E Production Rx-7 Build

#201

Fabrineer

Thread Starter

Painted the Differential Case and Cover

I got some Dupont Automotive paint and painted the differential case and cover today. I prepped the aluminum cover by masking off the machined surfaces and all holes leading to the inside and sandblasting. That thing was pretty nasty to start, I wish I had taken pictures of it before I did the work.

I also masked off the differential carrier (ring and pinion) with a couple plastic bags and some tape and went at the differential case with an air powered wire brush. It seemed to work pretty well, but cleaning with some solvents to remove all the dust was a pain in the ***.

Painting is not ideal in these cold conditions.... I heated the whole thing up in the shop by sticking it next to the waste oil heater and hitting it with a heat gun, then wheeled it outside, shot it quickly, and hit it again with the paint gun. I've never used a proper automotive acrylic enamel or a paint gun before, so I hope this was OK to do.

Note, the next 2 shots are taken before I had fully scrubbed the dust and residue off, there was a light coating of rust dust there, but I got it off. Hope I did a good enough job, I don't want this flaking or chipping as easily as rattle can seems to do...

First Coat

Second Coat

Finished

I also masked off the differential carrier (ring and pinion) with a couple plastic bags and some tape and went at the differential case with an air powered wire brush. It seemed to work pretty well, but cleaning with some solvents to remove all the dust was a pain in the ***.

Painting is not ideal in these cold conditions.... I heated the whole thing up in the shop by sticking it next to the waste oil heater and hitting it with a heat gun, then wheeled it outside, shot it quickly, and hit it again with the paint gun. I've never used a proper automotive acrylic enamel or a paint gun before, so I hope this was OK to do.

Note, the next 2 shots are taken before I had fully scrubbed the dust and residue off, there was a light coating of rust dust there, but I got it off. Hope I did a good enough job, I don't want this flaking or chipping as easily as rattle can seems to do...

First Coat

Second Coat

Finished

#207

Fabrineer

Thread Starter

I plan on using a heat exchanger to pull the heat from the gears. I'm getting some advice from a certain Eaton engineer on the proper design of gear cooling. He may or may not be patrolling this thread... :o)

#208

Fabrineer

Thread Starter

Differential Heat Exchanger Design Discussion

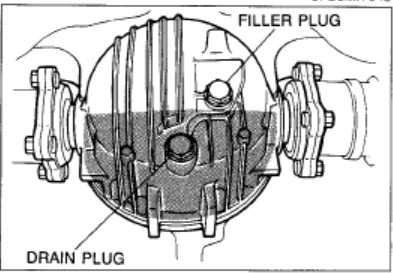

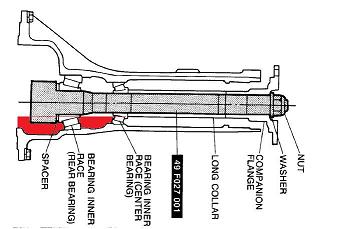

Supercharged FC, the pinion sits lower than the axle center line. I looked through my Rx-7 manuals and found this picture for the stock fluid level:

This indicates to me that the pinion is at least partially submerged in the gear oil. So, perhaps simply exchanging the fluid as opposed to designing a complex squirter will be sufficient.

From what I can find, most of the 350z and E46 guys are just simply exchanging the oil.

This indicates to me that the pinion is at least partially submerged in the gear oil. So, perhaps simply exchanging the fluid as opposed to designing a complex squirter will be sufficient.

From what I can find, most of the 350z and E46 guys are just simply exchanging the oil.

#209

Senior Member

iTrader: (7)

Join Date: Jul 2008

Location: Seneca, SC

Posts: 352

Likes: 0

Received 0 Likes

on

0 Posts

Diff cooler ideas

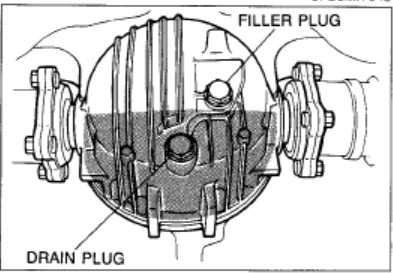

I'm still looking into this but I got a quick pointer from my friend at the upside down axle company. You need one roller submerged of the highest bearing. You can verify this with the sight tube test. In most cases this is the front pinion bearing but in a RX7 it might be the stub shaft bearings.

