new PFC idle sticking problem solving strategy (ISC installed)

#1

new PFC idle sticking problem solving strategy (ISC installed)

I've been working on this maddening problem for a little while now. The typical symptoms: idle randomly sticks or maybe surges on decel, especially as the engine warms up. On this car, a series 4 2nd gen turbo car, I had the worst of both worlds: random stalling and random idle sticking. I think I may have found a new strategy for attacking this, by adjusting a setting that most people mostly overlook.

One solution to some of the PFC idle difficulties is to remove the ISC and adjust everything manually. I've done this before, and I recommend PMing cewrx7r1 about his tuning notes which cover this. It simplifies things and solves certain problems, but I really do not like having no idle up for my cooling fan or other electrical loads (and I don't even have A/C). At night the battery voltage can drop even further without the idle up function, unless you raise the base idle speed higher than I would prefer. Without an ISC the engine seems more sensitive to idle timing values as well. But that whole debate belongs in another thread.

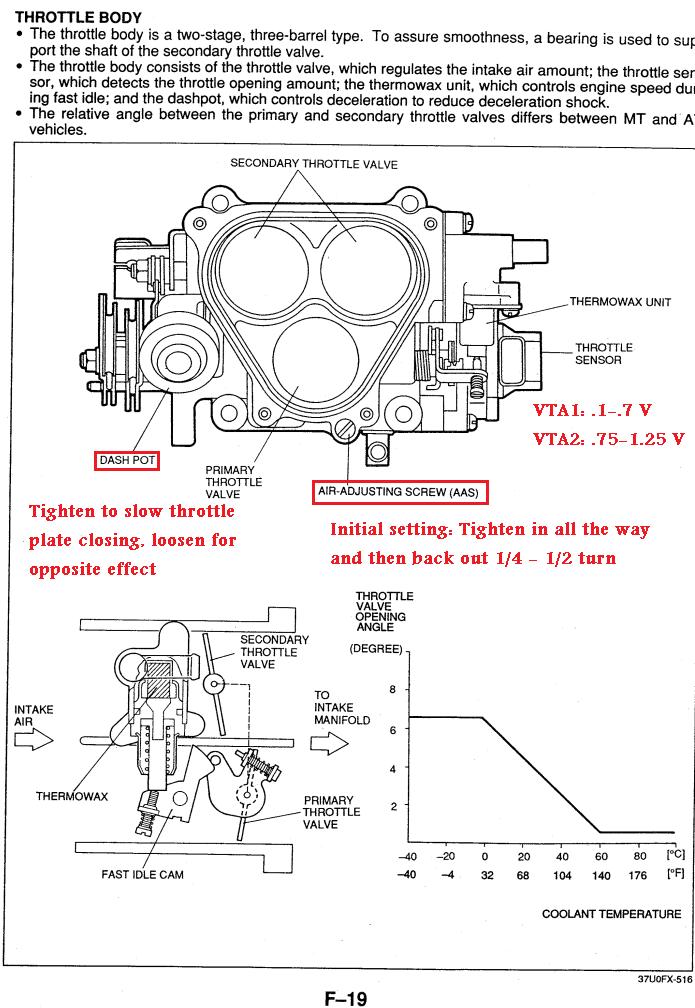

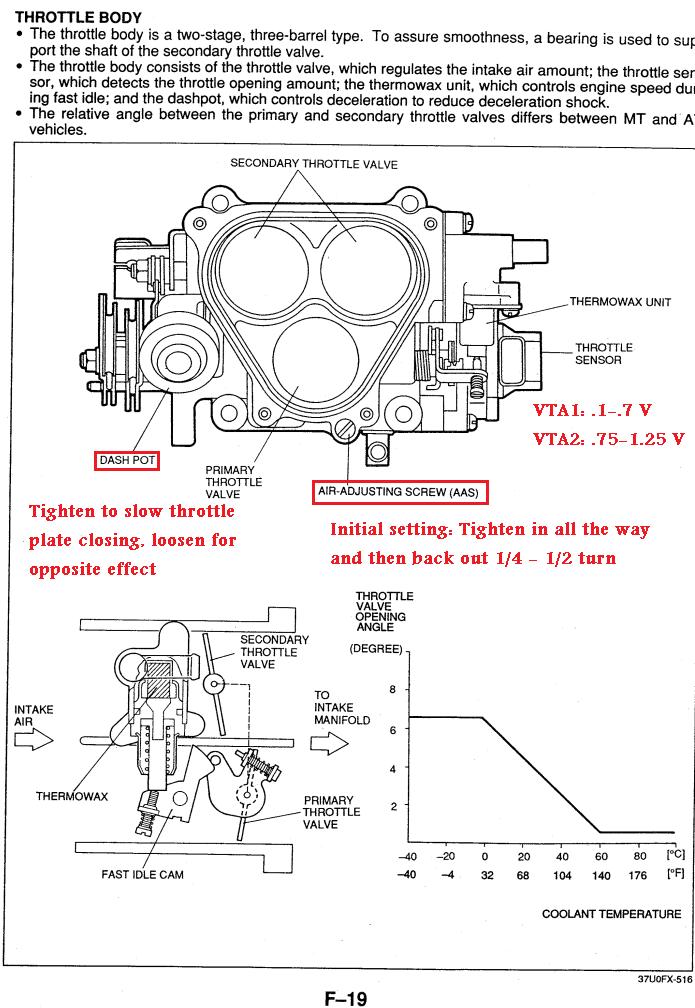

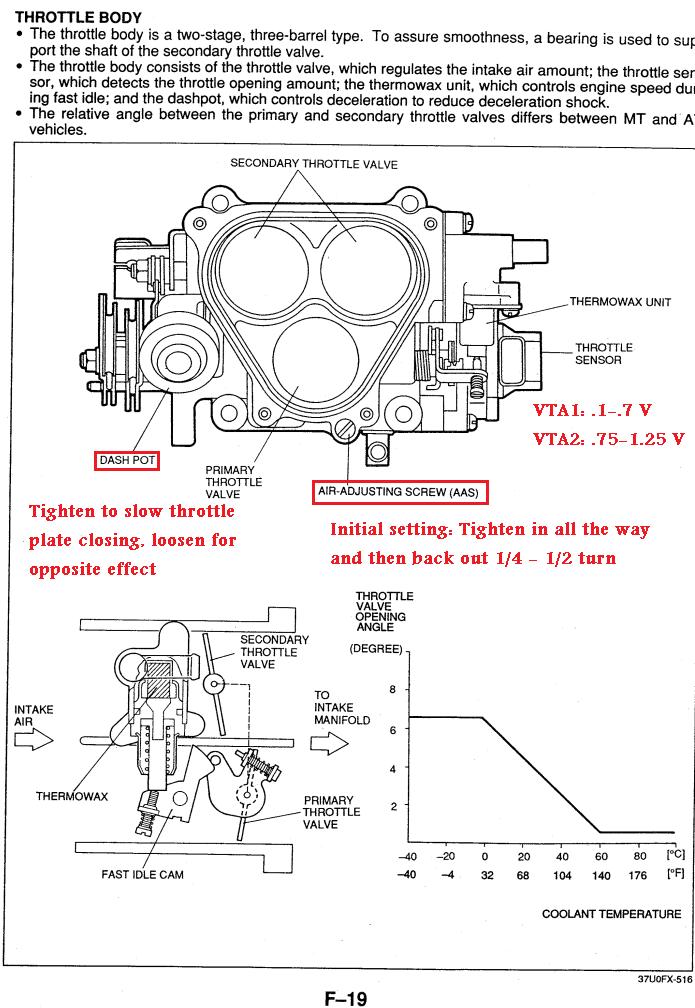

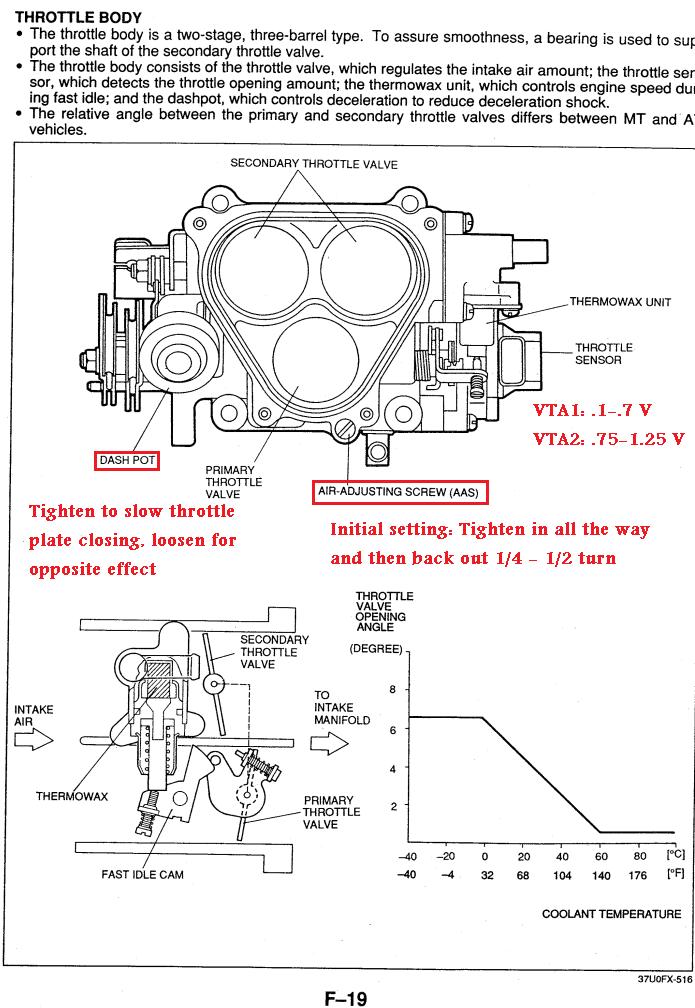

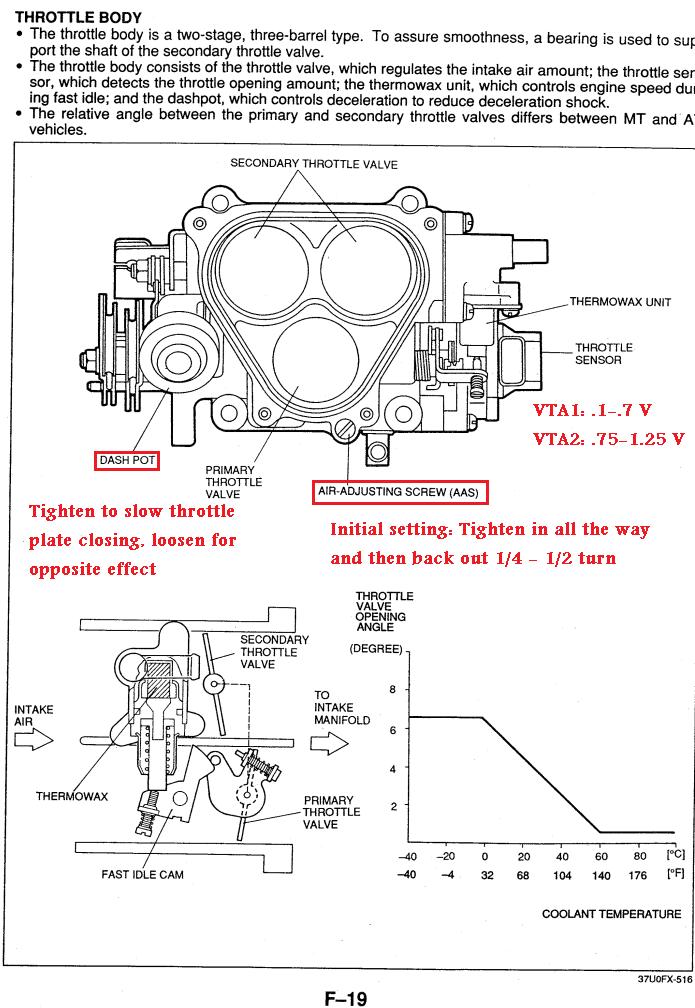

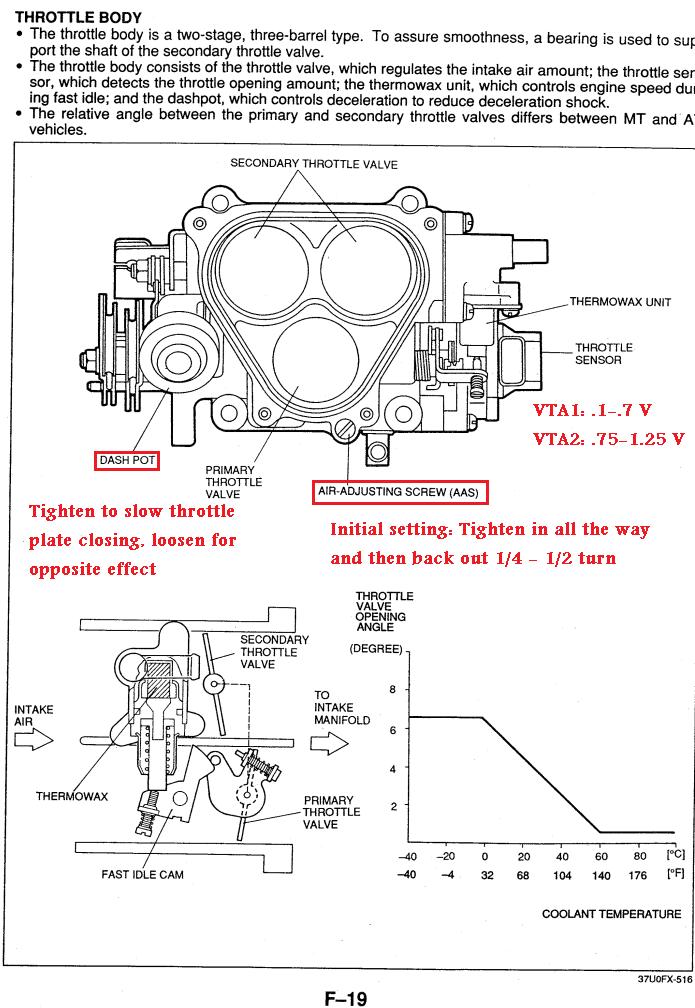

The standard advice given for addressing the idle sticking problem is to reduce bypass air on the TB, make sure the TPS is adjusted correctly, and perform the idle learning procedure in the PFC manual. I've covered the idle learning procedure in this thread: https://www.rx7club.com/attachment.p...1&d=1243110575

