1984 5-letter / S5 "Selene"

#127

It runs

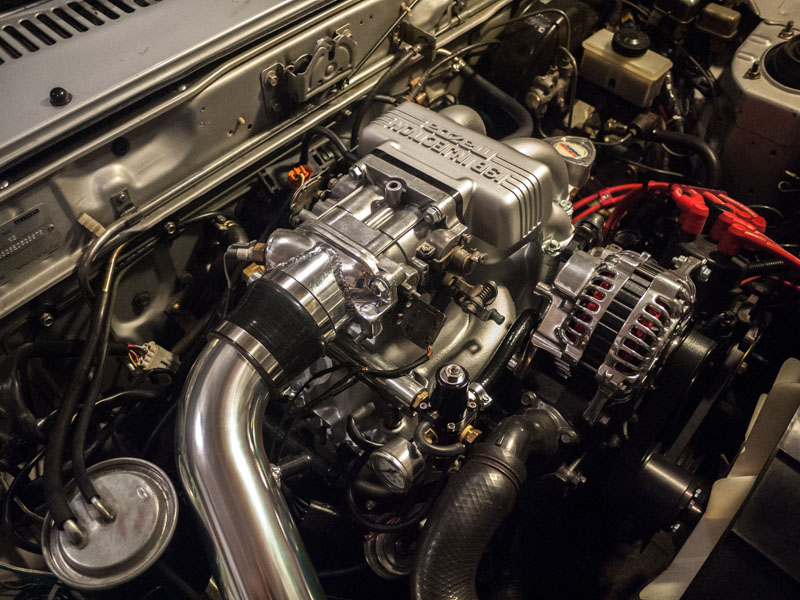

So i have succesfully started it up and set the idle, mapped basic fuel up to about 2500 rpm. Before mapping higher, i need to get the 6 ports and VDI hooked up, otherwise i'll be wasting time trying to tune.

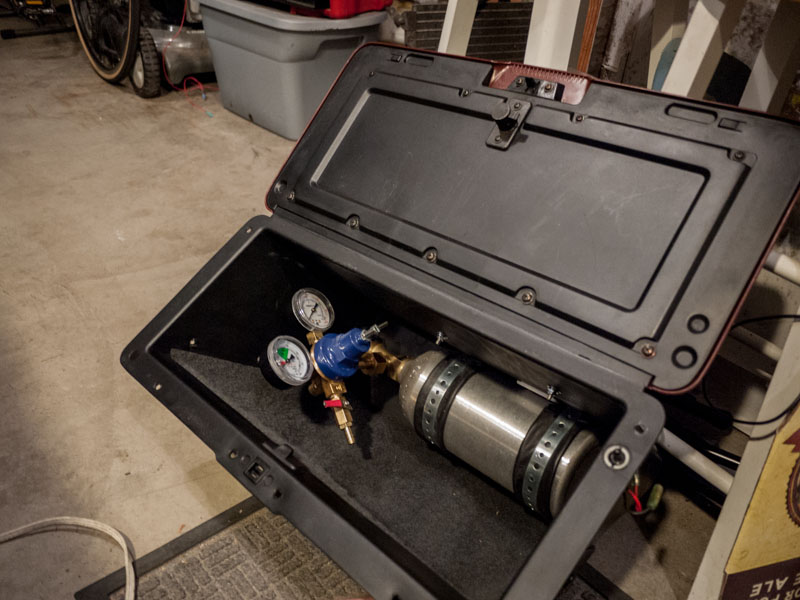

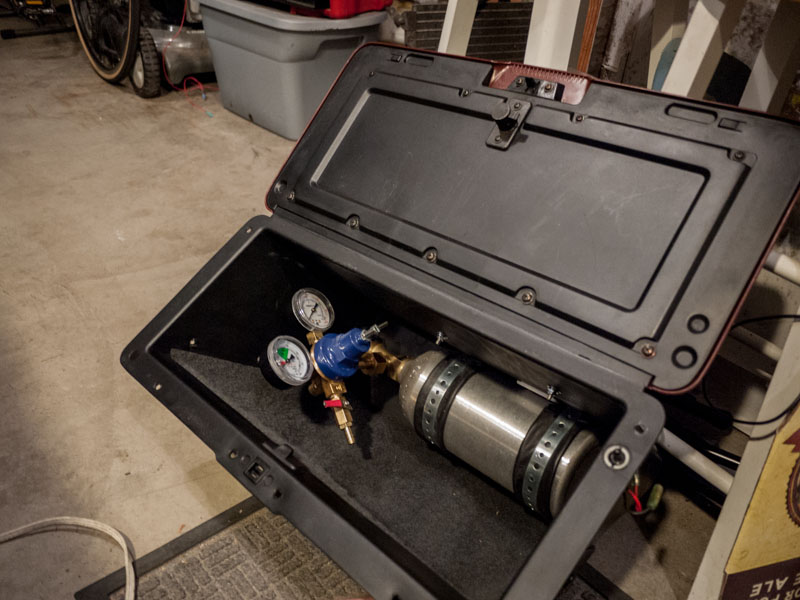

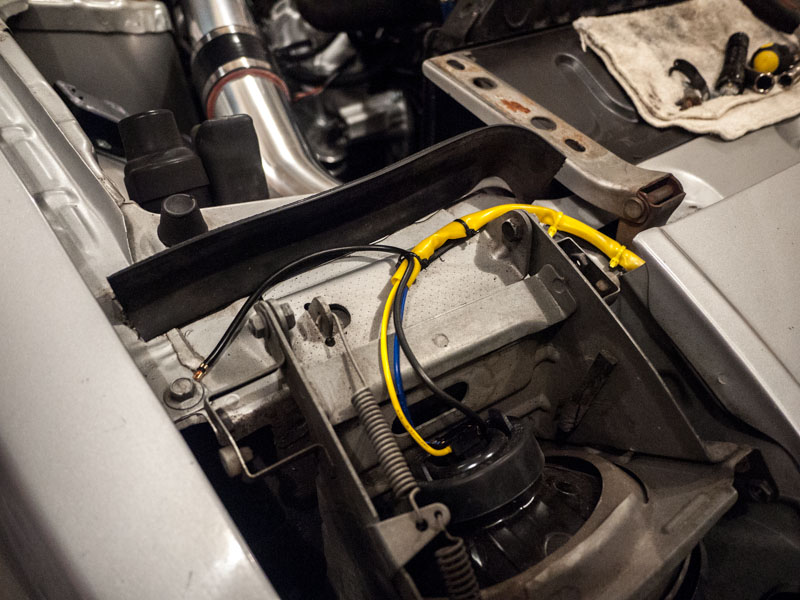

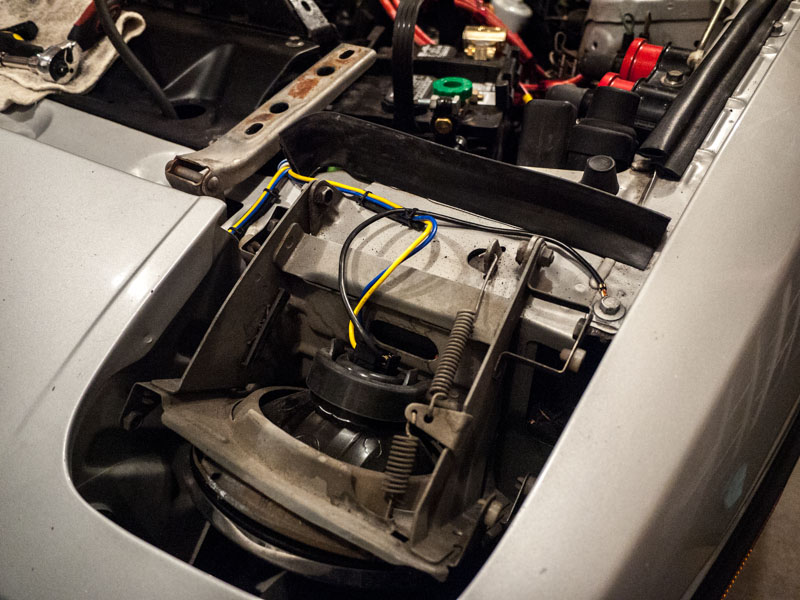

Got the CO2 tank mounted into the driver's storage bin - it ain't goin nowhere. Where you goin? NOWEAH.