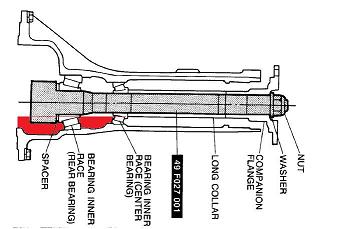

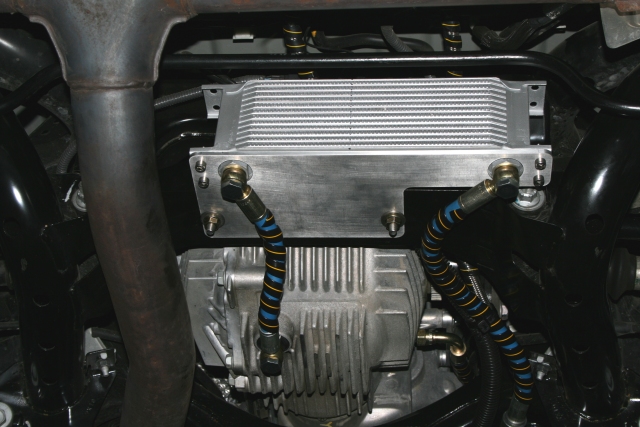

The biggest issue you might run into is having to over filled system to keep the cooler filled or making foam with pump. Overfilling would cause the system to overheat and lead to seal issues. In an ideal world your cooler could be lower than the fill plug. Like these -

In an RX7 I would shoot for something like this GTR (or the white 350Z above). Note the fittings are on the top of the cooler preventing the excess oil from running into the diff. This can also be accomplished with check valves, thermostats, or regulator valves (opens when pump creates sufficient pressure). I also dig the location of this cooler: lots of air, short hoses.

With mechanical pump you need a pressure regulator to handle warm up. With an electric system you could simply wait until it heats up, but having a thermostat system could be beneficial.

The biggest issue you might run into is having to over filled system to keep the cooler filled or making foam with pump. Overfilling would cause the system to overheat and lead to seal issues. In an ideal world your cooler could be lower than the fill plug. Like these -

In an RX7 I would shoot for something like this GTR (or the white 350Z above). Note the fittings are on the top of the cooler preventing the excess oil from running into the diff. This can also be accomplished with check valves, thermostats, or regulator valves (opens when pump creates sufficient pressure). I also dig the location of this cooler: lots of air, short hoses.

With mechanical pump you need a pressure regulator to handle warm up. With an electric system you could simply wait until it heats up, but having a thermostat system could be beneficial.

#211

Senior Member

iTrader: (7)

Join Date: Jul 2008

Location: Seneca, SC

Posts: 352

Likes: 0

Received 0 Likes

on

0 Posts

Diff cooler

I was talking to the lube lady about this and you should try to keep your temps diff lube temps below 250F-300F depending on your additive package. 180F is a good target temp for 75W90. Also you shouldn't have issue with foaming 75W90.

Getting a temperature sensor that you can datalog with would be a good first step. You can adjust the system from there.

I'm guessing you are running a stock TII LSD, which means some sort of additive package for the clutch packs (which can be mostly smoke and mirrors), but if ever switch to a torsion or want to play with blending you might try Road Ranger 75W-90 FE. It has been shown to reduce running temperatures (designed for Fuel Economy hince FE).

Just some ideas

Getting a temperature sensor that you can datalog with would be a good first step. You can adjust the system from there.

I'm guessing you are running a stock TII LSD, which means some sort of additive package for the clutch packs (which can be mostly smoke and mirrors), but if ever switch to a torsion or want to play with blending you might try Road Ranger 75W-90 FE. It has been shown to reduce running temperatures (designed for Fuel Economy hince FE).

Just some ideas

#212

Fabrineer

Thread Starter

I am running an NA diff as dictated by the rules. I had to sell my KAAZ :-(

I recently picked up a rebuilt stock NA diff with 4.30 gears in it and oversized shim plates on the clutch pack. We will see what condition it is in, but just for the gears, I can't complain about the price.

I am currently working on a duct design. My idea on ducting the heat exchanger is that I can get away with a smaller exchanger for the same amount of heat rejection, thus saving weight and having a nicely packaged system. I will be validating my design with the use of CFD, mostly in order to get an idea of the flow across the heat exchanger. I'd like to do some iterative design work; that is, make some changes and see the results. Look back in a few weeks or so to see the process.

Something just popped in my head. Can't I use the same oil in the transmission as the differential? Front drive cars do, and for this reason, I could use the same cooling system to cut down on complexity and weight.

Given that they would likely heat at different rates, I could still use separate thermostat systems on each one, and do a neat-o squiter on each gear for the trans (although I would like to save that for the dog box).

Can you think of a reason that mixing the oils isn't OK? I tend to think it is given the racing history of Hondas and other FWD cars...

I recently picked up a rebuilt stock NA diff with 4.30 gears in it and oversized shim plates on the clutch pack. We will see what condition it is in, but just for the gears, I can't complain about the price.

I am currently working on a duct design. My idea on ducting the heat exchanger is that I can get away with a smaller exchanger for the same amount of heat rejection, thus saving weight and having a nicely packaged system. I will be validating my design with the use of CFD, mostly in order to get an idea of the flow across the heat exchanger. I'd like to do some iterative design work; that is, make some changes and see the results. Look back in a few weeks or so to see the process.

Something just popped in my head. Can't I use the same oil in the transmission as the differential? Front drive cars do, and for this reason, I could use the same cooling system to cut down on complexity and weight.

Given that they would likely heat at different rates, I could still use separate thermostat systems on each one, and do a neat-o squiter on each gear for the trans (although I would like to save that for the dog box).

Can you think of a reason that mixing the oils isn't OK? I tend to think it is given the racing history of Hondas and other FWD cars...

