Intake surface texture, boundary layer question

#1

Junior Member

Thread Starter

Join Date: May 2011

Location: Australia

Posts: 3

Likes: 0

Received 0 Likes

on

0 Posts

I'm currently porting/tidying up my UIM, LIM and TB (just because I am bored and I have the time).

I am thinking of leaving an 80 grit finish on not only my intake runners, but also the intercooler pipes and TB walls in an attempt to promote a turbulent boundary layer throughout the entire intake.

From my understanding, the airflow is in a state of turbulence (with no boundary layer of any kind) from the moment it leaves the turbo and will never be laminer at any stage as it travels through the intake system. So smooth intercooler pipes and TB walls will only create more aerodynamic drag.

There is no way a laminer boundary layer can be maintained throughout the intake, so why have any smooth surfaces to promote one?

Any ideas?

I am thinking of leaving an 80 grit finish on not only my intake runners, but also the intercooler pipes and TB walls in an attempt to promote a turbulent boundary layer throughout the entire intake.

From my understanding, the airflow is in a state of turbulence (with no boundary layer of any kind) from the moment it leaves the turbo and will never be laminer at any stage as it travels through the intake system. So smooth intercooler pipes and TB walls will only create more aerodynamic drag.

There is no way a laminer boundary layer can be maintained throughout the intake, so why have any smooth surfaces to promote one?

Any ideas?

#2

I need a new user title

Join Date: Oct 2005

Location: Yaizu, Japan

Posts: 2,646

Likes: 0

Received 0 Likes

on

0 Posts

Er, what? Turbulent flow has no boundary layer?  I think you're confused.

I think you're confused.

For turbulent flow, the friction factor goes up with relative roughness. In other words, a rough pipe causes more head loss than a smooth one.

I think you're confused.

I think you're confused.For turbulent flow, the friction factor goes up with relative roughness. In other words, a rough pipe causes more head loss than a smooth one.

#3

Junior Member

Thread Starter

Join Date: May 2011

Location: Australia

Posts: 3

Likes: 0

Received 0 Likes

on

0 Posts

I am talking about trying to create a boundary layer, where there is none. Tripping a turbulent boundary layer to reduce aerodynamic drag.

But you raise a valid point...hmmm so what is your opinion on the rough finish on intake manifolds?

The flow in the entire intake system will always be turbulent, so will it be possible to trip a boundary layer to increase flow momentum?

But you raise a valid point...hmmm so what is your opinion on the rough finish on intake manifolds?

The flow in the entire intake system will always be turbulent, so will it be possible to trip a boundary layer to increase flow momentum?

Last edited by FSEE3S; 05-18-11 at 05:06 AM.

#4

I am talking about trying to create a boundary layer, where there is none. Tripping a turbulent boundary layer to reduce aerodynamic drag.

But you raise a valid point...hmmm so what is your opinion on the rough finish on intake manifolds?

The flow in the entire intake system will always be turbulent, so will it be possible to trip a boundary layer to increase flow momentum?

But you raise a valid point...hmmm so what is your opinion on the rough finish on intake manifolds?

The flow in the entire intake system will always be turbulent, so will it be possible to trip a boundary layer to increase flow momentum?

basically what i mean is why spend 40 hours smoothing or roughing up the flow path where you can spend half that time turning up the boost and retuning the car, or upgrading other things that make a more noticable difference. unless you are limited by some class ruling for ITS or some other racing class, which also usually has many limitations on altering airflow anyways which makes the point moot again.

if anything i would prefer smooth, to keep oil from building up with dirt and crap in the intake tract which eventually WILL reduce performance regardless of what either side sais about rough or smooth being better.

Last edited by RotaryEvolution; 05-18-11 at 11:54 AM.

#5

I need a new user title

Join Date: Oct 2005

Location: Yaizu, Japan

Posts: 2,646

Likes: 0

Received 0 Likes

on

0 Posts

I am talking about trying to create a boundary layer, where there is none. Tripping a turbulent boundary layer to reduce aerodynamic drag.

But you raise a valid point...hmmm so what is your opinion on the rough finish on intake manifolds?

The flow in the entire intake system will always be turbulent, so will it be possible to trip a boundary layer to increase flow momentum?

But you raise a valid point...hmmm so what is your opinion on the rough finish on intake manifolds?