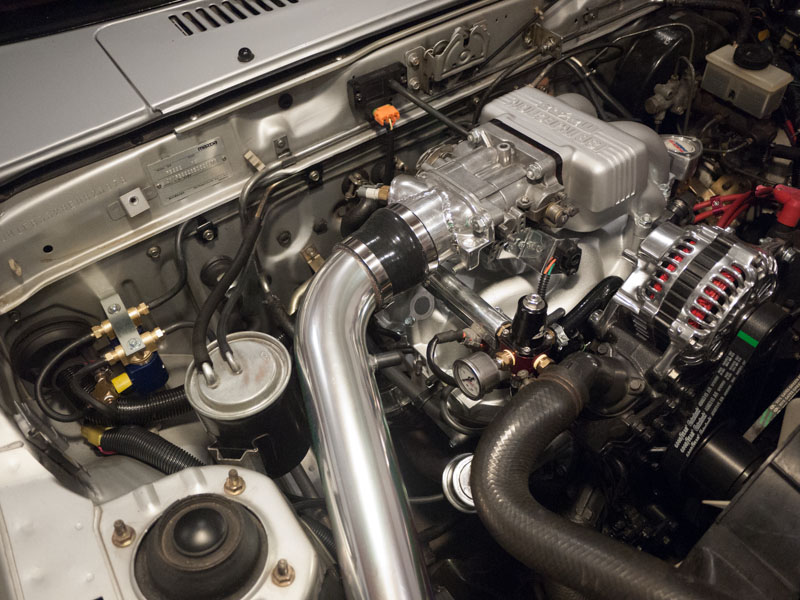

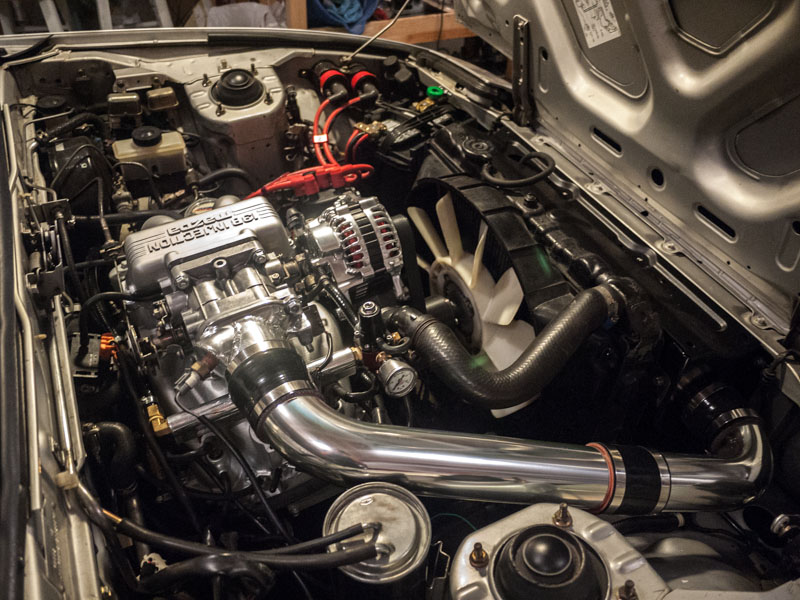

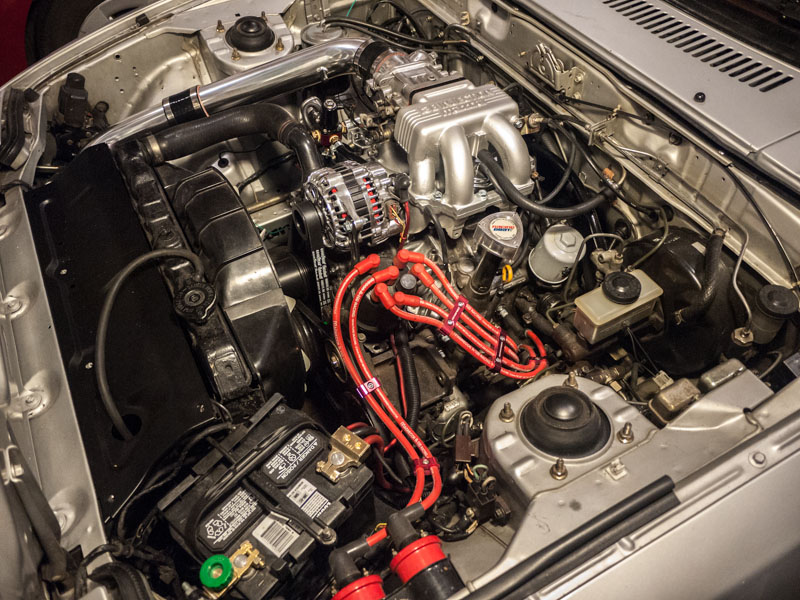

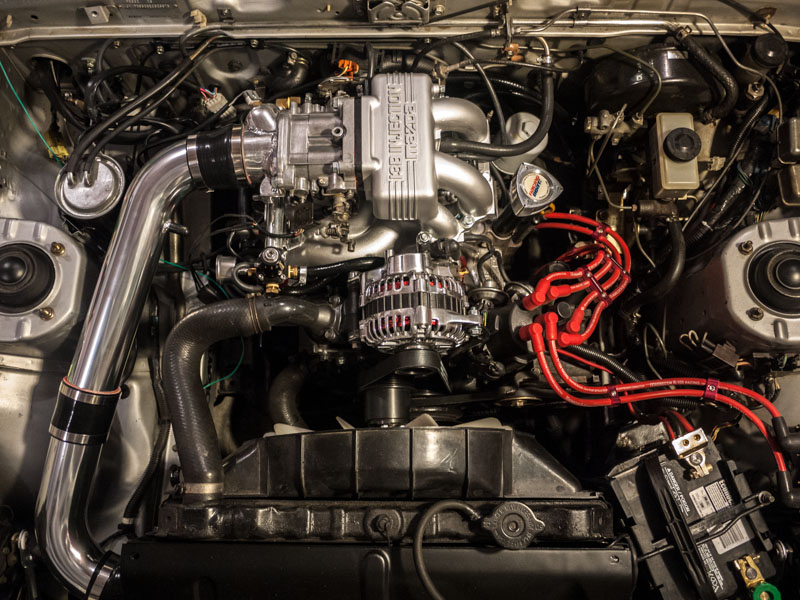

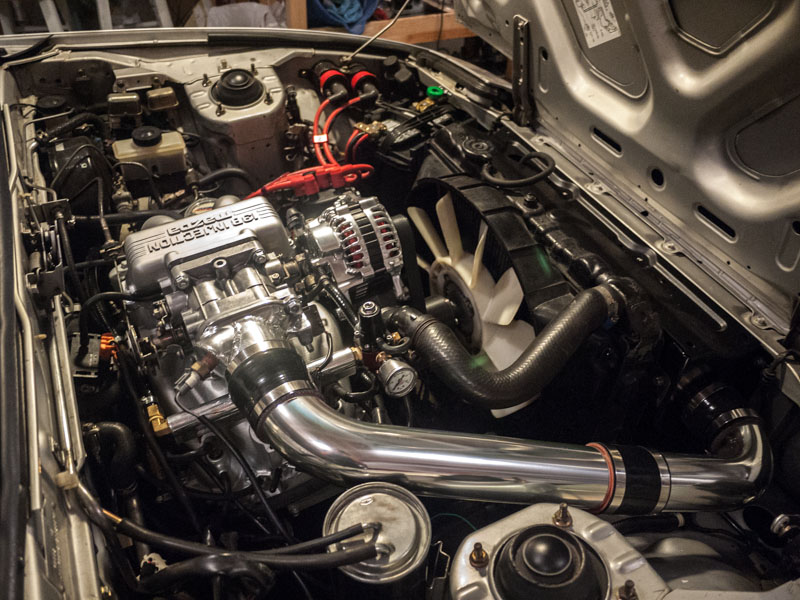

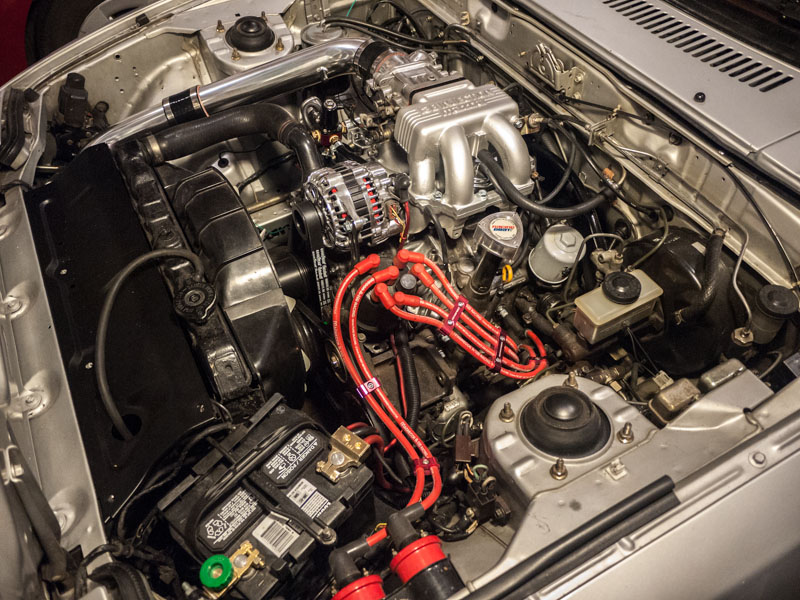

I haven't yet done the wire tuck, and the ECU harness is just a jumbly mess in the corner, but all the basic systems are in place. Still waiting on a full-swing throttle position sensor, then hook up the mechanical OMP to the throttle linkage once I know what sort of sensor/mount situation i'll be dealing with.

Hooked up all the vacuum systems, however I want to take a look with a vacuum gauge to see which ports pull the most, hook that up to MAP sensor and vacuum advance.

Relocated the coolant overflow in front of the radiator - noticed some black chunks in the coolant. NO BUENO! I ordered a fresh aluminum radiator off eBay today.

Ew! Look at that nasty radiator!

Still have yet to finalize my wire routing and tuck, will do that once the correct TPS is installed.

Got the CO2 tank mounted into the driver's storage bin - it ain't goin nowhere. Where you goin? NOWEAH.

I haven't yet done the wire tuck, and the ECU harness is just a jumbly mess in the corner, but all the basic systems are in place. Still waiting on a full-swing throttle position sensor, then hook up the mechanical OMP to the throttle linkage once I know what sort of sensor/mount situation i'll be dealing with.

Hooked up all the vacuum systems, however I want to take a look with a vacuum gauge to see which ports pull the most, hook that up to MAP sensor and vacuum advance.

Relocated the coolant overflow in front of the radiator - noticed some black chunks in the coolant. NO BUENO! I ordered a fresh aluminum radiator off eBay today.

Ew! Look at that nasty radiator!

Still have yet to finalize my wire routing and tuck, will do that once the correct TPS is installed.

#129

installed co2

CO2 now installed and hooked up.

also messed with the stereo wiring today. i'm having a heck of a time figuring out how to mount the amplifier. there's plenty of room between the two storage bins, but how to mount the amp down solid, with the proper side up, with accessibility to tuning functionality..... not sure if thats gonna happen.

also messed with the stereo wiring today. i'm having a heck of a time figuring out how to mount the amplifier. there's plenty of room between the two storage bins, but how to mount the amp down solid, with the proper side up, with accessibility to tuning functionality..... not sure if thats gonna happen.

