Huyler's Street & HPDE Build

#126

ancient wizard...

A suggestion,yes another one...If you have known good oil pressure and cooling system can keep temps where you want, take car for several 1/2 hr or so rides to help it to break in. You want it to cool down between each drive.Don't beat on it just drive it to run in a bit more each time.

Don't think giving to dyno guy a good idea til reasonable amount of break in miles on it. Again,recommend replacing/saving those expensive plugs and put in a set of SE plugs til you get break in/tuning process a little farther along so you don't end up sooting/fouling the good ones.

Is the ecu receiving known accurate info from coolant sensor,have you tested calibration of sensor,GM? If you know original application,you can look up cold to hot volts/resistance values in tables in service manual to help determine where trouble lies. I have service info,all i need is vehicle year/engine sensor fits and i can get those tables for you.

Are you getting proper source/return voltage to/from sensor? Do you have a base map loaded in ecu,where from? Datalogging capability?

What's your fuel pressure engine running,can you see it bump up @10 psi when you blip throttle. Is that pressure same you see when key on before cranking/starting engine?

Don't think giving to dyno guy a good idea til reasonable amount of break in miles on it. Again,recommend replacing/saving those expensive plugs and put in a set of SE plugs til you get break in/tuning process a little farther along so you don't end up sooting/fouling the good ones.

Is the ecu receiving known accurate info from coolant sensor,have you tested calibration of sensor,GM? If you know original application,you can look up cold to hot volts/resistance values in tables in service manual to help determine where trouble lies. I have service info,all i need is vehicle year/engine sensor fits and i can get those tables for you.

Are you getting proper source/return voltage to/from sensor? Do you have a base map loaded in ecu,where from? Datalogging capability?

What's your fuel pressure engine running,can you see it bump up @10 psi when you blip throttle. Is that pressure same you see when key on before cranking/starting engine?

#127

All your suggestions have been great so far, so keep them coming!

I'll walk you through the setup.

First, I started with a S4 RX7 basemap from Adaptronic. They didn't have one for a 12a. Then I grabbed a 12a timing/fuel table from this website. I forget what thread it was, but someone had created tables for all the motors including one that said "12a turbo". I don't have a turbo, but I figured the timing would be about the same. At 101kPa it's 24 degrees. It drops in boost which I'll never see, and it goes higher in vacuum. When I first started the motor I set the fuel table to 80%VE across the board. After I got it running I ended up dropping this down a bit. It was very close to the fuel map that was in the "12a turbo" file so I copied that over as a starting point. I tweaked some other stuff based on the work I did for my REPU. I set up the inputs and outputs accordingly. Adaptronic just got back to me on the correct setup for the DLG-1/LC2 wideband and I had that configured wrong. It should work tomorrow when I start it up again.

Coolant, Oil, and Air sensors are GM. I don't recall where I got the calibration tables for them, somewhere online when I searched for "GM coolant sensor and Adaptronic". If 175 sounds about right for middle of the factory dial, then I know the coolant sensor is at least ballpark correct. Where would the best place to check with my infrared temp gauge? I get lots of different readings between the radiator inlet, the hose, the water neck, and the water pump assembly. I don't know what I should rely upon. I was using the same GM air sensor in the REPU but the temps for that one don't make sense. My garage is around 40-50 degrees in the morning and the second I turn the key it reads 80 and will jump to 120-150 while running, even with the hood open. The air temp correction table is flat, so it shouldn't be affecting the tune at this time anyway.

For fuel pressure, I set it to 43 with the car off, it drops a bit under vacuum to less than 40, haven't checked since I got the car to idle below 1500.

Tomorrow I'm going to mess with the cranking table. It's got settings of 180 for cold start. I have no idea if that is too high or too low, but I suspect it's too high because I've had to open the throttle all the way to clear the chambers the last two times I started it. I don't have an idle control valve so I assume I have to at least crack the throttle a little bit for the first minute or two of operation. I don't think timing alone is enough to get it to fast idle, or is it? Maybe I'll add an idle valve, but I didn't know where I could inject the air with ITBs. Is it safe to inject extra air further down the intake from the injectors?

I'll walk you through the setup.