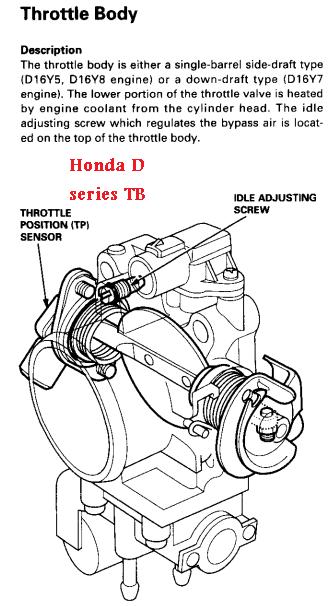

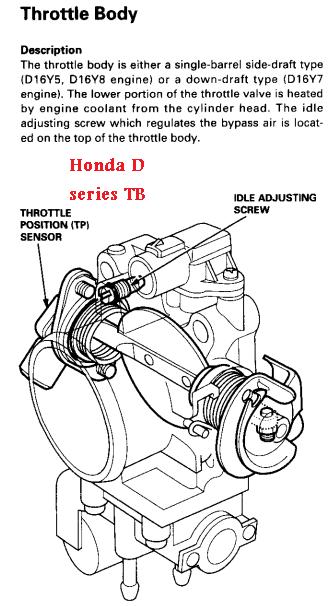

But that approach doesn't always solve the problem completely. I've got a new strategy I've been working on that appears to be showing some promise, although I think the proverbial jury is still out. I started thinking about Hondas for minute. I doubt many of you have done any Honda tuning, but their fuel injection system is very similar to the FD. It uses a MAP sensor only, and has a very similar ISC valve.

It also has no mechanical dashpot on the TB, unlike the FD. The purpose of a dashpot is to slow the closing of the throttle plates on deceleration to prevent stalling. This part of the TB is very useful when you have blocked off the ISC, and I never recommend its complete removal. But now I'm beginning to think that with a PFC and the ISC valve retained, I am beginning to agree with the people who have already suggested that the dashpot can cause idle sticking problems.

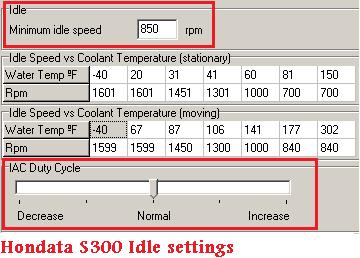

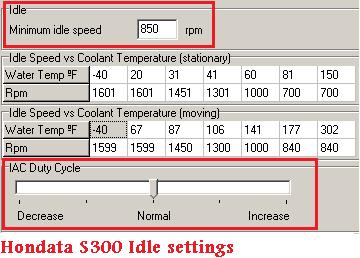

So how do you adjust deceleration on the Hondas? In the Hondata software they have a setting called "IAC Duty Cycle" :

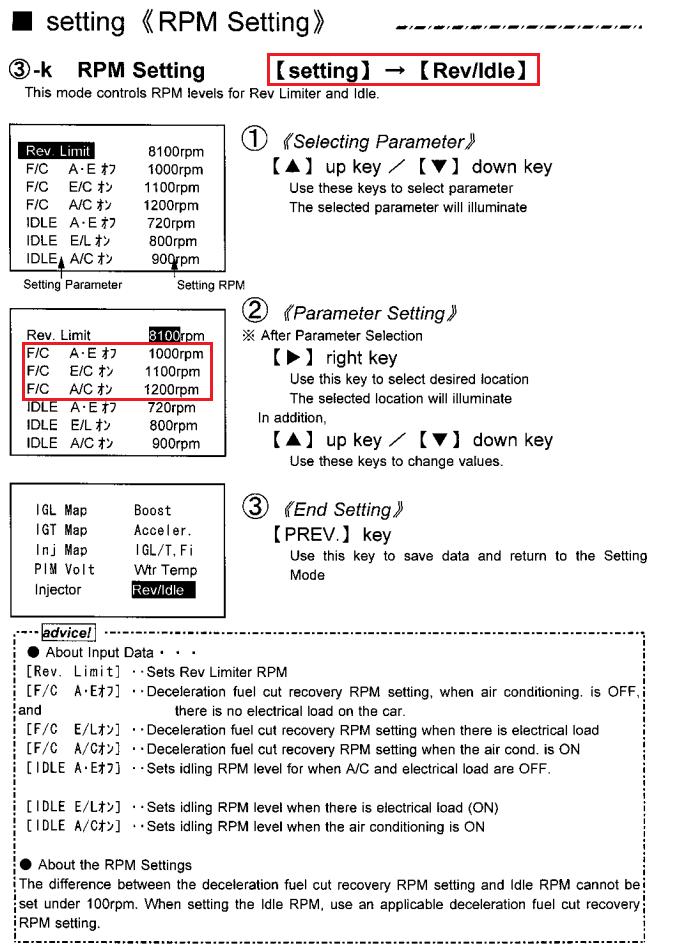

Proper adjustment of this setting depends on the opening angle of the Honda throttle plate and the setting of the Honda air adjust screw. Too much duty results in sticking and surging (not unlike the FD) and too little duty results in stalling usually. For a long time I have been trying to figure out what the closest equivalent setting would be in the PFC, and I think I may have found it:

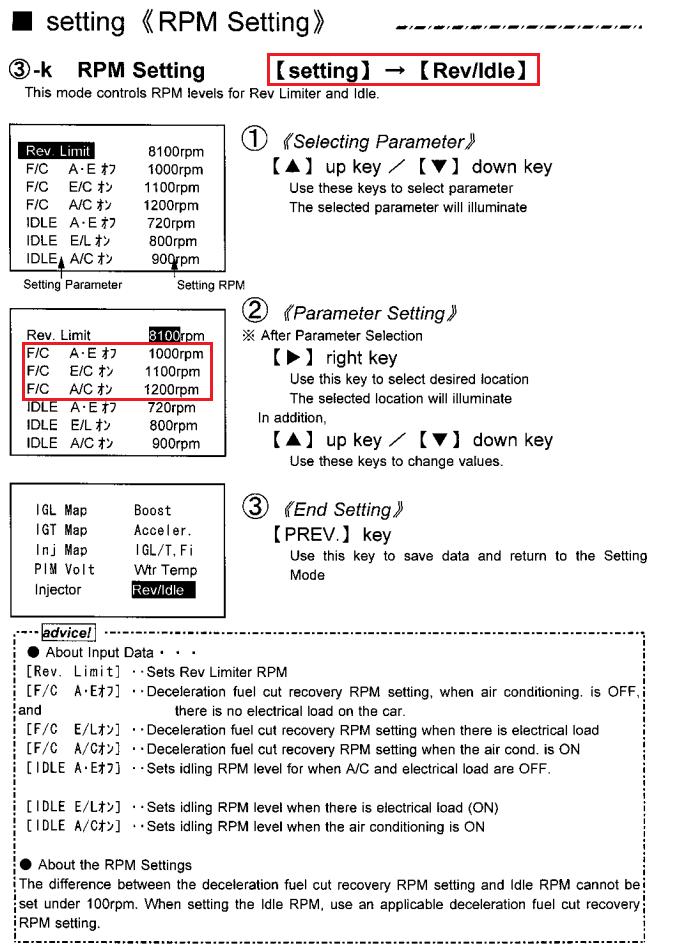

This is listed as a fuel cut recovery setting, and that is true. If you raise that rpm value high enough and decelerate below that threshold value, the car will not cut fuel. If the ISC is disabled that's all this setting does. But I have figured out now that this setting can at least on my car have a huge effect on the deceleration ISC control logic in the PFC.

This setting is adjustable in increments of 10 rpm, and the PFC seems very sensitive to it. Here's what I've been doing. I loosened the dashpot to the point where it basically does nothing and does not slow the throttle plates down. Then I adjust all three F/C settings at the same time and then try different types of throttle movements.

What we're trying to do here is lower the fuel cut setting so much that the idle stumbles on decel instead of sticks. Then, in very small increments, add rpm to the fuel cut settings and test to see if the idle stumbles or sticks. I have a Datalogit but I actually prefer using the Commander for this.