The flow in the entire intake system will always be turbulent, so will it be possible to trip a boundary layer to increase flow momentum?

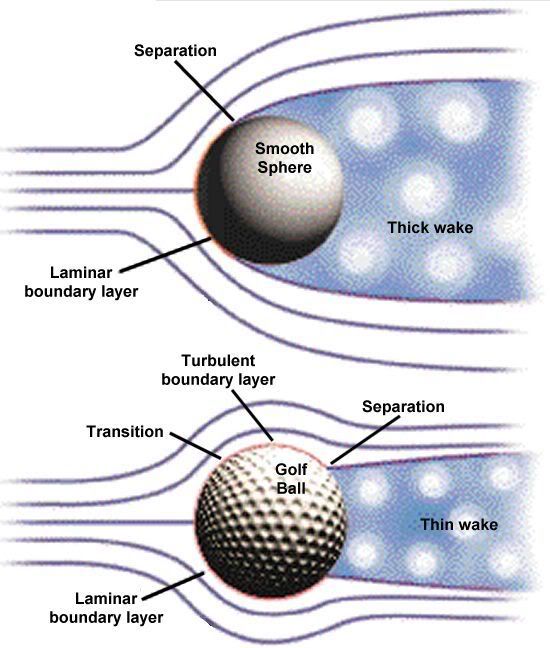

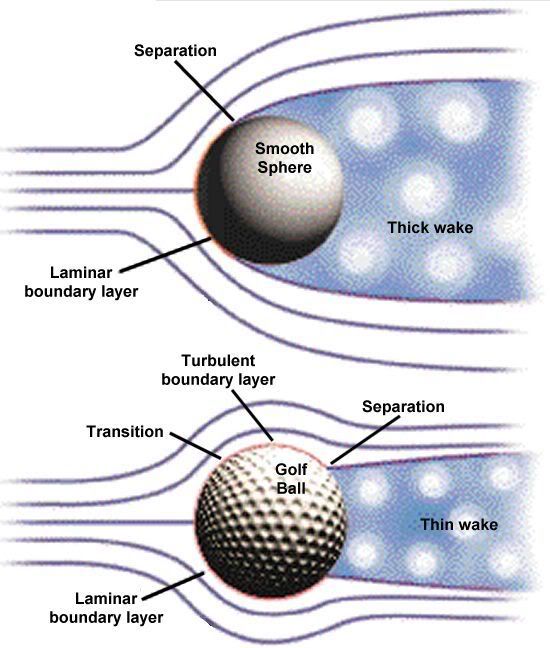

"Tripping" the boundary layer refers to inducing a laminar boundary layer into becoming a turbulent boundary layer earlier than it would normally. If the boundary layer is already turbulent, all you're doing is further increasing the skin drag. In any case, I'm skeptical as to how much a turbulent boundary layer would actually help you in an intercooler pipe system, but that would require an actual CFD analysis.

I agree with Karack: the pipe surface is going to make so little difference in the flow of the system that it's not worth it to even worry about it. You're better off directing your effort elsewhere. Make some vortex generators for the outside of the car or something. That's an application of boundary layer tripping that I bet would net you some real results.

#6

Junior Member

Thread Starter

Join Date: May 2011

Location: Australia

Posts: 3

Likes: 0

Received 0 Likes

on

0 Posts

Ah ok, thanks.

I have looked at situations where the boundary layer actually separates from the surface of a moving object, although I'm unsure if it applies in this 'pipe' application...just one more thing, what is your opinion then on porting the TB, BDC style, to (direct airflow better)?

I have looked at situations where the boundary layer actually separates from the surface of a moving object, although I'm unsure if it applies in this 'pipe' application...just one more thing, what is your opinion then on porting the TB, BDC style, to (direct airflow better)?

#7

tard of teh century

The only place you want turbulence is inside the combustion chamber. The surface finish is more important the closer you are too it and has less effect the further out. No matter how the airflow is going through all the piping as soon as it hits the plenum it's going to change dramatically. You're better off just reducing friction as much as possible as people have mentioned, with that being smooth and laminar. Also, since we're mostly turbocharged it's a little pointless to spend so much effort creating positive boost and then making the air jump through all kinds of hoops which just creates more and more head less.