First, I started with a S4 RX7 basemap from Adaptronic. They didn't have one for a 12a. Then I grabbed a 12a timing/fuel table from this website. I forget what thread it was, but someone had created tables for all the motors including one that said "12a turbo". I don't have a turbo, but I figured the timing would be about the same. At 101kPa it's 24 degrees. It drops in boost which I'll never see, and it goes higher in vacuum. When I first started the motor I set the fuel table to 80%VE across the board. After I got it running I ended up dropping this down a bit. It was very close to the fuel map that was in the "12a turbo" file so I copied that over as a starting point. I tweaked some other stuff based on the work I did for my REPU. I set up the inputs and outputs accordingly. Adaptronic just got back to me on the correct setup for the DLG-1/LC2 wideband and I had that configured wrong. It should work tomorrow when I start it up again.

Coolant, Oil, and Air sensors are GM. I don't recall where I got the calibration tables for them, somewhere online when I searched for "GM coolant sensor and Adaptronic". If 175 sounds about right for middle of the factory dial, then I know the coolant sensor is at least ballpark correct. Where would the best place to check with my infrared temp gauge? I get lots of different readings between the radiator inlet, the hose, the water neck, and the water pump assembly. I don't know what I should rely upon. I was using the same GM air sensor in the REPU but the temps for that one don't make sense. My garage is around 40-50 degrees in the morning and the second I turn the key it reads 80 and will jump to 120-150 while running, even with the hood open. The air temp correction table is flat, so it shouldn't be affecting the tune at this time anyway.

For fuel pressure, I set it to 43 with the car off, it drops a bit under vacuum to less than 40, haven't checked since I got the car to idle below 1500.

Tomorrow I'm going to mess with the cranking table. It's got settings of 180 for cold start. I have no idea if that is too high or too low, but I suspect it's too high because I've had to open the throttle all the way to clear the chambers the last two times I started it. I don't have an idle control valve so I assume I have to at least crack the throttle a little bit for the first minute or two of operation. I don't think timing alone is enough to get it to fast idle, or is it? Maybe I'll add an idle valve, but I didn't know where I could inject the air with ITBs. Is it safe to inject extra air further down the intake from the injectors?

Last edited by chuyler1; 03-28-19 at 11:25 PM.

#128

A few other things I took care of tonight. The interior is back together now that I know my wiring is done. I didn't get the speed sensor working, but it's hooked up to the right input. I'll message Adaptronic about that to see if it will even support the signal from my speedometer gauge. I also reinstalled the AFR gauge and added some red vinyl to the display so it would closely match the rest of the lighting.

Then I pulled the struts out so I could replace the top hats with ones that have longer studs, which allowed me to install the final piece of the puzzle, the RB cross bar!

Then I pulled the struts out so I could replace the top hats with ones that have longer studs, which allowed me to install the final piece of the puzzle, the RB cross bar!

#129

ancient wizard...

In what I can see of your setup,I don’t see anIAC motor. Do you have a throttle opener for when you start engine? If not you need to crack throttle open @1/4” to let engine have enough air to start cold,may have to feather it to keep running til warms a bit. May or may not have to open throttle for hot restart after tube is dialed in.

If you give me oe app for coolant and air temp sensors,I can give you a graph from cold to hit and all temps in between in bolts/resistance so you can check they’re sending right info to Ecu.

If you give me oe app for coolant and air temp sensors,I can give you a graph from cold to hit and all temps in between in bolts/resistance so you can check they’re sending right info to Ecu.

#130

I don't have a throttle opener yet. I was going to maybe use the choke cable, or just get an IACV. The issue with a valve is I'd like to put it on the 3/8 NPT fitting on the vacuum manifold, which would inject air into the the primary port runners on the manifold...but that air has to mix with the rest of the air coming from the throttle body, and I didn't know if that would mess up the mixture and just dump air into the chambers without any fuel from the throttle body. So I sidelined that part of the build thinking I would just connect the choke cable and do it manually, keeping it original so to say. I could control the choke release from the ECU if need be. Might be cool to have a manual choke on an EFI car LOL, but I'd have to figure out the linkage for that. My final thought was that Jenvey sells a very expensive drive-by-wire motor that works with this throttlebody. Anyway, just want to get the rest of the car working at this point, I can worry about that stuff later.

