Newbie preparing for a clutch job, and maybe flywheel resurface.

#1

Newbie preparing for a clutch job, and maybe flywheel resurface.

Hi

I am planning to replace my clutch this summer, along with a few other things (some bushings, engine mounts). It seems to be slipping in 4th and 5th gear when 2nd turbo comes online.

Since i have litte experience with FDs, i want to be as prepared as i can. So, are there any special things and smart tricks i need to know before i start? The car is a 35k miles stock car, without any engine or driveline modifications that i know of.

So far, i have understood that there are a few tools that are recommended and required:

- 54mm socket for the flywheel nut (this is just a regular one right, no special voodoo socket needed?)

- Flywheel stopper (stops it from turning when removing the bolts (can be bought from Atkins)

- Bearing puller (is this needed or can i use some other of the shelf tool?)

Then for the work itself, i am thinking it should be pretty straight forward? But i guess the downpipe and heat shields need to go?

Also, since the FD is a pull type clutch, does that change it from a regular clutch job that i have done previously?

The kit i am getting is ACT Performance Street Disc Kit ZX6-HDSS from Banzai, and that comes with both pilot and release bearing, along with alignment tool needed.

Anything else i need to or should change while im at it?

Im also suspecting i need to resurface the flywheel. How do i tell if its usable as is, or if it need rework?

I am planning to replace my clutch this summer, along with a few other things (some bushings, engine mounts). It seems to be slipping in 4th and 5th gear when 2nd turbo comes online.

Since i have litte experience with FDs, i want to be as prepared as i can. So, are there any special things and smart tricks i need to know before i start? The car is a 35k miles stock car, without any engine or driveline modifications that i know of.

So far, i have understood that there are a few tools that are recommended and required:

- 54mm socket for the flywheel nut (this is just a regular one right, no special voodoo socket needed?)

- Flywheel stopper (stops it from turning when removing the bolts (can be bought from Atkins)

- Bearing puller (is this needed or can i use some other of the shelf tool?)

Then for the work itself, i am thinking it should be pretty straight forward? But i guess the downpipe and heat shields need to go?

Also, since the FD is a pull type clutch, does that change it from a regular clutch job that i have done previously?

The kit i am getting is ACT Performance Street Disc Kit ZX6-HDSS from Banzai, and that comes with both pilot and release bearing, along with alignment tool needed.

Anything else i need to or should change while im at it?

Im also suspecting i need to resurface the flywheel. How do i tell if its usable as is, or if it need rework?

#2

Downpipe can stay, it isn't in the way to drop the box.

Yep, it's just a normal big hex socket.

Flywheel stopper does make it easy, you can use a chain and a few bolts, but the stopper is a nicer solution.

An old prop front section is handy as you can stick this in when you drop the prop and get away without draining the box oil.

A standard off the shelf small internal puller will work fine for the pilot bearing.

Flywheels are pretty easy to inspect, if it's nice and flat it'll be fine. If it's scored or feels uneven it'll need resurfacing. But why not take the opportunity to fit a lighter flywheel while it's all apart?

Yep, it's just a normal big hex socket.

Flywheel stopper does make it easy, you can use a chain and a few bolts, but the stopper is a nicer solution.

An old prop front section is handy as you can stick this in when you drop the prop and get away without draining the box oil.

A standard off the shelf small internal puller will work fine for the pilot bearing.

Flywheels are pretty easy to inspect, if it's nice and flat it'll be fine. If it's scored or feels uneven it'll need resurfacing. But why not take the opportunity to fit a lighter flywheel while it's all apart?

Last edited by Ceylon; 02-12-18 at 05:04 AM.

The following users liked this post:

Zepticon (02-12-18)

#3

Downpipe can stay, it isn't in the way to drop the box.

Yep, it's just a normal big hex socket.

Flywheel stopper does make it easy, you can use a chain and a few bolts, but the stopper is a nicer solution.

An old prop front section is handy as you can stick this in when you drop the prop and get away without draining the box oil.

A standard off the shelf small internal puller will work fine for the pilot bearing.

Flywheels are pretty easy to inspect, if it's nice and flat it'll be fine. If it's scored or feels uneven it'll need resurfacing.

Yep, it's just a normal big hex socket.

Flywheel stopper does make it easy, you can use a chain and a few bolts, but the stopper is a nicer solution.