Trending Topics

#8

Without all the science bc it's to much to get into you want velocity in the entire intake track, however I would leave the lower intake manifold a little rough for turbulence specifically for fuel atomization

#9

I need a new user title

Join Date: Oct 2005

Location: Yaizu, Japan

Posts: 2,646

Likes: 0

Received 0 Likes

on

0 Posts

Ah ok, thanks.

I have looked at situations where the boundary layer actually separates from the surface of a moving object, although I'm unsure if it applies in this 'pipe' application...just one more thing, what is your opinion then on porting the TB, BDC style, to (direct airflow better)?

I have looked at situations where the boundary layer actually separates from the surface of a moving object, although I'm unsure if it applies in this 'pipe' application...just one more thing, what is your opinion then on porting the TB, BDC style, to (direct airflow better)?

As for porting the TB, I'm sure it would be beneficial if done right. How beneficial? No idea.

#10

There was another thread about something similar.

https://www.rx7club.com/naturally-aspirated-performance-forum-220/reshape-combustion-chamber-864087/page3/

I mentioned the golf ball dimples as an example and found that there is some interesting information on engine applications. Such as dimpled valves.

I would love to see an entire intake tract dimpled and see what, if any, gains could be had.

This is pretty neat too... Mythbusters prove that a dimpled car gets better gas mileage... LoL!

http://www.autoblog.com/2009/10/22/m...-dimpling-mpg/

https://www.rx7club.com/naturally-aspirated-performance-forum-220/reshape-combustion-chamber-864087/page3/

I mentioned the golf ball dimples as an example and found that there is some interesting information on engine applications. Such as dimpled valves.

I would love to see an entire intake tract dimpled and see what, if any, gains could be had.

This is pretty neat too... Mythbusters prove that a dimpled car gets better gas mileage... LoL!

http://www.autoblog.com/2009/10/22/m...-dimpling-mpg/

#11

basically what i mean is why spend 40 hours smoothing or roughing up the flow path where you can spend half that time turning up the boost and retuning the car, or upgrading other things that make a more noticable difference. unless you are limited by some class ruling for ITS or some other racing class, which also usually has many limitations on altering airflow anyways which makes the point moot again.

if anything i would prefer smooth, to keep oil from building up with dirt and crap in the intake tract which eventually WILL reduce performance regardless of what either side sais about rough or smooth being better.

if anything i would prefer smooth, to keep oil from building up with dirt and crap in the intake tract which eventually WILL reduce performance regardless of what either side sais about rough or smooth being better.

#12

Junior Member

Thread Starter

Join Date: May 2011

Location: Australia

Posts: 3

Likes: 0

Received 0 Likes

on

0 Posts

Thanks for the response guys. Just thought I'd bounce some ideas around.

I've already polished the runners, I think I'll just leave them as is.

My car is off the road for yet another build, changing a few things around.

It's no effort for me to do it, I have the time, and I enjoy doing little things like this. It's all part of the journey.

I'm at the point where I'm happy with the set up and have more than enough power for my application, so I just wanted to refine and make the whole thing as efficient as possible.

Cheers.

I've already polished the runners, I think I'll just leave them as is.

My car is off the road for yet another build, changing a few things around.

It's no effort for me to do it, I have the time, and I enjoy doing little things like this. It's all part of the journey.

I'm at the point where I'm happy with the set up and have more than enough power for my application, so I just wanted to refine and make the whole thing as efficient as possible.

Cheers.

#13

The runners should be a little rough, the intercooler pipes probably don't matter. The velocity in the IC pipes is very low compared to the final intake tract.

Air reacts differently to the surface as the velocity changes. You can do things that will have a big effect on low velocities that have almost no effect on high velocity air flow.

Working on the TB will net you results, there is probably no other place on the car where the air travels as fast as it does there.

Qualifier: I own not one, but two, flow benches.

Air reacts differently to the surface as the velocity changes. You can do things that will have a big effect on low velocities that have almost no effect on high velocity air flow.

Working on the TB will net you results, there is probably no other place on the car where the air travels as fast as it does there.

Qualifier: I own not one, but two, flow benches.

#14

There was another thread about something similar.

I would love to see an entire intake tract dimpled and see what, if any, gains could be had.

http://www.autoblog.com/2009/10/22/m...-dimpling-mpg/

I would love to see an entire intake tract dimpled and see what, if any, gains could be had.

http://www.autoblog.com/2009/10/22/m...-dimpling-mpg/