For reference, my car has a large street port with idle AFR's in the high 12's. O2 feedback is off, but Idle IG control is on and I actually like that setting after I did a bunch of testing with it. All three idle speeds are set to 850, although the PFC will still bump the idle up about 50 rpm when electrical load is applied to the engine.

Getting back to the fuel cut settings: First I tried a lower number (all 3 values were set the same), in my case 1200 rpm but the default values are lower than that. I would hit the pedal a tiny bit (VERY small throttle movements like you would use when parking) and the engine would stumble. So I tried a value of 1500--way too high. Now it was sticking at 1200 or 1500 rpm. What I ended up doing was ramping it up in 10 rpm increments up from 1200. I think I settled on 1280 for all three settings, with the mechanical dashpot disengaged.

I haven't done too much road testing yet because I discovered that I have coolant dripping from a heater hose that I never should have reused, so I have to take care of that before I can drive very far. But right now, hard revving makes the idle drop quickly at first and then slow down when it hits about 1300-1400 rpm, until it finally settles at 850.

I'm going to do some more testing in the coming weeks to see if I've really figured something out here.

One solution to some of the PFC idle difficulties is to remove the ISC and adjust everything manually. I've done this before, and I recommend PMing cewrx7r1 about his tuning notes which cover this. It simplifies things and solves certain problems, but I really do not like having no idle up for my cooling fan or other electrical loads (and I don't even have A/C). At night the battery voltage can drop even further without the idle up function, unless you raise the base idle speed higher than I would prefer. Without an ISC the engine seems more sensitive to idle timing values as well. But that whole debate belongs in another thread.

The standard advice given for addressing the idle sticking problem is to reduce bypass air on the TB, make sure the TPS is adjusted correctly, and perform the idle learning procedure in the PFC manual. I've covered the idle learning procedure in this thread: https://www.rx7club.com/attachment.p...1&d=1243110575

But that approach doesn't always solve the problem completely. I've got a new strategy I've been working on that appears to be showing some promise, although I think the proverbial jury is still out. I started thinking about Hondas for minute. I doubt many of you have done any Honda tuning, but their fuel injection system is very similar to the FD. It uses a MAP sensor only, and has a very similar ISC valve.

It also has no mechanical dashpot on the TB, unlike the FD. The purpose of a dashpot is to slow the closing of the throttle plates on deceleration to prevent stalling. This part of the TB is very useful when you have blocked off the ISC, and I never recommend its complete removal. But now I'm beginning to think that with a PFC and the ISC valve retained, I am beginning to agree with the people who have already suggested that the dashpot can cause idle sticking problems.

So how do you adjust deceleration on the Hondas? In the Hondata software they have a setting called "IAC Duty Cycle" :

Proper adjustment of this setting depends on the opening angle of the Honda throttle plate and the setting of the Honda air adjust screw. Too much duty results in sticking and surging (not unlike the FD) and too little duty results in stalling usually. For a long time I have been trying to figure out what the closest equivalent setting would be in the PFC, and I think I may have found it:

This is listed as a fuel cut recovery setting, and that is true. If you raise that rpm value high enough and decelerate below that threshold value, the car will not cut fuel. If the ISC is disabled that's all this setting does. But I have figured out now that this setting can at least on my car have a huge effect on the deceleration ISC control logic in the PFC.

This setting is adjustable in increments of 10 rpm, and the PFC seems very sensitive to it. Here's what I've been doing. I loosened the dashpot to the point where it basically does nothing and does not slow the throttle plates down. Then I adjust all three F/C settings at the same time and then try different types of throttle movements.

What we're trying to do here is lower the fuel cut setting so much that the idle stumbles on decel instead of sticks. Then, in very small increments, add rpm to the fuel cut settings and test to see if the idle stumbles or sticks. I have a Datalogit but I actually prefer using the Commander for this.

For reference, my car has a large street port with idle AFR's in the high 12's. O2 feedback is off, but Idle IG control is on and I actually like that setting after I did a bunch of testing with it. All three idle speeds are set to 850, although the PFC will still bump the idle up about 50 rpm when electrical load is applied to the engine.

Getting back to the fuel cut settings: First I tried a lower number (all 3 values were set the same), in my case 1200 rpm but the default values are lower than that. I would hit the pedal a tiny bit (VERY small throttle movements like you would use when parking) and the engine would stumble. So I tried a value of 1500--way too high. Now it was sticking at 1200 or 1500 rpm. What I ended up doing was ramping it up in 10 rpm increments up from 1200. I think I settled on 1280 for all three settings, with the mechanical dashpot disengaged.

I haven't done too much road testing yet because I discovered that I have coolant dripping from a heater hose that I never should have reused, so I have to take care of that before I can drive very far. But right now, hard revving makes the idle drop quickly at first and then slow down when it hits about 1300-1400 rpm, until it finally settles at 850.

I'm going to do some more testing in the coming weeks to see if I've really figured something out here.

The following users liked this post:

adey (09-06-20)

#2

Great post! I've been having identical problems with a sticking and sometimes stumbling idle. It's also nice that those of us without a datalogit can play around with this setting. I'll give this a try and see how it goes...

Also, I also found that disengaging the dashpot altogether seems to decrease the problem drastically. I've been driving with mine connected, but not making contact with the throttle plate level for over a month with improved idle.

Also, I also found that disengaging the dashpot altogether seems to decrease the problem drastically. I've been driving with mine connected, but not making contact with the throttle plate level for over a month with improved idle.

Last edited by moehler; 07-22-09 at 09:00 PM. Reason: added dashpot note

#3

So I finally tried this yesterday and it worked perfectly. Idle falls to about 1280 and then quickly settles to 950. The fields were set at 1500 and the idle would fall to 1500 and stay for 10 seconds or more before settling down slowly. I've been trying to sovle the sticking problem for a while now, so thank you.

#4

Excellent! I'm waiting to sell some stuff so I can use the money to get the heater hose and a couple other things I need from Mazda, so I haven't had a chance to mess with the car since I made this thread.

So did you just put in a value of 1280 for all three fuel cut settings and it fixed the sticking immediately? Or did you have to fiddle with different settings for a while like I did? I doubt that 1280 is some kind of magic number. It just seems that high rpm values (1400-1500) for the fuel cut settings are best for cars with the ISC removed.

Also, if the idle sticking comes back please post about it, including as many details as possible about ambient conditions, water and air temps, and the type of driving you are doing. I want to give this some more time and testing before I update my PFC Commander adjustment thread.

So did you just put in a value of 1280 for all three fuel cut settings and it fixed the sticking immediately? Or did you have to fiddle with different settings for a while like I did? I doubt that 1280 is some kind of magic number. It just seems that high rpm values (1400-1500) for the fuel cut settings are best for cars with the ISC removed.

Also, if the idle sticking comes back please post about it, including as many details as possible about ambient conditions, water and air temps, and the type of driving you are doing. I want to give this some more time and testing before I update my PFC Commander adjustment thread.

#5

Excellent! I'm waiting to sell some stuff so I can use the money to get the heater hose and a couple other things I need from Mazda, so I haven't had a chance to mess with the car since I made this thread.

So did you just put in a value of 1280 for all three fuel cut settings and it fixed the sticking immediately? Or did you have to fiddle with different settings for a while like I did? I doubt that 1280 is some kind of magic number. It just seems that high rpm values (1400-1500) for the fuel cut settings are best for cars with the ISC removed.