#131

September 8th

Cheers brother

~ ~ ~

LOTS of progress today.

Hooked the RPM switches back up to the CO2 system, both the 6-ports and VDI are now functional. I'm noticing that the OEM solenoids are not wanting to relieve the pressure. Perhaps I've got it turned up a bit too much and its jamming them. I'll play around with lower PSI tomorrow. Right now its at 10psi which i know is a bit much, the OEM system was around 3-7.

Now that those are functioning properly, I decided to give another pass at tuning in the fuel maps. Bueno! As it was just me flying solo today, I could only really do zero-load condition mapping, but i got it mapped up to about 5k rpm. I'm still waiting on the throttle position sensor, the S4 TPS (i'm using an S4 throttle body) only measures the bottom 15-20% of the throttle, before the secondary throttle plates open.

However, i got it running, idling, revving OK, and the gas tank was almost empty. I turned the car off, fired it right back up (hot start is a different map), and decided to tempt fate: I drove around the block! She ran SMOOTh but no power, under load she's leaning way out. BUT, she ran well enough that I decided to roll down to the gas station and fill her up.

She ALMOST didnt start afterwards, but some bumping the throttle convinced her. Rolled back home, and was so pleased that I decided to give her a much-needed wash.

I was on such a roll that I decided it was finally time to finish the headlight upgrade, so I dusted off the relay harness from Black Dragon, put the easy-out onto the drill, and backed out the stripped headlight cover bolts. Got the new harness installed and routed - step 1 in the wire tuck! I was hoping i could figure something shui out, and so far I'm pleased.

Used the quarter-panel bolt for the headlight harness grounds:

The driver's side is where the relay harness connects to the OEM harness, so I will need to do some pondering as to where I'm going to route this, but I have a feeling it will just drop down into the nose cone where I intend on routing the factory harness.

I KNOW for a fact that I purchased replacement hardware for those STUPID phillips-head lid bolts that freeze into the headlight cages, but I couldn't for the life of me find them. So, this was my stopping point for today.

~ ~ ~

LOTS of progress today.