Here are the sensors I used:

One other quick question, I've read that with a large cam, or in my case a large streetport that has some overlap, the wideband can give false lean readings. How do I know when/if this is happening?

Here are the sensors I used:

One other quick question, I've read that with a large cam, or in my case a large streetport that has some overlap, the wideband can give false lean readings. How do I know when/if this is happening?

#131

ancient wizard...

Intake air temp sensor resistance specs:

7500 ohms at 40 degrees

3400 ohms at 70 degrees

1800 ohms at 100 degrees

450 ohms at 160 degrees

Key on engine running voltage should be about:

4.5 VDC at 32 degrees

4.0 VDC at 68 degrees

1.5 VDC at 158 degrees

Coolant sensor resistance specs:

9500 ohms at 32 degrees

3700 ohms at 68 degrees

450 ohms at 158 degrees

250 ohms at 194 degrees

Key on engine running voltage should be about 1.5-2.0 VDC at 185-194 degrees

If sensor readings are out of range,hook up one lead of multimeter on ECU ground,the other on a "known" good ground. Voltage should be below 100mv for a good circuit. Key on for this test.

Hope info is helpful to chasing your gremlins. I try to use brand name sensors when servicing vehicles,GM,NAPA Echlin,Standard ignition in that order. Have found a lot of inconsistencies in brand X sensors. Not worth my time to unknowingly build in a problem by using them and then have to chase the "new" issue.

7500 ohms at 40 degrees

3400 ohms at 70 degrees

1800 ohms at 100 degrees

450 ohms at 160 degrees

Key on engine running voltage should be about:

4.5 VDC at 32 degrees

4.0 VDC at 68 degrees

1.5 VDC at 158 degrees

Coolant sensor resistance specs:

9500 ohms at 32 degrees

3700 ohms at 68 degrees

450 ohms at 158 degrees

250 ohms at 194 degrees

Key on engine running voltage should be about 1.5-2.0 VDC at 185-194 degrees

If sensor readings are out of range,hook up one lead of multimeter on ECU ground,the other on a "known" good ground. Voltage should be below 100mv for a good circuit. Key on for this test.

Hope info is helpful to chasing your gremlins. I try to use brand name sensors when servicing vehicles,GM,NAPA Echlin,Standard ignition in that order. Have found a lot of inconsistencies in brand X sensors. Not worth my time to unknowingly build in a problem by using them and then have to chase the "new" issue.

Last edited by GSLSEforme; 03-29-19 at 01:48 PM.

#132

Thanks, I'll look up how to translate these into the Adaptronic tables tonight.

I spent my lunch break addressing the oil leak. Rookie mistake, the engine builder didn't mask off the oil filter pedestal when he painted the block. I wasn't paying attention and dropped the adapter on it without scraping off the paint. The o-rings didn't seal against the paint. I got new rings anyway.

Thought it would take 10 minutes, but getting the bolts back on was tricky.

I didn't get a chance to fire it up again. Hopefully I'll have time this weekend to at least get some baseline startup and idle settings plugged in. Rain in the forecast so I probably won't be driving it.

I spent my lunch break addressing the oil leak. Rookie mistake, the engine builder didn't mask off the oil filter pedestal when he painted the block. I wasn't paying attention and dropped the adapter on it without scraping off the paint. The o-rings didn't seal against the paint. I got new rings anyway.

Thought it would take 10 minutes, but getting the bolts back on was tricky.

I didn't get a chance to fire it up again. Hopefully I'll have time this weekend to at least get some baseline startup and idle settings plugged in. Rain in the forecast so I probably won't be driving it.

#133

Awesome updates and troubleshooting.

Cool to read about throttle body EFI details on an N/A car and tuning etc.

What about the possible coolant leak between iron and housing? Engine builder typically does a coolant system pressure test up to 1 ATM to make sure water seals are ok.

Gonna sound awesome once its broken in/tuned. The sound my Dellorto side draft makes is one of my favorite parts about driving the car haha.

Cool to read about throttle body EFI details on an N/A car and tuning etc.

What about the possible coolant leak between iron and housing? Engine builder typically does a coolant system pressure test up to 1 ATM to make sure water seals are ok.

Gonna sound awesome once its broken in/tuned. The sound my Dellorto side draft makes is one of my favorite parts about driving the car haha.

