Possible Flaw in Common Aftermarket 2 piece Seal Design

#1

Possible Flaw in Common Aftermarket 2 piece Seal Design

Recently I've been thinking about 2 piece apex seal design. This started when as I was cleaning my old 13b engine parts to rebuild that I sold to someone. It has 2 piece ceramic seals and they are a little different then most common aftermarket 2 piece apex seal designs. I made a picture to show what I'm talking about....

Basically, the whole point of a 2 piece design is to make up for the extra clearance between the apex seals and the irons. That is why Mazda designed the 2 piece apex seal instead of one solid piece. Unfortunately, the way Mazda designed it was for maximum sealing efficiency and they created a weak point on the seal which is the seal edge that connects to the corner piece.

Some of aftermarket companies had the bright idea to change the angle that the seal is cut and beef up the corner piece so its no longer a sharp thin edge that can chip easily. But I think this defeats the purpose of the 2 piece seal so that having a 1 piece would actually be preferable in regards to sealing. I don't think the corner piece is providing any additional sealing and is in fact creating a negative impact on sealing in certain conditions. I tried to demonstrate my thought process in the picture.

Anyway, what NRS did instead was to make the corner piece even smaller so it beefs up the edge to create the extra strength. This way the corner piece still does its job of coming out and sealing the extra space between the apex seal and the iron and only sacrifices a very small part that can't self clearance. I think this design still does something and is useful compared to the common design.

I'm not saying that one seal is better then the other in regards to material, they all have their applications. But possible instead of a 2 piece design for the common seal, it should be a 1 piece design instead. Or possibly a design change to the common seal. I will be talking to Jonathan @ Goopy about this but anyone else have any thoughts?

thewird

Basically, the whole point of a 2 piece design is to make up for the extra clearance between the apex seals and the irons. That is why Mazda designed the 2 piece apex seal instead of one solid piece. Unfortunately, the way Mazda designed it was for maximum sealing efficiency and they created a weak point on the seal which is the seal edge that connects to the corner piece.

Some of aftermarket companies had the bright idea to change the angle that the seal is cut and beef up the corner piece so its no longer a sharp thin edge that can chip easily. But I think this defeats the purpose of the 2 piece seal so that having a 1 piece would actually be preferable in regards to sealing. I don't think the corner piece is providing any additional sealing and is in fact creating a negative impact on sealing in certain conditions. I tried to demonstrate my thought process in the picture.

Anyway, what NRS did instead was to make the corner piece even smaller so it beefs up the edge to create the extra strength. This way the corner piece still does its job of coming out and sealing the extra space between the apex seal and the iron and only sacrifices a very small part that can't self clearance. I think this design still does something and is useful compared to the common design.

I'm not saying that one seal is better then the other in regards to material, they all have their applications. But possible instead of a 2 piece design for the common seal, it should be a 1 piece design instead. Or possibly a design change to the common seal. I will be talking to Jonathan @ Goopy about this but anyone else have any thoughts?

thewird

#2

Engine, Not Motor

iTrader: (1)

Join Date: Feb 2001

Location: London, Ontario, Canada

Posts: 29,789

Likes: 0

Received 108 Likes

on

91 Posts

Except the one piece is clearanced once and then cannot self adjust. While even though the two piece with the larger corner won't necessarily seal as well, it will self adjust and eventually wear in as everything changes dimensions.

Always tradeoffs. Mazda's primary concern always seems to be sealing, which makes sense. But sadly results in such atrocities as the 2nd gen 3 piece seal.

Always tradeoffs. Mazda's primary concern always seems to be sealing, which makes sense. But sadly results in such atrocities as the 2nd gen 3 piece seal.

#3

4th string e-armchair QB

iTrader: (11)

Join Date: May 2005

Location: North Bay, Ontario

Posts: 2,745

Likes: 0

Received 0 Likes

on

0 Posts

Mazda's 3-piece design couldn't have been that bad if Amemiya bought up all the NOS they could to use it in their N/A race engines. Everything has a place and purpose, they were designed to seal as well as possible. In a turbo engine? Useless.

I agree that the small part of 2-piece design that are designed with a small section of surface that contacts the rotor housing is not a good design, as it defeats the purpose of having continuous contact the way the factory 2-piece seals had whenever there is wear or change in clearance.

I think the reason some people (like Atkins) introduced this style:

was to prevent some wear along the rotor housing from the sharp point of the triangle piece in a factory-style 2-piece once the sides wear a bit and gain clearance. Problem with this design (as thewird alluded to, and I'll expand on) is when the clearance changes.

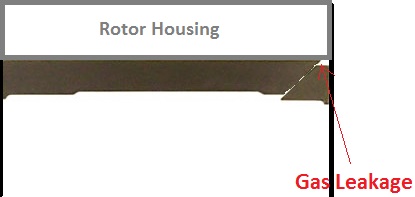

When you have too little clearance, the triangle piece is pushed up in the rotor and creates an area of gas leakage above it:

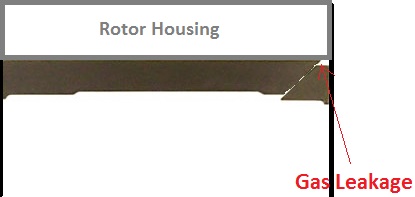

When you have too much clearance, there is a gap in which the larger of the apex seal pieces can lift from centrifugal force (with only the small apex seal spring applying pressure) and can gause greater gas leakage:

So IMO, with this style of 2-piece apex seal, if you're going to use it it is VERY important to clearance them to the rotor housing. I think you'd be about as well off with a 1-piece design, since the negatives of a 1-piece still exist with this style of 2-piece, but none of the positives (like strength and sealing power due to spring pressure) are there.