Hooked the RPM switches back up to the CO2 system, both the 6-ports and VDI are now functional. I'm noticing that the OEM solenoids are not wanting to relieve the pressure. Perhaps I've got it turned up a bit too much and its jamming them. I'll play around with lower PSI tomorrow. Right now its at 10psi which i know is a bit much, the OEM system was around 3-7.

Now that those are functioning properly, I decided to give another pass at tuning in the fuel maps. Bueno! As it was just me flying solo today, I could only really do zero-load condition mapping, but i got it mapped up to about 5k rpm. I'm still waiting on the throttle position sensor, the S4 TPS (i'm using an S4 throttle body) only measures the bottom 15-20% of the throttle, before the secondary throttle plates open.

However, i got it running, idling, revving OK, and the gas tank was almost empty. I turned the car off, fired it right back up (hot start is a different map), and decided to tempt fate: I drove around the block! She ran SMOOTh but no power, under load she's leaning way out. BUT, she ran well enough that I decided to roll down to the gas station and fill her up.

She ALMOST didnt start afterwards, but some bumping the throttle convinced her. Rolled back home, and was so pleased that I decided to give her a much-needed wash.

I was on such a roll that I decided it was finally time to finish the headlight upgrade, so I dusted off the relay harness from Black Dragon, put the easy-out onto the drill, and backed out the stripped headlight cover bolts. Got the new harness installed and routed - step 1 in the wire tuck! I was hoping i could figure something shui out, and so far I'm pleased.

Used the quarter-panel bolt for the headlight harness grounds:

The driver's side is where the relay harness connects to the OEM harness, so I will need to do some pondering as to where I'm going to route this, but I have a feeling it will just drop down into the nose cone where I intend on routing the factory harness.

I KNOW for a fact that I purchased replacement hardware for those STUPID phillips-head lid bolts that freeze into the headlight cages, but I couldn't for the life of me find them. So, this was my stopping point for today.

#132

CO2 now installed and hooked up.

also messed with the stereo wiring today. i'm having a heck of a time figuring out how to mount the amplifier. there's plenty of room between the two storage bins, but how to mount the amp down solid, with the proper side up, with accessibility to tuning functionality..... not sure if thats gonna happen.

also messed with the stereo wiring today. i'm having a heck of a time figuring out how to mount the amplifier. there's plenty of room between the two storage bins, but how to mount the amp down solid, with the proper side up, with accessibility to tuning functionality..... not sure if thats gonna happen.

Mount the amp vertically outside the bins, behind the drivers seat. Cover it with an extra piece of carpet and some Velcro.

As for your 6 ports, why aren't you using the Haltech to trigger them? I thought the S5 6 ports were electricallly (motor) controlled, not by air or exhaust? I could be wrong, it's been a while for me.

#133

Mount the amp vertically outside the bins, behind the drivers seat.

Cover it with an extra piece of carpet and some Velcro. As for your 6 ports, why aren't you using the Haltech to trigger them? I thought the S5 6 ports were electricallly (motor) controlled, not by air or exhaust? I could be wrong, it's been a while for me.

Cover it with an extra piece of carpet and some Velcro. As for your 6 ports, why aren't you using the Haltech to trigger them? I thought the S5 6 ports were electricallly (motor) controlled, not by air or exhaust? I could be wrong, it's been a while for me.

s5 6ports and vdi were controlled by rats nest solenoids pushed by the air pump and controlled by the ecu. the haltech has only 1 custom output, and im thinking of using it for a vacuum advance solenoid for the ignition system to emulate OEM spec as close as possible. hence the co2 system

control of the vdi and 6ports will be handled by two digital rpm switches pulled off the ecu harness. i currently have them pulled off their own wire straight off the coil, but the signal is bad and i think it be best to draw the signal and ground from the main electrical systems that the mazda engineers designed. the efi book ive been reading made a point that really resonated with me on how its crucial to wire sensors in series with the ecu harness, so as to eliminate ground loop noise which will throw off valuable readings for the ecu.

it also cued me in that i shouldnt be pulling my gauges power from the stereo harness, just because its handy. gotta keep that **** tight - integrated with the system its a part of. as soon as i tapped those gauges imto the stereo, it introduced line noise.

so ive pulled the factory pinout of the ecu harness on page 4B-70 of the 1985 factory service manual, fuel and emissions - control unit.

#134

The thing is, that the ports are should not be activated solely by a given RPM. Stock, they open based off LOAD. It's very different to be accelerating at 4000 rpm, as opposed to cruising at 4000 rpm. The ECU should read load based of engine speed, gear, and or throttle position. A fixed "on-off" switch RPM switch will not have torque in the right place, and fuel economy would suffer as well.

I am not trying to **** in your Cheerios- at all. I just want you to enjoy it like you intend to. Since you are not using the S5 ECU to control the actuators, and their transitions, it's gonna drive poorly in all regards except WOT. That why I asked if you are using the Haltech trigger.

If I was in your shoes... I would use an S4 lower intake and use the exhaust actuated ports. Another option is to pull the sleeves out and keep them always open (at the expense of low end torque though).

I am not trying to **** in your Cheerios- at all. I just want you to enjoy it like you intend to. Since you are not using the S5 ECU to control the actuators, and their transitions, it's gonna drive poorly in all regards except WOT. That why I asked if you are using the Haltech trigger.

If I was in your shoes... I would use an S4 lower intake and use the exhaust actuated ports. Another option is to pull the sleeves out and keep them always open (at the expense of low end torque though).

#141

what I was saying is that the s5 6ports and vdi are pressurized by the air pump, and actuated with an on/off solenoid, not a variable valve. i believe the renesis is the same. It's entirely rpm based and not load based.

Plus with a 3" exhaust there would be no backpressure to push the 6ports or vdi open anyways.

Today I made a bunch of progress, tapped everything in to the factory harness, finished routing wires for the RPM switch / CO2 system, finished pulling the Haltech harness tight. All thats left is mounting the ECU and plugging in the last few wires, then time to tune!

Plus with a 3" exhaust there would be no backpressure to push the 6ports or vdi open anyways.

Today I made a bunch of progress, tapped everything in to the factory harness, finished routing wires for the RPM switch / CO2 system, finished pulling the Haltech harness tight. All thats left is mounting the ECU and plugging in the last few wires, then time to tune!

#142

Installed.