#214

Fabrineer

Thread Starter

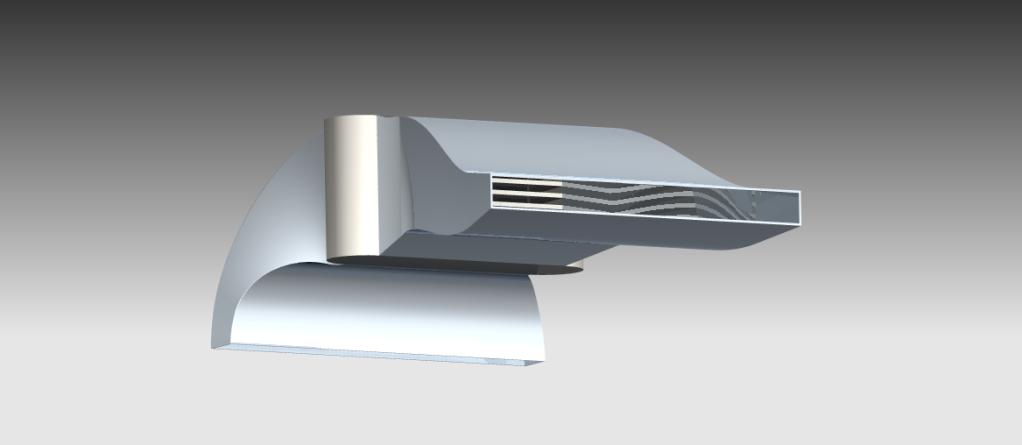

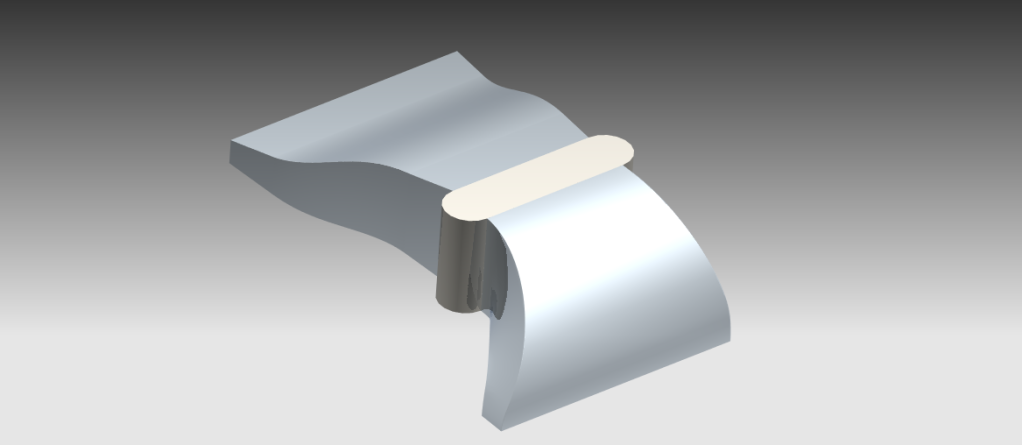

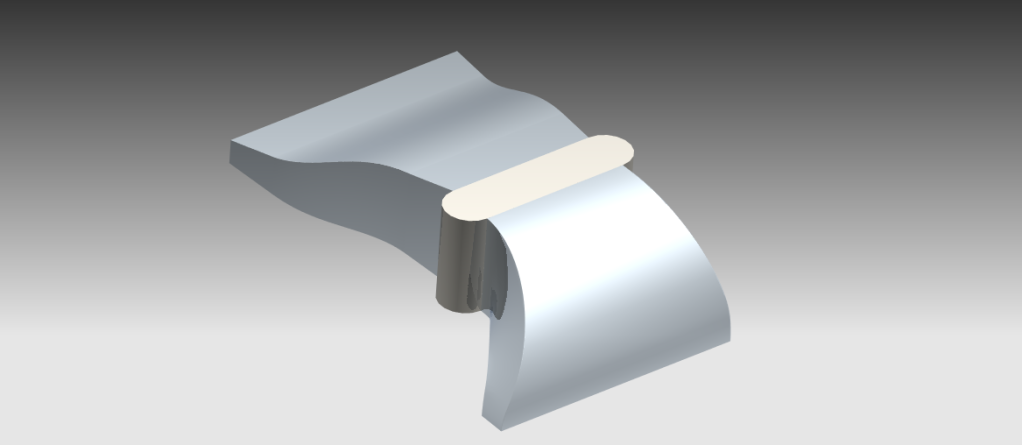

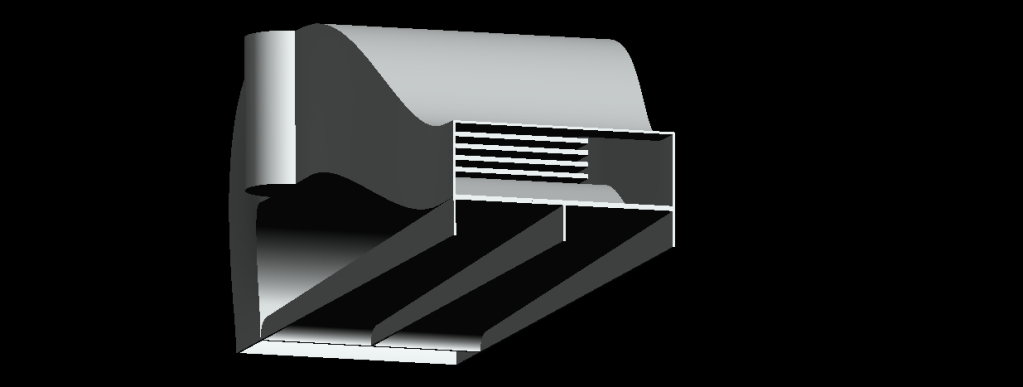

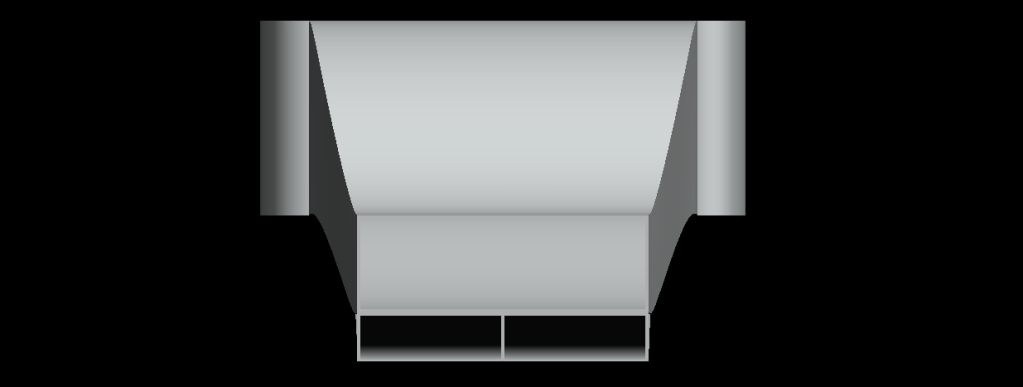

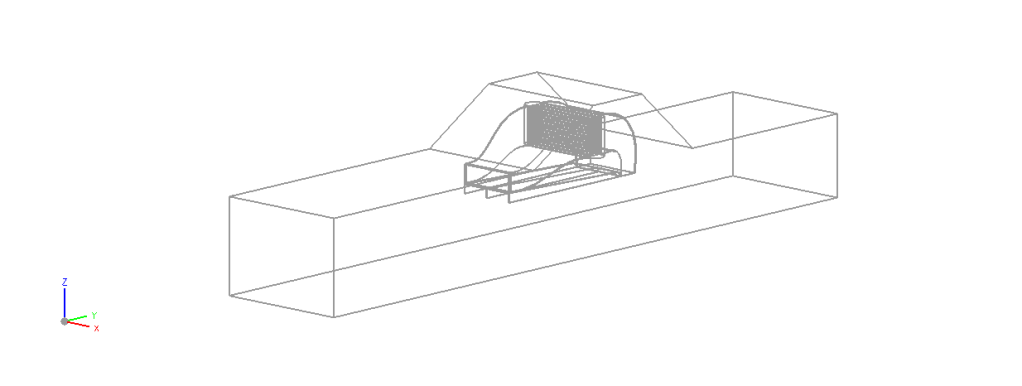

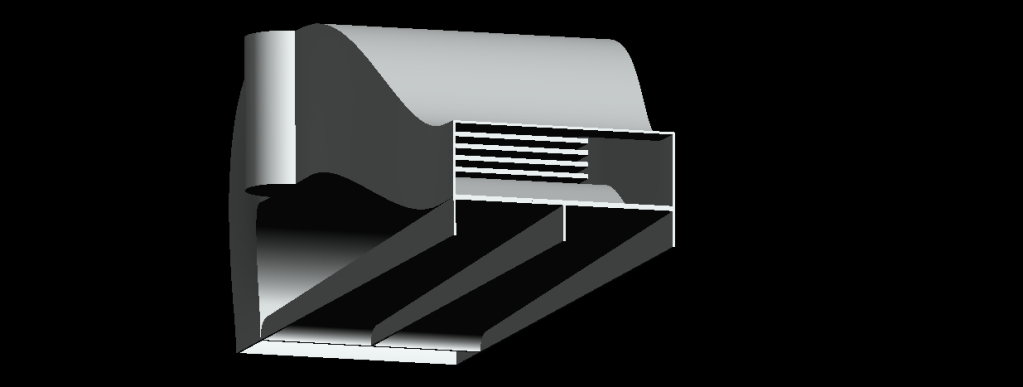

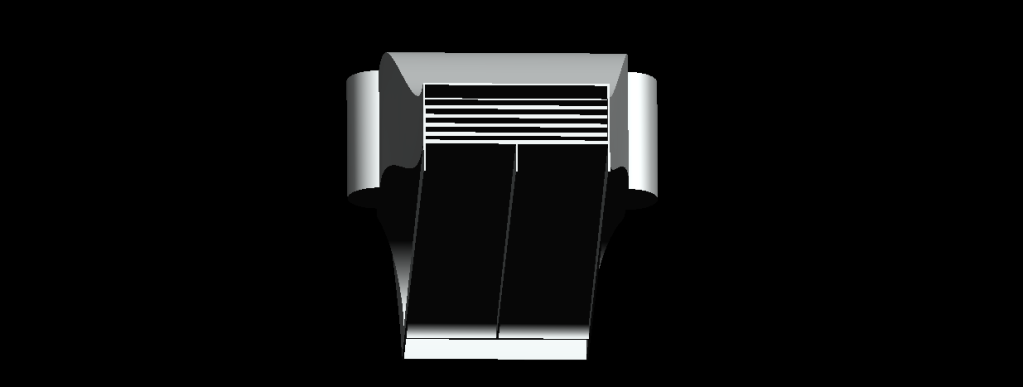

Very Quick CAD Work on Duct Design

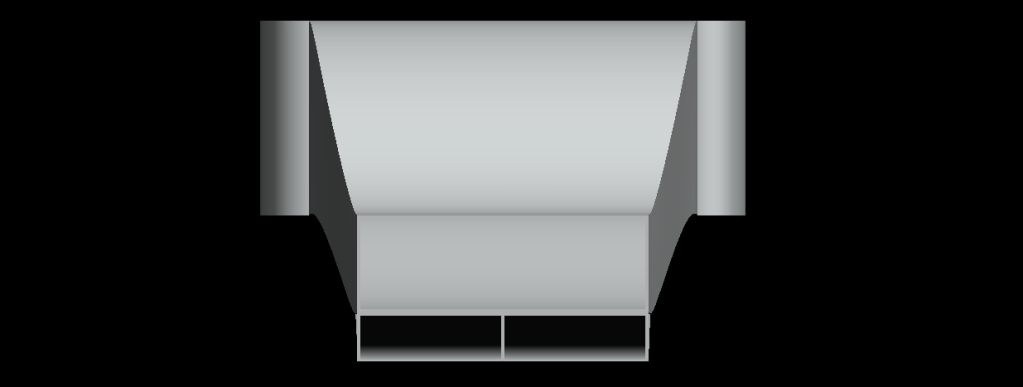

Here's a quick idea on what I have in mind for the cooler.

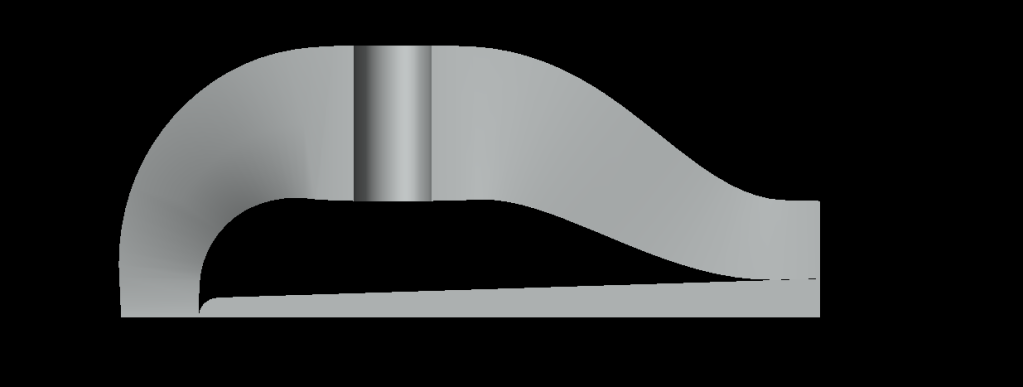

Basically, I have a diffuser, which turns the low pressure, high velocity air from under the car into high pressure, low velocity air (much like how duct work for a radiator is designed). Then, I have the reverse of that on the other side of the heat exchanger, which turns it back into high velocity, low pressure air.

Not modeled here is the freeflow "ramp" which will cause the air inside the exiting duct to be a lower pressure than the air flowing over it, which will give a favorable pressure differential for the flow to exit.

Once this system is modeled, I will verify with CFD in order to maximize the flow across the heat exchanger. I will use this iteratively to select my heat exchanger.

Any racers out there that have temperature taps on their diffs, speak up, I would like to know the conditions that cause the highest temperatures, and size accordingly.

Basically, I have a diffuser, which turns the low pressure, high velocity air from under the car into high pressure, low velocity air (much like how duct work for a radiator is designed). Then, I have the reverse of that on the other side of the heat exchanger, which turns it back into high velocity, low pressure air.

Not modeled here is the freeflow "ramp" which will cause the air inside the exiting duct to be a lower pressure than the air flowing over it, which will give a favorable pressure differential for the flow to exit.

Once this system is modeled, I will verify with CFD in order to maximize the flow across the heat exchanger. I will use this iteratively to select my heat exchanger.

Any racers out there that have temperature taps on their diffs, speak up, I would like to know the conditions that cause the highest temperatures, and size accordingly.

#215

Fabrineer

Thread Starter

I may gut mine and buy the gear... Haven't wanted to part with that much money yet.

