Benefits of Lapping?

#1

Full Member

Thread Starter

Join Date: Jun 2005

Location: East Bay Area, CA

Posts: 75

Likes: 0

Received 0 Likes

on

0 Posts

Benefits of Lapping?

What are the benefits to lapping the side housings? $280 plus shipping (RB) doesnt make me all that enthusiastic. The housings have 99k miels on it and seem still in great shape no abnormal wear. When the engine is rebuilt with new parts how would the wear patterns change on the side housings? (they wouldnt) so why would u want a new surface if its just going to wear exactly the same especially if the wear present is within spec? Thanks guys

#2

Senior Member

Join Date: Nov 2001

Location: Brampton, Ontario

Posts: 552

Likes: 0

Received 0 Likes

on

0 Posts

The wear gets worse over time, so lapping them buys you more time. That's the theory, anyway! I was considering getting my side housings lapped, but the consensus seems pretty split between doing it and not doing it. I ended up buying a good used motor, so I never had to make a decision.

On the pro side, you get a perfectly flat surface - like new. On the con side, I've read that the surface has a thin nitride coating for hardness, and that coating gets removed when the plates are lapped. So, lapped plates wear faster and the end result lifespan is no different then using used plates that are still in-spec.

Most of the big names seem to lap, but the ones that don't are pretty vocal about it. I really don't know who to believe, or what the real truth of the matter is.

On the pro side, you get a perfectly flat surface - like new. On the con side, I've read that the surface has a thin nitride coating for hardness, and that coating gets removed when the plates are lapped. So, lapped plates wear faster and the end result lifespan is no different then using used plates that are still in-spec.

Most of the big names seem to lap, but the ones that don't are pretty vocal about it. I really don't know who to believe, or what the real truth of the matter is.

#3

Eye In The Sky

iTrader: (2)

Join Date: Feb 2001

Location: In A Disfunctional World

Posts: 7,892

Likes: 0

Received 114 Likes

on

66 Posts

(1) The wear gets worse over time, so lapping them buys you more time. That's the theory, anyway! I was considering getting my side housings lapped, but the consensus seems pretty split between doing it and not doing it. I ended up buying a good used motor, so I never had to make a decision.

Lapping the side housing is like honing a cylinder bore. It improves compression and thus will give more HP and better mileage. Also less blowby means less fuel dilution of the oil. It is not a theory.

(2) On the con side, I've read that the surface has a thin nitride coating for hardness, and that coating gets removed when the plates are lapped. So, lapped plates wear faster and the end result lifespan is no different then using used plates that are still in-spec.

The nitride layer does get thinner the lower you go but the basic housing material is still very hard. Rotor Sports Racing said it really does not matter as long as the water seal grouve is not so shallow that the seals get over compressed.

Lapping the side housing is like honing a cylinder bore. It improves compression and thus will give more HP and better mileage. Also less blowby means less fuel dilution of the oil. It is not a theory.

(2) On the con side, I've read that the surface has a thin nitride coating for hardness, and that coating gets removed when the plates are lapped. So, lapped plates wear faster and the end result lifespan is no different then using used plates that are still in-spec.

The nitride layer does get thinner the lower you go but the basic housing material is still very hard. Rotor Sports Racing said it really does not matter as long as the water seal grouve is not so shallow that the seals get over compressed.

#4

Safety Guy

iTrader: (3)

Join Date: Jan 2002

Location: Apple Valley area in MN

Posts: 1,433

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by johnnyg

The wear gets worse over time, so lapping them buys you more time. That's the theory, anyway! I was considering getting my side housings lapped, but the consensus seems pretty split between doing it and not doing it. I ended up buying a good used motor, so I never had to make a decision.

On the pro side, you get a perfectly flat surface - like new. On the con side, I've read that the surface has a thin nitride coating for hardness, and that coating gets removed when the plates are lapped. So, lapped plates wear faster and the end result lifespan is no different then using used plates that are still in-spec.

Most of the big names seem to lap, but the ones that don't are pretty vocal about it. I really don't know who to believe, or what the real truth of the matter is.

On the pro side, you get a perfectly flat surface - like new. On the con side, I've read that the surface has a thin nitride coating for hardness, and that coating gets removed when the plates are lapped. So, lapped plates wear faster and the end result lifespan is no different then using used plates that are still in-spec.

Most of the big names seem to lap, but the ones that don't are pretty vocal about it. I really don't know who to believe, or what the real truth of the matter is.