Also, if the idle sticking comes back please post about it, including as many details as possible about ambient conditions, water and air temps, and the type of driving you are doing. I want to give this some more time and testing before I update my PFC Commander adjustment thread.

So did you just put in a value of 1280 for all three fuel cut settings and it fixed the sticking immediately? Or did you have to fiddle with different settings for a while like I did? I doubt that 1280 is some kind of magic number. It just seems that high rpm values (1400-1500) for the fuel cut settings are best for cars with the ISC removed.

Also, if the idle sticking comes back please post about it, including as many details as possible about ambient conditions, water and air temps, and the type of driving you are doing. I want to give this some more time and testing before I update my PFC Commander adjustment thread.

#6

what size injectors do you have moehler? I have a single turbo streetport car and I cant get idle to lean out past mid 11's when warm, it smells horrible. I would love to get it in the high 12's. My afr's are good across the entire map except at warm idle. Im using 850 primaries.

Trending Topics

#8

what size injectors do you have moehler? I have a single turbo streetport car and I cant get idle to lean out past mid 11's when warm, it smells horrible. I would love to get it in the high 12's. My afr's are good across the entire map except at warm idle. Im using 850 primaries.

. My tuner couldn't do anything about it due to the 850's. The 550's make for a much better idle with almost no smell at all.

. My tuner couldn't do anything about it due to the 850's. The 550's make for a much better idle with almost no smell at all.

#9

I am running 720 primary's, top feed, lag of +.04 or so with base fuel pressure of 40psi. Although technically I don't use the normal lag correction table, I leave that at 0 and input the entire map of injector lag vs battery voltage next to it in settings 5 of the Datalogit software. Anyway, it seems that 850 side feed primary's are the difficult ones to get to idle. Usually you have to dial in about -.40 lag in the primary injector settings and retune the whole car as everything leans out from that.

#10

I tried this approach on my friend's FD (street ported, 3mm seals, stock sequential twins, 550/1300) the other day and it worked well. I dropped his fuel cut settings from 1500 to 1420. The idle drops to 1100 (used to be 1500) as you are decelerating now, and when you reach a full stop it settles at 850. Fuel cut settings under 1400 resulted in some stalling on decel on that car.

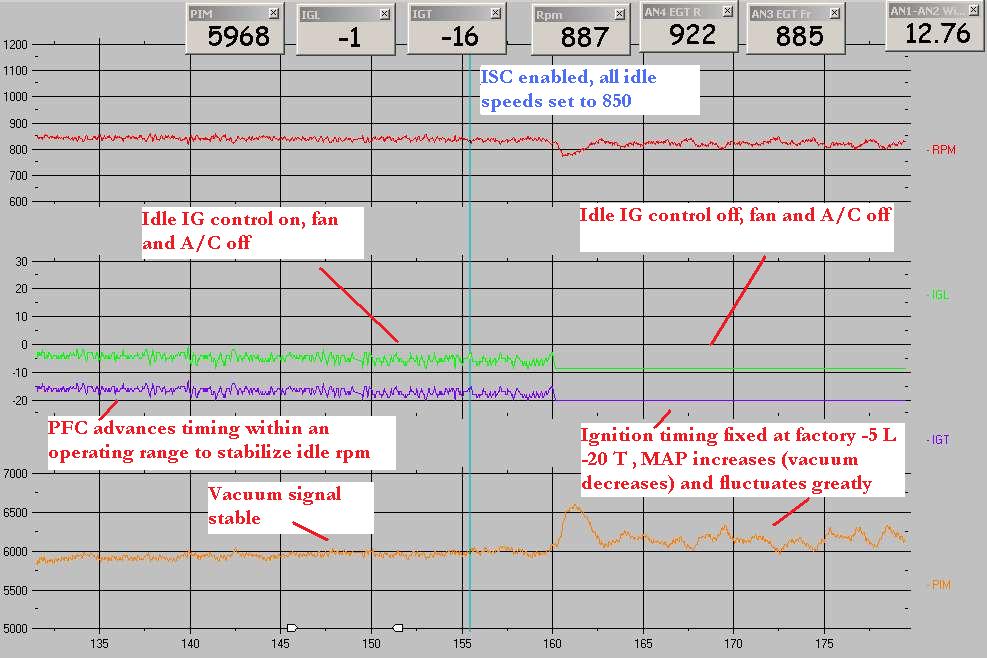

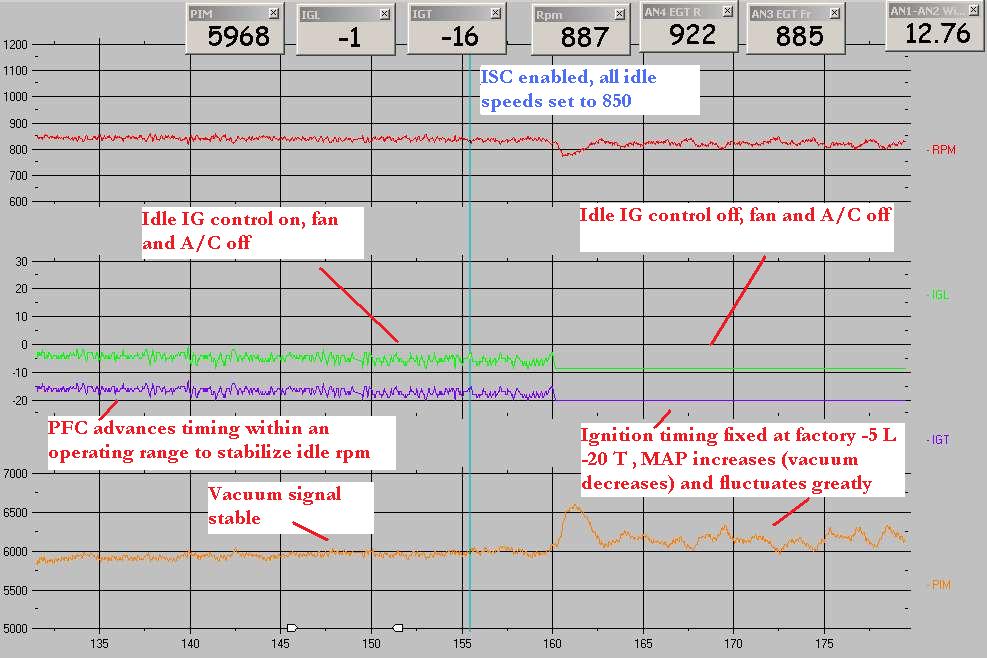

I am also using idle IG control on both cars (my FC, my friend's FD) now. My testing indicates favorable results:

this is on my FC. When I switched idle IG control back on on the FD, I noticed the vacuum signal fluctuates a lot less on that car as well. Note that neither car has an airpump.

I am also using idle IG control on both cars (my FC, my friend's FD) now. My testing indicates favorable results:

this is on my FC. When I switched idle IG control back on on the FD, I noticed the vacuum signal fluctuates a lot less on that car as well. Note that neither car has an airpump.

#11

Rotary Freak

iTrader: (28)

Join Date: Jun 2009

Location: Ontario, Canada

Posts: 2,089

Likes: 0

Received 0 Likes

on

0 Posts

I just got my engine rebuilt. It was done with a small street port. My mods are a dp, racing beat exhaust, a high flow cat, larger intercooler, fluidyne rad, and a power fc with commander.

I have had an erratic idle so I tried your above mentioned suggestions( in the learning function ).

The car went through the steps like the article said. Each time it went as described, the car settled in nicely, for all three steps.