An old prop front section is handy as you can stick this in when you drop the prop and get away without draining the box oil.

A standard off the shelf small internal puller will work fine for the pilot bearing.

Flywheels are pretty easy to inspect, if it's nice and flat it'll be fine. If it's scored or feels uneven it'll need resurfacing.

Yeah, i thought i could just as well get a stopper since its a nice to have thing

And i could rent it out to friends for a few bucks when they need one

And i could rent it out to friends for a few bucks when they need one

Ill consider a lighter flywheel when i take out the engine for a rebuild and some modifications in the future, but right now im pretty satisfied with the stock setup.

#5

RX-7 Bad Ass

iTrader: (55)

Good thing that you're planning everything in advance! Really makes a difference when the big day comes.

FD clutch job isn't hard. If you have access to air tools, that makes it WAY easier, a lift even more so.

As stated, you can cap up the end of the transmission and not drain gear oil, but IMHO you're better off going ahead and draining it and putting fresh gear oil in.

I would have a friend handy for the job, the transmission is heavy and you don't want to be in a situation where it slips off a jack or something - that thing can cause real harm. Having a second person handy makes a huge difference.

On the flywheel, this is the tricky part. In my opinion most times flywheels can be used as-is. Rough up the surface with sandpaper, clean well, and you're done. Yes, there will be "burn" marks on the flywheel - EVERY flywheel on Earth has these, period. It sounds like your car is pretty close to stock and is low mileage - I don't think you will gain anything by pulling the flywheel and having it resurfaced.

The early FD's had a weak clutch disc, Mazda revised the part later to fix the problem. Back in the day I did a number of FD clutch jobs with the same 35-40k mileage with badly slipping clutches. The friction material isn't up to the job and prematurely wears thin. It sounds like you're getting into it right when you should, I did one car that was slipping so badly I could barely get it up on ramps.

Pilot bearing is probably OK, I would pull and replace the seal, grease the bearing, and be done with it. Again, you're more likely to have a problem trying to pull the bearing and trying to properly install a new one than just leaving it be. The seal does age and wear out and it's easy to replace, that can be popped out with a flathead screwdriver.

Believe me, I think a job should be done right, but there's doing it right and there's fixing problems that aren't there. This is based on my experience of doing clutch jobs in cars very similar to yours.

But, I will say to give yourself enough time that if you see something wrong or bad that you can stop, regroup, order parts or tools, and come back to it.

If you do need to get into the flywheel, you don't really need to have a special torque wrench, I just impact that nut on until it won't turn any more. The big thing is you are pressing the flywheel onto the taper on the eccentric shaft. You will need a real, air-powered gun, a battery powered gun probably won't have the torque for this. People get really excited about this nut and it isn't a big deal - it's usually not that hard to get off, and re-installing isn't bad either. The front pulley bolt, now THAT will make you a man to remove that joker.

All that said, what you should have on hand -

- Clutch kit (duh) with clutch alignment tool. Cut about a 1/2" off the tip of the tool, it will fit way better and center the disc properly.

- Clutch release bearing (probably comes with the clutch kit)

- Pilot bearing seal. This will NOT come with the clutch, many times you will get the bearing but never the seal. It's a cheap part, should only be a few bucks for a new one.

- 3 quarts of gear oil. Idemitsu has a really nice gear oil. Use synthetic whatever you do. May wan to get some extra and do the diff oil while it's up in the air and you have a gear oil pump.

- Plenty of brake cleaner and paper towels.

Special tools -

- Gear oil pump to get the gear oil into the gearbox once it's installed.

- About 3 feet of 1/2" drive extensions and 1/2" drive universal, makes it way easier to get to the top bell housing bolts. If you have an impact gun, all those bolts are a breeze with the right extensions and a universal.

- If you have to get into the flywheel, 54mm (2 1/8") socket for the flywheel nut and a flywheel stopper.

- Good flashlight and long enough pry bar or screwdriver to pop the clutch release bearing free.

Take your time, ask questions, and read up some. Really it's not that bad. On a lift with air tools I can do this job in 2 hours. Probably another hour to do it on jack stands.

Dale

FD clutch job isn't hard. If you have access to air tools, that makes it WAY easier, a lift even more so.

As stated, you can cap up the end of the transmission and not drain gear oil, but IMHO you're better off going ahead and draining it and putting fresh gear oil in.