If you lap it is not going to remove a portion of the stock nitriding...it will remove all of it because it is only a few 10000's thick. So who cares if you remove the stock nitriding... go get it nitrided again. It's not that big of a deal and is there for a reason; to help in reducing wear. Besides, there are much better coatings than the stock nitriding anyhow out there.

#5

Full Member

Thread Starter

Join Date: Jun 2005

Location: East Bay Area, CA

Posts: 75

Likes: 0

Received 0 Likes

on

0 Posts

thnx guys thats some good info. I was thinking of sending my housings to racing beat. how do they compare to others? How much is nitriding? I really dont have the greatest of funds to go all out with this motor and i dont really intend to so is the lapping really worth it in my case? Or thats probably something that i have to figure out my self??

#6

Eye In The Sky

iTrader: (2)

Join Date: Feb 2001

Location: In A Disfunctional World

Posts: 7,892

Likes: 0

Received 114 Likes

on

66 Posts

A good nitriding job is going to be costly. First the surface has to be lapped to true it up. Then the nitriding which really heats up the housing and can cause minor warping plus the new surface will be rough. Then they have to be relapped again. You could forgo the first lapping, but then the nitride layer after the last lapping will be uneven.

Have you researched how they nitirde objects. There is a newer lower temperature way using plasma.

Have you researched how they nitirde objects. There is a newer lower temperature way using plasma.

#7

Rotary Enthusiast

When I took in my irons to Racing Beat, I talked with them about this and they said not to worry about it. First, after 50K you end up rubbing most of it away anyhow. Just look at / measure the wear grooves; they're much deeper than the thickness of the nitride coating. Older rotary engines didn't have the nitride coating done, I think they said it may be only on the 2nd and 3rd gens?

They didn't have a problem wearing, of course those engines didn't have as much power.

