My custom "HD" aux injection system - LONG

#1

Rotary Enthusiast

Thread Starter

iTrader: (5)

Join Date: Mar 2005

Location: Boxford, MA

Posts: 791

Likes: 0

Received 0 Likes

on

0 Posts

My custom "HD" aux injection system - LONG

A while ago I started working on my own auxiliary injection system because at the time I couldn't find two features I wanted in the off-the-shelf systems. The first was integrated boost control - meaning that the water injection controller could cut boost if it detected a fault. It only seemed sensible and I also still run sequential turbos (BNR IIIs) so I wanted a boost controller designed to properly control the prespool and wastegate. I also wanted the controller to inject water/meth as a percentage of the current fuel flow. Apparently both of these features are available now but I don't think anybody has successfully implemented a proper sequential turbo control. I'll describe my thought process in laying out every aspect of the system:

INJECTORS

I decided to at least test out fuel injectors with a fuel pump since there has obviously been a lot of effort put into their nozzle design and reliability over the past 50 or so years. If they can achieve an acceptable spray pattern and not suffer corrosion-related failures with a water/meth mix then they would be the nozzle of choice since they have excellent pulsed flow characteristics. My fuel system consists of stock 550cc primaries and overbored secondaries which come out to around 1550 cc/min. That gives me a total fuel injection capacity of 4200 cc/min. I wanted to be able to inject 20% of that in water/meth with 2 easily available new injectors so I would have a reasonable amount of resolution and reliability. The units I chose are the Bosch 0-280-156-127 injectors from 2004 Ford SVT Cobras (I think they're also known as "blue giants"). They are nominally rated at 436 cc/min which gets me right around 21% with two of them. They cost about $50 apiece and I had read that they have a very efficient spray pattern so they seemed like a good choice for starters. They're also from a relatively new car so it was likely that they were designed to withstand ethanol and/or e85, which makes them more likely to be built to hold up to a meth/water mix.

I decided to install the injectors in a Greddy elbow facing the throttle body. I just did this based on intuition since I have yet to see any data suggesting there are better approaches. I drew up a fuel rail and mounting block and had my welder make them. The injector install is shown below:

FUEL PUMP

I chose the Summit Racing SUM-G3138 EFI inline fuel pump because it was reasonably cheap and could supply 85 psi.

INJECTANT

I wanted to use the stock windshield washer tank as a supply and I didn't want to lose the ability to clean my windshield so the logical choice was windshield washer fluid. I've read from a few sources that the cheap walmart-brand -20F blue stuff is about 40% meth/60% water, which is fine for me. There are probably minor amounts of detergent in it as well but they did not seem to affect performance.

PRESSURE REGULATOR

I chose to use an SX fuel pressure regulator with a return line since it is compatible with water and meth.

So here's what the basic hardware looks like:

FAILSAFES

Reliability is of primary concern here so I wanted as many failsafe mechanisms as possible. I got a float switch from devilsown that will trigger a boost cut if the tank runs low. I also got a fuel pressure sender which I installed in the pressure regulator. If the line pressure dips, the microcontroller will shut off the system and cut boost. The other thing I would like is a means of detecting whether the injectors are actually injecting but there is no terribly easy means of doing that so I'll just have some faith for the moment.

CONTROLLER

The controller I'm building uses a Microchip PIC18 with 4 PWM outputs, 9 10-bit A/D inputs and plenty of digital I/O. I've worked with PICs before so it was an obvious choice. 2 of the PWM outputs will control the injectors and 2 will control boost solenoids. The pump has a control bit and I have one auxiliary power control line. Not sure if I'll ever use it. The controller has 2 Freescale MPX4250 pressure sensors which will be used to control boost. Only one is needed but I am thinking about having a boost line from both the turbo outlet and the UIM while I do my boost control algorithm testing. I made a harness that plugs into the primary and secondary injector harness to measure injector pulse width. The microcontroller will read that and calculate water injection pulse width based on a percentage of the fuel being injected. I will only have it trigger above a certain level of boost that I can control, probably around 2-5 psi. There is also a "control box" which I will keep in the cabin that has an LCD screen with status information and a control wheel to change settings.