#134

I haven't figured out the water leak yet. It could be the drain plug on the center plate. I need to put a paper towel or something underneath and watch carefully during the next start. After it cooled down last time the water level was on the low mark, and I had filled it to the high mark. That could just be air bubbles being released from the system, or that could be a signal as to how much is leaking. I'll know more after the next startup. I do know the builder did not pressure test the system as he only built the keg and I was with him the day he finished the build and put the front cover on. I installed the water neck and pump later.

#135

Went for 30 minute drive today and water level only dropped in the tank by at most 1/4", didn't see anything under the car after we stopped and let it cool down.

Electric fan needed more adjustment, I saw the temp spike to 3/4 on the factory dial (about 195 from the GM sensor on the ECU) after coming off the highway and parking. I lowered the pot on the fan controller another turn.

My friend helped me out with setting some decent AFRs while we were driving around. It's quite sluggish right now but I think it still needs to break in some compression.

Startup is really rough. I have no idea what I'm doing with the cranking table, I can't tell if it's too high or too low.

It stalled a few times coming off high RPM down to idle, I think the idle control PID settings need to be more aggressive to catch it.

A quick video, mostly for the sound. Buzzer is going off at 6k and that's as far as I'm pushing it right now.

Electric fan needed more adjustment, I saw the temp spike to 3/4 on the factory dial (about 195 from the GM sensor on the ECU) after coming off the highway and parking. I lowered the pot on the fan controller another turn.

My friend helped me out with setting some decent AFRs while we were driving around. It's quite sluggish right now but I think it still needs to break in some compression.

Startup is really rough. I have no idea what I'm doing with the cranking table, I can't tell if it's too high or too low.

It stalled a few times coming off high RPM down to idle, I think the idle control PID settings need to be more aggressive to catch it.

A quick video, mostly for the sound. Buzzer is going off at 6k and that's as far as I'm pushing it right now.

#136

Update from the previous list:

1) Oil Leaks: The oil cooler hoses are dry. I'm still seeing some seepage from the oil filter pedestal, but I think it's actually between the pedestal and the Racing Beat adapter plate or one of the two ports on it. I have an oil temp gauge in one, the other is blocked off. I used pipe dope on both. Not a lot is coming out, just enough to show up on a blue shop paper towel I have wedged in that spot after driving 10-15 miles.

2) Water leaks: I have not seen any more water on the garage floor and the coolant level appears to have stabilized. I drove it a few more miles today and I'll check the level one more time after it cools.

3) ECU AFR: I'm still not getting the AFR values from the DLG-1/LC2 to report to the ECU. Oddly though, I'm getting EGT2 and EGT4 values. Waiting to hear back from Adaptronic as this means I cannot use any of the adaptive tuning functions or closed loop.

4) ECU Speed: Solved this. I switched the MVSS mode from reluctor to digital and started getting speed readings. Even after calibrating the values, the speed is wrong, but it at least knows when I'm moving and when I'm not.

5) Cooling: Solved this. I haven't seen any spikes in coolant temps, although it has been cold lately so I will have to revisit this when the temps warm back up. It hovers around 165F water temp and 170F oil temp while cruising around in 40 degree weather. The temp gauge barely moved past center when I stopped and let it idle for a few minutes.

6) Cruise Control: Not on my previous list, but I turned it on for the first time and it actually worked! Haven't tried it on the highway but it kept me going 40 mph for a few minutes on a back road and I could hear it opening and closing the throttle. Not sure I shared my linkage with everyone but I'm using the stock vacuum actuated diaphragm with a new cable that can pull on the throttle separate from the main throttle.

The new list:

1) There is some off-throttle bucking. I thought it was timing related but lowering the timing under high vacuum didn't seem to solve it. I tried enabling throttle off overrun but I don't think I have the settings right. All that did was cause the car to stall instead of idling when I pushed the clutch in.

2) I'm trying to use ignition PID for idle control. As mentioned above, something isn't right. It will idle if I get it down there gently, but occasionally it gets stuck above 1,500RPM or it goes right past idle and stalls.

3) Cold and hot starts need significant throttle application, but prior to me increasing the cranking enrichments it didn't want to catch at all. I'll probably leave this for the experts at the dyno shop.