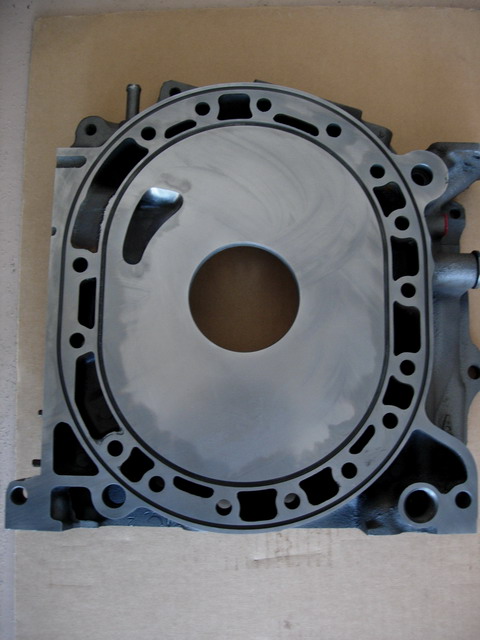

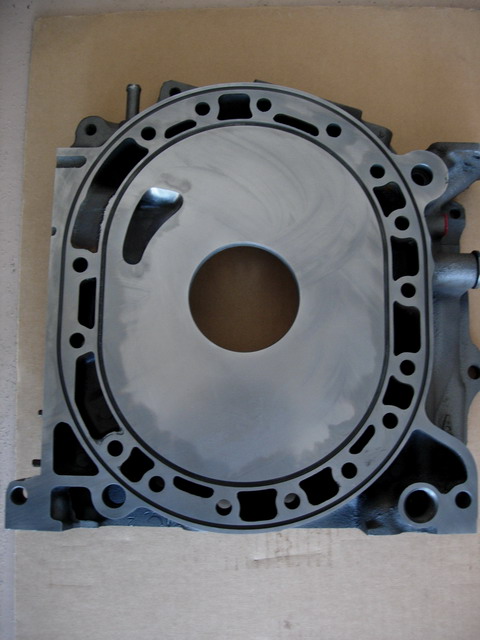

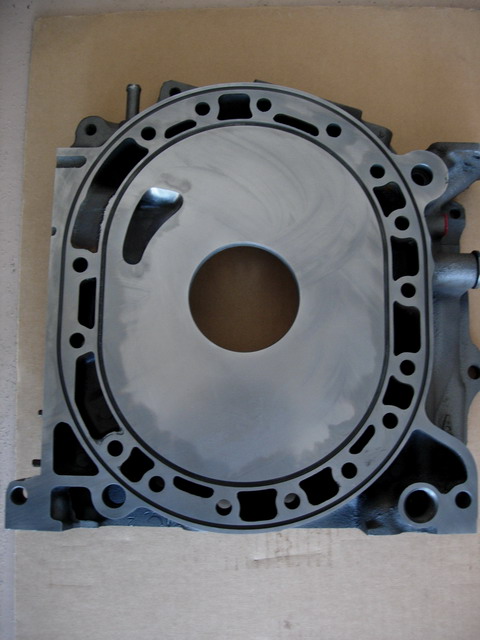

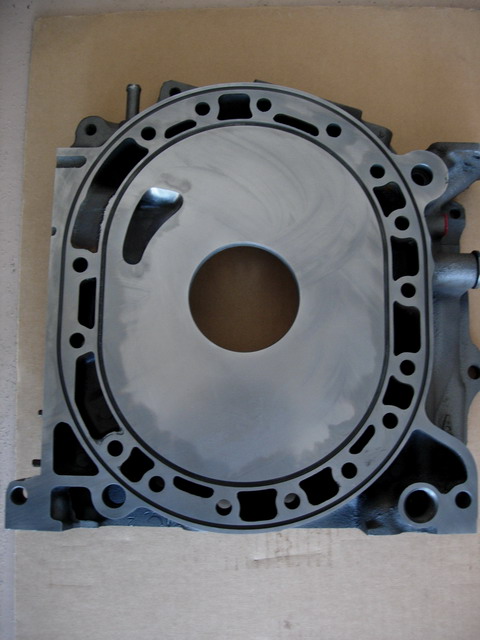

After having mine lapped, they looked great!

Lapping not only makes sure that the surface is as true as possible, but helps 'fix' the water seal grooves in that it gives them back the sharp edges to protect the seals.

They didn't have a problem wearing, of course those engines didn't have as much power.

After having mine lapped, they looked great!

Lapping not only makes sure that the surface is as true as possible, but helps 'fix' the water seal grooves in that it gives them back the sharp edges to protect the seals.

Last edited by atihun; 07-29-05 at 05:19 PM.

Trending Topics

#8

I would say lapping is like milling the deck of a piston motor to make it nice and even so there are no high spots due to wear which gives the side seals, corner seals, and oil seals a better chance of sealing properly. My $0.02. I got mine done for around $150...racing beat will get you every time.

As Nike says, Just Do It....a little $$ that will save you in the long run.

As Nike says, Just Do It....a little $$ that will save you in the long run.

#9

Full Member

Thread Starter

Join Date: Jun 2005

Location: East Bay Area, CA

Posts: 75

Likes: 0

Received 0 Likes

on

0 Posts

wow thanks for pic! those do look great! if racing beat ports and laps ur housings its like $444 but if u have then just port then its $331 so thats only $113 for lapping. But then if u only want the lapping then its $70 per side...$280. more than double. I want to port the engine my self so thats why i have to pay the $280. totally sux

Antihun- Did you have RB street port ur housings too? could u possibly send pics of the porting? Especially the intermediate housings and do u have pics of the exhaust porting too? any pics would be very helpful. Thanks a lot!

Antihun- Did you have RB street port ur housings too? could u possibly send pics of the porting? Especially the intermediate housings and do u have pics of the exhaust porting too? any pics would be very helpful. Thanks a lot!

#10

Rotary Enthusiast

Pics of the ported irons and rotor housings are here:

https://www.rx7club.com/single-turbo-rx-7s-23/gt35r-here-i-come-d-406183/

https://www.rx7club.com/single-turbo-rx-7s-23/gt35r-here-i-come-d-406183/

#11

Rotary Enthusiast

Originally Posted by RX-17

wow thanks for pic! those do look great! if racing beat ports and laps ur housings its like $444 but if u have then just port then its $331 so thats only $113 for lapping. But then if u only want the lapping then its $70 per side...$280. more than double. I want to port the engine my self so thats why i have to pay the $280. totally sux

Antihun- Did you have RB street port ur housings too? could u possibly send pics of the porting? Especially the intermediate housings and do u have pics of the exhaust porting too? any pics would be very helpful. Thanks a lot!

Antihun- Did you have RB street port ur housings too? could u possibly send pics of the porting? Especially the intermediate housings and do u have pics of the exhaust porting too? any pics would be very helpful. Thanks a lot!

Since you are sending them everything have them do the porting as well, they do an excellent job. It's probably going to cost you 50 to 100 to ship them, they weigh a total of about 80+ lbs. I sold a set and had to ship them to Texas so that's how I know.

#12

Full Member

Thread Starter

Join Date: Jun 2005

Location: East Bay Area, CA

Posts: 75

Likes: 0

Received 0 Likes

on

0 Posts

damn thanks for those pictures those are awesome! that will really help me since i really want to say that i did the porting myself. what a sense of accomplishment. your car is gorgeous and you really did a beautiful porting job! if u ever have any suggestions how the process or what to u how to gauge how deep to go anything you can think of that u have the time for would be very highly appreciated!