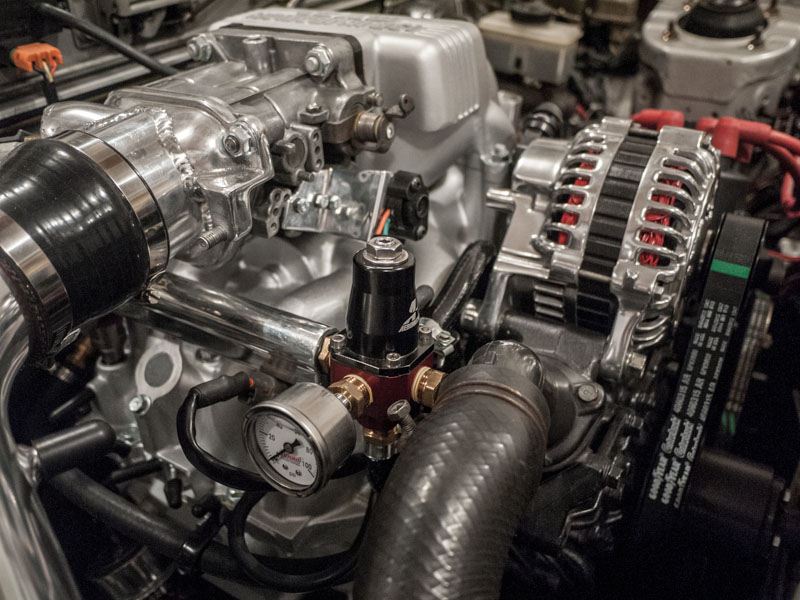

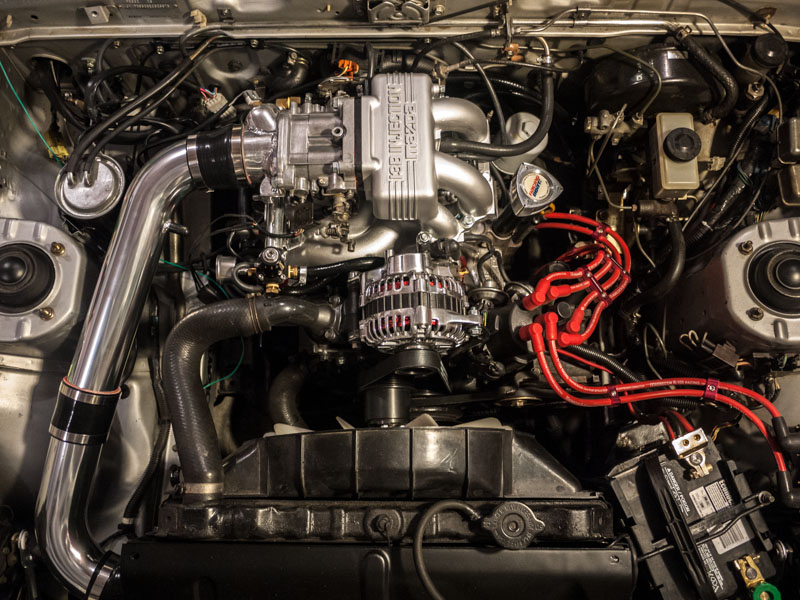

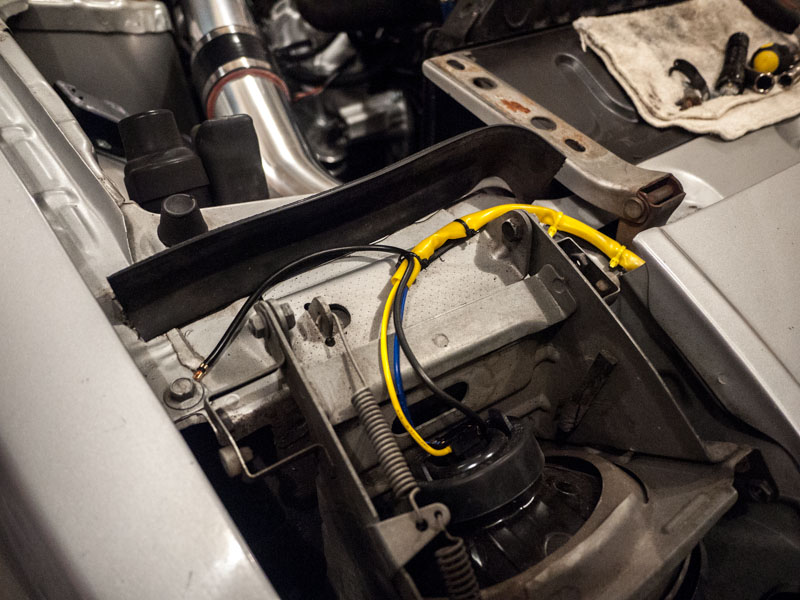

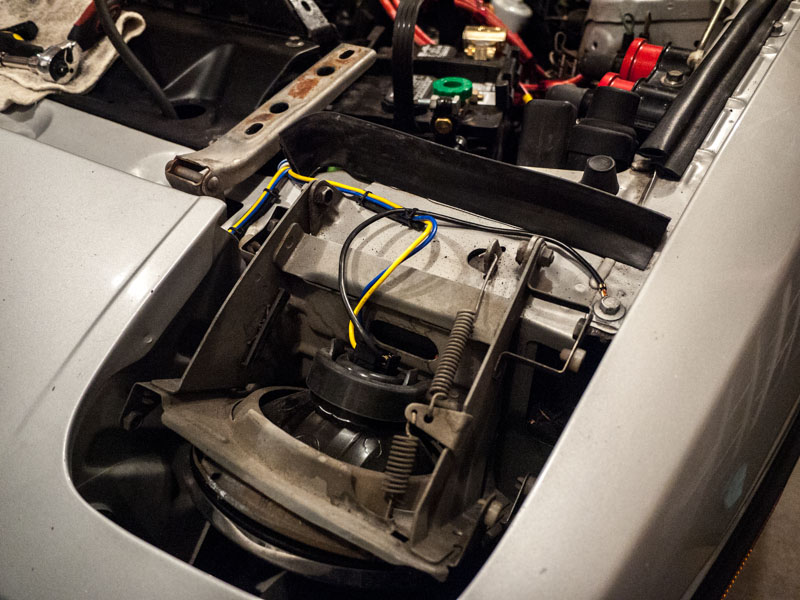

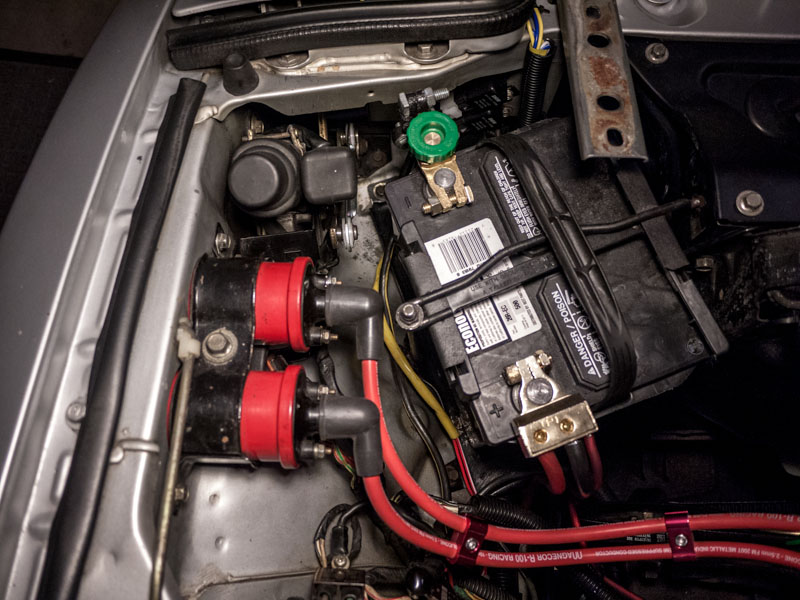

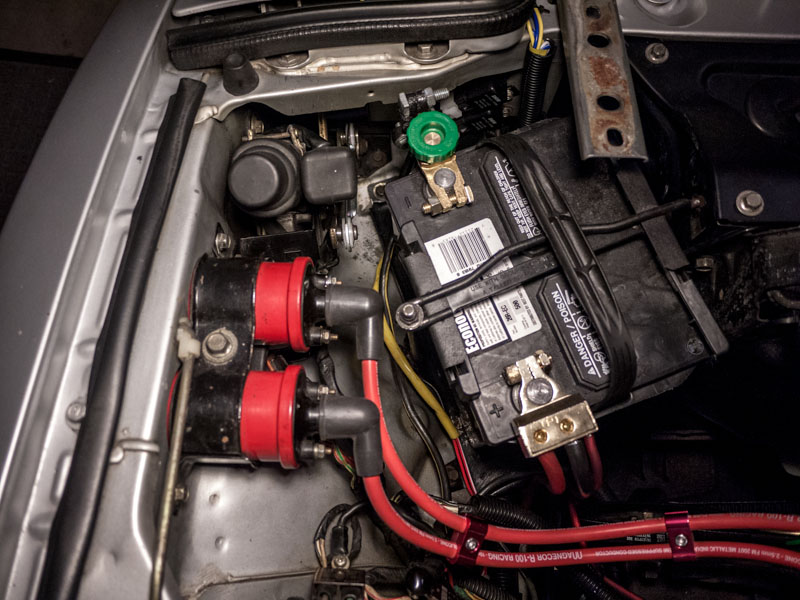

Got the Haltech and 6port/vdi rpm switch & solenoid system completely tapped into the factory harness.

I made sure to crimp all connections securely, used bulb grease on all the connectors and grounds. Grounded all ECU-connected components to the exact same spot.

Re-routed almost all custom wires, a-pillar gauge leads, made sure the audio system is completely isolated from the ECU systems.

The RPM signal leads were looking quite sad, one of them completely snapped off its solder connection. Cleaned those up and did some fresh shrink wrap over top

