Compression on street ported motors?

#1

Junior Member

Thread Starter

Join Date: Aug 2008

Location: MA

Posts: 35

Likes: 0

Received 0 Likes

on

0 Posts

Compression on street ported motors?

Here's a question about compression.

What is a healthy compression for motors that either have a small street port all the way to a large street port? . I'll be in the market for a rx7 in the near future and would like to pick one up that has a street port done to it and id like to know who to look for compression wise,

.

Thank you

What is a healthy compression for motors that either have a small street port all the way to a large street port? . I'll be in the market for a rx7 in the near future and would like to pick one up that has a street port done to it and id like to know who to look for compression wise,

.

Thank you

#2

Here's a question about compression.

What is a healthy compression for motors that either have a small street port all the way to a large street port? . I'll be in the market for a rx7 in the near future and would like to pick one up that has a street port done to it and id like to know who to look for compression wise,

.

Thank you

What is a healthy compression for motors that either have a small street port all the way to a large street port? . I'll be in the market for a rx7 in the near future and would like to pick one up that has a street port done to it and id like to know who to look for compression wise,

.

Thank you

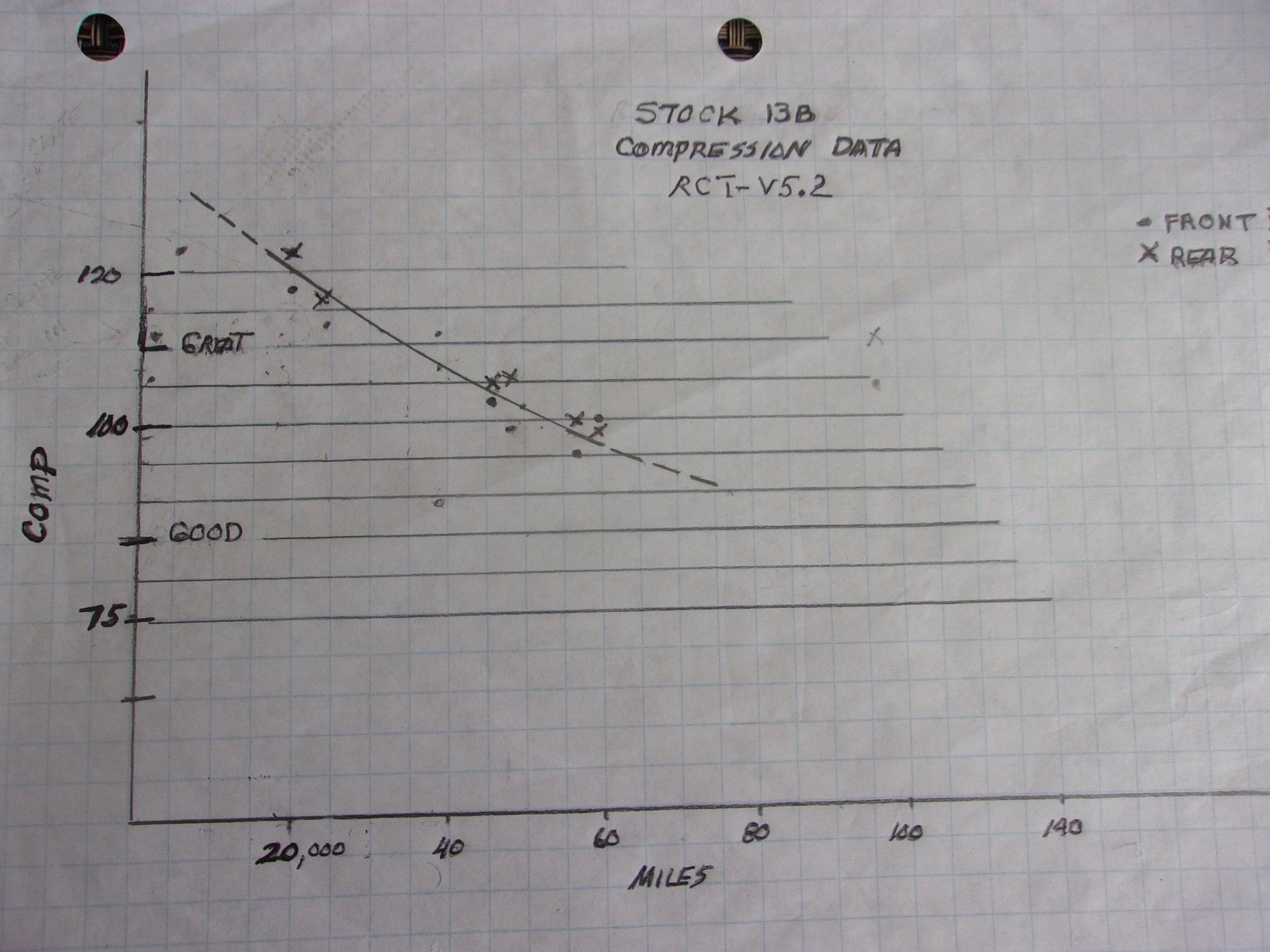

a NEW engine should usually be around 120+psi

MOSt engines now days that are original, or rebuilt, 90-100 psi is the norm

if its below 90psi, be a littler leary, shes starting to get tired, or it wasn't rebuilt properly

also, always do a compression test with the engine HOT, I get its a pain in the **** with the hot plugs, hot wires, hot everything, but it will give you a better idea on the health of the engine

The following users liked this post:

diabolical1 (08-16-23)

#3

porting has nothing to do with the compression of an engine

a NEW engine should usually be around 120+psi

MOSt engines now days that are original, or rebuilt, 90-100 psi is the norm

if its below 90psi, be a littler leary, shes starting to get tired, or it wasn't rebuilt properly

also, always do a compression test with the engine HOT, I get its a pain in the **** with the hot plugs, hot wires, hot everything, but it will give you a better idea on the health of the engine