I would have a friend handy for the job, the transmission is heavy and you don't want to be in a situation where it slips off a jack or something - that thing can cause real harm. Having a second person handy makes a huge difference.

On the flywheel, this is the tricky part. In my opinion most times flywheels can be used as-is. Rough up the surface with sandpaper, clean well, and you're done. Yes, there will be "burn" marks on the flywheel - EVERY flywheel on Earth has these, period. It sounds like your car is pretty close to stock and is low mileage - I don't think you will gain anything by pulling the flywheel and having it resurfaced.

The early FD's had a weak clutch disc, Mazda revised the part later to fix the problem. Back in the day I did a number of FD clutch jobs with the same 35-40k mileage with badly slipping clutches. The friction material isn't up to the job and prematurely wears thin. It sounds like you're getting into it right when you should, I did one car that was slipping so badly I could barely get it up on ramps.

Pilot bearing is probably OK, I would pull and replace the seal, grease the bearing, and be done with it. Again, you're more likely to have a problem trying to pull the bearing and trying to properly install a new one than just leaving it be. The seal does age and wear out and it's easy to replace, that can be popped out with a flathead screwdriver.

Believe me, I think a job should be done right, but there's doing it right and there's fixing problems that aren't there. This is based on my experience of doing clutch jobs in cars very similar to yours.

But, I will say to give yourself enough time that if you see something wrong or bad that you can stop, regroup, order parts or tools, and come back to it.

If you do need to get into the flywheel, you don't really need to have a special torque wrench, I just impact that nut on until it won't turn any more. The big thing is you are pressing the flywheel onto the taper on the eccentric shaft. You will need a real, air-powered gun, a battery powered gun probably won't have the torque for this. People get really excited about this nut and it isn't a big deal - it's usually not that hard to get off, and re-installing isn't bad either. The front pulley bolt, now THAT will make you a man to remove that joker.

All that said, what you should have on hand -

- Clutch kit (duh) with clutch alignment tool. Cut about a 1/2" off the tip of the tool, it will fit way better and center the disc properly.

- Clutch release bearing (probably comes with the clutch kit)

- Pilot bearing seal. This will NOT come with the clutch, many times you will get the bearing but never the seal. It's a cheap part, should only be a few bucks for a new one.

- 3 quarts of gear oil. Idemitsu has a really nice gear oil. Use synthetic whatever you do. May wan to get some extra and do the diff oil while it's up in the air and you have a gear oil pump.

- Plenty of brake cleaner and paper towels.

Special tools -

- Gear oil pump to get the gear oil into the gearbox once it's installed.

- About 3 feet of 1/2" drive extensions and 1/2" drive universal, makes it way easier to get to the top bell housing bolts. If you have an impact gun, all those bolts are a breeze with the right extensions and a universal.

- If you have to get into the flywheel, 54mm (2 1/8") socket for the flywheel nut and a flywheel stopper.

- Good flashlight and long enough pry bar or screwdriver to pop the clutch release bearing free.

Take your time, ask questions, and read up some. Really it's not that bad. On a lift with air tools I can do this job in 2 hours. Probably another hour to do it on jack stands.

Dale

The following users liked this post:

Zepticon (02-12-18)

#6

I do no have access to a lift unfortunatley, so this will be jackstands only

I would have a friend handy for the job, the transmission is heavy and you don't want to be in a situation where it slips off a jack or something - that thing can cause real harm. Having a second person handy makes a huge difference.

On the flywheel, this is the tricky part. In my opinion most times flywheels can be used as-is. Rough up the surface with sandpaper, clean well, and you're done. Yes, there will be "burn" marks on the flywheel - EVERY flywheel on Earth has these, period. It sounds like your car is pretty close to stock and is low mileage - I don't think you will gain anything by pulling the flywheel and having it resurfaced.

On the flywheel, this is the tricky part. In my opinion most times flywheels can be used as-is. Rough up the surface with sandpaper, clean well, and you're done. Yes, there will be "burn" marks on the flywheel - EVERY flywheel on Earth has these, period. It sounds like your car is pretty close to stock and is low mileage - I don't think you will gain anything by pulling the flywheel and having it resurfaced.

