Water temp sender location?

#1

DRIVE THE ROTARY SPORTS

Thread Starter

iTrader: (5)

Join Date: May 2003

Location: CA (Bay Area)

Posts: 4,150

Likes: 0

Received 0 Likes

on

0 Posts

I've read a number of threads dating back to '02 but still can decide where the best place to put an aftermarket gauge sender would be. My waterpump housing is off so that was my first choice (though not after the thermostat for obvious reasons). I've only found a couple suitable locations to drill/tap. Are there any disadvantages for to following locations? (the motor is out of the car as well so a location in the block is also not a big problem)

#2

RX-7 Bad Ass

iTrader: (55)

The first location won't be accessible with the water pump on the engine - that will be pushed against the front iron.

Are you retaining the water lines running through the throttle body? If not you can remove the water nipple that's below and to the left of the coolant temp sensor in the first pic and use that hole.

Or, just make a brass T for the water line going from the back of the block to the throttle body. I've done a big writeup on it some time back - it works great and is dead reliable.

Dale

Are you retaining the water lines running through the throttle body? If not you can remove the water nipple that's below and to the left of the coolant temp sensor in the first pic and use that hole.

Or, just make a brass T for the water line going from the back of the block to the throttle body. I've done a big writeup on it some time back - it works great and is dead reliable.

Dale

#5

DRIVE THE ROTARY SPORTS

Thread Starter

iTrader: (5)

Join Date: May 2003

Location: CA (Bay Area)

Posts: 4,150

Likes: 0

Received 0 Likes

on

0 Posts

I had a drill bit, 1/8" NPT tap, and drill sitting suspiciously close to the housing lastnight and was tempted multiple times to grab them and start drilling... glad I didnt. I'm moving the tools into a locked box in a different room so I don't do anything spontaneously before asking

I had a drill bit, 1/8" NPT tap, and drill sitting suspiciously close to the housing lastnight and was tempted multiple times to grab them and start drilling... glad I didnt. I'm moving the tools into a locked box in a different room so I don't do anything spontaneously before asking

In case I do end up needing that nipple on the pump housing, any thoughts on the following two locations?

Thanks Dale! -Heath

#7

DRIVE THE ROTARY SPORTS

Thread Starter

iTrader: (5)

Join Date: May 2003

Location: CA (Bay Area)

Posts: 4,150

Likes: 0

Received 0 Likes

on

0 Posts

so I was a little impulsive and just picked a spot shooting from the hip (hopefully it wont hit anything that may be behind it). Worst comes, I have another WP housing.