a NEW engine should usually be around 120+psi

MOSt engines now days that are original, or rebuilt, 90-100 psi is the norm

if its below 90psi, be a littler leary, shes starting to get tired, or it wasn't rebuilt properly

also, always do a compression test with the engine HOT, I get its a pain in the **** with the hot plugs, hot wires, hot everything, but it will give you a better idea on the health of the engine

maybe the difference is too small to matter much but i too would like to know.

#4

Rotary Enthusiast

I might be wrong, but since the compression is taken at the plug, then the rotor isn't even on the exhaust or intake ports... it coul not possibly effect compression ever, period, point blank?

The following users liked this post:

diabolical1 (08-16-23)

#5

F'n Newbie...

iTrader: (6)

Porting will/should have an impact on vacuum readings though.

The following 3 users liked this post by fendamonky:

#6

if you think about how compression ratio is derived for a piston engine (i don't know how to calculate it for a rotary), then you will see that what ATC529R posted is a key point as to why porting makes no difference. it's based heavily on (and the measurement is taken at) the compression chamber. porting changes neither of these in a rotary. in a piston engine, porting can matter a bit, but unless you change the recess on the rotor, it won't matter on a rotary.

#7

Original Gangster/Rotary!

iTrader: (213)

Don't confuse cranking compression with compression ratio--- two completely different things.

I've always loved seeing when some guys try and sell their FD with compression in say the 80s, and try and imply that it's a solid reading based on the 'heavily ported' engine. Hogwash.

I've always loved seeing when some guys try and sell their FD with compression in say the 80s, and try and imply that it's a solid reading based on the 'heavily ported' engine. Hogwash.

The following 2 users liked this post by GoodfellaFD3S:

diabolical1 (08-17-23),

Relisys190 (11-13-23)

Trending Topics

#8

if you think about how compression ratio is derived for a piston engine (i don't know how to calculate it for a rotary), then you will see that what ATC529R posted is a key point as to why porting makes no difference. it's based heavily on (and the measurement is taken at) the compression chamber. porting changes neither of these in a rotary. in a piston engine, porting can matter a bit, but unless you change the recess on the rotor, it won't matter on a rotary.