STATUS

This is still very much a work in progress and I'll keep updating if people are interested. I decided to post about it now because I've gotten through my preliminary injector testing and I'm pretty happy with the results. I have had no signs of failure after 3 ~2 hr sessions of continuous running. Last night and today I flow tested the injectors and found that their output was very linear and there were no obvious issues with the water. I used a graduated cylinder to measure washer fluid flowed with 40, 50, 60, and 70 psi line pressure and injector duty cycles from 10-100%. The results are below:

I also calculated injector lag times from these tests, which were as follows:

40 psi - .79 ms

50 psi - .74 ms

60 psi - .79 ms

70 psi - .88 ms

I found that the spray pattern is evenly distributed but not as well atomized as I'd like at the lower line pressures. It looks much better at 70 psi so I think I will try to run that in operation.

Also, I have drawn up a pc board for the controller and it's in fab now. Hopefully soon I'll be ready to do some in-car testing.

I would love to hear comments or questions on this and any suggestions for additional testing that would be useful to myself or others. I still can't say for sure whether fuel injectors/pumps are a good choice but I see no signs of problems yet.

INJECTORS

I decided to at least test out fuel injectors with a fuel pump since there has obviously been a lot of effort put into their nozzle design and reliability over the past 50 or so years. If they can achieve an acceptable spray pattern and not suffer corrosion-related failures with a water/meth mix then they would be the nozzle of choice since they have excellent pulsed flow characteristics. My fuel system consists of stock 550cc primaries and overbored secondaries which come out to around 1550 cc/min. That gives me a total fuel injection capacity of 4200 cc/min. I wanted to be able to inject 20% of that in water/meth with 2 easily available new injectors so I would have a reasonable amount of resolution and reliability. The units I chose are the Bosch 0-280-156-127 injectors from 2004 Ford SVT Cobras (I think they're also known as "blue giants"). They are nominally rated at 436 cc/min which gets me right around 21% with two of them. They cost about $50 apiece and I had read that they have a very efficient spray pattern so they seemed like a good choice for starters. They're also from a relatively new car so it was likely that they were designed to withstand ethanol and/or e85, which makes them more likely to be built to hold up to a meth/water mix.

I decided to install the injectors in a Greddy elbow facing the throttle body. I just did this based on intuition since I have yet to see any data suggesting there are better approaches. I drew up a fuel rail and mounting block and had my welder make them. The injector install is shown below:

FUEL PUMP

I chose the Summit Racing SUM-G3138 EFI inline fuel pump because it was reasonably cheap and could supply 85 psi.

INJECTANT

I wanted to use the stock windshield washer tank as a supply and I didn't want to lose the ability to clean my windshield so the logical choice was windshield washer fluid. I've read from a few sources that the cheap walmart-brand -20F blue stuff is about 40% meth/60% water, which is fine for me. There are probably minor amounts of detergent in it as well but they did not seem to affect performance.

PRESSURE REGULATOR

I chose to use an SX fuel pressure regulator with a return line since it is compatible with water and meth.

So here's what the basic hardware looks like:

FAILSAFES

Reliability is of primary concern here so I wanted as many failsafe mechanisms as possible. I got a float switch from devilsown that will trigger a boost cut if the tank runs low. I also got a fuel pressure sender which I installed in the pressure regulator. If the line pressure dips, the microcontroller will shut off the system and cut boost. The other thing I would like is a means of detecting whether the injectors are actually injecting but there is no terribly easy means of doing that so I'll just have some faith for the moment.

