But the engine walls are less than 150C. Otherwise the aluminum would soften and fail (that's probably why the rotors are iron). In reality the aluminum temperature is probably very close to the coolant temperature. So the dT from the coolant to the engine walls is less than 70C and the dT from the middle of the combustion chamber to the combustion chamber walls is over 1930C. That goes to show right there how much insulating is done simply with air.

Here's a way to illustrate. Pour coffee in an aluminum, paper cup and then plastic cup. Even the plastic does next to nothing to stop the heat. Yet it's 10 times better than ceramic and 10 times thicker than most coatings. Now go to Starbucks where you'll get a cheap paper sleeve on a paper cup, with folds in it to create a tiny air gap between the two papers.

Q = kA / t * dT or dT = Qt / (kA)

Q = heat transfer

A = area

k = material constant. 200 W/m*K for aluminum, 1 W / m*K for ceramic.

t = THICKNESS

dT = temperature differental across the coating.

A super thin coating cannot insulate. Period. Anyone claiming such is stealing your money. The poor convection in that thin layer of air is a better insulator than that coating. With piston engines that layer of air isn't so thin, hence the better thermal efficiency.

The combustion chamber temperature can get up to ~2000 C. The coolant temperature is about 80C. So dT from the engine to the coolant is huge. But the engine walls are less than 150C. Otherwise the aluminum would soften and fail (that's probably why the rotors are iron). In reality the aluminum temperature is probably very close to the coolant temperature. So the dT from the coolant to the engine walls is less than 70C and the dT from the middle of the combustion chamber to the combustion chamber walls is over 1930C. That goes to show right there how much insulating is done simply with air.

Here's a way to illustrate. Pour coffee in an aluminum, paper cup and then plastic cup. Even the plastic does next to nothing to stop the heat. Yet it's 10 times better than ceramic and 10 times thicker than most coatings. Now go to Starbucks where you'll get a cheap paper sleeve on a paper cup, with folds in it to create a tiny air gap between the two papers.

Last edited by ericgrau; 09-27-07 at 07:46 PM.

#14

Senior Member

Thread Starter

Join Date: Jul 2007

Location: fl

Posts: 306

Likes: 0

Received 0 Likes

on

0 Posts

Periods are your friends.

Q = kA / t * dT or dT = Qt / (kA)

Q = heat transfer

A = area

k = material constant. 200 W/m*K for aluminum, 1 W / m*K for ceramic.

t = THICKNESS

dT = temperature differental across the coating.

A super thin coating cannot insulate. Period. Anyone claiming such is stealing your money. The poor convection in that thin layer of air is a better insulator than that coating. With piston engines that layer of air isn't so thin, hence the better thermal efficiency.

The combustion chamber temperature can get up to ~2000 C. The coolant temperature is about 80C. So dT from the engine to the coolant is huge. But the engine walls are less than 150C. Otherwise the aluminum would soften and fail (that's probably why the rotors are iron). In reality the aluminum temperature is probably very close to the coolant temperature. So the dT from the coolant to the engine walls is less than 70C and the dT from the middle of the combustion chamber to the combustion chamber walls is over 1930C. That goes to show right there how much insulating is done simply with air.

Here's a way to illustrate. Pour coffee in an aluminum, paper cup and then plastic cup. Even the plastic does next to nothing to stop the heat. Yet it's 10 times better than ceramic and 10 times thicker than most coatings. Now go to Starbucks where you'll get a cheap paper sleeve on a paper cup, with folds in it to create a tiny air gap between the two papers.

Q = kA / t * dT or dT = Qt / (kA)

Q = heat transfer

A = area

k = material constant. 200 W/m*K for aluminum, 1 W / m*K for ceramic.

t = THICKNESS

dT = temperature differental across the coating.

A super thin coating cannot insulate. Period. Anyone claiming such is stealing your money. The poor convection in that thin layer of air is a better insulator than that coating. With piston engines that layer of air isn't so thin, hence the better thermal efficiency.

The combustion chamber temperature can get up to ~2000 C. The coolant temperature is about 80C. So dT from the engine to the coolant is huge. But the engine walls are less than 150C. Otherwise the aluminum would soften and fail (that's probably why the rotors are iron). In reality the aluminum temperature is probably very close to the coolant temperature. So the dT from the coolant to the engine walls is less than 70C and the dT from the middle of the combustion chamber to the combustion chamber walls is over 1930C. That goes to show right there how much insulating is done simply with air.