Recall the ideal gas law, which is applicable here as a pretty good approximation of what goes on when we test compression: PV = nRT, where P = Pressure (what we're measuring), T = Temperature, V = Volume, and "n" = the amount of gas/substance, and R = the ideal gas constant. V will be based on your CR, and I agree is the same whether the engine is ported or not; T depends on ambient conditions when you test - let's assume we're keep T constant when we test our ported and OEM/un-ported engines; R is a constant. But "n" is different between the ported & OEM engine because of port overlap, and for an aggressively ported engine with lots of overlap, I'd expect "n" to be smaller than in an OEM ported engine, hence the lower P measurement when all other factors including CR being equal.

Make sense?

The following 2 users liked this post by Pete_89T2:

diabolical1 (08-17-23),

Howard Coleman (08-17-23)

#9

in case of 6-port (with aux ports open), semipp or full peripheral, won't the late closing intake timing lose some compression at low rpm like during the test?

also, the compression can be bumped by running heavy on premix or adding some oil to the intake before the test

also, the compression can be bumped by running heavy on premix or adding some oil to the intake before the test

Last edited by neit_jnf; 08-17-23 at 08:06 PM.

#10

Don’t forget cranking rpm either

and yes it does matter; static and dynamic CR are not the same thing as Goodfella pointed out

Generally speaking an engine that favors higher rpm operation is not going to exhibit as good of dynamic CR at low rpm/cranking compared to an engine that favors low rpm operation. Which is part of why they do what they do.

that a Renesis has zero intake/exhaust overlap is why the factory primary intake port can be positioned to open at 3° ABDC, still idle smoothly, and yet still be capable of 270 bhp NA. While a factory REW intake port opens at 45° ABDC. The only way to achieve the same Renesis primary opening point on the REW is with a Bridgeport, but the overlap greatly exacerbates low rpm operation, and cranking CR too.

.

and yes it does matter; static and dynamic CR are not the same thing as Goodfella pointed out

Generally speaking an engine that favors higher rpm operation is not going to exhibit as good of dynamic CR at low rpm/cranking compared to an engine that favors low rpm operation. Which is part of why they do what they do.

that a Renesis has zero intake/exhaust overlap is why the factory primary intake port can be positioned to open at 3° ABDC, still idle smoothly, and yet still be capable of 270 bhp NA. While a factory REW intake port opens at 45° ABDC. The only way to achieve the same Renesis primary opening point on the REW is with a Bridgeport, but the overlap greatly exacerbates low rpm operation, and cranking CR too.

.

Last edited by TeamRX8; 08-17-23 at 01:34 PM.

The following users liked this post:

diabolical1 (08-17-23)

#11

Racing Rotary Since 1983

iTrader: (6)

i am w PETE.

for sure the comp ratio doesn't change w ports but the Combustion Chamber Pressure (CCP) does. if there is a bunch of additional overlap less air will get in the motor. less air, less CCP. eventually velocity trumps the loss from overlap and additional power is made but at 250 rpm the additional overlap from porting decreases CCP... which we are measuring.

for sure the comp ratio doesn't change w ports but the Combustion Chamber Pressure (CCP) does. if there is a bunch of additional overlap less air will get in the motor. less air, less CCP. eventually velocity trumps the loss from overlap and additional power is made but at 250 rpm the additional overlap from porting decreases CCP... which we are measuring.

The following 4 users liked this post by Howard Coleman:

#12

for sure the comp ratio doesn't change w ports but the Combustion Chamber Pressure (CCP) does. if there is a bunch of additional overlap less air will get in the motor. less air, less CCP. eventually velocity trumps the loss from overlap and additional power is made but at 250 rpm the additional overlap from porting decreases CCP... which we are measuring.

other explanations in this thread make sense, but i think this one is great because i can actually visualize it. so, if i understand you, you're saying porting can affect a dynamic compression measurement?

thank you.