CONTROLLER

The controller I'm building uses a Microchip PIC18 with 4 PWM outputs, 9 10-bit A/D inputs and plenty of digital I/O. I've worked with PICs before so it was an obvious choice. 2 of the PWM outputs will control the injectors and 2 will control boost solenoids. The pump has a control bit and I have one auxiliary power control line. Not sure if I'll ever use it. The controller has 2 Freescale MPX4250 pressure sensors which will be used to control boost. Only one is needed but I am thinking about having a boost line from both the turbo outlet and the UIM while I do my boost control algorithm testing. I made a harness that plugs into the primary and secondary injector harness to measure injector pulse width. The microcontroller will read that and calculate water injection pulse width based on a percentage of the fuel being injected. I will only have it trigger above a certain level of boost that I can control, probably around 2-5 psi. There is also a "control box" which I will keep in the cabin that has an LCD screen with status information and a control wheel to change settings.

STATUS

This is still very much a work in progress and I'll keep updating if people are interested. I decided to post about it now because I've gotten through my preliminary injector testing and I'm pretty happy with the results. I have had no signs of failure after 3 ~2 hr sessions of continuous running. Last night and today I flow tested the injectors and found that their output was very linear and there were no obvious issues with the water. I used a graduated cylinder to measure washer fluid flowed with 40, 50, 60, and 70 psi line pressure and injector duty cycles from 10-100%. The results are below:

I also calculated injector lag times from these tests, which were as follows:

40 psi - .79 ms

50 psi - .74 ms

60 psi - .79 ms

70 psi - .88 ms

I found that the spray pattern is evenly distributed but not as well atomized as I'd like at the lower line pressures. It looks much better at 70 psi so I think I will try to run that in operation.

Also, I have drawn up a pc board for the controller and it's in fab now. Hopefully soon I'll be ready to do some in-car testing.

I would love to hear comments or questions on this and any suggestions for additional testing that would be useful to myself or others. I still can't say for sure whether fuel injectors/pumps are a good choice but I see no signs of problems yet.

#2

Racing Rotary Since 1983

iTrader: (6)

very nice. and thanks for the info

FJO has used -40 degree winshield solvant for 2 years on their in house camaro. twin turbos and 1200 rwhp. no problems w "bug juice" as they call it.

your setup looks good on paper please do keep us upated.

hc

FJO has used -40 degree winshield solvant for 2 years on their in house camaro. twin turbos and 1200 rwhp. no problems w "bug juice" as they call it.

your setup looks good on paper please do keep us upated.

hc

#4

Rotary Enthusiast

Thread Starter

iTrader: (5)

Join Date: Mar 2005

Location: Boxford, MA

Posts: 791

Likes: 0

Received 0 Likes

on

0 Posts

Howard, thanks for the support.

SirCygnus, do you have pcb fab facilities or something? I'd consider marketing this thing but I don't think I'd be interested in just handing over my work for somebody else to profit from. Not trying to imply that's what you're doing.

SirCygnus, do you have pcb fab facilities or something? I'd consider marketing this thing but I don't think I'd be interested in just handing over my work for somebody else to profit from. Not trying to imply that's what you're doing.

Trending Topics

#9

Rotary Enthusiast

Thread Starter

iTrader: (5)