Here's a way to illustrate. Pour coffee in an aluminum, paper cup and then plastic cup. Even the plastic does next to nothing to stop the heat. Yet it's 10 times better than ceramic and 10 times thicker than most coatings. Now go to Starbucks where you'll get a cheap paper sleeve on a paper cup, with folds in it to create a tiny air gap between the two papers.

even jhbperformance.com are similar in thinking:

"In combustion chambers you want to retain the heat energy to push against the piston or rotor rather than transfer it to the oil or coolant. In a performance rotary engine coated rotors help reduce bearing temperature and failure as well as increase the output of the engine."

alexdimen is right jhb coatings didnt improve either power or fuel economy but neither was it meant to insulate. it was more made for reducing friction between the apex seals and housing but thats not where the most heat is produced so the thermal benefits are nominal. theres been plenty of thermally coated rotors out there. thermally barrier coating the rotors is a very good step in the right direction therefore reducing the heat lost to oil cooling but i'd like to see if that can be taken one step further to reduce heat loss to coolant also. and ur right again eric that the dT is high between coolant and combustion temp but think about how large our radiators are, the fact that we also have oil coolers and how fast coolant and oil is being flowed together to cool the engine. what im trying to say is think of how much heat energy is actually being displaced. what if hypothetically the water pump fails for 20mins, what then would dT be then? alot closer to zero is for sure. only then can you truely appreciate mazda's beefy cooling system. not to mention how much energy you really are losing to the cooling system. yes piston engines are also very thermally inefficient but although i dont have cold hard facts i believe rotarys are even more thermally inefficient and that can and should be improved upon to the level of piston engines. if mazda hasnt already with the renesis but what of the earlier series that would like the new age efficiency and power of the renesis with what they already have?

Last edited by hhn2002; 09-27-07 at 10:46 PM. Reason: proofreading

#17

Senior Member

Thread Starter

Join Date: Jul 2007

Location: fl

Posts: 306

Likes: 0

Received 0 Likes

on

0 Posts

#18

Lives on the Forum

I think the oil cooling is a design by necessity.

The interior of the rotor needs to be cooled as this is very close to the combustion chamber.

How do you get oil inside the spinning rotor?

Oil was conveniently used cause the rotor bearings are right there.

Can you imagine trying to get coolant in the rotors?

-Ted

The interior of the rotor needs to be cooled as this is very close to the combustion chamber.

How do you get oil inside the spinning rotor?

Oil was conveniently used cause the rotor bearings are right there.

Can you imagine trying to get coolant in the rotors?

-Ted

#19

Senior Member

Thread Starter

Join Date: Jul 2007

Location: fl

Posts: 306

Likes: 0

Received 0 Likes

on

0 Posts

I think the oil cooling is a design by necessity.

The interior of the rotor needs to be cooled as this is very close to the combustion chamber.

How do you get oil inside the spinning rotor?

Oil was conveniently used cause the rotor bearings are right there.

Can you imagine trying to get coolant in the rotors?

-Ted

The interior of the rotor needs to be cooled as this is very close to the combustion chamber.

How do you get oil inside the spinning rotor?

Oil was conveniently used cause the rotor bearings are right there.

Can you imagine trying to get coolant in the rotors?

-Ted

#20

Yes, the rotary does put out much more heat than the piston engine due to the higher surface area to volume ratio in the combustion chamber. And though I talked about "coolant", yeah, the oil does cooling too of course.

Though I don't know much about them, I can see the value of a ceramic coating (or other hard coating) to reduce wear. A hard coating is standard practice in a lot of applications.

There is one material I should have mentioned earlier. Aerogel is an extremely good insulator which is basically a foam with a vacuum inside. No air. It is extremely expensive though. It can handle temps up to 1500F and it feels like styrafoam. So you'd need some kind of metal on top of it to protect it from wear and you couldn't let the inner sidewall temp get over 1500F (just don't use too much insulation).

Here are some thermal conductivites to give you an idea:

ceramic: k = 1 W/m*C. Usually an ultra-thin coating.

plastic: 0.6.

typical insulation (styrafoam, fiberglass, etc.): 0.03. Usually about 1-3 inches thick.

aerogel: .03 to .004 (or lower?). So you could replace an inch of typical insulation with 0.1" of aerogel.