#216

The 5.12 and 4.88 are spendy but worth it. Most of the tracks in the area will have similar top speeds, even though their layouts are vastly different. An E-prod car is probably going to see a terminal speed of around 135-140 at M-O, ORP, and Grattan. Easy enough to figure out top gear and r&p will work.

Any idea what you're going to do for a trans?

Any idea what you're going to do for a trans?

#217

Fabrineer

Thread Starter

The 5.12 and 4.88 are spendy but worth it. Most of the tracks in the area will have similar top speeds, even though their layouts are vastly different. An E-prod car is probably going to see a terminal speed of around 135-140 at M-O, ORP, and Grattan. Easy enough to figure out top gear and r&p will work.

Any idea what you're going to do for a trans?

Any idea what you're going to do for a trans?

Seth

#218

Banned. I got OWNED!!!

iTrader: (1)

Join Date: Jun 2006

Location: Denver

Posts: 697

Likes: 0

Received 0 Likes

on

0 Posts

I believe the issue you will runinto ina RWD car on slicks is that to protect the diff and its clutch plates and R&P your going to want to use something along the lines of Redline Shockproof "Heavy" with some amount of fritcion modifier, and in the gearbox you will likely want to run Shockproof Liteweight or similar. I would not mix the two.

FWD/AWD cars get away with one oil but its usually a compromise and they are somewhat traction challenged, where a RWD car with 55 to 60% rear bias and good tires does not suffer this issue.

FWD/AWD cars get away with one oil but its usually a compromise and they are somewhat traction challenged, where a RWD car with 55 to 60% rear bias and good tires does not suffer this issue.

#219

Senior Member

iTrader: (7)

Join Date: Jul 2008

Location: Seneca, SC

Posts: 352

Likes: 0

Received 0 Likes

on

0 Posts

Something just popped in my head. Can't I use the same oil in the transmission as the differential? Front drive cars do, and for this reason, I could use the same cooling system to cut down on complexity and weight.

Given that they would likely heat at different rates, I could still use separate thermostat systems on each one, and do a neat-o squiter on each gear for the trans (although I would like to save that for the dog box).

Can you think of a reason that mixing the oils isn't OK? I tend to think it is given the racing history of Hondas and other FWD cars...

Given that they would likely heat at different rates, I could still use separate thermostat systems on each one, and do a neat-o squiter on each gear for the trans (although I would like to save that for the dog box).

Can you think of a reason that mixing the oils isn't OK? I tend to think it is given the racing history of Hondas and other FWD cars...

I know it is common practice but there lots of engineering that goes into both for their particular needs. I run Roadranger CD 50 transmission oil (uses different viscosity ratings) in my TII trany and have seen benefits in cold and high rpm shifting.

It will depend on what box you run in the end.

Combining the cooler and pump (as done in F1), assuming like oils, would be interesting but also adds risk if you get a leak. Blowing a mazda diff is much better than $3K race box. Also use a good filter, small debris can have a huge effect on bearing performance.

I sent you some light reading in an email, we can talk through some things if you are serious about adding forced lubrication to your transmission. I would hestitate on a high dollar race box unless there is precedence, but on a TII or NA I'm all in.

Keep working, I want to watch you race next summer!

#221

Fabrineer

Thread Starter

Well, I won't be getting the dog box for a little while, so the idea of the combined system was a little far fetched anyway.

