Going to make my own WI kit

#126

Rotary Enthusiast

add to my post,

water when brought to 212F turns to steam,a lot of energy used to bring up to steam temp, how about startin at 200f,

also tests have proven water expands 1700 times its original volume=pressure, when going to vapor, at ambient temps.

what takes place at comp. wheel OD,with incredible temps.,and shearing effects.

anyway, we may not know all there is to preturb. but we do know it works.

water when brought to 212F turns to steam,a lot of energy used to bring up to steam temp, how about startin at 200f,

also tests have proven water expands 1700 times its original volume=pressure, when going to vapor, at ambient temps.

what takes place at comp. wheel OD,with incredible temps.,and shearing effects.

anyway, we may not know all there is to preturb. but we do know it works.

#127

Brent, FYI, I found this Japanese manufacturer that publishes a lot of technical data on their atomizing nozzles. I though you would be interested in it as a reference and perhaps comparison against the conditions used in your application (assuming "all" the atomizing nozzles would more or less perform the same).

http://www.everloy-spray-nozzles.com...nternal08.html

http://www.everloy-spray-nozzles.com...xternal03.html

I wish every manufacturer would test and public data like that... I asked Spray if they have similar data for their SUE series.

- Sandro

http://www.everloy-spray-nozzles.com...nternal08.html

http://www.everloy-spray-nozzles.com...xternal03.html

I wish every manufacturer would test and public data like that... I asked Spray if they have similar data for their SUE series.

- Sandro

#128

Are you sure about this? Let's assume we inject saturated steam at 260F. Guess what happens [in the chamber] during the compression and power strokes as a result of the increase in pressure....said steam will [begin to] condense until/unless sufficient heat is infused from the compression and combustion process to sustain the phase change. Accordingly, additional sensible heat is removed to latent heat with the result being superheated steam.

#129

I did run across some technical information for the spray system sue nozzles, although I can't recall if they had water droplet sizes listed and such, they did have the spray width, height, & lengths listed, as well as flow rates and spray angle. They have a US site and a spanish site with a little different layout, but I found that the information for the same nozzle was not always consistent. I really wouldn't even know what droplet size is large or small when referring to atomizing nozzles, I figure the more they flow the larger the droplet will be. Plus I drilled mine out, so any technical information wouldn't apply to what I have anymore.

On that site how do the flow rates equate to gal/hr or cc/min? I don't know what "m" is in flow terms. I'm also curious of the cost comparison, for what they are it seems the flow systems nozzles are on the expensive side.

On that site how do the flow rates equate to gal/hr or cc/min? I don't know what "m" is in flow terms. I'm also curious of the cost comparison, for what they are it seems the flow systems nozzles are on the expensive side.

#130

Are you sure about this? Let's assume we inject saturated steam at 260F. Guess what happens [in the chamber] during the compression and power strokes as a result of the increase in pressure....said steam will [begin to] condense until/unless sufficient heat is infused from the compression and combustion process to sustain the phase change. Accordingly, additional sensible heat is removed to latent heat with the result being superheated steam.

EDIT: Another thought, if the steam condenses back into water, wouldn't that mean the heat absorbed from the turbo outlet air is now released back into the intake system. Effectively changing nothing or very little in regards to intake temps?

#131

Are you sure about this? Let's assume we inject saturated steam at 260F. Guess what happens [in the chamber] during the compression and power strokes as a result of the increase in pressure....said steam will [begin to] condense until/unless sufficient heat is infused from the compression and combustion process to sustain the phase change. Accordingly, additional sensible heat is removed to latent heat with the result being superheated steam.

- Sandro

#132

I did run across some technical information for the spray system sue nozzles, although I can't recall if they had water droplet sizes listed and such, they did have the spray width, height, & lengths listed, as well as flow rates and spray angle. They have a US site and a spanish site with a little different layout, but I found that the information for the same nozzle was not always consistent. I really wouldn't even know what droplet size is large or small when referring to atomizing nozzles, I figure the more they flow the larger the droplet will be. Plus I drilled mine out, so any technical information wouldn't apply to what I have anymore.

On that site how do the flow rates equate to gal/hr or cc/min? I don't know what "m" is in flow terms. I'm also curious of the cost comparison, for what they are it seems the flow systems nozzles are on the expensive side.

On that site how do the flow rates equate to gal/hr or cc/min? I don't know what "m" is in flow terms. I'm also curious of the cost comparison, for what they are it seems the flow systems nozzles are on the expensive side.

No clue on pricing. Sales are managed centrally from Japan; no US representative. I sent them an email, we'll see. Yes, there are some data on Spray catalogs, but more about coverage area and flows, not much about droplet size and how it gets affected by other parameters, particularly air flow/pressure and air/water ratios. But it is safe to assume I guess that at least qualitatively - not the numbers - similar relationships may exist for all the atomizing nozzles..