The early FD's had a weak clutch disc, Mazda revised the part later to fix the problem. Back in the day I did a number of FD clutch jobs with the same 35-40k mileage with badly slipping clutches. The friction material isn't up to the job and prematurely wears thin. It sounds like you're getting into it right when you should, I did one car that was slipping so badly I could barely get it up on ramps.

Pilot bearing is probably OK, I would pull and replace the seal, grease the bearing, and be done with it. Again, you're more likely to have a problem trying to pull the bearing and trying to properly install a new one than just leaving it be. The seal does age and wear out and it's easy to replace, that can be popped out with a flathead screwdriver.

Do you have a part number available for the bearing seal.

If you do need to get into the flywheel, you don't really need to have a special torque wrench, I just impact that nut on until it won't turn any more. The big thing is you are pressing the flywheel onto the taper on the eccentric shaft. You will need a real, air-powered gun, a battery powered gun probably won't have the torque for this. People get really excited about this nut and it isn't a big deal - it's usually not that hard to get off, and re-installing isn't bad either. The front pulley bolt, now THAT will make you a man to remove that joker.

- Clutch kit (duh) with clutch alignment tool. Cut about a 1/2" off the tip of the tool, it will fit way better and center the disc properly.

- Clutch release bearing (probably comes with the clutch kit)

- Pilot bearing seal. This will NOT come with the clutch, many times you will get the bearing but never the seal. It's a cheap part, should only be a few bucks for a new one.

- 3 quarts of gear oil. Idemitsu has a really nice gear oil. Use synthetic whatever you do. May wan to get some extra and do the diff oil while it's up in the air and you have a gear oil pump.

- Plenty of brake cleaner and paper towels.

- Clutch release bearing (probably comes with the clutch kit)

- Pilot bearing seal. This will NOT come with the clutch, many times you will get the bearing but never the seal. It's a cheap part, should only be a few bucks for a new one.

- 3 quarts of gear oil. Idemitsu has a really nice gear oil. Use synthetic whatever you do. May wan to get some extra and do the diff oil while it's up in the air and you have a gear oil pump.

- Plenty of brake cleaner and paper towels.

- Gear oil pump to get the gear oil into the gearbox once it's installed.

- About 3 feet of 1/2" drive extensions and 1/2" drive universal, makes it way easier to get to the top bell housing bolts. If you have an impact gun, all those bolts are a breeze with the right extensions and a universal.

- If you have to get into the flywheel, 54mm (2 1/8") socket for the flywheel nut and a flywheel stopper.

- Good flashlight and long enough pry bar or screwdriver to pop the clutch release bearing free.

- About 3 feet of 1/2" drive extensions and 1/2" drive universal, makes it way easier to get to the top bell housing bolts. If you have an impact gun, all those bolts are a breeze with the right extensions and a universal.

- If you have to get into the flywheel, 54mm (2 1/8") socket for the flywheel nut and a flywheel stopper.

- Good flashlight and long enough pry bar or screwdriver to pop the clutch release bearing free.

If i am lucky enough to avoid the flywheeel.

If i am lucky enough to avoid the flywheeel.Thanks a lot for taking the time to write all this

#7

*Consider replacing the rear transmission seal. They’re like $12 and takes all of 2 minutes to replace with no special tools.

* I understand the car is low mileage but if the clutch needs changing it’s had some use and your replacement ACT pressure plate may be a little stiffer than stock. I think I’d replace the clutch fork as they have some history of a weak design and occasionally failing. They’re not really cheap...last I knew about $100. But it would suck to have to pull the trans. again to replace.

* I understand the car is low mileage but if the clutch needs changing it’s had some use and your replacement ACT pressure plate may be a little stiffer than stock. I think I’d replace the clutch fork as they have some history of a weak design and occasionally failing. They’re not really cheap...last I knew about $100. But it would suck to have to pull the trans. again to replace.

The following users liked this post:

Zepticon (02-12-18)

Trending Topics

#8

Senior Member

^These guys hit everything on the head. Inspecting the clutch fork and possibly replacing is a good idea when using this clutch. I put 100 miles on a similar setup and had to pull my tranny because my clutch fork broke from wear and tear (I would assume). At least a tranny pull isn't that bad on these cars. Good luck and have fun!