I removed the hacked-in lead I was pulling for the RPM switches and tapped them directly in at the ECU harness plug, and grounded the rpm switches back to the same ECU ground. I now have a solid RPM signal - before the RPM signal was jumping all over the place, i must have been creating a mad ground loop through the chassis.

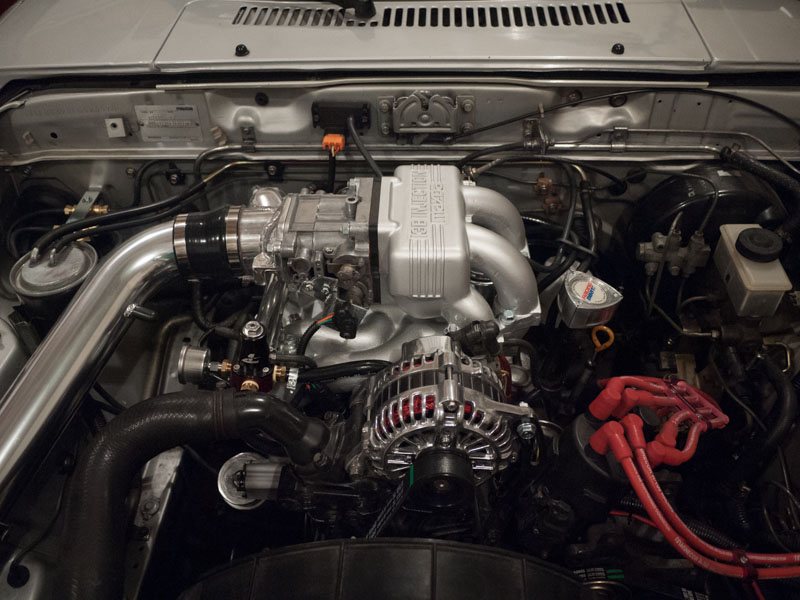

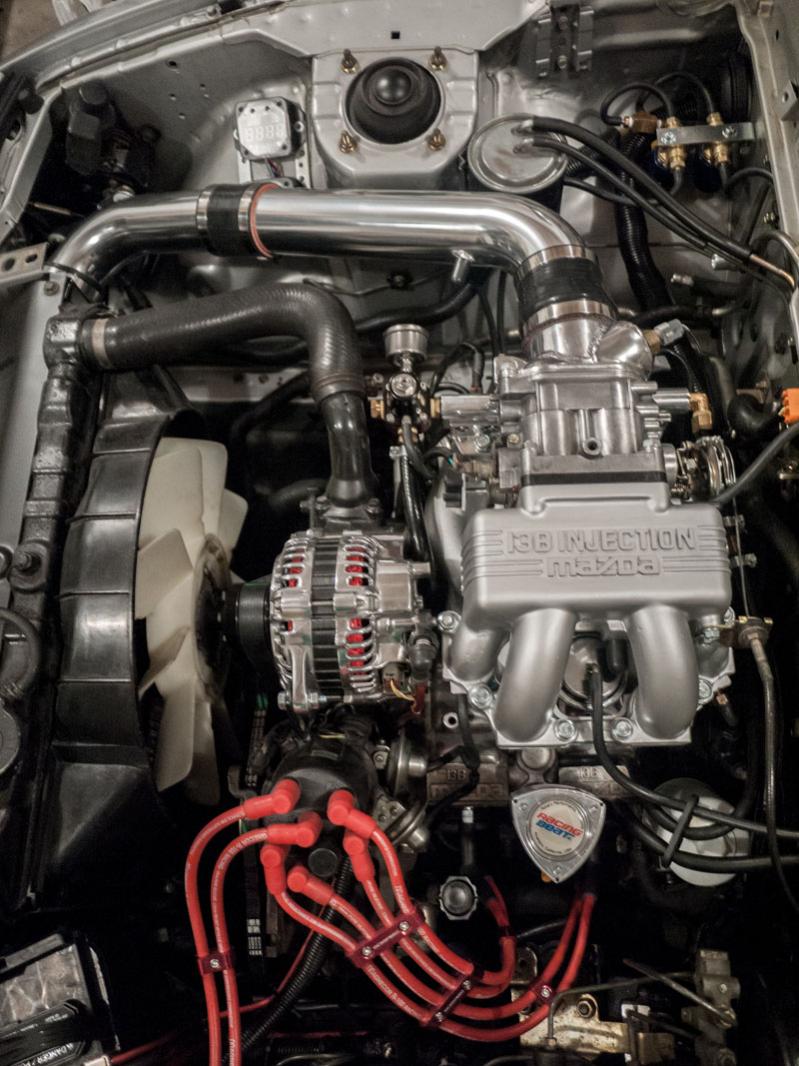

I am now calling the engine bay "done" for the time being. I have a few more ideas to clean it up a bit, and the driver's side still needs more love (and fresh paint, the battery acid seems to have had a go at it in a few spots), but overall i'm quite happy with how its looking.