Last edited by diabolical1; 08-17-23 at 05:09 PM.

#15

Consider boost pressure vs porting level relative to power output, it’s all relative to how much the sieve leaks and where it leaks … blowing air/fuel out the exhaust during overlap spools a turbo better. Mazdas latest turbo wankel patent employs an exhaust port valve mechanism attempting to do just that while also meeting ever increasing emissions requirements

reminds me of the one engine dyno thread on here where someone had an EFR7670 on a full bridge ported REW that made 430 whp at 13 - 14 psig, vs a street port engine at mid-20 psig or higher to do the same.

which leads to a discussion about rotor CR relative to porting level imo … no different than the same for piston/head CR relative to camshaft duration and overlap.

.

reminds me of the one engine dyno thread on here where someone had an EFR7670 on a full bridge ported REW that made 430 whp at 13 - 14 psig, vs a street port engine at mid-20 psig or higher to do the same.

which leads to a discussion about rotor CR relative to porting level imo … no different than the same for piston/head CR relative to camshaft duration and overlap.

.

Last edited by TeamRX8; 08-18-23 at 09:13 AM.

#16

Old [Sch|F]ool

Overlap has zero to do with compression, and you would have to have an extremely efficient turbo setup to have less pressure in the exhaust than the intake BEFORE the turbo spools up, let alone after.

#17

Peejay, exhaust manifold pressure is not as harmful to the effects of rotary overlap at wide open throttle as a static exhaust manifild pressure versus intake manifild pressure comparison would seem to indicate.

That is intake/fuel loss out the exhaust does not stop or reverse at wot when emp reaches 1:1 or greater with map.

One has to look at the rotary specific dynamics of overlap and of course it is relative to porting.

Specifically, as the intake stroke is starting and overlaping the exhaust stroke there is very low intake velocity entering the engine and on the other side of the apex seal and in communication through the exhaust port much higer pressure and (relative to intake) high velocity exhaust gas exiting the exhaust port.

If you assemble a side housing, rotor housing, e-shaft and rotor and rotate you will see the exhaust flow on the (bottom) exhaust stroke side of the apex seal creates a siphon on the (top) exhaust and intake stroke side of the apex seal as the rotor tip and apex seal traverse the exhaust port.

This siphon is a strong dynamic in the rotary and only interfered with when you close the throttle plate. In closing the throttle plate the vacuum of the expanding intake stroke (not able to draw intake now) overpowers the vacuum of siphon of the exhaust stroke and exhaust is pulled into the intake stroke (not pushed in).

One could create a direct injection throttle plate-less rotary with compression bypass (ball valve window in side housing sealed by side seal grid mirroring a side intake port) and have all the benifits of rotary overlap without any downsides (even huge porting as the compression bypass would maintain intake velocity at low power request).

That is intake/fuel loss out the exhaust does not stop or reverse at wot when emp reaches 1:1 or greater with map.

One has to look at the rotary specific dynamics of overlap and of course it is relative to porting.

Specifically, as the intake stroke is starting and overlaping the exhaust stroke there is very low intake velocity entering the engine and on the other side of the apex seal and in communication through the exhaust port much higer pressure and (relative to intake) high velocity exhaust gas exiting the exhaust port.

If you assemble a side housing, rotor housing, e-shaft and rotor and rotate you will see the exhaust flow on the (bottom) exhaust stroke side of the apex seal creates a siphon on the (top) exhaust and intake stroke side of the apex seal as the rotor tip and apex seal traverse the exhaust port.

This siphon is a strong dynamic in the rotary and only interfered with when you close the throttle plate. In closing the throttle plate the vacuum of the expanding intake stroke (not able to draw intake now) overpowers the vacuum of siphon of the exhaust stroke and exhaust is pulled into the intake stroke (not pushed in).

One could create a direct injection throttle plate-less rotary with compression bypass (ball valve window in side housing sealed by side seal grid mirroring a side intake port) and have all the benifits of rotary overlap without any downsides (even huge porting as the compression bypass would maintain intake velocity at low power request).