Join Date: Mar 2005

Location: Boxford, MA

Posts: 791

Likes: 0

Received 0 Likes

on

0 Posts

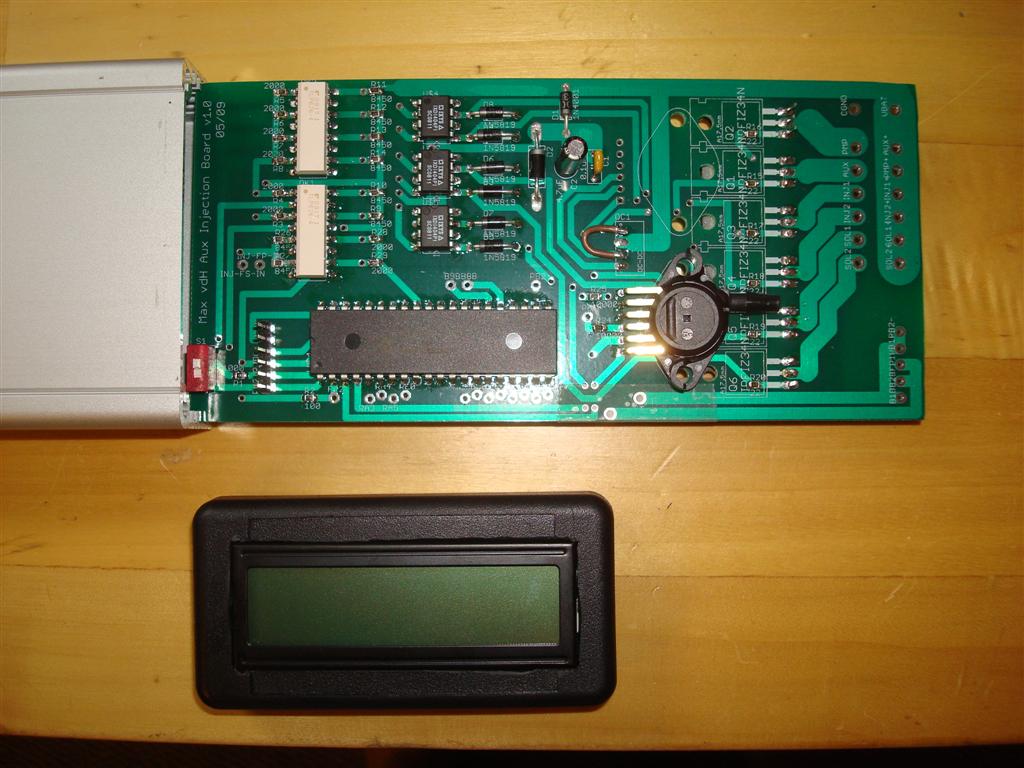

Assembled my controller board and the handheld readout/settings adjustment box. There are a couple of minor packaging issues I'll have to correct if I do this again but overall I'm pretty happy with it. Time for more coding and testing!

#11

Rotary Enthusiast

Thread Starter

iTrader: (5)

Join Date: Mar 2005

Location: Boxford, MA

Posts: 791

Likes: 0

Received 0 Likes

on

0 Posts

Update: I'm having some trouble with my LCD display on the new board. I've been playing with things for a while but I haven't figured out what the problem is. Everything else, as far as driving the injectors and solenoids, seems to work fine though so I should be back to testing as soon as I sort this out.

#12

Rotary Enthusiast

Thread Starter

iTrader: (5)

Join Date: Mar 2005

Location: Boxford, MA

Posts: 791

Likes: 0

Received 0 Likes

on

0 Posts

I think I found the problem with the LCD which reminds me that I am in fact not an electrical engineer. I neglected to add a couple of necessary capacitors. I will probably update again next week.

#13

Rotary Enthusiast

Thread Starter

iTrader: (5)

Join Date: Mar 2005

Location: Boxford, MA

Posts: 791

Likes: 0

Received 0 Likes

on

0 Posts

It's been a long time since I updated this thread. I took some time off from the project to try to get my A/C going. However, the time off has helped advance the project a bit -

The Summit Racing fuel pump has seized. It worked for a few weeks while I was testing a while ago but sitting for a few months has allowed it to corrode I believe. So to all that shunned fuel pumps for water/meth injection systems, you were right. But I'm glad I know for sure now. I now need to pick out a more appropriate pump. I'm thinking I'll probably go with one of the shurflo pumps unless somebody has better suggestions. I only need ~100 psi capability since I don't want to run more than that through the injectors. Flow requirement is about .3 gallon/minute.

Can anybody recommend a reliable pump meeting that requirement?

The Summit Racing fuel pump has seized. It worked for a few weeks while I was testing a while ago but sitting for a few months has allowed it to corrode I believe. So to all that shunned fuel pumps for water/meth injection systems, you were right. But I'm glad I know for sure now. I now need to pick out a more appropriate pump. I'm thinking I'll probably go with one of the shurflo pumps unless somebody has better suggestions. I only need ~100 psi capability since I don't want to run more than that through the injectors. Flow requirement is about .3 gallon/minute.