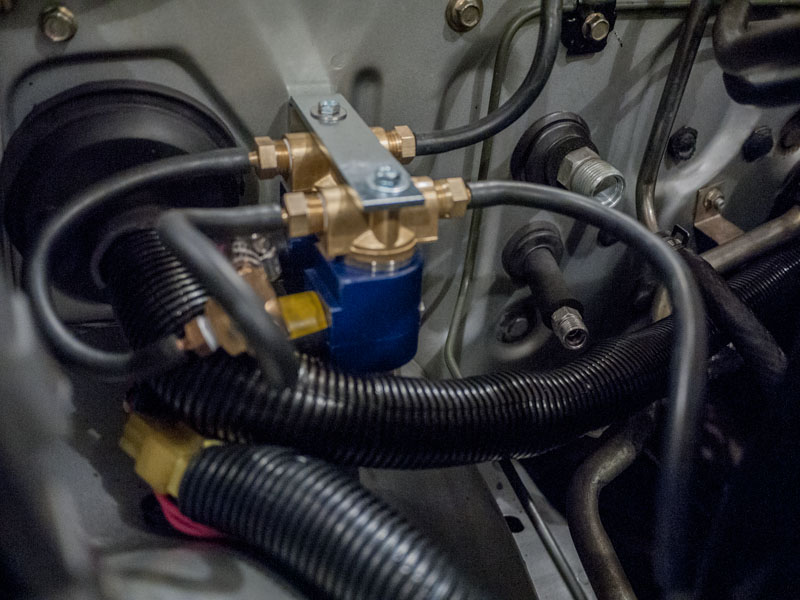

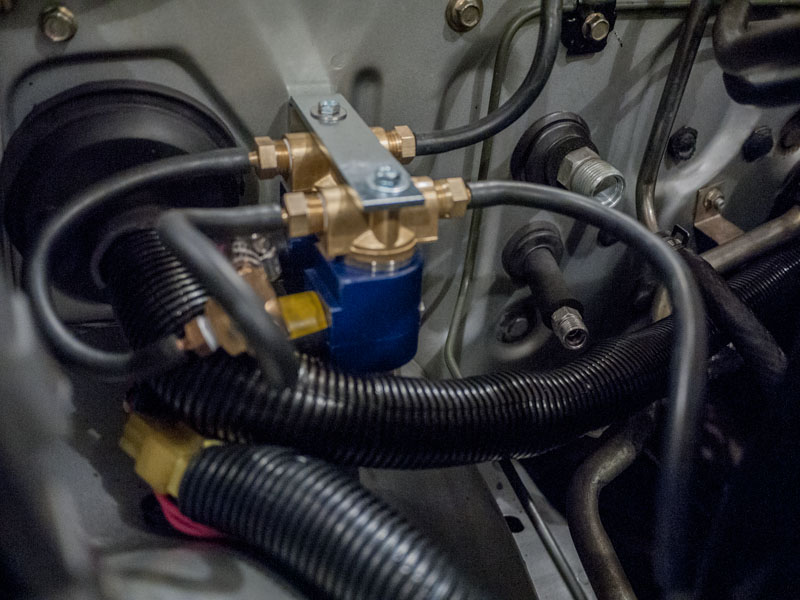

I replaced the OEM 25 year old pressure solenoids for the 6port and VDI system with some $30 ebay specials. these are high quality units, brass valves and tubing, can handle up to 120psi, no need to worry about blowing or wearing them out. The exhaust vent is on the bottom of the blue plastic part.

Another angle of the rpm switch harness (left), haltech harness (center), and CO2 6port/VDI solenoid system.

I made sure to crimp all connections securely, used bulb grease on all the connectors and grounds. Grounded all ECU-connected components to the exact same spot.

Re-routed almost all custom wires, a-pillar gauge leads, made sure the audio system is completely isolated from the ECU systems.

The RPM signal leads were looking quite sad, one of them completely snapped off its solder connection. Cleaned those up and did some fresh shrink wrap over top

I removed the hacked-in lead I was pulling for the RPM switches and tapped them directly in at the ECU harness plug, and grounded the rpm switches back to the same ECU ground. I now have a solid RPM signal - before the RPM signal was jumping all over the place, i must have been creating a mad ground loop through the chassis.

I am now calling the engine bay "done" for the time being. I have a few more ideas to clean it up a bit, and the driver's side still needs more love (and fresh paint, the battery acid seems to have had a go at it in a few spots), but overall i'm quite happy with how its looking.

I replaced the OEM 25 year old pressure solenoids for the 6port and VDI system with some $30 ebay specials. these are high quality units, brass valves and tubing, can handle up to 120psi, no need to worry about blowing or wearing them out. The exhaust vent is on the bottom of the blue plastic part.

Another angle of the rpm switch harness (left), haltech harness (center), and CO2 6port/VDI solenoid system.

#145

Erratic RPM Switch

I initially wrote this as an email to Doug_Ingraham, but I figured I should put it open-forum so we could all help each other out in these situations for google purposes.

So I finished her all up this weekend, got the wiring checked and double checked, every connection properly crimped and using dielectric grease, fired her up and began tuning.

Got my timing marks on the pulley, supposedly in the correct place... it still seems to me like it runs better with the timing significantly more advanced, but that's another conversation altogether.

What i'm most curious about, and what's preventing me from truly tuning in the engine, is the erratic operation of the Summit Digital RPM switches. For my rough-draft-will-it-work hack I had the signal coming from its own lead from the trailing coil (-) post, and grounded the RPM Switches to the nearest chassis ground. The signal was erratic then, and each rpm switch would show a slightly different rpm during idle, + or - 100 rpm.

I figured, sure, its an old distributor system so fine the signal will waver 100 rpm here or there, no problem. but it didnt seem nearly as significant until i got the new solenoids, which make a significant *click* when they activate. I would hear them repeatedly clicking on and off at crank and idle, however the RPM switches that control them are set to actuate at 3800 and 5400 rpms...

I got out to inspect what was going on, and sure enough the signal on the rpm switch would suddenly jump to 9000 (or so) rpm then 0 then 900 where it should be.

I have since tapped the RPM switch signal wire to the trailing (-) signal from the factory harness plug at the ECU, and grounded them to the same exact spot as the entire ECU harness. I was sure this would stabilize the signal, but my efforts were in vain - it behaves exactly the same.

The real hitch of the whole thing is that the haltech is ALSO tapped into the exact same spot, both for tach signal, system power, and ground. it can read the rpm signal in 20rpm increments, and is DEAD on. The signal does not waver at all.

Maybe the RPM switches are overheating??? they are certainly warm to the touch, but my macbook gets WAY hotter and runs mostly fine.

Perhaps I'll tuck them in front of the radiator and see if that helps. It's not a permanent solution from the moisture factor, but will at least isolate that variable. Although I gotta say I figured Summit Racing - that's gotta be some burly stuff built for underhood environments.

I'm also wondering if there are electrical gremlins somewhere, a short in the chassis thats glitching **** out. I know that the previous owner had hacked an alarm system into the car, and the guy i bought it from (Army of One here on the forums, who was selling it for the PO) had done a lot of work to restore the factory harness (thank you! i can barely tell they did anything). He also had to replace the main relay with a 2nd gen higher amperage one because it kept blowing the gsl-se relay. i'm not sure i know what that means in terms of diagnostics.

Would you have any insight as to what might be causing this behavior with this specific system? Its both rpm switches, independent of each other. they display different RPM signals even though they're drawing off the EXACT same lead,

Summit RPM Activated Switch Diagnostics:

Symptom: The two RPM Switches (often) have differing signals, + or - 100-200 rpm, despite being wired in series to the same signal.

Symptom: The RPM Switch signal jumps around displaying very high or 0 rpm erratic signal blips:

So I finished her all up this weekend, got the wiring checked and double checked, every connection properly crimped and using dielectric grease, fired her up and began tuning.

Got my timing marks on the pulley, supposedly in the correct place... it still seems to me like it runs better with the timing significantly more advanced, but that's another conversation altogether.