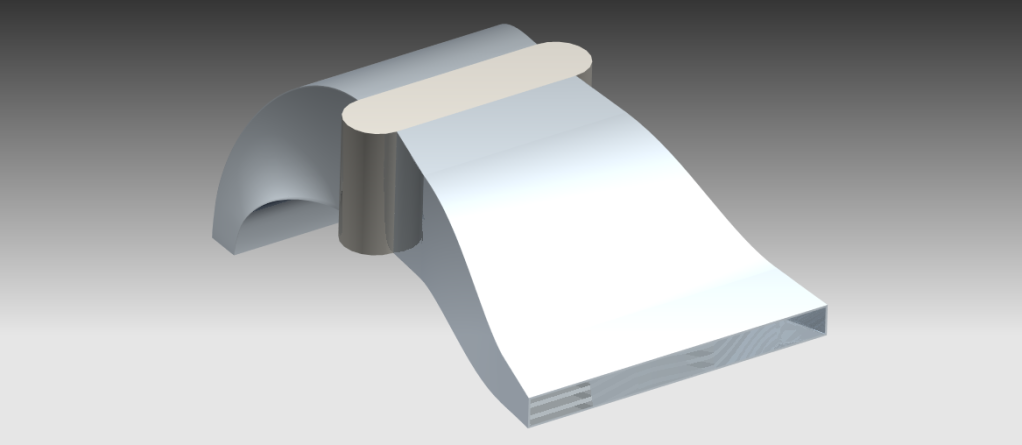

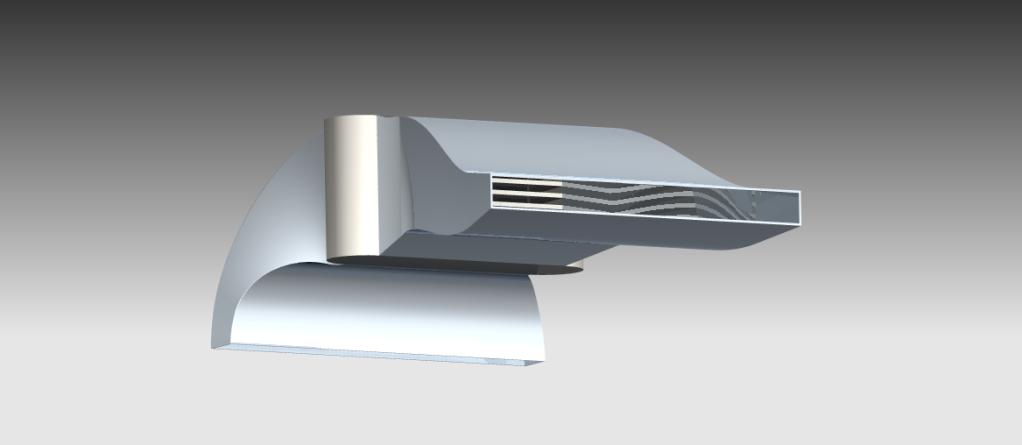

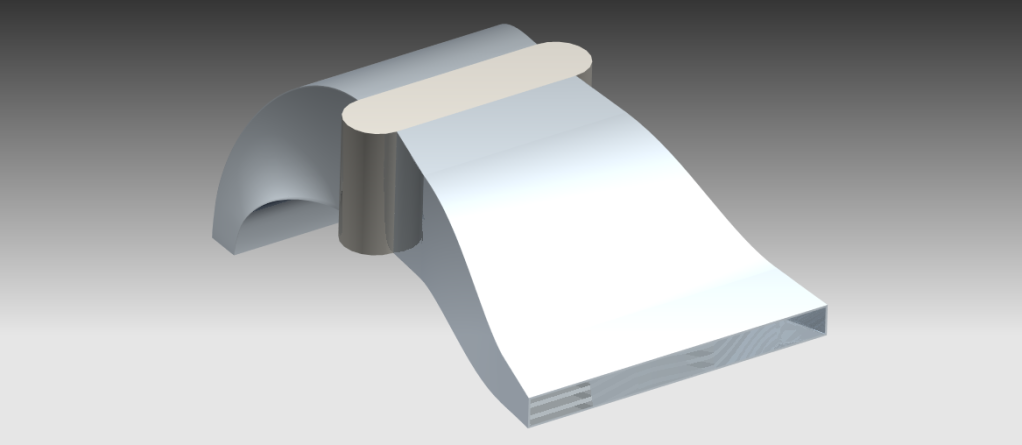

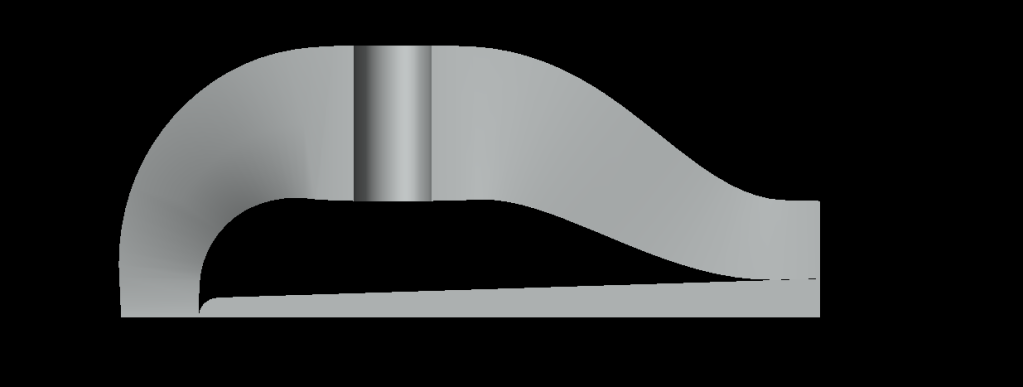

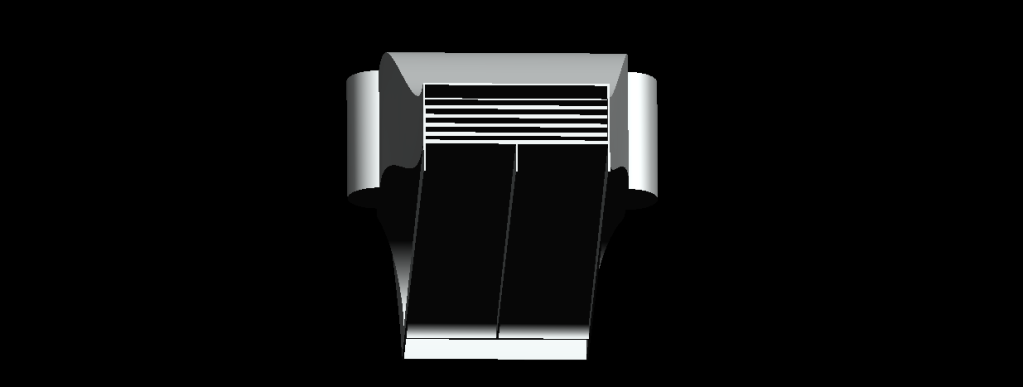

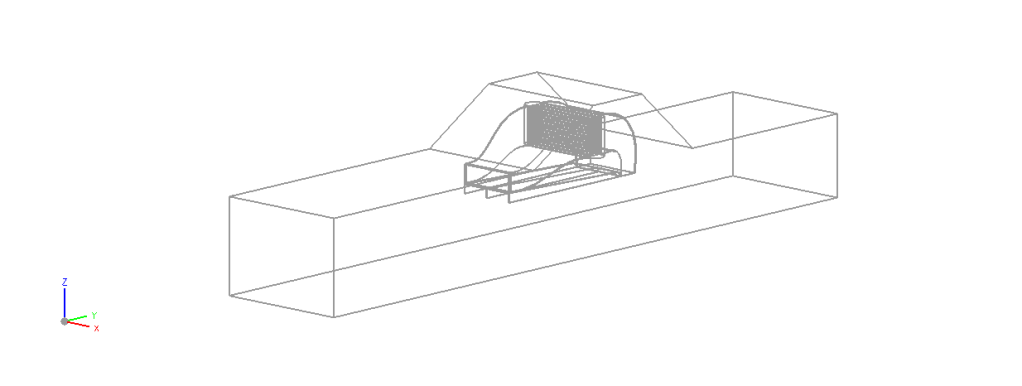

Here is some advancement on the duct design. I'm in the middle of meshing the part, then I'll get some CFD done on it. Here you can see the ramp that I mentioned earlier. Hopefully, this will create a pressure differential between the air in the outlet duct, and the air just outside the outlet duct.

I'll be running 4 speed cases, one at each vehicle speed:

-50 MPH

-75 MPH

-100 MPH

-135 MPH

More pics:

This last picture shows the fluid domain that I'm analyzing around the duct. I haven't put much thought into this part, and it will probably need changed. I haven't taken any pictures of under the car or where I will be putting this cooler, so the actual cooler design and ducting will change from what is seen here. This is just a practice to see if the theory works out.

The fluid domain basically represents flow under the vehicle, with one wall being the undercarriage, one being the road surface, and the other two being either an exhaust, fuel cell, driveshaft, or something like that. Its a little bit crude, but the idea is there.

Here is some advancement on the duct design. I'm in the middle of meshing the part, then I'll get some CFD done on it. Here you can see the ramp that I mentioned earlier. Hopefully, this will create a pressure differential between the air in the outlet duct, and the air just outside the outlet duct.

I'll be running 4 speed cases, one at each vehicle speed:

-50 MPH

-75 MPH

-100 MPH

-135 MPH

More pics:

This last picture shows the fluid domain that I'm analyzing around the duct. I haven't put much thought into this part, and it will probably need changed. I haven't taken any pictures of under the car or where I will be putting this cooler, so the actual cooler design and ducting will change from what is seen here. This is just a practice to see if the theory works out.