Spray (actually Almaka Corp) has initially replied to my email. I am now in touch with one of their sales engineer. See below... I'll keep you posted.

--------------------------------------

Hi Bob.

I am planning on evaluating the effect of evaporative cooling - if any - along the compressor of a turbocharger (automotive application)

Liquid is water

Pressure/air flow to be provided at the outlet of the compressor in a range 7-18 psi

Water at the same pressure as air (stored in a tank pressurized by the same compressor)

Thank you.

Sandro

- Hide quoted text -

On Tue, Dec 15, 2009 at 7:11 AM, Titchenell, Robert <Bob.Titchenell@spray.com> wrote:

Sandro,

What is your application? What are liquid are you spraying? What are the pressure ranges for the air and liquid.

We normally do not have this information for distribution however, I may be able to give you a range of drop sizes.

Bob Titchenell

Almaka Corp.

Spraying Systems Co.®

Experts in Spray Technology

Phone Office (610)-459-5913

Cell (610)-505-3404

Fax (610)-459-8273

E-Mail: Bob.Titchenell@spray.com

www.spray.com

#133

Brent,

Bob of Spray/Almaka answered: "roughly about 80 - 90 microns"

As I suspected - after looking at the charts provided by the other Japanese manufacturer - these kind of nozzles need a lot of air at high pressure to atomize water down to the sub 20 micron. Like 1,000 air-to-water volume ratio and 0.2-0.3 MPa (@30-45 psi) as indicated in the chart of the Japanese manufacturer.

I am inclined now to use the Bete PJ direct pressure nozzles instead http://www.bete.com/pdfs/BETE_PJ-metric.pdf

They make 50 micron droplets already at "only" 4 bar.

- Sandro

Bob of Spray/Almaka answered: "roughly about 80 - 90 microns"

As I suspected - after looking at the charts provided by the other Japanese manufacturer - these kind of nozzles need a lot of air at high pressure to atomize water down to the sub 20 micron. Like 1,000 air-to-water volume ratio and 0.2-0.3 MPa (@30-45 psi) as indicated in the chart of the Japanese manufacturer.

I am inclined now to use the Bete PJ direct pressure nozzles instead http://www.bete.com/pdfs/BETE_PJ-metric.pdf

They make 50 micron droplets already at "only" 4 bar.

- Sandro

#134

Based on a google search the average human hair is about 70 microns, and the average person can visually see an object only 40 microns across, Beach sand is 700 microns.

I can't say for certain the size droplets the nozzle I'm using produces, but it puts out a very fine mist, and it also seems the mist gets finer the further from the nozzle the water is. When I bench test the system the water just kinda floats off rather then falls to the ground. In any case the compressor wheel is all good which is the main factor in preturbo systems.

The PJ nozzles shown in the PDF you posted don't list which particular models go down to 50 microns at 4 bar. I imagine the smaller nozzles have an easier time then the larger ones at accomplishing this. My nozzle would flow right between the PJ32 and PJ40 nozzles which are the larger ones on the PDF. Also my particular system will never see anything close to 4 bar. Thats almost 60 psi. So in a pump driven setup those nozzles would probably work well, but I don't think so in a low pressure mechanical system. In a mechanical driven setup I think it would be extremely hard to match the droplet size you get by mixing air with the water in the air atomizing nozzles.

In a direct flow nozzle the more water you flow, the larger the droplets will be. There isn't really a way around this. You can increase the pressure in a pump style system to a point, but in a mechanical system the pressure will only go as high as the boost pressure you run.

Is your system mechanical or pump driven?

I can't say for certain the size droplets the nozzle I'm using produces, but it puts out a very fine mist, and it also seems the mist gets finer the further from the nozzle the water is. When I bench test the system the water just kinda floats off rather then falls to the ground. In any case the compressor wheel is all good which is the main factor in preturbo systems.

The PJ nozzles shown in the PDF you posted don't list which particular models go down to 50 microns at 4 bar. I imagine the smaller nozzles have an easier time then the larger ones at accomplishing this. My nozzle would flow right between the PJ32 and PJ40 nozzles which are the larger ones on the PDF. Also my particular system will never see anything close to 4 bar. Thats almost 60 psi. So in a pump driven setup those nozzles would probably work well, but I don't think so in a low pressure mechanical system. In a mechanical driven setup I think it would be extremely hard to match the droplet size you get by mixing air with the water in the air atomizing nozzles.

In a direct flow nozzle the more water you flow, the larger the droplets will be. There isn't really a way around this. You can increase the pressure in a pump style system to a point, but in a mechanical system the pressure will only go as high as the boost pressure you run.