The following users liked this post:

Zepticon (02-12-18)

#9

RX-7 Bad Ass

iTrader: (55)

To answer some questions -

Here is the pilot bearing and seal. Not sure of the part number, didn't dig around that hard -

74-11 Rx7 & Rx8 Pilot Bearing & Seal (ARE82) (1881-11-404) (N326-11-D03)

At least you can see what it looks like.

The pilot bearing can be VERY tricky to remove without the Mazda slide hammer tool. I've seen people attempt to remove it and damage the end of the eccentric shaft or take HOURS trying to remove it. It's not as easy as it looks. With the Mazda tool it's SUPER easy to do, but it's a pricey tool to have for the one time.

The seal is pretty small - think about a man's wedding ring, about that size. It has a soft metal for the body of it so it deforms very easily if you pry against it. A screwdriver will pop it out quickly then just use a socket and a hammer to drive the new one in.

+1 on the rear trans seal, it's a piece of cake to do with the trans out and a pain in the car.

On the gear oil, I have a cut off end of an old driveshaft that I stick in a transmission when doing work. I doubt most people have that, though. Even though it sucks you'll be ahead of the game draining and re-filling the trans, if you try and "be careful" with the trans it will dump out the end and make a BIG smelly mess that you'll be laying in. Not fun at all. You could drain it into a clean pan then put it into a bottle that you can fill from, but you'll need a little extra to account for fluid loss in the gear pump, in the pan, etc. May just be better off getting a few new quarts.

Dale

Here is the pilot bearing and seal. Not sure of the part number, didn't dig around that hard -

74-11 Rx7 & Rx8 Pilot Bearing & Seal (ARE82) (1881-11-404) (N326-11-D03)

At least you can see what it looks like.

The pilot bearing can be VERY tricky to remove without the Mazda slide hammer tool. I've seen people attempt to remove it and damage the end of the eccentric shaft or take HOURS trying to remove it. It's not as easy as it looks. With the Mazda tool it's SUPER easy to do, but it's a pricey tool to have for the one time.

The seal is pretty small - think about a man's wedding ring, about that size. It has a soft metal for the body of it so it deforms very easily if you pry against it. A screwdriver will pop it out quickly then just use a socket and a hammer to drive the new one in.

+1 on the rear trans seal, it's a piece of cake to do with the trans out and a pain in the car.

On the gear oil, I have a cut off end of an old driveshaft that I stick in a transmission when doing work. I doubt most people have that, though. Even though it sucks you'll be ahead of the game draining and re-filling the trans, if you try and "be careful" with the trans it will dump out the end and make a BIG smelly mess that you'll be laying in. Not fun at all. You could drain it into a clean pan then put it into a bottle that you can fill from, but you'll need a little extra to account for fluid loss in the gear pump, in the pan, etc. May just be better off getting a few new quarts.

Dale

The following users liked this post:

Zepticon (02-12-18)

#10

Aha, that looks nothing like any pilot bearing i ever saw, and i can understand that its a lot harder to swap than the regular ones i have seen (standard ballbearing ones).

I will strongly consider the tip to drain the trans! I think it might be usefull as you say to change the rear seal.

As for part numbers, i found this:

Pilot Bearing Seal -- 1881-11-404A

Rear Transmission Seal -- R501-17-335A

Clutch Fork -- N315-16-520B

I am way to easy to convince into buying new OEM parts. x)

I will be doing an order from Amayama soon anyway so ill get that stuff in too.