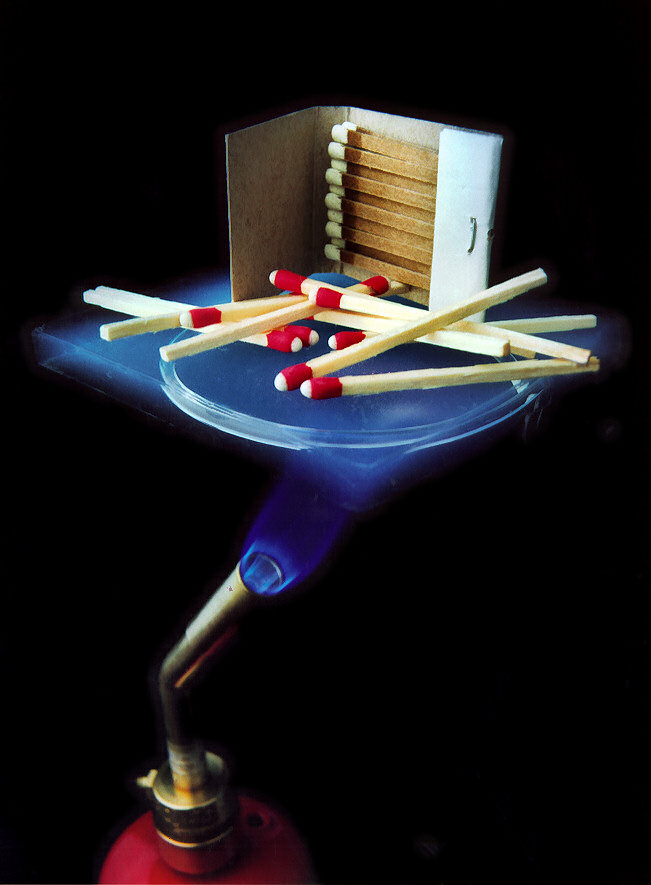

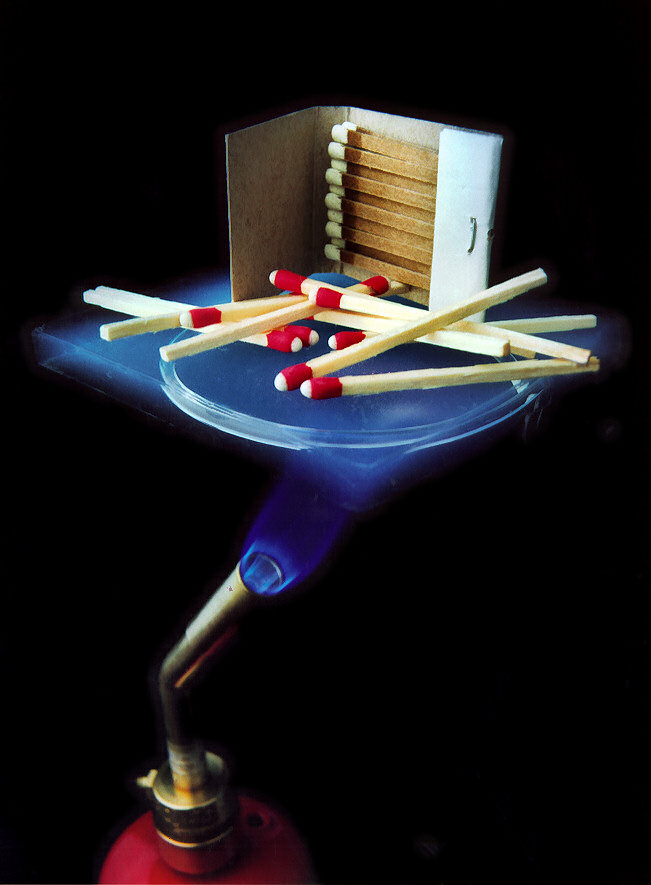

Here's a pic of aerogel. It's that ghostly blue rectangular stuff. That disc below is probably glass. Aerogel probably looks like that because there's such little material in it. It is extremely light; it gently floats around in air (still slightly heavier than air though). I'm too lazy to find the better pick I saw of a rose on top of a piece of aerogel, and a torch underneath. The rose was not wilted or affected at all.

Though I don't know much about them, I can see the value of a ceramic coating (or other hard coating) to reduce wear. A hard coating is standard practice in a lot of applications.

There is one material I should have mentioned earlier. Aerogel is an extremely good insulator which is basically a foam with a vacuum inside. No air. It is extremely expensive though. It can handle temps up to 1500F and it feels like styrafoam. So you'd need some kind of metal on top of it to protect it from wear and you couldn't let the inner sidewall temp get over 1500F (just don't use too much insulation).

Here are some thermal conductivites to give you an idea:

ceramic: k = 1 W/m*C. Usually an ultra-thin coating.

plastic: 0.6.

typical insulation (styrafoam, fiberglass, etc.): 0.03. Usually about 1-3 inches thick.

aerogel: .03 to .004 (or lower?). So you could replace an inch of typical insulation with 0.1" of aerogel.

Here's a pic of aerogel. It's that ghostly blue rectangular stuff. That disc below is probably glass. Aerogel probably looks like that because there's such little material in it. It is extremely light; it gently floats around in air (still slightly heavier than air though). I'm too lazy to find the better pick I saw of a rose on top of a piece of aerogel, and a torch underneath. The rose was not wilted or affected at all.

#22

It has been years since I took Fluid Thermal Dynamics theory......(2003 Automotive Tech College) I was always under the assumption that the combustion chamber temps were low (but consistent do to the nature of always being the expansion chamber. Not getting cold charged gas/air) and the exhaust being hotter due to the HC's and lower Oxides of nitrogen???

and yes the oil is 30-40% of the engine cooling I think it is more in the 30% but I do not have my references with me(Laptop/notebook)

P.S my instructor hated me, all my eg were rotary engines!!!! and most of my questions hahaha

and yes the oil is 30-40% of the engine cooling I think it is more in the 30% but I do not have my references with me(Laptop/notebook)

P.S my instructor hated me, all my eg were rotary engines!!!! and most of my questions hahaha

Thread

Thread Starter

Forum

Replies

Last Post

datfast1

Old School and Other Rotary

18

06-20-19 10:53 PM

Under PSI

3rd Generation Specific (1993-2002)

19

09-23-15 11:47 PM