I've never seen the NRS 2-piece seals, I only have a set of 1-piece. But along the same lines, if clearance increases (seal wears a bit) then wouldn't it seal no better than a 1-piece? I'm confused at the purpose of the corner piece of the NRS seals if it doesn't taper all the way down to the sealing surface...

I agree that the small part of 2-piece design that are designed with a small section of surface that contacts the rotor housing is not a good design, as it defeats the purpose of having continuous contact the way the factory 2-piece seals had whenever there is wear or change in clearance.

I think the reason some people (like Atkins) introduced this style:

was to prevent some wear along the rotor housing from the sharp point of the triangle piece in a factory-style 2-piece once the sides wear a bit and gain clearance. Problem with this design (as thewird alluded to, and I'll expand on) is when the clearance changes.

When you have too little clearance, the triangle piece is pushed up in the rotor and creates an area of gas leakage above it:

When you have too much clearance, there is a gap in which the larger of the apex seal pieces can lift from centrifugal force (with only the small apex seal spring applying pressure) and can gause greater gas leakage:

So IMO, with this style of 2-piece apex seal, if you're going to use it it is VERY important to clearance them to the rotor housing. I think you'd be about as well off with a 1-piece design, since the negatives of a 1-piece still exist with this style of 2-piece, but none of the positives (like strength and sealing power due to spring pressure) are there.

I've never seen the NRS 2-piece seals, I only have a set of 1-piece. But along the same lines, if clearance increases (seal wears a bit) then wouldn't it seal no better than a 1-piece? I'm confused at the purpose of the corner piece of the NRS seals if it doesn't taper all the way down to the sealing surface...

#5

4th string e-armchair QB

iTrader: (11)

Join Date: May 2005

Location: North Bay, Ontario

Posts: 2,745

Likes: 0

Received 0 Likes

on

0 Posts

Lol everything wears, don't kid yourself bud. The ceramics just not nearly as much.

I see that they are just like the factory seals though, in that the cut for the triangle piece goes down to nearly the sealing edge, they just beefed it up and rounded the edge. Looks like a good design to me... I'd bet they still ask that you clearance them to the rotor housings when you get a new set though.

I see that they are just like the factory seals though, in that the cut for the triangle piece goes down to nearly the sealing edge, they just beefed it up and rounded the edge. Looks like a good design to me... I'd bet they still ask that you clearance them to the rotor housings when you get a new set though.

#6

The wear is probably insignificant if it does. My old 13b had around 60k on it with not exaggerating, at least 40 track days on it of heavy abuse, 20 psi, water injection etc. If you saw the seals and housings, you might have the same mindset as I do. The seals look like I just pulled them out of the box that they come in from NRS and the housings which were new when it was assembled, still look like new.

thewird

thewird

#7

Senior Member

iTrader: (1)

Join Date: Jan 2003

Location: Edmonton, Alberta, Canada

Posts: 640

Likes: 0

Received 0 Likes

on

0 Posts

You cannot make a steel seal in 1pc, the clearances needed for it not to touch the end plates would never start the engine. Mazda made it 2pc because they had no choice.

Last edited by Glassman; 11-28-13 at 04:02 PM. Reason: added to comment

Trending Topics

#8

Senior Member

iTrader: (1)

Join Date: Jan 2003

Location: Edmonton, Alberta, Canada

Posts: 640

Likes: 0

Received 0 Likes

on

0 Posts

I've never seen the NRS 2-piece seals, I only have a set of 1-piece. But along the same lines, if clearance increases (seal wears a bit) then wouldn't it seal no better than a 1-piece? I'm confused at the purpose of the corner piece of the NRS seals if it doesn't taper all the way down to the sealing surface...

#9

4th string e-armchair QB

iTrader: (11)

Join Date: May 2005

Location: North Bay, Ontario

Posts: 2,745

Likes: 0

Received 0 Likes

on

0 Posts

Sven, I hadn't seen your design of corner piece before thewird posted the pictures. I can't remember but I think the seals I sent to you for trade were just 2mm 1-piece as well. I understand the design now that I've seen them. The picture I had in my mind was a corner piece that is 'broken off' the main seal piece nearly half way up the seal, like thewird's second picture titled "other 2 aftermarket 2 piece." That's why I said afterwards "I see that they are just like the factory seals though, in that the cut for the triangle piece goes down to nearly the sealing edge, they just beefed it up [by not tapering at a 45* angle straight to a point] and rounded the edge."

Your seals are the ****.

Your seals are the ****.

#11

4th string e-armchair QB

iTrader: (11)

Join Date: May 2005

Location: North Bay, Ontario

Posts: 2,745

Likes: 0

Received 0 Likes

on

0 Posts

Hmm. Since were on the topic, I'm building my engine with some lightly used semi-pp housings and new NRS seals. I was planning on either sending them to goopy to get resurfaced or lapping them with fine grit sandpaper and a straight edge myself. Would either or make for a smooth enough surface for the ceramics to seal? Hoping Sven can chime in, I know I had asked before but can't remember getting an answer.

#12

Senior Member

iTrader: (1)

Join Date: Jan 2003

Location: Edmonton, Alberta, Canada

Posts: 640

Likes: 0

Received 0 Likes

on

0 Posts

Hmm. Since were on the topic, I'm building my engine with some lightly used semi-pp housings and new NRS seals. I was planning on either sending them to goopy to get resurfaced or lapping them with fine grit sandpaper and a straight edge myself. Would either or make for a smooth enough surface for the ceramics to seal? Hoping Sven can chime in, I know I had asked before but can't remember getting an answer.

Thread

Thread Starter

Forum

Replies

Last Post

GrossPolluter

Suspension/Wheels/Tires/Brakes

12

08-15-15 10:32 PM