What i'm most curious about, and what's preventing me from truly tuning in the engine, is the erratic operation of the Summit Digital RPM switches. For my rough-draft-will-it-work hack I had the signal coming from its own lead from the trailing coil (-) post, and grounded the RPM Switches to the nearest chassis ground. The signal was erratic then, and each rpm switch would show a slightly different rpm during idle, + or - 100 rpm.

I figured, sure, its an old distributor system so fine the signal will waver 100 rpm here or there, no problem. but it didnt seem nearly as significant until i got the new solenoids, which make a significant *click* when they activate. I would hear them repeatedly clicking on and off at crank and idle, however the RPM switches that control them are set to actuate at 3800 and 5400 rpms...

I got out to inspect what was going on, and sure enough the signal on the rpm switch would suddenly jump to 9000 (or so) rpm then 0 then 900 where it should be.

I have since tapped the RPM switch signal wire to the trailing (-) signal from the factory harness plug at the ECU, and grounded them to the same exact spot as the entire ECU harness. I was sure this would stabilize the signal, but my efforts were in vain - it behaves exactly the same.

The real hitch of the whole thing is that the haltech is ALSO tapped into the exact same spot, both for tach signal, system power, and ground. it can read the rpm signal in 20rpm increments, and is DEAD on. The signal does not waver at all.

Maybe the RPM switches are overheating??? they are certainly warm to the touch, but my macbook gets WAY hotter and runs mostly fine.

Perhaps I'll tuck them in front of the radiator and see if that helps. It's not a permanent solution from the moisture factor, but will at least isolate that variable. Although I gotta say I figured Summit Racing - that's gotta be some burly stuff built for underhood environments.

I'm also wondering if there are electrical gremlins somewhere, a short in the chassis thats glitching **** out. I know that the previous owner had hacked an alarm system into the car, and the guy i bought it from (Army of One here on the forums, who was selling it for the PO) had done a lot of work to restore the factory harness (thank you! i can barely tell they did anything). He also had to replace the main relay with a 2nd gen higher amperage one because it kept blowing the gsl-se relay. i'm not sure i know what that means in terms of diagnostics.

Would you have any insight as to what might be causing this behavior with this specific system? Its both rpm switches, independent of each other. they display different RPM signals even though they're drawing off the EXACT same lead,

Summit RPM Activated Switch Diagnostics:

Symptom: The two RPM Switches (often) have differing signals, + or - 100-200 rpm, despite being wired in series to the same signal.

Symptom: The RPM Switch signal jumps around displaying very high or 0 rpm erratic signal blips:

- (often) during initial crank of engine

- - (sometimes) once per crank, but (often) repeatedly.

- (seldomly) during normal idle & smooth acceleration.

- (often) during rapid acceleration

- (rarely if ever) during deceleration

#146

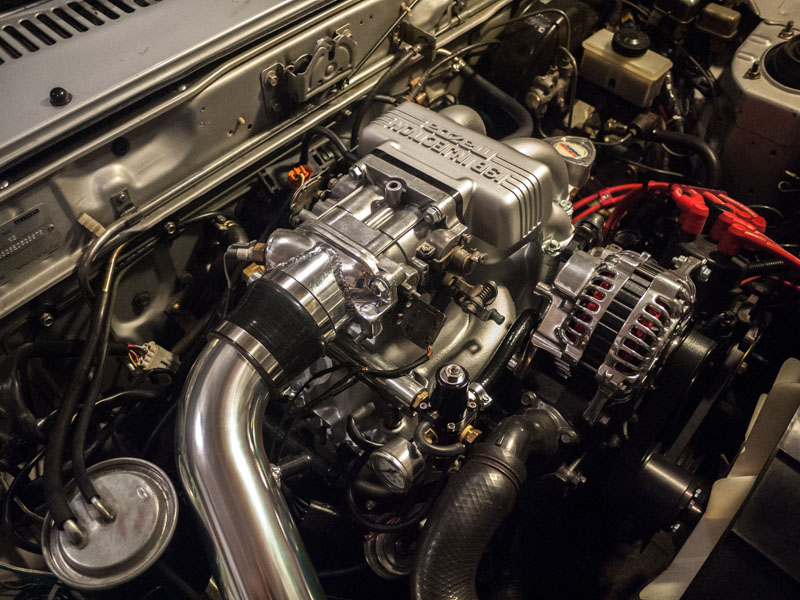

By the way - everything you see in the photos above thats shiney is from RotaryShack:

3" Throttle body inlet

s4 throttle body with TPS mounting bracket

s5 intake manifold (ceramic coated by Performance Coating in Auburn, WA)

custom fuel rails

3" MaxPower header

s6 alt

haltech ECU

power steering pump (ok not shiney but it doesnt leak! )

)

3" Throttle body inlet

s4 throttle body with TPS mounting bracket

s5 intake manifold (ceramic coated by Performance Coating in Auburn, WA)

custom fuel rails

3" MaxPower header

s6 alt

haltech ECU

power steering pump (ok not shiney but it doesnt leak!

)

)

#147

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,819

Received 2,590 Likes

on

1,839 Posts

#148

Geoff,

I don't know much about these particular systems but if you have access to a scope (or a friend with a scope) you might take a look at the tach signal and see if it is noisy. You can try something simple like adding a 1k ohm pullup resistor between the signal and 12 volts. This could improve rise time which might be affected by the additional load of your devices. Talk to the vendor and see what kind of signal they are expecting to see. They might have some suggestions.

If I was closer I could take a look. I've got a new scope and an old scope. The old one is 10 years older than your car.

I don't know how useful any of that is. I hope someone who is using the same stuff sees it and gives you a solution.

I don't know much about these particular systems but if you have access to a scope (or a friend with a scope) you might take a look at the tach signal and see if it is noisy. You can try something simple like adding a 1k ohm pullup resistor between the signal and 12 volts. This could improve rise time which might be affected by the additional load of your devices. Talk to the vendor and see what kind of signal they are expecting to see. They might have some suggestions.

If I was closer I could take a look. I've got a new scope and an old scope. The old one is 10 years older than your car.

I don't know how useful any of that is. I hope someone who is using the same stuff sees it and gives you a solution.

#149

I have an aux output on the haltech, so i may just let the rpm switch trigger the above 3800 condition, and let the haltech control power to the rpm switch for the air flow adjustment.

Doug - the EFI book im reading suggested getting an oscilliscope too for ignition stuff. Sounds like it might be handy. They even say a USB one is good, and can datalog. Thanks!!

#150

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,819

Received 2,590 Likes

on

1,839 Posts

Directfreak, j9 - thanks for the info! Its odd that in ALL the threads discussing 6port / VDI function, nobody has ever mentioned that before, just that they need to open above 3800 rpm. I will dig through the manuals and check that out. I haven't come across it yet, but then i've only been reading the spec manual and "additional info" manual for the s5.

I have an aux output on the haltech, so i may just let the rpm switch trigger the above 3800 condition, and let the haltech control power to the rpm switch for the air flow adjustment.

Doug - the EFI book im reading suggested getting an oscilliscope too for ignition stuff. Sounds like it might be handy. They even say a USB one is good, and can datalog. Thanks!!

I have an aux output on the haltech, so i may just let the rpm switch trigger the above 3800 condition, and let the haltech control power to the rpm switch for the air flow adjustment.

Doug - the EFI book im reading suggested getting an oscilliscope too for ignition stuff. Sounds like it might be handy. They even say a USB one is good, and can datalog. Thanks!!