#13

Senior Member

Join Date: Aug 2003

Location: Alabama just east of B'ham

Posts: 445

Likes: 0

Received 0 Likes

on

0 Posts

My engine builder won't build an engine without lapping the plates first. He took 6 months to build his own lapping table. Experimenting with the rpm's and positioning of the plate.

#14

Rotary Enthusiast

Originally Posted by RX-17

if u ever have any suggestions how the process or what to u how to gauge how deep to go anything you can think of that u have the time for would be very highly appreciated!

Get a set of port templates, Tri-Point, Mazdatrix, Racing Beat, or whomever sells them. Even the experts use them.

Get a set of junk plates and housings. Try it out!

Once you feel comfortable with the process, dig into some of the ports to see where the water jackets are for reference.

Once you feel comfortable with the process, dig into some of the ports to see where the water jackets are for reference.Go slow, it's easier to take material off than put it back on!

Oh, and make sure your neighbors like you. Do it in a closed garage for noise abatement, wear eye protection and some heavy duty ear/hearing protection.

#15

Safety Guy

iTrader: (3)

Join Date: Jan 2002

Location: Apple Valley area in MN

Posts: 1,433

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by atihun

When I took in my irons to Racing Beat, I talked with them about this and they said not to worry about it. First, after 50K you end up rubbing most of it away anyhow. Just look at / measure the wear grooves; they're much deeper than the thickness of the nitride coating. Older rotary engines didn't have the nitride coating done, I think they said it may be only on the 2nd and 3rd gens?

They didn't have a problem wearing, of course those engines didn't have as much power.

After having mine lapped, they looked great!

Lapping not only makes sure that the surface is as true as possible, but helps 'fix' the water seal grooves in that it gives them back the sharp edges to protect the seals.

They didn't have a problem wearing, of course those engines didn't have as much power.

After having mine lapped, they looked great!

Lapping not only makes sure that the surface is as true as possible, but helps 'fix' the water seal grooves in that it gives them back the sharp edges to protect the seals.

Like I said earlier, nitriding is 2/10,000's of an inch thick...OEM specs are measure in 1/1000's; most are 3-5/1000"s... you will not know the difference unless doing this to all the housings and at most you'll get an increase of 1/1000".

Lapping does not "fix" the O-ring grooves, it removes material from the surface plane and you must therefore compensate your O-ring depth by whatever amount was lapped to correct to OEM tolerances, ensure the ring seats properly and does not get squished.

#16

Safety Guy

iTrader: (3)

Join Date: Jan 2002

Location: Apple Valley area in MN

Posts: 1,433

Likes: 0

Received 0 Likes

on

0 Posts

And yes...plasma coating is exactly the application process I'm referring to  and no it does not warp housings (assuming temperature controls are done slowly up/down of course and there is no thermal shock).

and no it does not warp housings (assuming temperature controls are done slowly up/down of course and there is no thermal shock).

and no it does not warp housings (assuming temperature controls are done slowly up/down of course and there is no thermal shock).

and no it does not warp housings (assuming temperature controls are done slowly up/down of course and there is no thermal shock).

#17

Rotary Enthusiast

Originally Posted by Turbo 3

Lapping does not "fix" the O-ring grooves, it removes material from the surface plane and you must therefore compensate your O-ring depth by whatever amount was lapped to correct to OEM tolerances, ensure the ring seats properly and does not get squished.

As for squishing the O-rings, they are supposed to be squished. They get flattened quite a bit. There is as you said though a minimal depth that you cannot go beyond. That was determined during the lapping process, on how much they could remove before they would make the grooves too shallow.

#18

Safety Guy

iTrader: (3)

Join Date: Jan 2002

Location: Apple Valley area in MN

Posts: 1,433

Likes: 0

Received 0 Likes

on

0 Posts

Sorry, I should have been more specific and said "crushed" vs. squished. Say the depth of the ring is 20 thousands so say if you remove 10 from the housing surface you'd need to compensate depth of the O ring groove by 10 otherwise when bolting the housings together the ring may split due to the lack of room for it to fill under load (squish).

Thread

Thread Starter

Forum

Replies

Last Post

23Racer

Race Car Tech

1

09-21-15 10:48 AM

rx8volks

Canadian Forum

0

09-16-15 09:07 PM

rx8volks

Canadian Forum

0

09-01-15 11:02 PM