I drove away and the erratic idle came back. I pulled over tried again. The car wouldn't settle this time. I shut the car off for a minute and tried again. This time it settled and I waited 10 minutes ( this time I only did the first step with no load as I was getting annoyed and hot.)

I drove away again and the erratic idle came back.

I have already checked my tps and it is in range. My idle screw, air screw, and throttle cable are all good. Any more suggestions that I could try?

I have had an erratic idle so I tried your above mentioned suggestions( in the learning function ).

The car went through the steps like the article said. Each time it went as described, the car settled in nicely, for all three steps.

I drove away and the erratic idle came back. I pulled over tried again. The car wouldn't settle this time. I shut the car off for a minute and tried again. This time it settled and I waited 10 minutes ( this time I only did the first step with no load as I was getting annoyed and hot.)

I drove away again and the erratic idle came back.

I have already checked my tps and it is in range. My idle screw, air screw, and throttle cable are all good. Any more suggestions that I could try?

#12

Rotary Freak

iTrader: (28)

Join Date: Jun 2009

Location: Ontario, Canada

Posts: 2,089

Likes: 0

Received 0 Likes

on

0 Posts

I should have added my air screw has around a 1/4 turn. When I say settled in the car idled @ 1400 when I had no load on it. Also 1400 when I had the rear defrost on. 1000 when I turned the AC and fan on full.

Not sure if that has any impact on what I mentioned above.

Not sure if that has any impact on what I mentioned above.

#13

I have had an erratic idle so I tried your above mentioned suggestions( in the learning function ).

The car went through the steps like the article said. Each time it went as described, the car settled in nicely, for all three steps.

I drove away and the erratic idle came back.

The car went through the steps like the article said. Each time it went as described, the car settled in nicely, for all three steps.

I drove away and the erratic idle came back.

Here's some steps I would try. You can either adjust everything to eliminate the sticking problem and have it idle well on the first try. Or you may keep adjusting the TB and the PFC so that the idle no longer sticks but actually stumbles. If it's stumbling it's not sticking anymore--then from there we can adjust the idle behavior back up to get it where it needs to be. It's like adjusting a carburetor; you might adjust too rich, then adjust too lean, then find some place in the middle that works. So try these steps:

1. disengage the dashpot completely:

See if that helps. If it doesn't, the next step is to

2. Set idle speeds to:

850

850 EL

950 A/C

F/C speeds to

950

950 EL

1050 A/C

The F/C speeds must be at least 100rpm more than the idle speeds, so that's the lowest you can go.

You may have to re-learn idle... but I'm not sure. With fuel cut speeds set that low, the ISC will kick in a lot less on deceleration and reduce the chance of sticking. You may have to change those F/C speeds later to correct a stalling problem. Don't worry about that right now. We need to solve the sticking first. If that does not correct the sticking problem,

3. you need to close the throttle adjust screw and possibly re learn idle again. I say "possibly" about idle learning because I'm not at your car right now so I can't make a perfect diagnosis, and idle learning is time consuming. It may help, it may not, I'm just throwing it out there.

When you turn this screw, the throttle plates close. If you close it enough, the chances of idle sticking will decrease, and at some point you can close it so much that the car barely idles. Idle air can only enter the engine from

1. the throttle plate opening angle (controlled by the fast idle cam, throttle adjust screw, and the throttle and cruise cables, both of which should have 1-2mm of freeplay)

2. a vacuum leak

3. air bypass through the air adjust screw

4. duty controlled bypass air from the ISC, controlled by PFC target idle speed (and the learning process) and the fuel cut settings, which indirectly determine ISC behavior on decel

Note that if you close the throttle adjust screw enough your TPS may get out of spec. At that point you will need to adjust the TPS to get it back in range. Also keep in mind that I like to keep Idle Ignition control on (it is enabled by default), which is under etc-->Function select.

I'm throwing a bunch of stuff out right now because again I'm not at your car. But it sounds like since you closed the air adjust screw to 1/4 turn and the car does idle stably at first, your sticking problem is more likely to be a function of the dashpot and fuel cut settings.

The following users liked this post:

adey (09-06-20)

#14

Just a few general observations, as I'm no expert on PFC matters. I run a large streetport engine in my daily driver (FD) and I have near perfect idle, off idle and decel response; so it is possible, and this is with an old purple box piggyback unit AND a functional ISC.

The large street port wants to idle at around 850 to 950 with a vacuum of typically 10 to 12" Hg. Because of the lower vacuum, a lower idle VE and exhaust gas dilution of the intake charge, some adjustments are required to get everything back into the range of the servos, in general:

1) Idle fuel can be reduced by 20 or more percent (in what ever manner is available) to get the idle back to being stable and at reasonable AFR;

2) additional air will need to be admitted in order to compensate for the lower vacuum signal. I added 1/4 of a turn to the secondary butterflies to achieve this. The primary throttle, TPS, dashpot, and idle air screw are properly adjusted at the factory recommended settings--(Mazda once explained to me that they calibrated each TB on a flow bench before sealing them for assembly in order to get the ISC in range.); and,

3) Idle, off idle, part throttle timing needs to be advanced substantially, this is not only to get a good idle, but to get a good, clean transition off of idle. There is a lot of benefit to be realized here and I think most could benefit from running a lot more advance down low. If you want to play with it, you can actually add timing till the engine starts to buck and back it off a bit. You're just not going to hurt the motor with timing down low and it can really wake things up....especially for the ported guys.

Someone mentioned carburetors above; interestingly, these adjustments are analogous to what we did back in the day to get carbureted cars with large ports and big cams to run. At the end of the day, there is a definite relationship between the foregoing adjustments that should get the engine to a point where the ISC servo loop can manage it.

Good luck.

The large street port wants to idle at around 850 to 950 with a vacuum of typically 10 to 12" Hg. Because of the lower vacuum, a lower idle VE and exhaust gas dilution of the intake charge, some adjustments are required to get everything back into the range of the servos, in general:

1) Idle fuel can be reduced by 20 or more percent (in what ever manner is available) to get the idle back to being stable and at reasonable AFR;

2) additional air will need to be admitted in order to compensate for the lower vacuum signal. I added 1/4 of a turn to the secondary butterflies to achieve this. The primary throttle, TPS, dashpot, and idle air screw are properly adjusted at the factory recommended settings--(Mazda once explained to me that they calibrated each TB on a flow bench before sealing them for assembly in order to get the ISC in range.); and,

3) Idle, off idle, part throttle timing needs to be advanced substantially, this is not only to get a good idle, but to get a good, clean transition off of idle. There is a lot of benefit to be realized here and I think most could benefit from running a lot more advance down low. If you want to play with it, you can actually add timing till the engine starts to buck and back it off a bit. You're just not going to hurt the motor with timing down low and it can really wake things up....especially for the ported guys.

Someone mentioned carburetors above; interestingly, these adjustments are analogous to what we did back in the day to get carbureted cars with large ports and big cams to run. At the end of the day, there is a definite relationship between the foregoing adjustments that should get the engine to a point where the ISC servo loop can manage it.

Good luck.

#15

this is with an old purple box piggyback unit AND a functional ISC.

1) Idle fuel can be reduced by 20 or more percent (in what ever manner is available) to get the idle back to being stable and at reasonable AFR;

2) additional air will need to be admitted in order to compensate for the lower vacuum signal. I added 1/4 of a turn to the secondary butterflies to achieve this. The primary throttle, TPS, dashpot, and idle air screw are properly adjusted at the factory recommended settings--(Mazda once explained to me that they calibrated each TB on a flow bench before sealing them for assembly in order to get the ISC in range.); and,

3) Idle, off idle, part throttle timing needs to be advanced substantially, this is not only to get a good idle, but to get a good, clean transition off of idle. There is a lot of benefit to be realized here and I think most could benefit from running a lot more advance down low. If you want to play with it, you can actually add timing till the engine starts to buck and back it off a bit. You're just not going to hurt the motor with timing down low and it can really wake things up....especially for the ported guys.