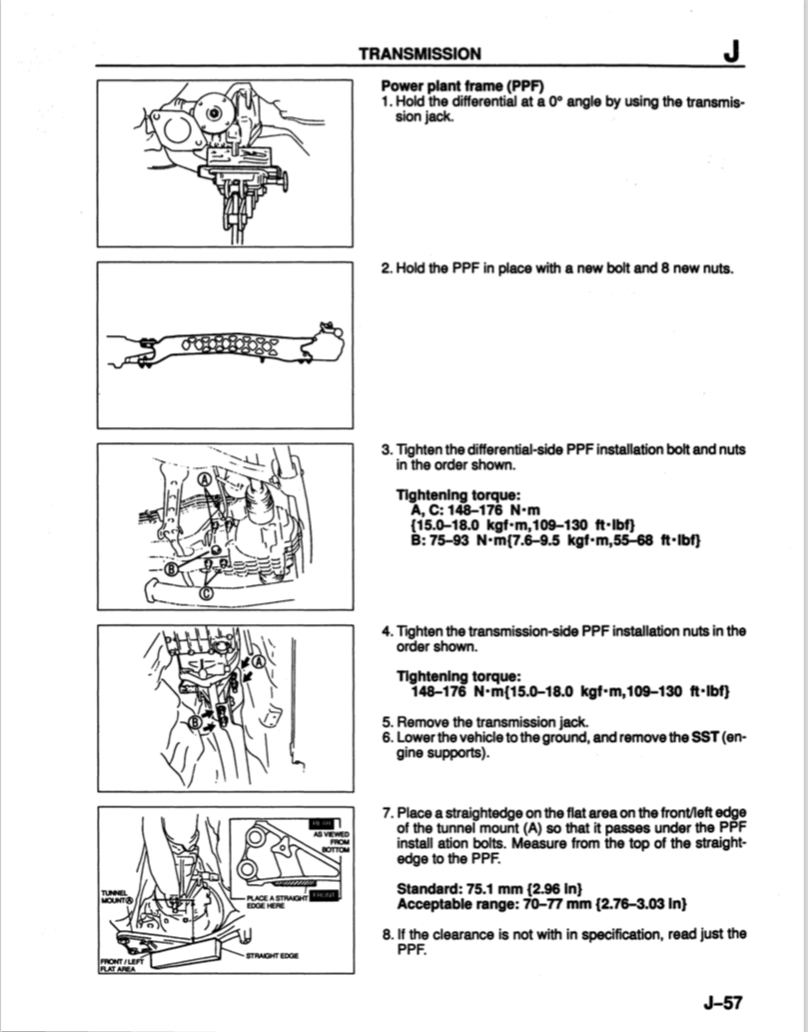

The next issue im a bit scared of is realigning the PPF. Since it has its own entry in the FSM. Also, there is no chance ill be able to get any meassurements from anywhere under the car while it sits on the wheels :S

I will strongly consider the tip to drain the trans! I think it might be usefull as you say to change the rear seal.

As for part numbers, i found this:

Pilot Bearing Seal -- 1881-11-404A

Rear Transmission Seal -- R501-17-335A

Clutch Fork -- N315-16-520B

I am way to easy to convince into buying new OEM parts. x)

I will be doing an order from Amayama soon anyway so ill get that stuff in too.

The next issue im a bit scared of is realigning the PPF. Since it has its own entry in the FSM. Also, there is no chance ill be able to get any meassurements from anywhere under the car while it sits on the wheels :S

#11

RX-7 Bad Ass

iTrader: (55)

There's nothing involved with aligning the PPF in my experience. There is an order for tightening the nuts/bolt up - you do the diff first, swing up to the trans, then do the trans nuts.

If the PPF is good and everything is straight, it's all straight. If it's bent, tough luck. There's really nothing I can see as far as adjustment.

Dale

If the PPF is good and everything is straight, it's all straight. If it's bent, tough luck. There's really nothing I can see as far as adjustment.

Dale

The following users liked this post:

Zepticon (02-13-18)

#12

....The pilot bearing can be VERY tricky to remove without the Mazda slide hammer tool. I've seen people attempt to remove it and damage the end of the eccentric shaft or take HOURS trying to remove it. It's not as easy as it looks. With the Mazda tool it's SUPER easy to do, but it's a pricey tool to have for the one time.

Dale

Dale

Sorry, I gave you approx. prices in U.S. and just noticed you're in NORWAY. Still, the seals are pretty cheap.

It's your call. But again with the low mileage on your car I agree that a SMALL amount of grease before reinstalling the transmission and you should be good to go. IF you do decide to replace there are some blind bearing pullers that are much less expensive. I have the MAZDA puller I picked up some years ago and never tried one of these personally, but see no reason they wouldn't do the job....

There are some YOUTUBE videos out there that will give you some idea of how they work if you're not already familiar.

Last edited by Sgtblue; 02-12-18 at 04:36 PM.

The following users liked this post:

Zepticon (02-13-18)

#13

Zepticon,

Sorry, I gave you approx. prices in U.S. and just noticed you're in NORWAY. Still, the seals are pretty cheap.