The fluid domain basically represents flow under the vehicle, with one wall being the undercarriage, one being the road surface, and the other two being either an exhaust, fuel cell, driveshaft, or something like that. Its a little bit crude, but the idea is there.

#222

I've never done it but thought about it quite a bit and a hybrid Miata/RX-7 box looks interesting. With the right r&p the Miata box can be combined with the short OD gear of one of the first gen boxes (forget which one) to produce a box with 4 usable gears. The Miata box has a lower input ratio than the RX-7 box along with a 2nd gear that's quite a bit taller. To get the right OD gear you'll need to actually count teeth and not rely on published ratios. The input ratio changed over the years, making the published numbers no an accurate representation of what you would need to look for. Forget which r&p would work well with it. Thinking the 4.88 or 4.77. I might have all the figures stashed away somewhere.

The synchros are still going to be a liability. You could have Liberty build the box and face plate it to eliminate the synchros and make for very quick upshifts, you would need to perfect double clutching to down shift though.

Gear strength with any of the stock boxes is marginal. We've had good luck with the Redline Shockproof in allowing the gear set to live. It's just not very synchro friendly, IMO.

#223

what are those made of? is that a hollow threaded tube? or are those ends just welded on? what are those ball joint things/where can i get em? im looking for them to make a torque brace..

asweoms build man. everything is incredibly impressive. im assuming youre using aluminum for all the fuel related stuff? tig? mig?

#224

Rotary Enthusiast

#225

Can Post Only in New Member Section

iTrader: (2)

Join Date: Jul 2004

Location: Calgary, Canada

Posts: 930

Likes: 0

Received 0 Likes

on

0 Posts

the first tool is called a contour gauge.

all those braces are a solid 1" aluminum round stock drilled and tapped then welded onto a hollow aluminum tube.

all those braces are a solid 1" aluminum round stock drilled and tapped then welded onto a hollow aluminum tube.