Can anybody recommend a reliable pump meeting that requirement?

#14

Rotary Enthusiast

Thread Starter

iTrader: (5)

Join Date: Mar 2005

Location: Boxford, MA

Posts: 791

Likes: 0

Received 0 Likes

on

0 Posts

Here's a picture of the handheld display contents - bar graph of boost pressure relative to target boost on the top line, boost pressure and aux injector duty on the lower line. Not sure if that's what I'll have it display in the final iteration but I'm not sure what else is really useful. I'm open to suggestions. The handheld display is mostly for setting/adjusting the control parameters.

#15

Nice work, I'm very interested to hear how the fuel injectors hold up in the long run.

It might be a good idea to use some rubbing alcohol and a rag to clean the flux residue off the solder joints. This not only makes them look much nicer but will prevent the flux from corroding things over time. Probably not a big deal for now, but it can make a difference a few years down the road.

It might be a good idea to use some rubbing alcohol and a rag to clean the flux residue off the solder joints. This not only makes them look much nicer but will prevent the flux from corroding things over time. Probably not a big deal for now, but it can make a difference a few years down the road.

#16

Rotary Enthusiast

Thread Starter

iTrader: (5)

Join Date: Mar 2005

Location: Boxford, MA

Posts: 791

Likes: 0

Received 0 Likes

on

0 Posts

Thanks. I didn't realize flux was corrosive, I've never cleaned it off of anything I've soldered before. Thanks for the tip. I'll let you know how the injectors are working after their 4 month break when I get a new pump.

#17

4th string e-armchair QB

iTrader: (11)

Join Date: May 2005

Location: North Bay, Ontario

Posts: 2,745

Likes: 0

Received 0 Likes

on

0 Posts

I'd go with one of the lower end shur-flo pumps (100 psi or so) any one of them should be able to handle the regulated pressure and put out the flow, only problem is they are noisy.

GL with the project, I would be skeptical of using automotive injectors for any form of water setup, due to the internal components susceptibility of corrosion, but I guess time will tell! Good on you for getting the right bits together.

GL with the project, I would be skeptical of using automotive injectors for any form of water setup, due to the internal components susceptibility of corrosion, but I guess time will tell! Good on you for getting the right bits together.

#18

Rotary Enthusiast

Thread Starter

iTrader: (5)

Join Date: Mar 2005

Location: Boxford, MA

Posts: 791

Likes: 0

Received 0 Likes

on

0 Posts

I have a new coolingmist pump on the way, should be here later this week. I'm a little worried about the corrosion too, but that's why I'm doing all this testing. If they're going to fail from corrosion, the past several months of neglect should have allowed that, so I'll probably make my decision after inspecting them and testing them once I get the new pump.

This past weekend I started wiring everything up in the car. I'm running power for everything directly from the battery into a relay. The relay will be switched on by the ignition switched 12V. I added a relay to run the pump as well although I was considering running that directly from the board. I'll add more pictures and test results next weekend hopefully.

This past weekend I started wiring everything up in the car. I'm running power for everything directly from the battery into a relay. The relay will be switched on by the ignition switched 12V. I added a relay to run the pump as well although I was considering running that directly from the board. I'll add more pictures and test results next weekend hopefully.

#19

Rotary Enthusiast

Thread Starter

iTrader: (5)

Join Date: Mar 2005

Location: Boxford, MA

Posts: 791

Likes: 0

Received 0 Likes

on

0 Posts

I just tested them and the injectors still work fine up to as much as 90 psi so I'm going to proceed with them. I'm trying to figure out where to mount my coolingmist pump in the engine bay. Has anybody used the bumper reinforcement? That seems like my best option.

Thread

Thread Starter

Forum

Replies

Last Post

82streetracer

1st Generation Specific (1979-1985)

7

08-23-15 09:28 AM