4) Even though AFRs are on target under throttle, it doesn't pull very hard, especially down low where I need to slip the clutch quite a bit to pull away from a stop. I imagine the street port is going to kill some low end power, but I'm just not feeling a punch. Might still need more break-in. I'll keep putting the miles on it before I pass final judgement.

5) There is a new sound, only heard from inside the cabin. Sounds like clacking of valves on a piston engine, only noticeable at low RPM, but I cannot really hear it in the engine bay. I thought maybe it was the fuel pressure regulator but when I disconnected the vacuum hose from it the sound didn't go away. Still scratching my head on that one.

1) Oil Leaks: The oil cooler hoses are dry. I'm still seeing some seepage from the oil filter pedestal, but I think it's actually between the pedestal and the Racing Beat adapter plate or one of the two ports on it. I have an oil temp gauge in one, the other is blocked off. I used pipe dope on both. Not a lot is coming out, just enough to show up on a blue shop paper towel I have wedged in that spot after driving 10-15 miles.

2) Water leaks: I have not seen any more water on the garage floor and the coolant level appears to have stabilized. I drove it a few more miles today and I'll check the level one more time after it cools.

3) ECU AFR: I'm still not getting the AFR values from the DLG-1/LC2 to report to the ECU. Oddly though, I'm getting EGT2 and EGT4 values. Waiting to hear back from Adaptronic as this means I cannot use any of the adaptive tuning functions or closed loop.

4) ECU Speed: Solved this. I switched the MVSS mode from reluctor to digital and started getting speed readings. Even after calibrating the values, the speed is wrong, but it at least knows when I'm moving and when I'm not.

5) Cooling: Solved this. I haven't seen any spikes in coolant temps, although it has been cold lately so I will have to revisit this when the temps warm back up. It hovers around 165F water temp and 170F oil temp while cruising around in 40 degree weather. The temp gauge barely moved past center when I stopped and let it idle for a few minutes.

6) Cruise Control: Not on my previous list, but I turned it on for the first time and it actually worked! Haven't tried it on the highway but it kept me going 40 mph for a few minutes on a back road and I could hear it opening and closing the throttle. Not sure I shared my linkage with everyone but I'm using the stock vacuum actuated diaphragm with a new cable that can pull on the throttle separate from the main throttle.

The new list:

1) There is some off-throttle bucking. I thought it was timing related but lowering the timing under high vacuum didn't seem to solve it. I tried enabling throttle off overrun but I don't think I have the settings right. All that did was cause the car to stall instead of idling when I pushed the clutch in.

2) I'm trying to use ignition PID for idle control. As mentioned above, something isn't right. It will idle if I get it down there gently, but occasionally it gets stuck above 1,500RPM or it goes right past idle and stalls.

3) Cold and hot starts need significant throttle application, but prior to me increasing the cranking enrichments it didn't want to catch at all. I'll probably leave this for the experts at the dyno shop.

4) Even though AFRs are on target under throttle, it doesn't pull very hard, especially down low where I need to slip the clutch quite a bit to pull away from a stop. I imagine the street port is going to kill some low end power, but I'm just not feeling a punch. Might still need more break-in. I'll keep putting the miles on it before I pass final judgement.

5) There is a new sound, only heard from inside the cabin. Sounds like clacking of valves on a piston engine, only noticeable at low RPM, but I cannot really hear it in the engine bay. I thought maybe it was the fuel pressure regulator but when I disconnected the vacuum hose from it the sound didn't go away. Still scratching my head on that one.

#137

Car was feeling sluggish in general. Turned out the '85 12a does not like a spark split of 10 degrees. I boosted it to 20 degrees and that really woke up the motor. I guess Racing Beat was right on that one. Literally night and day difference.

Still no clue on the sound in the dash, my current theories are, it's a ground loop that is ******* with one of the solenoids in the HVAC system, or it could be as simple as an imbalance in the throttle bodies projecting itself through the vacuum lines and causing the fuel pressure regulator to vibrate and reverberate through the firewall. I'll figure it out eventually.

Still no clue on the sound in the dash, my current theories are, it's a ground loop that is ******* with one of the solenoids in the HVAC system, or it could be as simple as an imbalance in the throttle bodies projecting itself through the vacuum lines and causing the fuel pressure regulator to vibrate and reverberate through the firewall. I'll figure it out eventually.