Is your system mechanical or pump driven?

#135

All true what you said.

But remember, my objective is to evaluate the effect of evaporative cooling - if any - inside the compressor.

Droplet size is a relevant parameter because evaporation rate is proportional to the droplet A/V (surface area over volume). A/V is inversely proportional to diameter. For instance, a 50 micron droplet has 80% more A/V over a 90 micron droplet.

Marketing material/ catalogs of nozzle manufacturers make a distinction between "fogging" nozzles and "misting" nozzles, where the former are categorized as having droplet sizes of 20 micron of less. Fogging nozzles based on direct injection - however - generally require upstream pressure like 1500-3000 psi. "Atomizing" nozzles - which use air flow to "atomize" the droplets - require much lower pressure. Based on this information, the atomizing nozzles appear as the only practical method for making "fog" droplets under the hood. However, when I looked at the correlations provided by that Japanese manufacturer, I suspected that such small droplets could only be obtained by using quite high air flow rates and pressures in any case higher than what stock twins could provide. This was eventually confirmed today by the last email I received from Spray.

Based of what I found so far, the Bete PJ nozzles are the only direct injection capable of making quite small droplets - although not fog like - at a relatively low pressure. They appear to be capable of achieving that because of their "impingement" design, which breaks water in very fine particles on impact. I spoke with Bete today. They claim that because of such mechanisms, even the bigger nozzles produce the majority of droplets in the 50 micron range; although - like you - I am a little skeptical on that. But this is not relevant to me because I am planning on using the smallest nozzles. Clearly, given the 4 bar threshold, I will have to use a pump for my test.

But remember, my objective is to evaluate the effect of evaporative cooling - if any - inside the compressor.

Droplet size is a relevant parameter because evaporation rate is proportional to the droplet A/V (surface area over volume). A/V is inversely proportional to diameter. For instance, a 50 micron droplet has 80% more A/V over a 90 micron droplet.

Marketing material/ catalogs of nozzle manufacturers make a distinction between "fogging" nozzles and "misting" nozzles, where the former are categorized as having droplet sizes of 20 micron of less. Fogging nozzles based on direct injection - however - generally require upstream pressure like 1500-3000 psi. "Atomizing" nozzles - which use air flow to "atomize" the droplets - require much lower pressure. Based on this information, the atomizing nozzles appear as the only practical method for making "fog" droplets under the hood. However, when I looked at the correlations provided by that Japanese manufacturer, I suspected that such small droplets could only be obtained by using quite high air flow rates and pressures in any case higher than what stock twins could provide. This was eventually confirmed today by the last email I received from Spray.

Based of what I found so far, the Bete PJ nozzles are the only direct injection capable of making quite small droplets - although not fog like - at a relatively low pressure. They appear to be capable of achieving that because of their "impingement" design, which breaks water in very fine particles on impact. I spoke with Bete today. They claim that because of such mechanisms, even the bigger nozzles produce the majority of droplets in the 50 micron range; although - like you - I am a little skeptical on that. But this is not relevant to me because I am planning on using the smallest nozzles. Clearly, given the 4 bar threshold, I will have to use a pump for my test.

#137

Car is stored for winter now. Will have to wait until spring. I will do some bench testing, calibration, etc. until then. I'll have to find where/how to install the nozzles. I was thinking two separate nozzles inside the intake air box pointing toward the two intake hoses. Probably using some logic/ solenoids to spray the primary first then add the secondary upon transition, don't know... any suggestion is clearly very welcome...

#139

Rotary Enthusiast

a lot of this info makes good sense, now, wether you win or lose a race, over 40 micron, or 70 micron droplet, I donno.

what has been established is, Preturbo AI seems to be a reasonable approach!

now wether the comp wheel will need replacement at 100,000miles or 200,000miles, id guess it wouldnt matter.

SAAB did preturb system back in early 80s, and gave a warrenty with it.

what has been established is, Preturbo AI seems to be a reasonable approach!

now wether the comp wheel will need replacement at 100,000miles or 200,000miles, id guess it wouldnt matter.

SAAB did preturb system back in early 80s, and gave a warrenty with it.