I have attempted to add timing off idle using the Datalogit IGN vs TPS map. I didn't notice much of an improvement. I did notice that adjusting tip-in fuel made a huge difference in response, using the Power FC INJ vs TPS, Accelerate Injector, Accel vs TPS 1 tables.

these adjustments are analogous to what we did back in the day to get carbureted cars with large ports and big cams to run. At the end of the day, there is a definite relationship between the foregoing adjustments that should get the engine to a point where the ISC servo loop can manage it.

The more I've become a semi-expert on Rx-7 idle adjustment, the more I realize that I ******* hate this antiquated ****. You don't realize how awesome drive-by-wire is until you see how much simpler they are mechanically and electrically, how much less maintainence they require, and how much more adjustable they are when you can edit the ECU calibration tables. The Rx-8 Drive-by-wire system has no cables, no ISC valves, no fast idle cams, no double throttle, no separate cruise control actuators or computers, and no bypass air or butterfly adjustment screws. And I haven't even started talking about all the other emissions simplification Mazda has accomplished. They really leave the FD in the dust. It's too bad Rx-8's aren't very fast.

#16

FREAK ALL OUT!!!

iTrader: (17)

Join Date: Jul 2006

Location: Vancouver, WA

Posts: 1,071

Likes: 0

Received 0 Likes

on

0 Posts

would you happen to know off the top of your head why my fd when moving in nuetral will idle at 1500 rpms then when I come to a stop it idles normal? This gets really annoying especially in traffic.

#17

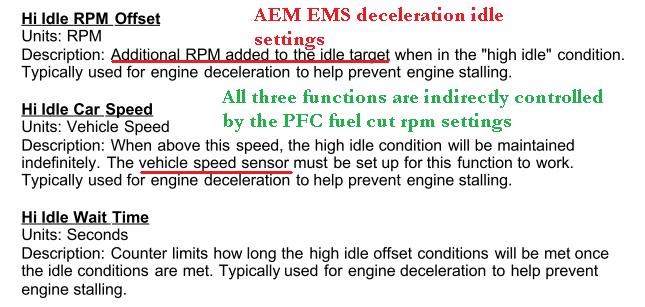

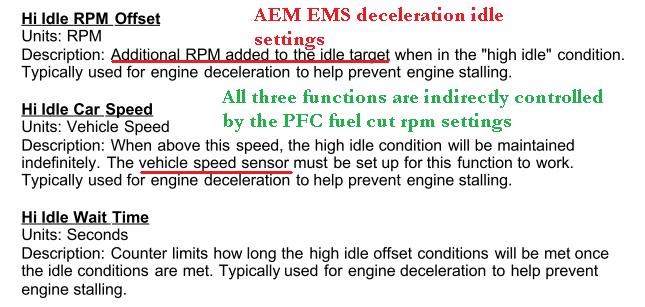

There is nothing unusual about an idle that is slightly higher than normal while the car is moving in neutral. My stock (fully functioning, low mileage) Infiniti Q45 does it, but I can't say for sure if a stock FD does it (stock ECU). The ISC valve is adding in extra air to keep you from stalling. But 1500rpm is high. Other EMS's give a lot of adjustability of ISC behavior but the PFC does not give you direct control unfortunately.

i have encountered the symptoms you described before and managed to drop the decel idle speed to about 1100 rpm, which is acceptable to me. I corrected it by dropping the fuel cut settings under settings-->rev/idle. On this particular car I had initially set them to 1500. After much fiddling I dropped them to 1420 and the idle would now hit about 1050-1100 during decel and then settles to 850 when the car comes to a complete stop. This is on an FD with sequential twins, street port, 550/1300, idle speeds set to 850/850/950 , fuel cut set to 1420/1420/1420 . Releasing the dashpot may also with this. You will have to figure out what fuel cut settings to use just through experimenting. If the settings are too low you may find the car actually stalling sometimes. Even a 10 or 20 rpm adjustment in these speeds can have a noticeable effect, as the PFC is sometimes very sensitive.

On my FC, I noticed that the idle speed does not stay higher while cruising in neutral, but I do not have a vehicle speed sensor wire hooked up to my PFC adapter harness. If a higher idle during decel really bothers you then cutting this wire might eliminate that behavior. I say "behavior" as opposed to "problem" because running a slightly higher idle during decel is not necessarily a problem. It's done intentionally for idle stability. We can see it in these calibration tables for AEM EMS idle adjustment:

So again, on a motor with no other mechanical or electrical issues, releasing the dashpot per my previous post and dropping the fuel cut speeds may help mitigate an excessively high idle during deceleration.

i have encountered the symptoms you described before and managed to drop the decel idle speed to about 1100 rpm, which is acceptable to me. I corrected it by dropping the fuel cut settings under settings-->rev/idle. On this particular car I had initially set them to 1500. After much fiddling I dropped them to 1420 and the idle would now hit about 1050-1100 during decel and then settles to 850 when the car comes to a complete stop. This is on an FD with sequential twins, street port, 550/1300, idle speeds set to 850/850/950 , fuel cut set to 1420/1420/1420 . Releasing the dashpot may also with this. You will have to figure out what fuel cut settings to use just through experimenting. If the settings are too low you may find the car actually stalling sometimes. Even a 10 or 20 rpm adjustment in these speeds can have a noticeable effect, as the PFC is sometimes very sensitive.

On my FC, I noticed that the idle speed does not stay higher while cruising in neutral, but I do not have a vehicle speed sensor wire hooked up to my PFC adapter harness. If a higher idle during decel really bothers you then cutting this wire might eliminate that behavior. I say "behavior" as opposed to "problem" because running a slightly higher idle during decel is not necessarily a problem. It's done intentionally for idle stability. We can see it in these calibration tables for AEM EMS idle adjustment:

So again, on a motor with no other mechanical or electrical issues, releasing the dashpot per my previous post and dropping the fuel cut speeds may help mitigate an excessively high idle during deceleration.

#18

Rotary Freak

iTrader: (28)

Join Date: Jun 2009

Location: Ontario, Canada

Posts: 2,089

Likes: 0

Received 0 Likes

on

0 Posts

My throttle doesn't really stick. Prior to my engine rebuild the throttle/idle was fine. My car is still in the break in period so it doesn't have the final tune and I believe many of my issues will be resolved then.

After the rebuild my I have a very brief throttle stick. Perhaps a quater of a second at most! Its not a big deal.

My problem is my damn erratic idle. The changes you mentioned in your first post have made a noticlable difference. The idle seems to be worlds better when I have the AC or head lights on. The issue is when I have no accesories on.

Not sure if that changes the answer you had previously given me.

After the rebuild my I have a very brief throttle stick. Perhaps a quater of a second at most! Its not a big deal.

My problem is my damn erratic idle. The changes you mentioned in your first post have made a noticlable difference. The idle seems to be worlds better when I have the AC or head lights on. The issue is when I have no accesories on.

Not sure if that changes the answer you had previously given me.

#20

Rotary Freak

iTrader: (28)

Join Date: Jun 2009

Location: Ontario, Canada

Posts: 2,089

Likes: 0

Received 0 Likes

on

0 Posts

In response your statement I'm wondering if I set my throttle screw incorreclty. I got a piece of paper and folded it twice. I inserted it under the idle screw and continued to wiggle it while tightening the screw. When the paper no longer moved freely I stopped tightening and removed the paper. After that I moved my tps to with in spec.