#139

Found a vacuum leak. The intake manifold gasket got wet from the freeze plugs not completely sealing. This also may have been the reason i saw a slight drop in coolant level. I have new o-ring seals to put in, I forgot about them before, and I ordered a new intake gasket.

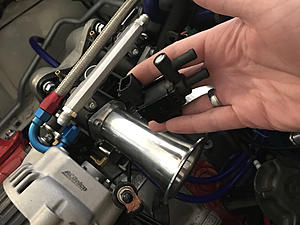

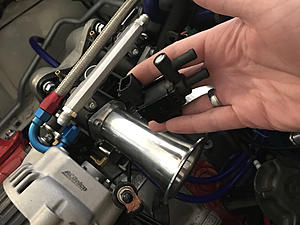

While the manifold is off, I figured I would wire up a basic idle air control valve. I grabbed this trick from the AW11 forums. The wax pellet module on the 4AGE doesn't work well so they replace it with this solenoid designed for boosting idle in more modern Toyotas when you turn on A/C. It has an adjustment screw so you can dial it in. My ECU has a PWM controller for idle but I'm guessing it won't work with this type of solenoid. I tested it quickly and at a low frequency it will cycle and limit airflow, but it isn't as precise as other idle valves. I'll probably just program it to be full open until the car has warmed up. The advantage though, is that it's cheap, very small, and you can connect hoses directly to it. I know a lot of people use Ford IACVs, but given I only have small 8mm hoses in the throttle bodies, I'm not going to get much more air flow from a larger valve.

I fabbed up this bracket last night. I will plum an inlet hose to the filter and the outlet hose will go to the center of the vacuum manifold shown in previous photos.

While the manifold is off, I figured I would wire up a basic idle air control valve. I grabbed this trick from the AW11 forums. The wax pellet module on the 4AGE doesn't work well so they replace it with this solenoid designed for boosting idle in more modern Toyotas when you turn on A/C. It has an adjustment screw so you can dial it in. My ECU has a PWM controller for idle but I'm guessing it won't work with this type of solenoid. I tested it quickly and at a low frequency it will cycle and limit airflow, but it isn't as precise as other idle valves. I'll probably just program it to be full open until the car has warmed up. The advantage though, is that it's cheap, very small, and you can connect hoses directly to it. I know a lot of people use Ford IACVs, but given I only have small 8mm hoses in the throttle bodies, I'm not going to get much more air flow from a larger valve.

I fabbed up this bracket last night. I will plum an inlet hose to the filter and the outlet hose will go to the center of the vacuum manifold shown in previous photos.

Last edited by chuyler1; 04-05-19 at 11:17 AM.

#140

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,780

Received 2,564 Likes

on

1,824 Posts

so basically best starting is with a mixture that is so rich its nearly flooding. timing cam mimic the distributor, if the engine is warm advancing the timing a bit helps, but too far and it will kick back/crank slower.

the tedious part is letting the car cool down to ambient temp. you then start it. let it cool. add fuel, and crank again. repeat until the car starts nicely. it might be best to start with the thing warmed up, and work your way colder.

once its running (Mazda uses 400-499rpm as the threshold between cranking and running) then adjust the coolant temp fuel map until it runs ok, ideally you want the main fuel map done first, but you can rought it in and come back later. Mazda considers 65c warmed up, so over that coolant correction should be zero.

have fun!

#141

Thanks, I need to sort out the vacuum leaks then I will make another pass at it. I could always get it to start with like 50% throttle and slowly closing it until it caught. But it did nothing at 0-3% throttle. I thought that meant there was too much fuel (and puff of smoke out the tail pipe confirmed) but cutting the fuel was just causing it to crank until it went into fuel cut. I need to start over from the beginning, make sure the idle cells are correct on the main map, plug in some realistic values into the coolant temp enrichment table, adjust the new idle air valve, then focus on the cranking values to get the mixture right for the amount of air.

#143

Rotary Enthusiast

I would zero out any tables except air that change fuel and spark based on temp. You should also have startup priming and enrichment maps that you can disable or zero out till your very table is decent.