#144

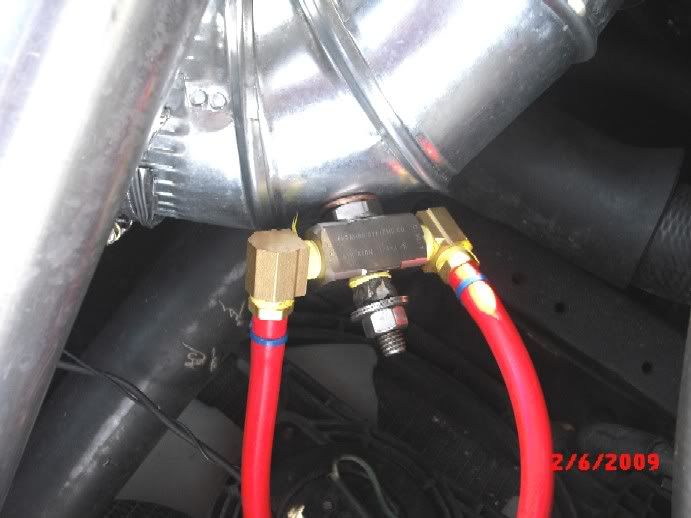

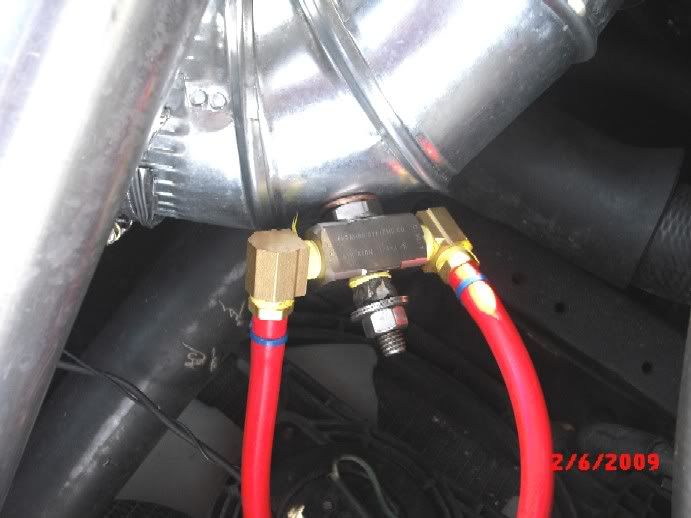

I thought I had updated the pics on this thread but I guess not. Here's the last pics I took of the system. I've also changed the solenoid out but don't have pics of that. I'm going to be doing a kit for another member and will be using push lock fittings and doing a couple other things slightly different. I'll take a few pics of it when I'm done, and I think he's going to do a video on it so that should be cool.

#145

can we get a over view type picture haha. like of the whole engine bay/ solinoid and such...my checks in the mail and you know ill be doing this promptly!. I know your going to change a few things around and thats what i wanna know is whats going to change. im also using the push fittings. As you know my tank will be in the trunk so will see how everything goes.

#147

Junior Member

Join Date: Jul 2005

Location: Australia

Posts: 49

Likes: 0

Received 0 Likes

on

0 Posts

I thought I had updated the pics on this thread but I guess not. Here's the last pics I took of the system. I've also changed the solenoid out but don't have pics of that. I'm going to be doing a kit for another member and will be using push lock fittings and doing a couple other things slightly different. I'll take a few pics of it when I'm done, and I think he's going to do a video on it so that should be cool.

Roughly how long does your water last before you need to refill - casually driving vs giving it **** etc?

What does it hold, about 1 litre?

Thanks

#148

Well i have been making drawings and mocking stuff up in my This is whats on my mind. Your pressurizing a half a gallon of water with 30psi roughly. well i will be running like 5 gallons 0f water. Im thiking that 30 psi pushing down on 5 gallons wont do **** the water will just driibble out the end of the jet or shoot a stream. What do you think?

#149

Junior Member

Join Date: Jul 2005

Location: Australia

Posts: 49

Likes: 0

Received 0 Likes

on

0 Posts

Well i have been making drawings and mocking stuff up in my This is whats on my mind. Your pressurizing a half a gallon of water with 30psi roughly. well i will be running like 5 gallons 0f water. Im thiking that 30 psi pushing down on 5 gallons wont do **** the water will just driibble out the end of the jet or shoot a stream. What do you think?

1) you don't position the tank too low in relation to the spray nozzle, ie negative head -> eg height (h) = a negative number. If this is the case, try to make h as close to zero as posible when mounting the tank & nozzle.

and,

2) you select an air atomising nozzle suited to your working pressure and required flows,

The mechanical system will perform its function,

Then you should have no problems. Trial operation of the nozzle on a test bench is a good way to remove any doubts.

HTH

#150

Hey dude, only new to this site, but after a lot of contemplating, i think this is an unreal kit. I'm going to look into making a kit for 3 cars, one a 13BT and 2 rb30 nissan engines.

I've looked at rice racing's kit and even talked to him, this is the best way to go. Just can't afford his kit, quite a bit for a simple system.

Good on ya, and thanks for sharing with us all your trials and tribulations.

Rob

I've looked at rice racing's kit and even talked to him, this is the best way to go. Just can't afford his kit, quite a bit for a simple system.

Good on ya, and thanks for sharing with us all your trials and tribulations.

Rob