#18

Rotary Enthusiast

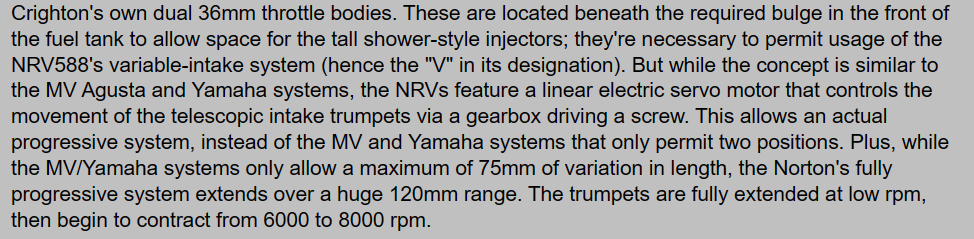

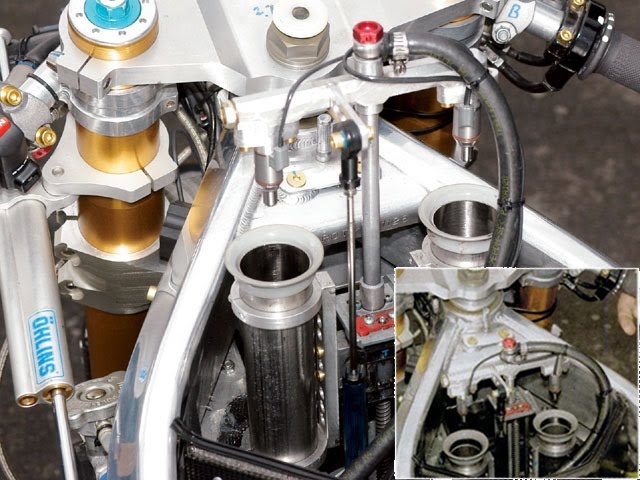

Not to hijack….. but why has the IMSA Mazda use of linear variable air intake systems not been used on the street?

seems relevant.

seems relevant.

#20

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,802

Received 2,577 Likes

on

1,831 Posts

The following users liked this post:

ATC529R (08-20-23)

#21

Norton NRV588 (motorcyclespecs.co.za)

The following 3 users liked this post by neit_jnf:

#22

Here’s one on a 20B

pretty rudimentary though; on/off at a certain rpm rather than PWM to rpm

there was one on an SCCA autox RX3, the internal UIM was spring load to lift up inside an air box above a certain rpm to then allow air to bypass directly into the LIM. EDIT: my recollection may not be 100%. It may have been open to atmospher unfiltered rather than in an air box. That was 10 or more years ago.

.

pretty rudimentary though; on/off at a certain rpm rather than PWM to rpm

there was one on an SCCA autox RX3, the internal UIM was spring load to lift up inside an air box above a certain rpm to then allow air to bypass directly into the LIM. EDIT: my recollection may not be 100%. It may have been open to atmospher unfiltered rather than in an air box. That was 10 or more years ago.

.

Last edited by TeamRX8; 08-21-23 at 08:00 AM.

The following users liked this post:

ATC529R (08-20-23)

The following 3 users liked this post by tomsn16:

#24

Full Member

I believe there are two factors in play that decrease the measured compression on a heavily ported engine:

1/If porting has increased the intake area of a port such that it remains open as the chamber enters the compression phase - some air is going to be pushed back into the intake due to slow speed of the rotor while testing.

2/In a hot engine any increased overlap will enable hotter air to be sucked in through the exhaust ports thereby reducing the density of the air which in turn reduces the pressure in CC.

1/If porting has increased the intake area of a port such that it remains open as the chamber enters the compression phase - some air is going to be pushed back into the intake due to slow speed of the rotor while testing.

2/In a hot engine any increased overlap will enable hotter air to be sucked in through the exhaust ports thereby reducing the density of the air which in turn reduces the pressure in CC.