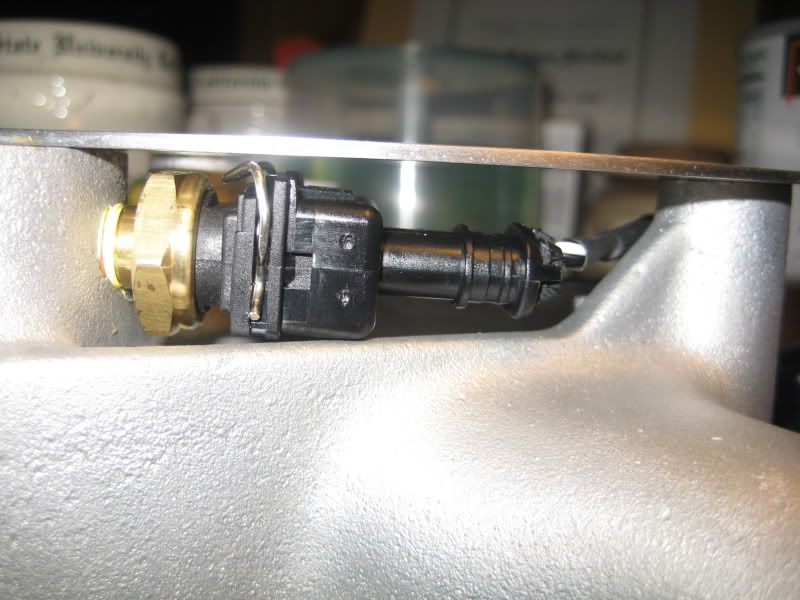

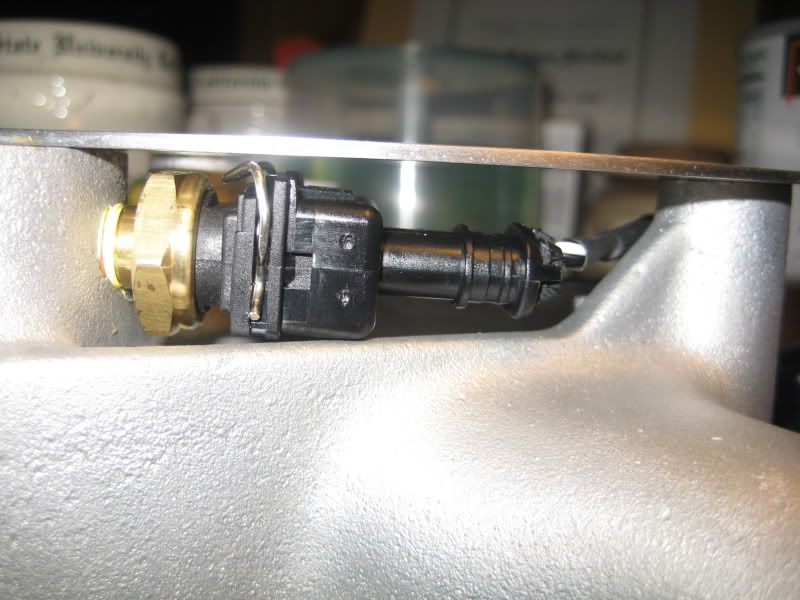

I had to modify the sensor clip a little so it would clear the front iron but that took all of 3 minutes to trim the excess plastic tabs and tweak the clip spring. Here's what I ended up with

Only problem I have (so far) is that I tapped it too deep so it's a little looser than I would like (with thread tape on ) I can't really add more tape as it just gets pushed off. Any recommendations for getting a tighter fit/better seal besides PTFE tape? I should have gone halfway or less with the tap, but I stupidly did nearly 3/4

) I can't really add more tape as it just gets pushed off. Any recommendations for getting a tighter fit/better seal besides PTFE tape? I should have gone halfway or less with the tap, but I stupidly did nearly 3/4

I had to modify the sensor clip a little so it would clear the front iron but that took all of 3 minutes to trim the excess plastic tabs and tweak the clip spring. Here's what I ended up with

Only problem I have (so far) is that I tapped it too deep so it's a little looser than I would like (with thread tape on

) I can't really add more tape as it just gets pushed off. Any recommendations for getting a tighter fit/better seal besides PTFE tape? I should have gone halfway or less with the tap, but I stupidly did nearly 3/4

) I can't really add more tape as it just gets pushed off. Any recommendations for getting a tighter fit/better seal besides PTFE tape? I should have gone halfway or less with the tap, but I stupidly did nearly 3/4

Trending Topics

#8

RX-7 Bad Ass

iTrader: (55)

Only problem with that location is it looks like you'd have to pull the water pump housing if you wanted to unplug or plug in that connector. Considering you'll probably put the motor in the car then run the harness to it and plug it in, that's something to consider.

For a better seal, might try the Teflon paste. Could also be worth dabbing some RTV around it to help it seal.

Or use my brass T idea that's "too ghetto" but works quickly and easily

Dale

For a better seal, might try the Teflon paste. Could also be worth dabbing some RTV around it to help it seal.

Or use my brass T idea that's "too ghetto" but works quickly and easily

Dale

Thread

Thread Starter

Forum

Replies

Last Post

sherff

Adaptronic Engine Mgmt - AUS

9

02-24-19 12:09 PM

befarrer

Microtech

3

08-22-15 05:52 PM