I will try backing out my throttle screw but I'm pretty confident it will not change any setting in my tps. After all how thick can paper be?

I will try backing out my throttle screw but I'm pretty confident it will not change any setting in my tps. After all how thick can paper be?

#21

Hmm. I did literally say "close" this screw when turning the screw clockwise may actually open the throttle plates more. What I meant was "close the throttle plates." It's been a while since I've had to mess with an FD throttle screw, sorry if I confused anyone. I've been working on my FC throttlebody a lot lately so the FD isn't so fresh in my mind. That's my mistake if I messed anyone up. I always look at TPS voltage when I adjust the screw, and sometimes I adjust it with the engine running.

With the engine warmed up, put the key in the ON position with the engine off. With your commander hooked up to the ECU, bring it into the engine bay. Loosen the lock nut under the throttle adjust screw.

Go to etc.--> sensor/sw check. As you turn the throttle adjust screw, you will see VTA2 change. VTA2 is your narrow range throttle sensor. it is designed to detect the throttle plate opening angle at idle. Increasing VTA2 means that you are increasing idle air (by changing the resting position of the throttle plate to allow more air), while decreasing VTA2 means that you are decreasing idle air. You can adjust the throttle screw in various ways to see how it affects idle, and keeping an eye on changes in VTA2 will give you a rough idea of how far you are adjusting the throttle plates from its prior position. So if your VTA2 was .80 volts (regardless of whether you adjusted the TPS or not) before you started messing with the screw, you can first try adjusting to .70 volts or whatever. And if that causes problems, you can put it back to .80 . Just make sure that before you go driving you adjust the sensor to get both VTA1 and VTA2 back into spec if you go out of range.

Check VTA2 after you tighten the locknut. I don't remember if the process of tightening the locknut affects the position of the screw or not on the FD throttlebody. I know it does on the FC, but the throttle adjust screw is a different design on the earlier engines. You will notice that with the engine completely cold, VTA2 will probably be over 1 volt if you have your fast idle system still on the car. Then as the engine warms up, VTA2 TPS voltage will drop slowly as the thermowax extends and rotates the fast idle cam. You can make a chart of VTA2 if you have a Datalogit by logging Sensor/SW VTA2.

The TPS voltage is all relative. They were set from the factory along with all the other stuff on the TB. When you open the throttle plates using the screw, you are going to change the TPS voltage. It's going to happen because the TPS is designed to detect changes in the opening angle of the throttle plates, and when you turn the throttle adjust screw you are by definition changing the opening angle provided that nothing else is holding them open.

Does this clarify the relationship between the throttle plate opening angle, the throttle adjust screw, and the TPS?

With the engine warmed up, put the key in the ON position with the engine off. With your commander hooked up to the ECU, bring it into the engine bay. Loosen the lock nut under the throttle adjust screw.

Go to etc.--> sensor/sw check. As you turn the throttle adjust screw, you will see VTA2 change. VTA2 is your narrow range throttle sensor. it is designed to detect the throttle plate opening angle at idle. Increasing VTA2 means that you are increasing idle air (by changing the resting position of the throttle plate to allow more air), while decreasing VTA2 means that you are decreasing idle air. You can adjust the throttle screw in various ways to see how it affects idle, and keeping an eye on changes in VTA2 will give you a rough idea of how far you are adjusting the throttle plates from its prior position. So if your VTA2 was .80 volts (regardless of whether you adjusted the TPS or not) before you started messing with the screw, you can first try adjusting to .70 volts or whatever. And if that causes problems, you can put it back to .80 . Just make sure that before you go driving you adjust the sensor to get both VTA1 and VTA2 back into spec if you go out of range.

Check VTA2 after you tighten the locknut. I don't remember if the process of tightening the locknut affects the position of the screw or not on the FD throttlebody. I know it does on the FC, but the throttle adjust screw is a different design on the earlier engines. You will notice that with the engine completely cold, VTA2 will probably be over 1 volt if you have your fast idle system still on the car. Then as the engine warms up, VTA2 TPS voltage will drop slowly as the thermowax extends and rotates the fast idle cam. You can make a chart of VTA2 if you have a Datalogit by logging Sensor/SW VTA2.

The TPS voltage is all relative. They were set from the factory along with all the other stuff on the TB. When you open the throttle plates using the screw, you are going to change the TPS voltage. It's going to happen because the TPS is designed to detect changes in the opening angle of the throttle plates, and when you turn the throttle adjust screw you are by definition changing the opening angle provided that nothing else is holding them open.

Does this clarify the relationship between the throttle plate opening angle, the throttle adjust screw, and the TPS?

The following users liked this post:

adey (09-06-20)

#23

^ it's either too little air or too little fuel. is your fast idle system (with associated thermowax hose) still there? The fast idle system controls idle air during warm up by opening the throttle plates:

The mixture is controlled mostly by the water temp correction table, accessible in the Commander by the water temp table under the Settings menu. If you have a wideband, what is the AFR right before it stalls?

The mixture is controlled mostly by the water temp correction table, accessible in the Commander by the water temp table under the Settings menu. If you have a wideband, what is the AFR right before it stalls?

#24

Full Member

iTrader: (3)

Join Date: Apr 2009

Location: Houston

Posts: 55

Likes: 0

Received 0 Likes

on

0 Posts

Thanks for the respond, i took out the fast idle a long time ago.... the car was running perfect until i install the powerFC last week.

The car start fine and idle around 920 or so, i let the engine warm to about a minute then drive off... almost 9 out of 10 time the engine stall during takeoff. The car also stall on the freeway when i put in neutral or doesn't shift fast enough and I noticed this only when I have my AC on ...

...

Iím going to check to see if there any vacuum leaks then play with the PowerFC settings again...

- the only thing i changed on the powerFC is the idle that you recommend.

- have downpipe, midetest pipe, and exhause.

- M2 intercooler, M2 intake, Koyo Radiator, still have airpump, Greedy boost-controll

The car start fine and idle around 920 or so, i let the engine warm to about a minute then drive off... almost 9 out of 10 time the engine stall during takeoff. The car also stall on the freeway when i put in neutral or doesn't shift fast enough and I noticed this only when I have my AC on

...

... Iím going to check to see if there any vacuum leaks then play with the PowerFC settings again...

- the only thing i changed on the powerFC is the idle that you recommend.

- have downpipe, midetest pipe, and exhause.

- M2 intercooler, M2 intake, Koyo Radiator, still have airpump, Greedy boost-controll

^ it's either too little air or too little fuel. is your fast idle system (with associated thermowax hose) still there? The fast idle system controls idle air during warm up by opening the throttle plates:

The mixture is controlled mostly by the water temp correction table, accessible in the Commander by the water temp table under the Settings menu. If you have a wideband, what is the AFR right before it stalls?

The mixture is controlled mostly by the water temp correction table, accessible in the Commander by the water temp table under the Settings menu. If you have a wideband, what is the AFR right before it stalls?

#25

so do these problems occur only when the car is cold as you originally indicated?

what idle settings are you running right now? you may need to raise your fuel cut settings. I've tried to make it clear that every engine is different and may need different adjustments of the TB and the PFC. just putting in some settings that you saw in this thread is not necessarily going to solve everything without you making adjustments on your own.

what idle settings are you running right now? you may need to raise your fuel cut settings. I've tried to make it clear that every engine is different and may need different adjustments of the TB and the PFC. just putting in some settings that you saw in this thread is not necessarily going to solve everything without you making adjustments on your own.