If a 20 split woke your engine up your timing is way off somehow. 10 to 12 is pretty normal for split. You can get away with 0 on an na car

I'd be curious about the noise you mentioned, I have something similar and it looks like we have the same for.

If you'd like I'll fire my car up and record it so you can see how an itb with no startup cranking correction sounds.

Did you fix your off throttle bucking ?

If a 20 split woke your engine up your timing is way off somehow. 10 to 12 is pretty normal for split. You can get away with 0 on an na car

I'd be curious about the noise you mentioned, I have something similar and it looks like we have the same for.

If you'd like I'll fire my car up and record it so you can see how an itb with no startup cranking correction sounds.

Did you fix your off throttle bucking ?

Last edited by mikey D; 04-09-19 at 08:02 PM.

#144

Originally Posted by mikey D

I would zero out any tables except air that change fuel and spark based on temp. You should also have startup priming and enrichment maps that you can disable or zero out till your very table is decent.

If a 20 split woke your engine up your timing is way off somehow. 10 to 12 is pretty normal for split. You can get away with 0 on an na car

I'd be curious about the noise you mentioned, I have something similar and it looks like we have the same for.

Did you fix your off throttle bucking ?

Right now the only thing really pissing me off is that the Adaptronic 440d isn't picking up the signal from the DLG1/LC2 wideband. I can't use any of the adaptive tuning functions. I know they don't work great, but they speed up the process of getting ballpark values for the fuel map.

#145

I had no luck this morning.

I changed the coil ground to the engine block and I still hear the buzzing sound. I have no idea what it is.

I tried the MAPxTPS tune for a while and it was horrible. I'm sure if I spent several hours trying to get it right i might have some luck but I couldn't even get it to stay running. I went back to my MAP based tune after about 30 minutes of fiddling.

I did however try to keep the TPS based transient throttle. That wasn't all that great either. As soon as I punch the throttle it dies. I tried boosting the gain as high as 50% and gave up. I need the ability to log what is going on to know whether it's the initial squirt or the longer enrichment that needs to change and I can't get the wideband to communicate with the ECU.

My idle control valve didn't help at all. It does work, but it isn't letting in the amount of air I need, or I just don't have the timing and fuel dialed in enough for it to be functional. I turned it off because it wasn't helping the idle at all.

I don't know, I'm frustrated because I feel like I'm fighting some issue in the ECU or the build that is preventing the tuning from going smoothly. I'm scheduled to drop it off at the tuning shop next week. I was hoping to have most of the issues sorted before then. It does run and drive...just not well. Whatever I can't figure out, I'm paying for them to figure out.

I changed the coil ground to the engine block and I still hear the buzzing sound. I have no idea what it is.

I tried the MAPxTPS tune for a while and it was horrible. I'm sure if I spent several hours trying to get it right i might have some luck but I couldn't even get it to stay running. I went back to my MAP based tune after about 30 minutes of fiddling.

I did however try to keep the TPS based transient throttle. That wasn't all that great either. As soon as I punch the throttle it dies. I tried boosting the gain as high as 50% and gave up. I need the ability to log what is going on to know whether it's the initial squirt or the longer enrichment that needs to change and I can't get the wideband to communicate with the ECU.

My idle control valve didn't help at all. It does work, but it isn't letting in the amount of air I need, or I just don't have the timing and fuel dialed in enough for it to be functional. I turned it off because it wasn't helping the idle at all.

I don't know, I'm frustrated because I feel like I'm fighting some issue in the ECU or the build that is preventing the tuning from going smoothly. I'm scheduled to drop it off at the tuning shop next week. I was hoping to have most of the issues sorted before then. It does run and drive...just not well. Whatever I can't figure out, I'm paying for them to figure out.

#146

Rotary Enthusiast

Can you record the noise?

I dont run any idle control and have no issues. Im setup map based only. I have paul yaws info somewhere, i dont recall anyone ever running that big a split. At high rpm the trailing would be very retarded wouldnt it?

are you still running your brake booster? Do you have a working check valve before the booster?

i had some if these issues myself and worked though them, it was very frustrating but im happy to act as a sounding board for you. If you want to upload logs i could take a look also

for bucking turn off the overrun cut till fully tuned. Also remove any negative numbers from acell enrichment.