It's your call. But again with the low mileage on your car I agree that a SMALL amount of grease before reinstalling the transmission and you should be good to go. IF you do decide to replace there are some blind bearing pullers that are much less expensive. I have the MAZDA puller I picked up some years ago and never tried one of these personally, but see no reason they wouldn't do the job....

https://www.amazon.com/Bearing-Pulle...SIN=B075ZW6GFP

There are some YOUTUBE videos out there that will give you some idea of how they work if you're not already familiar.

Sorry, I gave you approx. prices in U.S. and just noticed you're in NORWAY. Still, the seals are pretty cheap.

It's your call. But again with the low mileage on your car I agree that a SMALL amount of grease before reinstalling the transmission and you should be good to go. IF you do decide to replace there are some blind bearing pullers that are much less expensive. I have the MAZDA puller I picked up some years ago and never tried one of these personally, but see no reason they wouldn't do the job....

https://www.amazon.com/Bearing-Pulle...SIN=B075ZW6GFP

There are some YOUTUBE videos out there that will give you some idea of how they work if you're not already familiar.

I only use USD to reference car part prices

I only use USD to reference car part prices  Even when talking with friends here we are mostly using dollars, since everything is imported from Japan or US due to cost and availability here.

Even when talking with friends here we are mostly using dollars, since everything is imported from Japan or US due to cost and availability here.

#14

There's nothing involved with aligning the PPF in my experience. There is an order for tightening the nuts/bolt up - you do the diff first, swing up to the trans, then do the trans nuts.

If the PPF is good and everything is straight, it's all straight. If it's bent, tough luck. There's really nothing I can see as far as adjustment.

Dale

If the PPF is good and everything is straight, it's all straight. If it's bent, tough luck. There's really nothing I can see as far as adjustment.

Dale

#15

RX-7 Bad Ass

iTrader: (55)

Notice it doesn't say HOW to "adjust" it. There's really not much that can be done, there's not a lot of slop in the mounting holes or anything.

I've never had any issues from the MANY clutch jobs I've done. Only thing I've ever seen is making sure you put the bolts/nuts on the diff in the right order so the side bolt that goes in will go in properly and the hole is lined up. That's about it.

Dale

I've never had any issues from the MANY clutch jobs I've done. Only thing I've ever seen is making sure you put the bolts/nuts on the diff in the right order so the side bolt that goes in will go in properly and the hole is lined up. That's about it.

Dale

The following users liked this post:

Zepticon (02-14-18)

#16

A couple things (if not already mentioned).

- Get a transmission jack. Using a regular jack is dangerous

- I believe Mazda improved the clutch fork on the '94 models. If they did, you should be good. I also believe the '94 had improved shift select spindle and 5th gear syncro, otherwise they would be something to possibly replace.

Good luck

- Get a transmission jack. Using a regular jack is dangerous

- I believe Mazda improved the clutch fork on the '94 models. If they did, you should be good. I also believe the '94 had improved shift select spindle and 5th gear syncro, otherwise they would be something to possibly replace.

Good luck

The following users liked this post:

Zepticon (02-14-18)

#17

Pilot Bearing removal

In my build thread, I show how to remove and replace the pilot bearing easily. Use the Harbor Freight slide hammer bearing puller tool. Cheap. It’s the only one I found with a head small enough for the FD pilot bearing without getting into prices that make the Mazda SST viable for not much more.

Edit- the tool linked on Amazon looks identical to the Harbor Freight one. Just have to have the ultra small end attachment and you’re good to go.

Edit- the tool linked on Amazon looks identical to the Harbor Freight one. Just have to have the ultra small end attachment and you’re good to go.

Last edited by Monkman33; 02-13-18 at 10:31 PM.

The following users liked this post:

Zepticon (02-14-18)

#21

RX-7 Bad Ass

iTrader: (55)

Unbolting the pressure plate through the access panel isn't too bad, I had to do it once on a car with a seized up throwout bearing. But, if you know the trick, it doesn't take any time to do it.

The real bad time is when you DON'T do it and you're yanking on the trans trying to figure out why it won't come out - seen guys do that before!

Dale

The real bad time is when you DON'T do it and you're yanking on the trans trying to figure out why it won't come out - seen guys do that before!

Dale

Thread

Thread Starter

Forum

Replies

Last Post

rx78788

2nd Generation Specific (1986-1992)

13

01-01-05 09:32 AM

Piranha

2nd Generation Specific (1986-1992)

4

08-29-02 10:37 AM