I dont run any idle control and have no issues. Im setup map based only. I have paul yaws info somewhere, i dont recall anyone ever running that big a split. At high rpm the trailing would be very retarded wouldnt it?

are you still running your brake booster? Do you have a working check valve before the booster?

i had some if these issues myself and worked though them, it was very frustrating but im happy to act as a sounding board for you. If you want to upload logs i could take a look also

for bucking turn off the overrun cut till fully tuned. Also remove any negative numbers from acell enrichment.

Last edited by mikey D; 04-10-19 at 02:50 PM.

#147

Here's a recording of the sound, I also started a new thread to get a few more ears on it.

This afternoon I was reading through some more ITB links I googled related to Adaptronic. Most of them are for Miatas or 4AGE Toyota's. I can't seem to find a good TPS tune to start with as far as timing tables go. I was also just looking for optimal settings for the transient tables and settings. The motor falls on its face with any significant throttle input, especially if you lift off between shifting gears. I know the fuel table isn't perfect, but it mostly hovers between 12-14 AFR so it shouldn't be going full lean when I stomp on the gas.

The brake booster does have a check valve and it has all new hoses. I pulled the hoses off a few components like the FPR and cruise control just to see if idle would change. Right now at 900RPM I see a MAP value of 73 kPa, 0/20 degrees timing, about 2.3ms of fuel, and AFR at 13.7. The MAP value seems high, but I don't know if that's due to slight overlap with the large street port or the location of the MAP reading just below the throttle plates. Decelerating with 0 throttle at about 2,000RPM the MAP reading is 40kPa. There isn't much else to gain from the logs because I can't get it to read the AFR from the wideband.

This afternoon I was reading through some more ITB links I googled related to Adaptronic. Most of them are for Miatas or 4AGE Toyota's. I can't seem to find a good TPS tune to start with as far as timing tables go. I was also just looking for optimal settings for the transient tables and settings. The motor falls on its face with any significant throttle input, especially if you lift off between shifting gears. I know the fuel table isn't perfect, but it mostly hovers between 12-14 AFR so it shouldn't be going full lean when I stomp on the gas.

The brake booster does have a check valve and it has all new hoses. I pulled the hoses off a few components like the FPR and cruise control just to see if idle would change. Right now at 900RPM I see a MAP value of 73 kPa, 0/20 degrees timing, about 2.3ms of fuel, and AFR at 13.7. The MAP value seems high, but I don't know if that's due to slight overlap with the large street port or the location of the MAP reading just below the throttle plates. Decelerating with 0 throttle at about 2,000RPM the MAP reading is 40kPa. There isn't much else to gain from the logs because I can't get it to read the AFR from the wideband.

#148

Rotary Enthusiast

There's plenty to be had from logs without afr.

Also seeing your ve table and acell enrichment would say a lot. I haven't looked over in the adaptech section to see if your posting that kind of stuff already. I'll go look.

Far as timing I suggest duplicating how the dizzy worked to get started. 5-10 at idle ramp to 18 at 4k rps and carry it to redline. Put a ramp just behind idle of 12-14 and that'll help stabilize your idle and keep you from stalling. That is a safe starting point

Idle should be around 40-50kpa. State of tune can vary it quite a bit.

Interesting how different yours sounds. I barely hear that tick tick. I wonder if your bleeding energy at either end of your plug wires. Ever watch in the dark?

Nice project you've got going on here.

Also seeing your ve table and acell enrichment would say a lot. I haven't looked over in the adaptech section to see if your posting that kind of stuff already. I'll go look.

Far as timing I suggest duplicating how the dizzy worked to get started. 5-10 at idle ramp to 18 at 4k rps and carry it to redline. Put a ramp just behind idle of 12-14 and that'll help stabilize your idle and keep you from stalling. That is a safe starting point

Idle should be around 40-50kpa. State of tune can vary it quite a bit.

Interesting how different yours sounds. I barely hear that tick tick. I wonder if your bleeding energy at either end of your plug wires. Ever watch in the dark?

Nice project you've got going on here.

Last edited by mikey D; 04-10-19 at 04:40 PM.

#149

Rotary Enthusiast

I watched some of your other videos, that sounds like detonation to me. If you can get that noise happening by free rev do the stethoscope thing and listen to your engine.

...with a point by

...with a point by